2000 Cummins Surge/Dead Pedal

- Replies 55

- Views 9.7k

- Created

- Last Reply

Top Posters In This Topic

-

DunnerCummins24 25 posts

-

Tractorman 16 posts

-

Mopar1973Man 7 posts

-

IBMobile 7 posts

Most Popular Posts

-

Sounds like you have been thorough in taking care of things since you acquired the truck. Have you checked the conditions of all battery connections and frame / body wiring grounds?

-

I would do this step, first. It would be good to know whether or not a false signal is being generated at idle. Since the DTC states, "Idle Validation Signals Both Low Problem detected wi

-

It sounds like you have confirmed that a false signal is being generated in the APPS output circuit. It would stand to reason that the engine rpm's would increase if a signal is present. Back to a pr

Most Helpful Posts

-

This doesn't mean that the APPS is faulty - it just means that there is an output signal at idle when there shouldn't be. Need to know where it is coming from. More troubleshooting needed. Since I d

Hello everyone,

New to the forum here, have a 2000 Dodge 24 valve. I’m a mechanic by trade, bought the the truck off one of our customers. He had this issue towards the end of his ownership, truck would surge during idle and the odd time would throw APPS code but he could still drive it.

The trucks had a couple different APPS sensors, OEM and aftermarket. When I bought the truck last summer I did a ton of upgrades/maintenance, starter, alternator, 2 new batteries, FASS and sump, fuel pressure gauge and a bunch of other things non related to the problem. I did all the APPS testing between sensor and ECM and everything checked out.

