- Replies 102

- Views 23.2k

- Created

- Last Reply

Top Posters In This Topic

-

Me78569 34 posts

-

Mopar1973Man 26 posts

-

woodtrucker 12 posts

-

SpaceHiker 10 posts

Most Popular Posts

-

Well, since I've taken it upon myself today to solve the mystery of my truck's poor performance on 2-stroke oil (see cumminsforum), as a side effect I solved the mystery of the boost formula.

-

boost fooling from the ez. Remember the obdlink is showing you what the ECM is seeing, the Edge is limiting what hte ecm sees.

-

Hunting for hidden data that the VP44, ECM, PCM, ABS, SRS, etc might be talking over the bus and being able to read this hidden data. Later on like after 04.5 it seem most OBDII PID data is consistent

Ok gang... I'm going to share a few tidbit of information for advance OBDII tinkering.

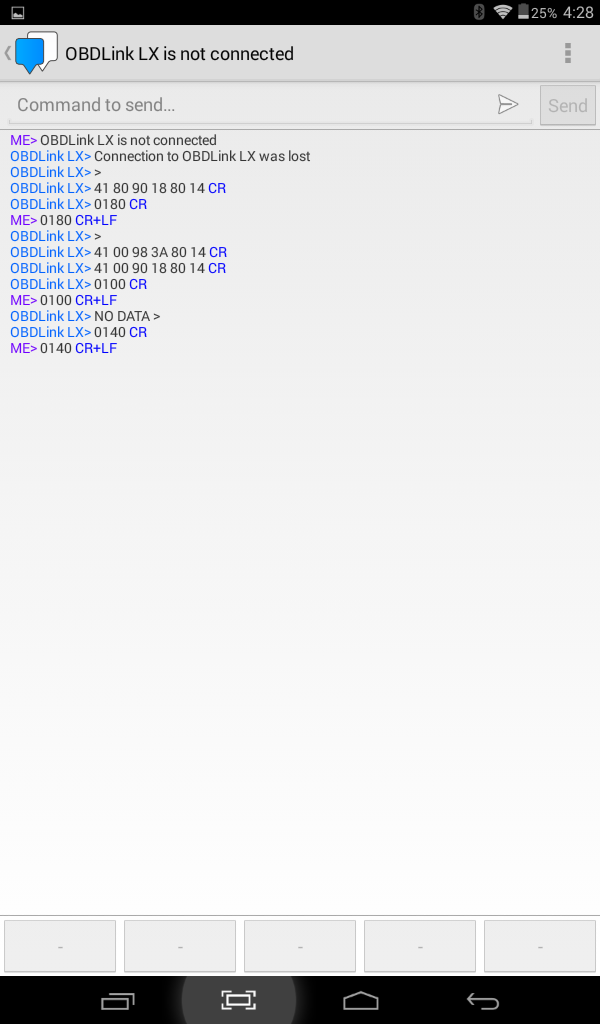

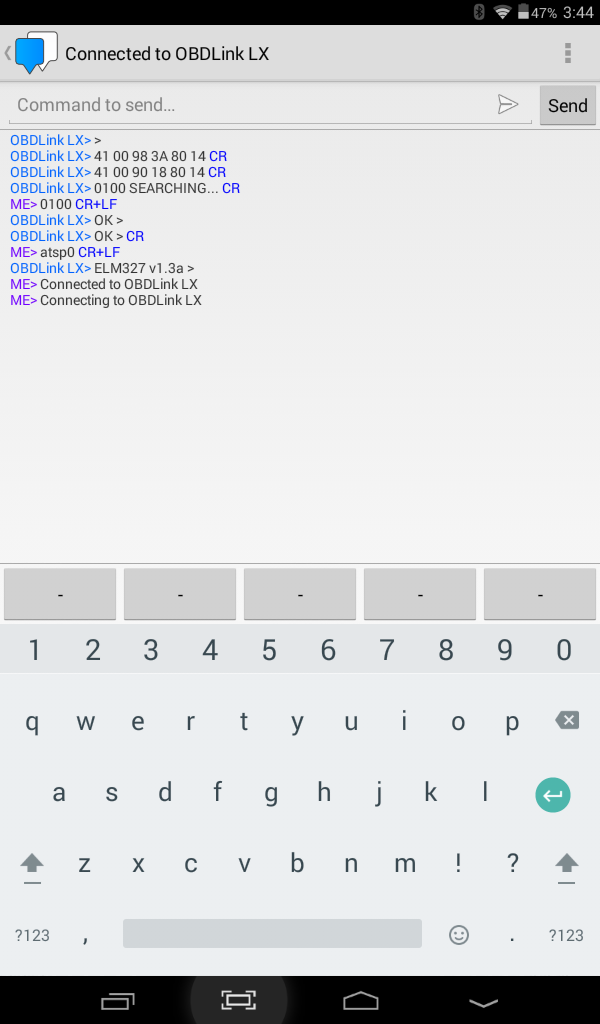

If you happen to have a OBDLink or ELM327 tool you should be able to tag along here. I will have to give a bit of thanks to @Me78569 for getting me started with the Bluetooth terminal on Android. Once I had that I could directly communicate with the OBDLink and pass commands to it. So starting out I passed the command...

ATSP0This basically tells the tool to communication with the detected protocol of the vehicle ours happens to be ISO 9141-2 protocol. After that I passed the command...

