- Replies 45

- Views 4.8k

- Created

- Last Reply

Top Posters In This Topic

-

jamesecox 18 posts

jamesecox 18 posts -

Mopar1973Man 8 posts

Mopar1973Man 8 posts -

2000Ram2500 6 posts

2000Ram2500 6 posts -

pepsi71ocean 5 posts

pepsi71ocean 5 posts

Most Popular Posts

-

How is beyond my expertise. Here is a list of rebuilders members have had good results with. A lot of folks claim they can do it but it seems they cannot. I had my bad experience years ago and

-

So step 1 today was checking the diode on the alternator. I'm going to assume it's bad as tr he lowest reading I got was 0.074 and at times it jumped to as high as 1.46 so I will be buying a diode and

-

That is true. When you start the engine the grid heater will cycle on and off for set time or till the vehicle reaches 20-25 MPH then the ECM disables the grid heater this is a reason I do not suggest

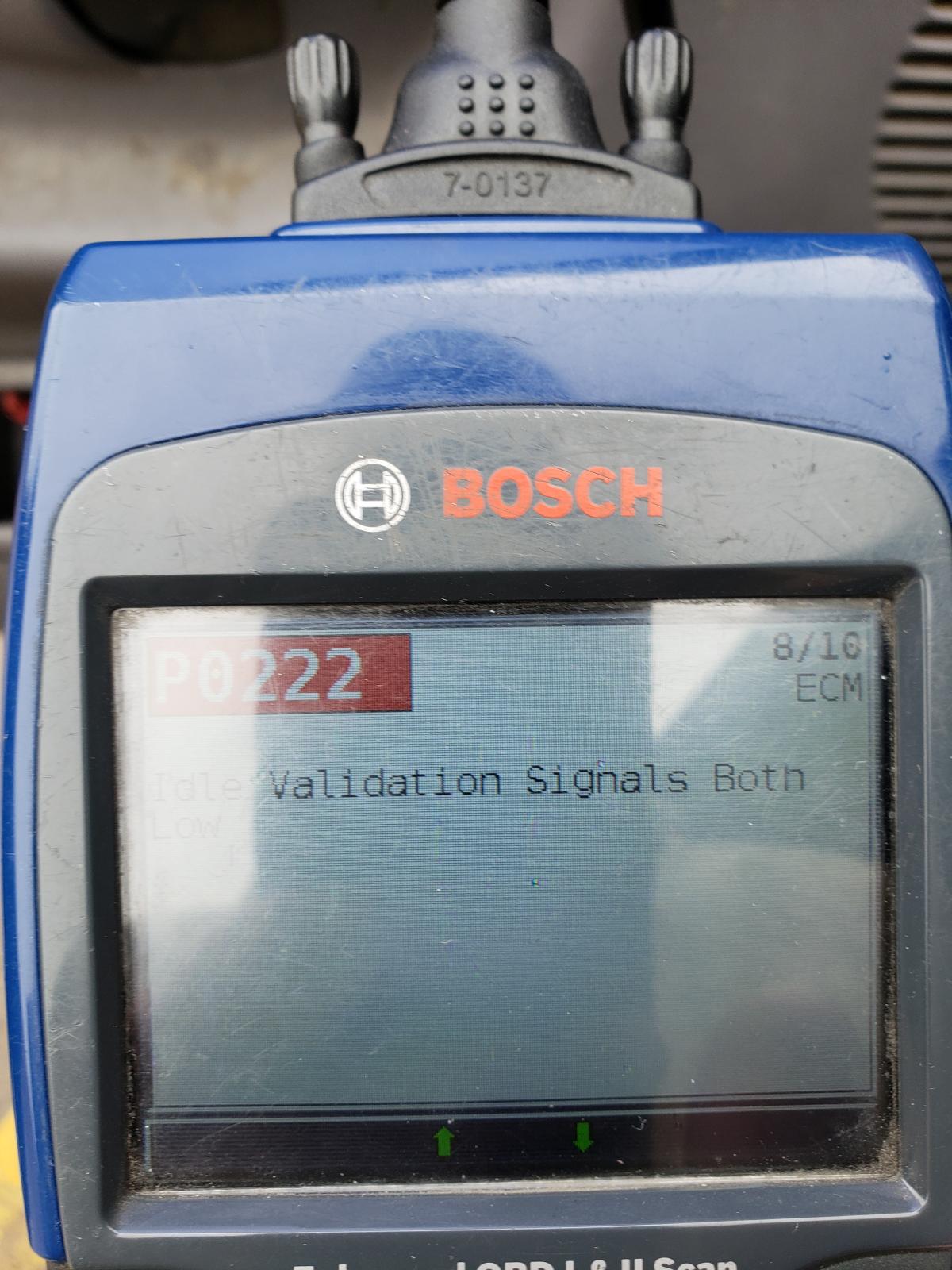

Ok so here I go, I have a 99 ram 2500 4x4 auto trans 24v 280k miles. I am having a gremlin and here are the symptoms and the story. It started with my transmission not shifting out of 1st no matter how few or many rpms you threw at it unless you let off the petal and kicked it down that way, so I replaced Gov pressure solenoid, transducer, and for good measure the o/d and lockup solenoids as well also tightened the bands to spec and put new fluid in. Did not fix the issue, then the next day driving to work my speedometer says I'm not working Monday and drops to 0, so i replace both the speed sensor in the transmission tail housing and the one in the rear axle. Fixes the speedo issue but not the shifting issue. Then i get a check engine code for my apps, i put the multimeter on it and it checked out fine but i replaced it anyway with the one sold on the store here code went away, UNTILL the truck is driven. Once I get up to about 1600-1800 rpm (rpm is the only factor I have found in when it goes off) the check engine light comes on, but here is the kicker when you shut the truck down it clears the check engine code from existence.

****an update on this as well, yesterday while driving home doing about 55mph the truck acted like it shifted from o/d into 2nd it was enough to pull me forward in my seat some from the force of the downshift. I also have a symptom of wait to start light not coming on right away it comes on about 45 seconds after you put the key in the on position and the truck will not fire unless you wait for it to go out, I do hear my lift pump kick on when the wait to start light comes on but not before.

This all kinda leads me to believe it's not a multitude of problems like I have been looking at it but some form of electrical or grounding gremlin (i know I know those are so rare) or even a bad ecm.

This is my daily driver so I need to get it back to a reliable state and help is greatly appreciated.