-

Throwing codes. Help please.

Alternator output is controlled by the PCM. Assuming there's nothing wrong with any of the wiring or the battery temperature sensor, then the PCM is probably at fault and would need to be replaced. John L. Sent from my iPad using Tapatalk HD

-

47 re problems

Have adjusted the bands, especially the front band, per the factory service manual?John L.Sent from my iPad using Tapatalk HD

-

47 re not shifting out of 1st as well as hard cranking after vp44 replacement

Many times... yes. However, the same symptoms can also be caused when the front band strut or the power wedge breaks or falls out. Either of these parts can be easily replaced with the transmission in place. Worst case the front band could be completely broken. That requires removing and disassembling the transmission. If he can't properly adjust the front band... if he can't torque the adjusting screw to the spec in the factory service manual... then that's the indication there's a problem with the front band parts. Often when the strut or power wedge break, pieces will be found in the pan. Best regards, John L. Sent from my iPad using Tapatalk HD

-

47 re not shifting out of 1st as well as hard cranking after vp44 replacement

Regarding the long cranking time:What's the fuel pressure at the VP44 inlet?Regarding the shifting problem:Have you adjusted the bands, especially the front band, per the factory service manual?Regards,John L.Sent from my iPad using Tapatalk HD

-

stumped

See THIS POST over on the Cummins Forum. John L. Sent from my iPhone using Tapatalk!

-

ScanGauge and boost pressure

Unless something has changed recently, the ScanGauge doesn't display boost directly. It displays Manifold Absolute Pressure derived from the ECM, which is boost pressure PLUS atmospheric pressure. When I was running a ScanGauge II, I found the MAP reading being displayed simply stopped increasing at some arbitrary point (I can't remember exactly what) which was well below maximum boost (stock level) even though the boost pressure was still increasing. I contacted ScanGauge about this phenomenon and they said it was the fault of the ECM's external data stream (or something to that effect). I've since switched to using an UltraGauge and it exhibits the exact same behavior. The bottom line: In my limited experience, using either a ScanGauge or an UltraGauge to monitor boost pressure is a waste of time. A good mechanical gauge is the way to go. Best regards, John L. Sent from my iPad using Tapatalk HD

-

Injectors

Not a thing if you'll cover the shipping. The important question is what will you do when you find out the pop pressures are all low and the nozzles leak prior to popping off? I guess the point I'm trying to stress is that you're probably wasting your time and money just having them tested... unless you're morbidly curious about how bad they really are. If they have 200k miles on them, at a minimum you'll need new nozzles if not the entire injector. Anyway, let me know if you want to send them over for testing and I'll PM you my address. Best regards, John L. Sent from my iPad using Tapatalk HD

-

Injectors

You're correct. However, somewhere between 75,000 to 100,000 miles they won't meet factory pop pressure specs anymore and the nozzles will leak. Assuming nothing else major goes wrong, this gradual deterioration doesn't seem to matter much. They're tough injectors! Regards, John L. Sent from my iPad using Tapatalk HD

-

stumped

Question: Have you tried hot wiring the VP44 to verify the engine will run without any connection to the ECM? Doing this would eliminate the possibility of a bad ECM or CTM (anti-theft). The engine only needs fuel (via a hot wired VP44) and air to run. Regards, John L. Sent from my iPad using Tapatalk HD

-

Injectors

AP, If you ship your injectors over to me (near Seattle) I'd be happy to bench test them for you and send them back. I have a couple of pop testers and all the appropriate fittings. However, if your injectors have more than 75,000 miles on them, then I can almost guaranty you it's a waste of time as the nozzles will be leaking (pissing) prior to popping off and they'll be opening at a lower pressure than spec. Low pop pressure can be adjusted by changing shim thickness under the spring inside the injector, but leaks prior to popping can't be corrected... at least that's been my experience. The only real solution for a leaky nozzle is to replace it with a new one... or buy an entirely new new injector of course. Best regards, John L. Sent from my iPad using Tapatalk HD

-

stumped

As you discovered, fuel CAN pass through a VP44 when it isn't operating. Here is a quote from Chrysler training publication 8169997178 "Cummins Electronic Fuel Injection" The VP44 injection pump is not self priming. At least two high pressure fuel lines atthe cylinder head must be loosened in order to bleed air from the system. The presence of fuel in the high pressure fuel lines at the cylinder head is not proof of the VP44 pump operating. Fuel can pass through the VP44 pump when it is not operating. Strong spurts of fuel at the loosened cylinder head fitting indicate that theVP44 pump is operating. Regards, John L.

