Pinion Bearing Stuck

- Replies 2

- Views 1.4k

- Created

- Last Reply

Popular Days

Most Popular Posts

-

I wouldn't touch it as you will only be able to change the outer one if you could get it out, to do the job right it's a full strip down of axle and I'd say just changing the outer bearing would chang

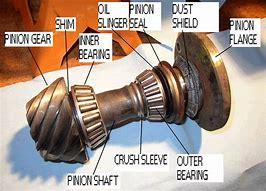

Replaced wheel bearing, seals, calipers and pads and thought while I'm there I'll replace pinion bearing and seal. It is froze on there, we pryed on it, hit shaft with dead blow hammer and we just put the seal in and and said run it.

Any tips on getting it out short of stripping rear end?