0100Which happens to be PID Mode 01 with the PID 00 which tells the vehicle to report back which ODBII PID are available. It returns back.

41 00 98 3A 80 14 41 00 90 18 80 14At this point the hexadecimal bytes you want are 98, 3A, 90, 18...

So now you need to take these 4 bytes on convert them to binary.

98 = 1001 1000

3A = 0011 1010

90 = 1001 0000

18 = 0001 1000

So now lay it all out in one long string. This is counting 20 hex (32 dec) from left to right.

1001 1000 0011 1010 1001 0000 0001 1000

So you have counting only the high bit (1's)...

01 - MIL Status Light

04 - Engine Load

05 - Coolant Temperature

(11) 0B - Manifold Pressure

(12) 0C - RPM

(13) 0D - MPH

(15) 0F - Intake Temperature

(17) 11 - APPS Sensor

(20) 14 (Unknown yet)

(28) 1C - OBD Compliance should report 05 hex.

(29) 1D - (Unknown yet)

NOTE: (number) is decimal... Just for the human side for counting placement. ECM/PCM use the hexadecimal values only.

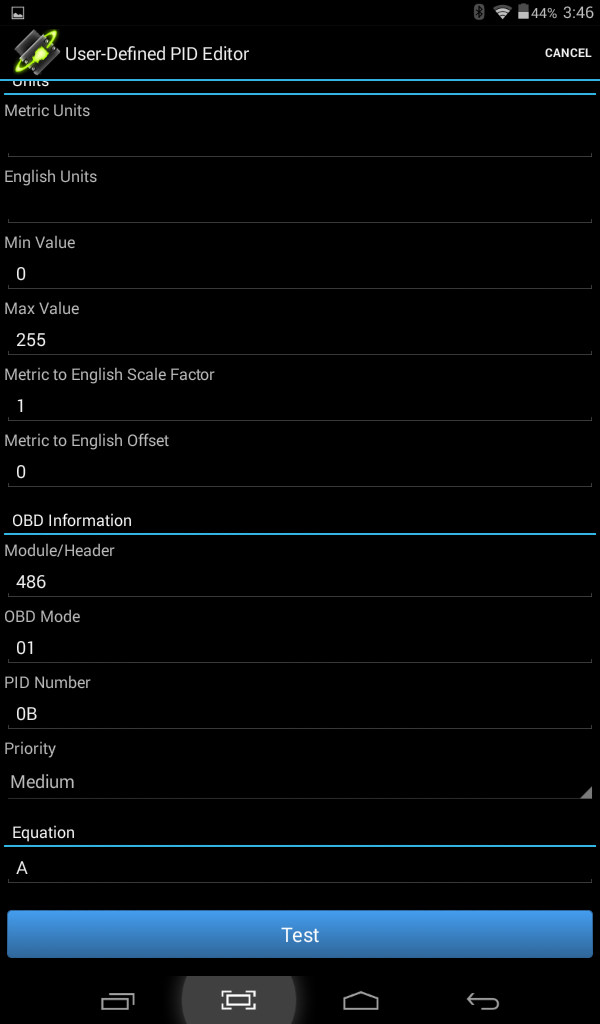

Now if you want to add any of these as a custom gauge.

Module/Header: 486

OBD Mode: 01

PID Number: (Any of the above will work use only the Hex number not the decimal)

Priority: Leave on High

Equation: Look it up on Wikipedia at https://en.wikipedia.org/wiki/OBD-II_PIDs

Edited by Mopar1973Man