- Replies 12

- Views 3.2k

- Created

- Last Reply

Top Posters In This Topic

-

Great work! 5 posts

-

Mopar1973Man 2 posts

-

wil440 2 posts

-

Linux 2 posts

Most Popular Posts

-

I spent better part of today modifying schematics and PCB layout. Version 2 now. My first layout passed the design rules check but I didn't like some of the tight spots that may short out. Hopefully s

-

This thread is the reason I joined the forum and "Great work!" is an appropriate handle for the OP. The possibilities are a joy to ponder given that this control along with something like a Holley dig

-

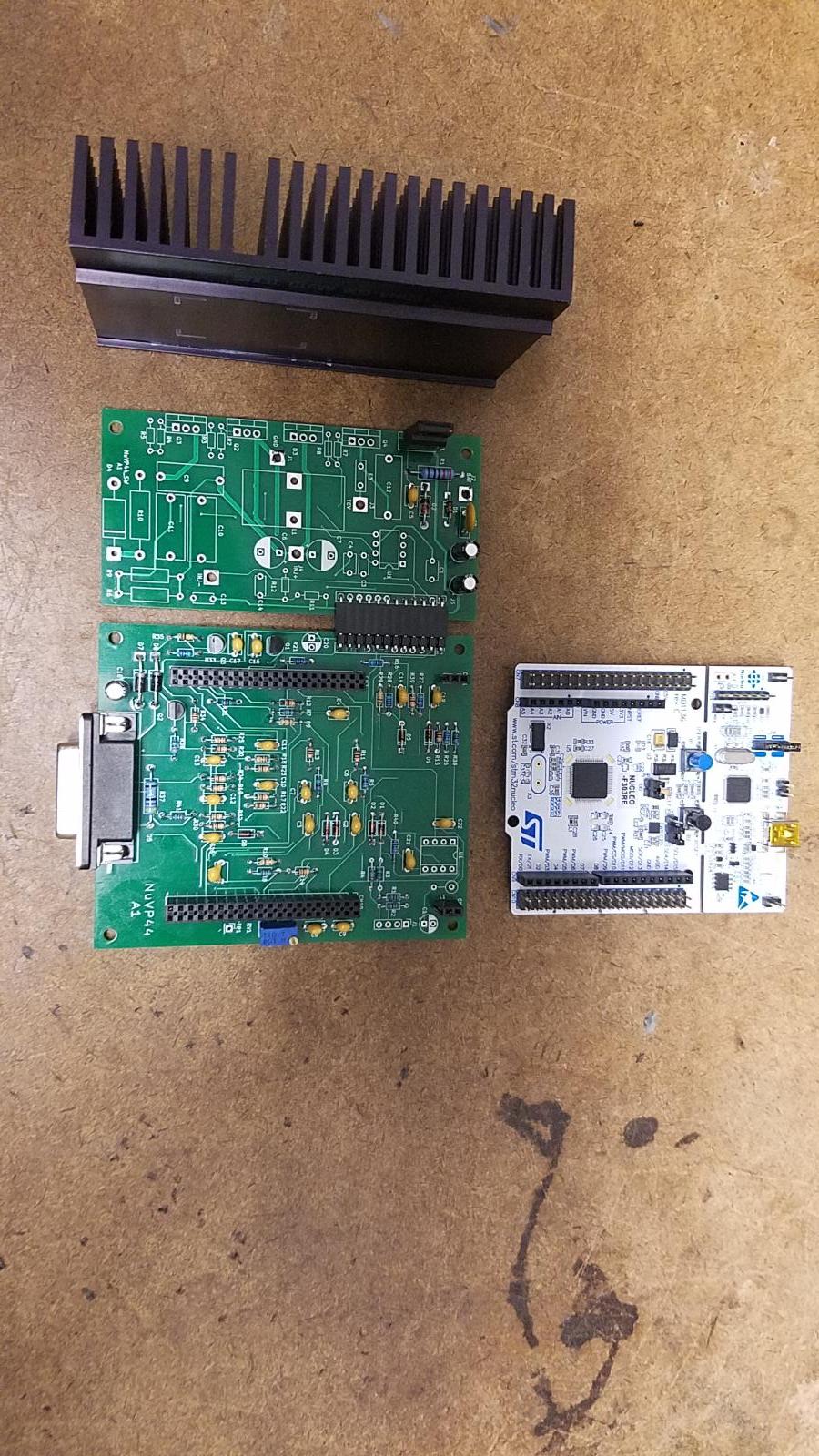

Update. The boards are here and look great. They were not that bad to design and the open source KiCad was pretty easy too learn. I did have to upgrade my PC though. The Gerber and drill files were se

So I've made some real progress the last couple weeks. Truck runs pretty well and cold starts are much better now.

Still have to harden the hardware to make it a daily driver. I got some open source schematic and PCB CAD generator

program called KiCAD, seems to work pretty good. Had some install issues because I'm still using Win 7 LOL but I found an older version that

works. I used to use Eagle CAD, not easy if you don't use it often and forget things like me.

