-

88 C2500 4.3 Supply/Return lines

Mike, thanks I do have an assortment of AC green O-Rings, I was unsure if they were suitable for gasoline.

-

88 C2500 4.3 Supply/Return lines

Hello, My fuel lines rusted and developed a leak. I found a Dorman replacement for the Supply, but none for the return line. Also, at the Fuel Module Connections for these lines, there are some very small O-rings on the Module end fittings which I want replace. Does anyone have experience with replacing these fuel lines and know a source for these O-rings and a new return line? Thanks

-

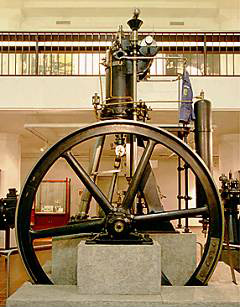

Wheel Bearings-mix or match?

I’ve keep this part in my tool box since 89. While in Cuba, I had an Old Willys Jeep. Engine had real issues, and guy wanted it gone, so I bought it. After I got into the engine, the part (pictured) was on each of the Main Bearing Saddles. It’s function was lock the main bearing half in place. But one saddle was missing one, which explained the noise. There was no Internet, and any attempt to find from the States was in vain. After exhausting every avenue, I remembered we had a Ship Repair Facility. Knowing they too are kept on a close leash, I, with “hat in hand”, found a Machinist and explained my dilemma, and showed him the part. He took measurements, made a perfect part, and then made a second one (one pictured) by sight only. He never measured the second free-hand one until he took it off the machine. It too was spot on. Drove Jeep for 2 years afterwards thanks to that Machinist.

-

Wheel Bearings-mix or match?

I was in a Shore Intermediate Maintenance Activity in Little Creek Va in 85. It was a “massive” Machine Shop that made parts for ships that were no longer available from manufacturers. Sailors would bring in old valves, parts from boilers, you name it. More often then not, they were critical parts from propulsion plant that prevented the ship from getting underway. It was amazing to watch them machine a new part from a failed part, and to such exacting standards. I can only imagine the advancements since then.

-

Wheel Bearings-mix or match?

OK. With +/- .00025 tolerances, my concerns about current day machining tolerances are assuaged. I’ll put the damn AZ Bearings from 2 different manufactures and call it done. Appreciate being brought up to 2021.

-

Wheel Bearings-mix or match?

Thanks.

-

Wheel Bearings-mix or match?

I attempted to get an answer from Timken and National using one of those “GFYS” Contact Links forms companies hide behind. Still waiting…could be a non-work day for Beijing employee tasked with providing a response. I was taught Bearings and Races come as a set and are not to be mixed. Also, new bearings of unlike brands are not to be mixed, as tolerances and metal may not be the same between companies. All my purchases until now consisted of a box containing a Bearing and it’s Race. Has this changed? AZ sold me 2 National 15101 Bearings. I asked where it’s Races were and was told they are sold separately and then offered 2 Timken 15245 Races. I found the same thing on O’Reilly and NAPA sites, Bearings with no accompanying race. I know most Aftermarket Rotors come with a Race installed, but I’ve punched them out and installed my own matched set. So what’s the deal? Thanks

-

LF Wheel Hub Play

Not a problem, I have a lot of fun with this Truck. I have still not found this fact in the FSM though. Unfortunately, my CRS gets worse with age. Before long I’ll be meeting long time family members and introducing myself like it’s our first meeting.

-

LF Wheel Hub Play

Appreciate the Feedback. Update: I like to have parts before I start. Rock Auto selection of Hubs has a sea of types depending upon ABS, 4WD, dual wheels etc. So I tried to narrow it down at AZ. Man at AZ kept talking/suggesting “regular wheel replacement bearings/races” and I would not listen, insisting bearing hubs were needed. Turns out, I don’t have bearing hubs. Both the Inner/Outer Bearing on my Front Wheels are replaceable. Perhaps having an Independent Front Suspension, 2WD is reason , I don’t know. ( Or, it could be linked to the different location of my Cruise Light is on the Cluster for those that might recall that rabbit hole I went into.) The strange thing is, I can’t find, or have not found a section in FSM that talks to this. Sadly, I was really looking forward to getting that OEM 22 year old hub, torqued to 280#, and exposed to the elements, but I’m sure there’s another character builder awaiting me in the future. Onward. Thanks Leaky

-

LF Wheel Hub Play

Thanks. I try to avoid pot holes etc.. Anyone know the longevity/mileage on these hubs?

-

LF Wheel Hub Play

Was checking front end before making an appointment for alignment and noticed LF wheel has play with hands at 12 and 6 O’clock but NOT at 3 and 9 O’clock. I really have to put some effort into it to feel it, but it’s there. Wheel spins both direction with no noise/grinding (All the bad stuff.) nor do I hear anything at Highway Speeds (If that is possible with a Diesel.) I was hoping it was a Ball Joint, but I see no issues. Any advice? Thanks Leaky.

-

Dash Indicator Light Replacement

I appreciate the Feedback. I am so overwhelmed with directions I can go now, I might just learn to do without the “Cruise” light.:) I need to stop looking for problems on this truck.

-

Dash Indicator Light Replacement

Thanks

-

Dash Indicator Light Replacement

Silverwolf, Mine is LCD display like a calculator.

-

Dash Indicator Light Replacement

By my calculations, 17 Bulbs total are needed. 7-194’s, 10-74’s. If I go with SuperBrightLed, and change everything to LED, total damage is $66.57. Hopefully the soothing glow of these LEDs will put me in a better mood.