-

code 1693?

Why the factory service manual of course! Try THIS LINK to download a copy. John L.

-

Early shifting and surging??

Regarding the transmission shifting issue...Try replacing the transmission output shaft speed sensor located in the tail housing and see if that fixes it. It's an inexpensive part available at most any auto parts store and literally takes 5 minutes to remove and reinstall.Regards,John L.Sent from my iPad using Tapatalk HD

-

injector shims

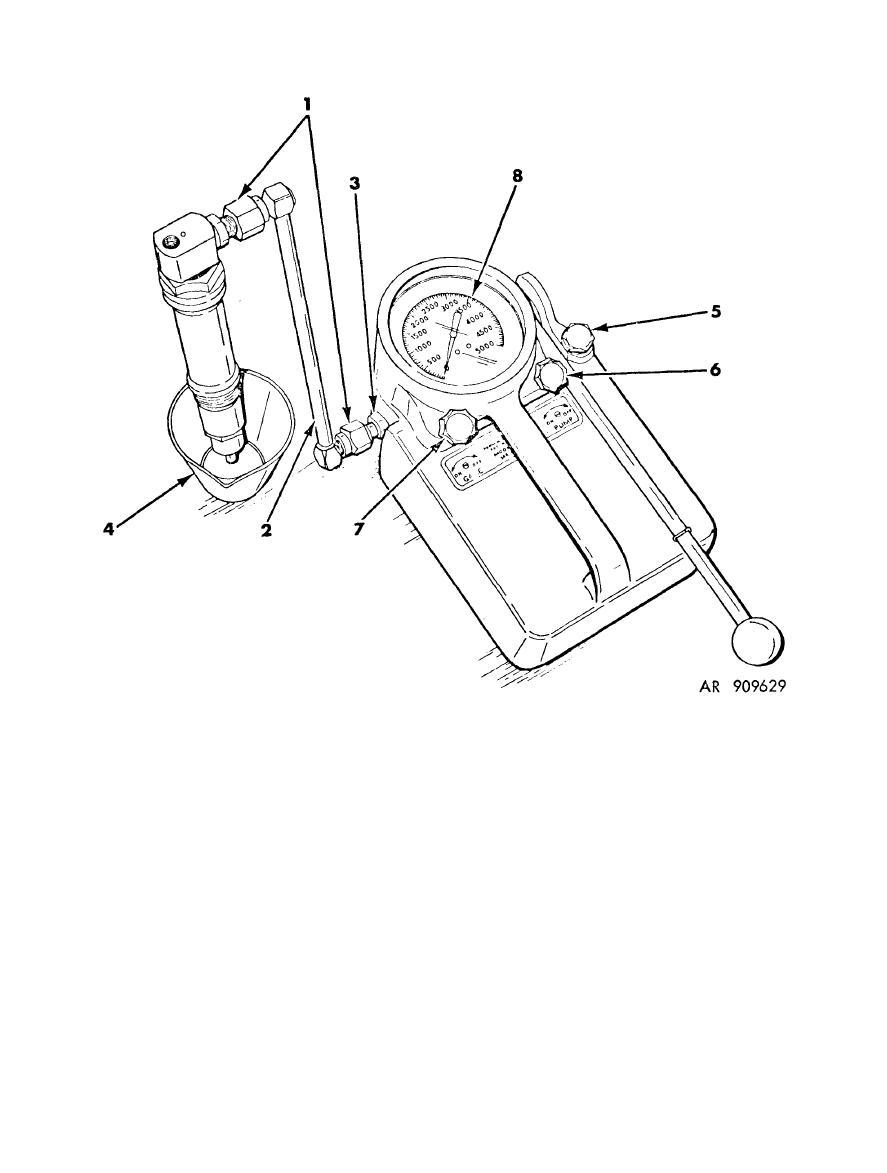

The best place to look for a good deal on one is probably eBay. I watched eBay for awhile and ultimately netted a heavy duty Army surplus injector tester made by Kiene Diesel (a Model DT-1300). It's capable of producing up to 7,500 psi, but mine has a 0-5,000 psi gauge. It came in a nice metal storage case complete with accessories. This illustration shows a sample setup when in use. When testing 24v Bosch injectors, you must use a Miller SPX 8301 adapter. I bought one on eBay also. Best regards, John L.

-

injector shims

Correct.They!re all the same diameter.As stated before (for clarity), the thickness of each shim may vary.John L.Sent from my iPhone using Tapatalk!