Got most of the sanity checks done and correlated with the usual DTC codes. Some took guess work there isn't much in depth

documentation on them. Thanks to the MoparMan forum I found most of what I needed. Thats the way things are getting Manufactures

keep a lot of secrets so they can keep the customer coming back to the dealership.

Most of the DTCs I included are VP44 side. Others are combined now. Example the crank sensor goes straight into my controller so skips a seperate

ECU.

I'm running out A to D channels for more sensors so I'm considering a seperate board to read all the other sensors, control the grid heaters

and lift pump and interface with the instument cluster and PCM. That may actually end up being where the Tunes are stored too. I can even

fool the TPS output signal to the PCM so that could be some interresting transmission tinkering. I might even be able to take control of the

overhead display unit for even more fun.

Code needs more work to handle multiple DTC's at once and store them so they can be read after powered down.

Code snip explains most of it.

void sanityCheck(void) { //Some original OBDII codes are no longer applicable with the new controller //0230, 0232, TODO DTC 1285 static int errCnt1, errCnt2; static int DTCpending; static uint32_t lastSanity_time; if (millis() - lastSanity_time > 500) { lastSanity_time = millis(); if (TPSv < 0.25) { DTCpending = 0122; //APPS voltage to Low errCnt1 += 2; } if (TPSv > 4.0) { DTCpending = 0123; //APPS voltage to High errCnt1 += 2; } if (TPSv > 1.5 && idle_valid) { DTCpending = 0121; //P0121 APPS Sensor Volts Do Not Agree Idle Validation Signal errCnt1 += 1; } if (BATv > 18.0) { DTCpending = 0563; //Battery voltage too High errCnt1 += 1; } if (BATv < 3.0) { DTCpending = 0215; //No voltage from fuel system relay / fuse errCnt1 += 1; } if (amps_ref1 > 2000) //raw ADC reading { DTCpending = 0251; //P0251 VP44 Pump Fuel Valve Feedback Circuit Fuel valve current detected when there sould be none errCnt1 += 3; } if (AMPS < 2.0 && crank && BATv > 11.0 ) { DTCpending = 0253; //P0253 Fuel Injection Pump Fuel Valve Open Circuit errCnt1 += 1; } if (AMPS > 15.0 && RPM > 800) { DTCpending = 0254; //P0254 VP44 Fuel Valve Current Too High errCnt1 += 2; } if (TimingRetrys > 5) { DTC = 0216; //actual timing not match commanded timing, >= 2 degrees mismatch and 5 re-try. TimingRetrys = 0; //comes from TCV servo function } if (MAPv < 0.1) { DTCpending = 0237; //MAP sensor too low errCnt1 += 1; } if (BOOST > 5 && RPM < 900 && Load < 10 ) { DTCpending = 238; // MAP sensor too high when it sould be low. errCnt1 += 1; } if (injMalfunction > 1) { DTCpending = 1688; //injection drive malfunction, inj. event counter incorect. errCnt1 += 1; } if (errCnt1 > 3) { DTC = DTCpending; //a pending error happend too many times, pending code becomes in effect errCnt1 = 0; DTCpending = 0; injMalfunction = 0; } if (!DTCpending) { errCnt1 = 0; //happy } //pulsing sensors checked every 0.5 seconds, is engine rotating? if (VPsync || CKPsync || CamSync) { errCnt2 ++; //errCnt2 increments fast or slow based on priority if (VPsync && !CKPsync && errCnt2 > 1) { DTC = 0336; //P0336 Crankshaft Position Sensor Signal } if (VPsync && !CamSync && errCnt2 > 1) { DTC = 0341; //P0341 Camshaft Position Sensor Signal Missing } if (CKPsync && !VPsync && errCnt2 > 1) { DTC = 0370; //P0370 VP44 Speed/Position Sensor Signal Lost } if (VPsync && CKPsync && CamSync) { errCnt2 = 0; //rotation sensors are happy so reset error counter } } if (!eepromValid) { DTC = 1691; //P1691 VP44 Controller Calibration Error. } if (WasIWDreset) { DTC = 1688; //prog crashed and internal watchdog reset CPU; P1688 Internal Fuel Injection Pump Failure } if (DTC == 0122 || DTC == 0123 || DTC == 0216 || DTC == 238 || DTC == 0336) { //run but power limited if (RPM > 800 && RevCounter > 60) { //some stabalizing time (60 crankshaft revolutions) to prevent false limp when started Limp = 1; //limp does not clear until ignition recycled, TODO } } if (DTC == 0563 || DTC == 0251 || DTC == 0254) { //critical errors shut off fuel system relay or risk burning inj. solenoid shutOff(); } } }//sanity done void shutOff(void) { TIM2->CCMR1 = FORCE_LOW; //FORCE low to drive inj sol off pinMode(PC12, OUTPUT); // Fuel system relay drive; end high Z state which allows hardware timeout and force off by software digitalWrite(PC12, LOW); // Turn off Fuel system relay. may already be off by hardware fault detection circuit Serial.print(" shut off DTC "); Serial.println(DTC); //show why it shut off }