KDP check at 155k miles

- Replies 5

- Views 1.5k

- Created

- Last Reply

Top Posters In This Topic

-

wil440 2 posts

-

IBMobile 1 post

-

CUMMINSDIESELPWR 1 post

-

Marcus2000monster 1 post

Popular Days

Most Popular Posts

-

Glade to hear that you're bringing it back to a respectable condition. Pictures if you would please. We like to see the transformations.

-

Like he said!

-

Mine is a 98.5 and the cover isn't updated as I can see the whole circumference of the dowel coming through the case by about 10 thou. Now i've looked at the picture again it almost looks like th

I've had this truck for just under a year and done a lot of repairs that the previous owner just didn't bother to do, as in both front brakes siezed so 1 new caliper as I'd got it in the garage, 1 new piston, seal kit and a slider kit, back brakes checked and freed off, ctm changed due to door locks not working, window runners fixed, Cat fuel filter complete fitted as previous plank decided it didn't need a filter and threw the whole lot away, luckily he only did about 100 miles in it afterwards, it had about 9 months MOT on it and our MOTs are strict usually so I'm guessing a mate did it.

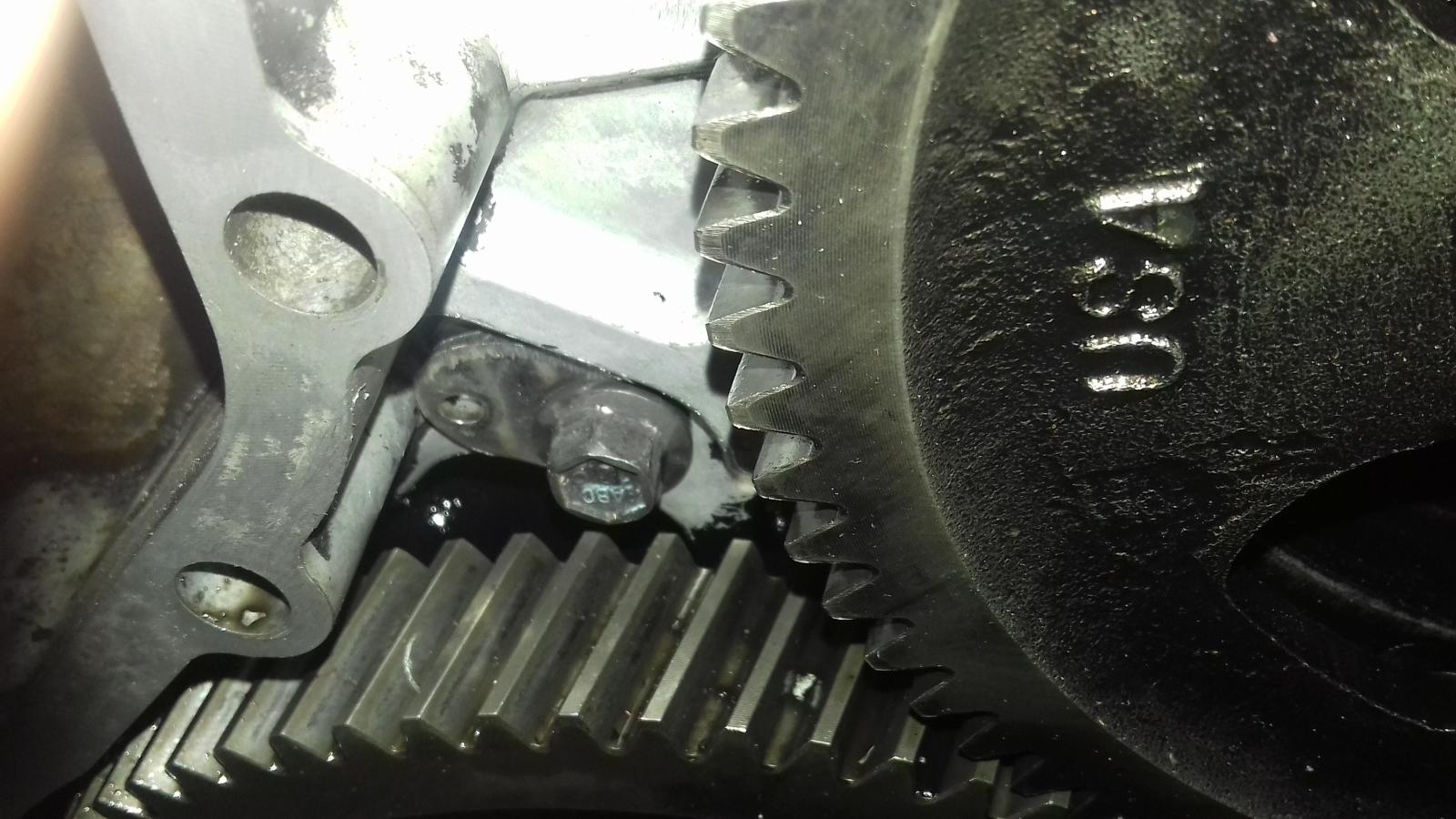

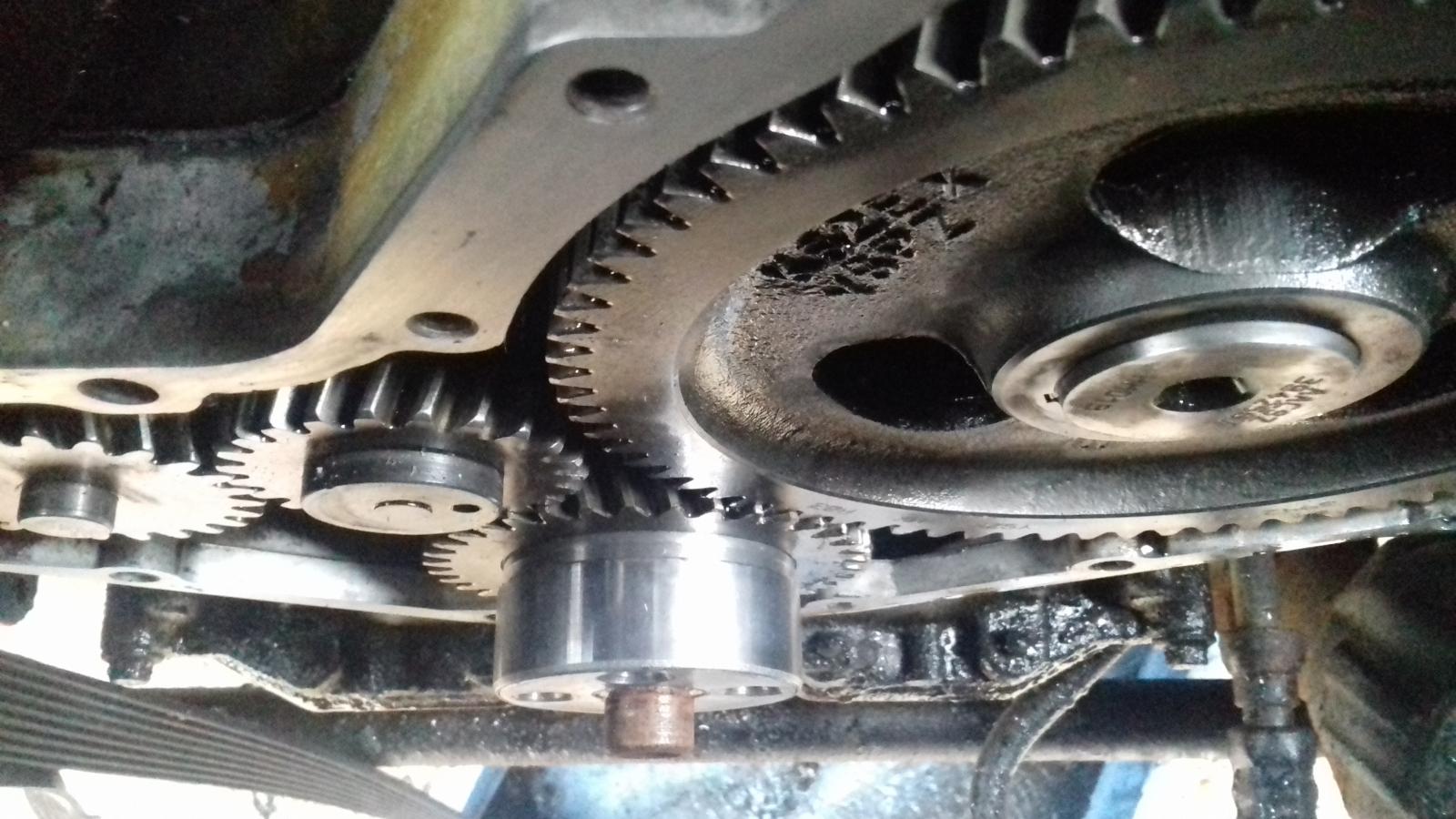

Anyway truck runs nice now, still more to do but I'd been thinking and reading and decided to check the timing cover dowel pin due to a little oil around the area and not wanting a grenade under the front, so holiday today and tomorrow, 3 hours in I'm looking at the pin which is all nice and tight in the case, the bolt next to it is not so happy and while not hanging out it was not tight by any means, so out it comes and the locktite has failed due to engine oil, I remembered I had a Lokar throttle cable return spring bracket off of a 440 somewhere so dug it out and minimal trimming and theres the retainer for the pin, all cleaned, locktite and torqued, new seal set in the cover to the right depth with sealant and the wear sleeve sat on top of our boiler doing a bit of expanding, hoping to slip it on tomorrow but if not will press it on using the pulley... seal from the USA $35 inc sleeve, landed here £70, UK customs are just great aren't they !

Next job in order... fuel lines then earths, then quad, then trans