- Replies 7

- Views 2.6k

- Created

- Last Reply

Top Posters In This Topic

-

Leaky88 3 posts

-

Mopar1973Man 2 posts

-

Dieselfuture 2 posts

Most Popular Posts

-

Could be it got overloaded and eye hole got bigger. On my mud truck bushings were gone so I just had a shop mill a DOM tube to fit tight inside the eye and had a hole for a 5/8 bolt. Then I drilled th

-

Diesel future, Thanks. Could very well be the issue. I bought it second hand, so I’m not sure of prior abuse. I took some measurements and it’s not a true eye hole. The Bushing has 1

Left Rear Support Bracket, beside fuel tank, rusted out and was replaced.

Removed the old front bushing, on Forward Eye, cleaned it up.

When I went to replace with new bushing, it fits, but it just slides in, there is no interference fit, and it requires no press.

Is this normal? I’ve checked the part number and it’s correct. O.D. Is 1-5/8.

When I did the rear smaller bushing, I needed a bolt and stack of washers to draw it in.

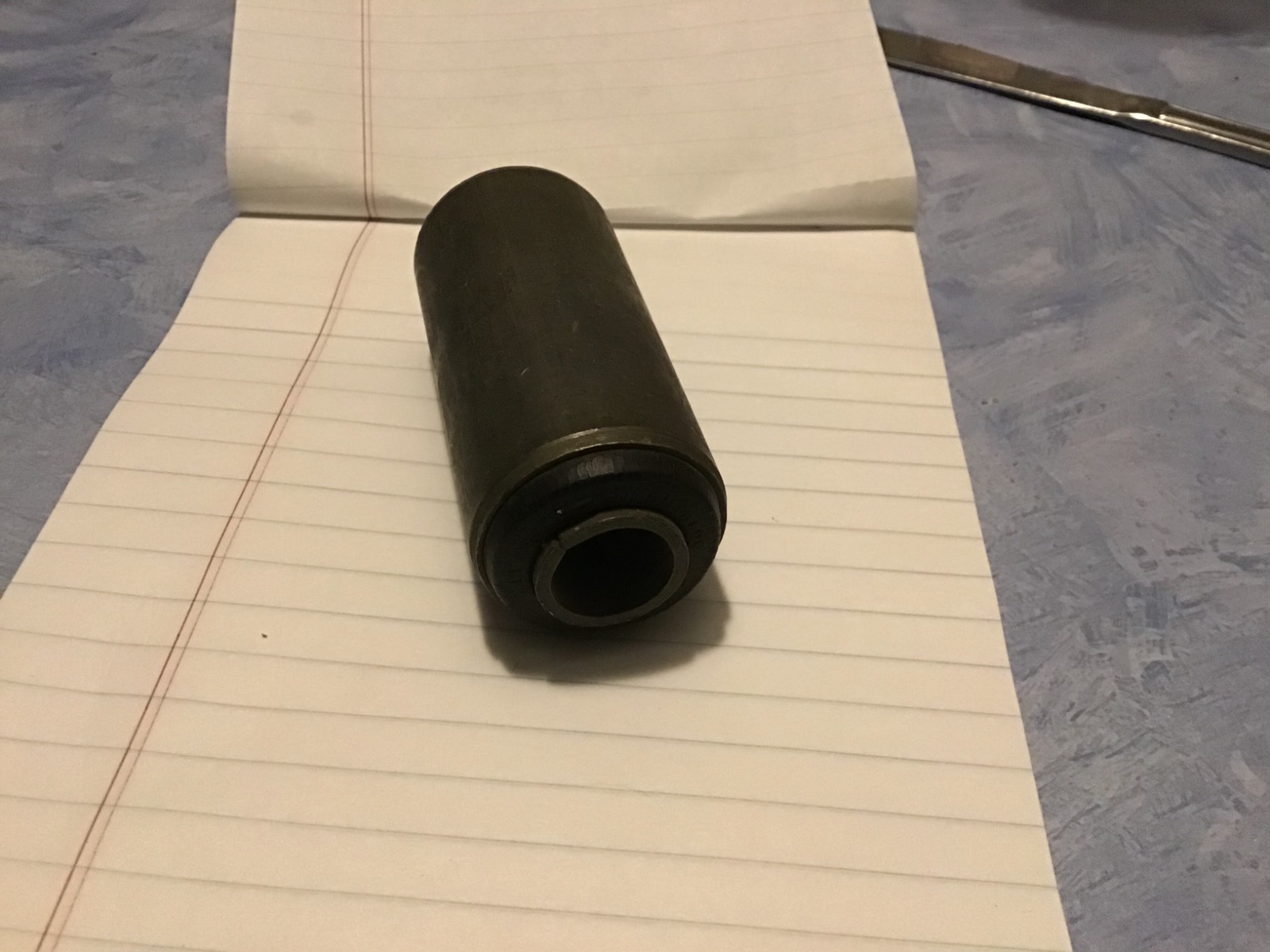

Picture is an “example” of the type of one piece bushing replacement I’m using. It smaller size used on rear end of leaf spring.

Any assistance would be appreciated.

Thanks

Leaky