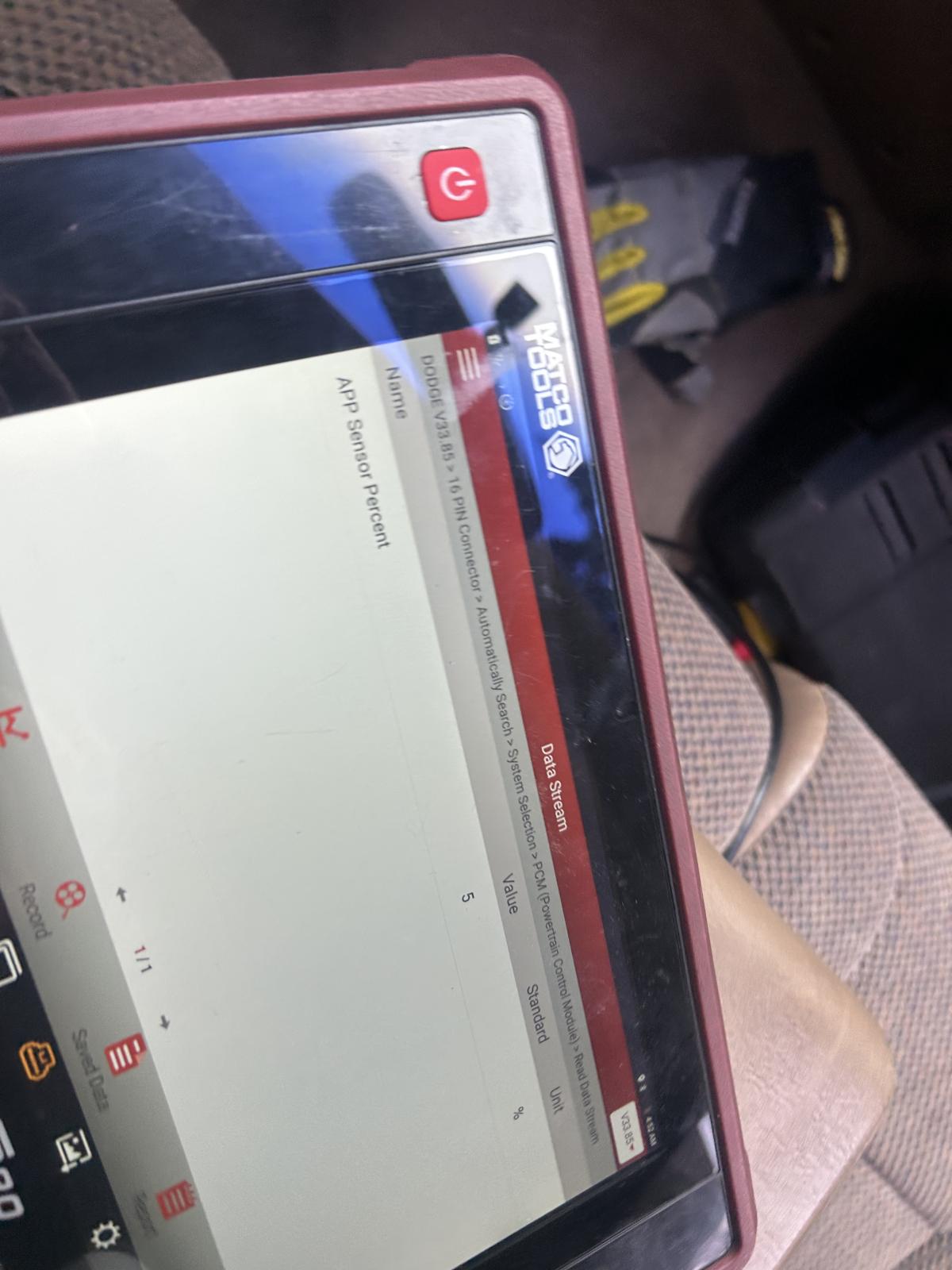

After doing the timbo APPS my issues seemed to go away (the alternator change was around this time too). We have a truck bed camper and went on a couple long trips with no issues. I don’t drive it much in the winter but again when I did, no issues. The start of this year also had no issues, and then things slowly started to creep back. I’d be sitting at a stop light and truck would kick up a bit, started becoming more frequent, and now it’s dead pedalling again, I’ll take off for work in the morning, I’ll be trying to come to a stop and RPMS will stay high, then 2 minutes later CEL comes on and no throttle. Takes me a while to get into the system with my scanner, I’ll clear it and I can drive but will either rev real high right away and trip the light or it’ll throw it a minute down the road again. But then if I work through it enough times, and the truck warms up enough I can get going with no issues. I can go somewhere, shut the truck off, go in somewhere and drive all the way home, again no issues. But if the trucks cold or sitting for days it’ll give me issues.

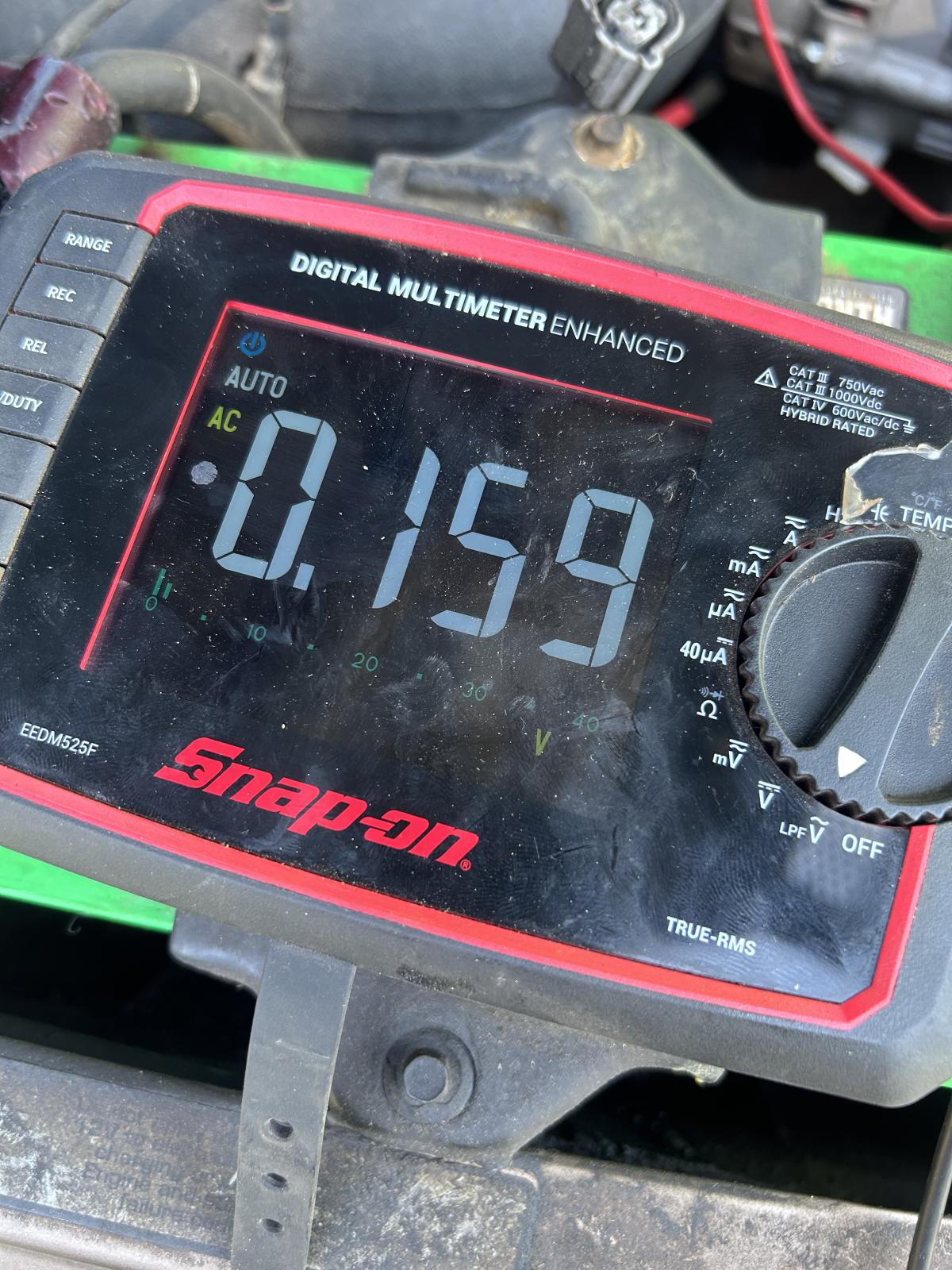

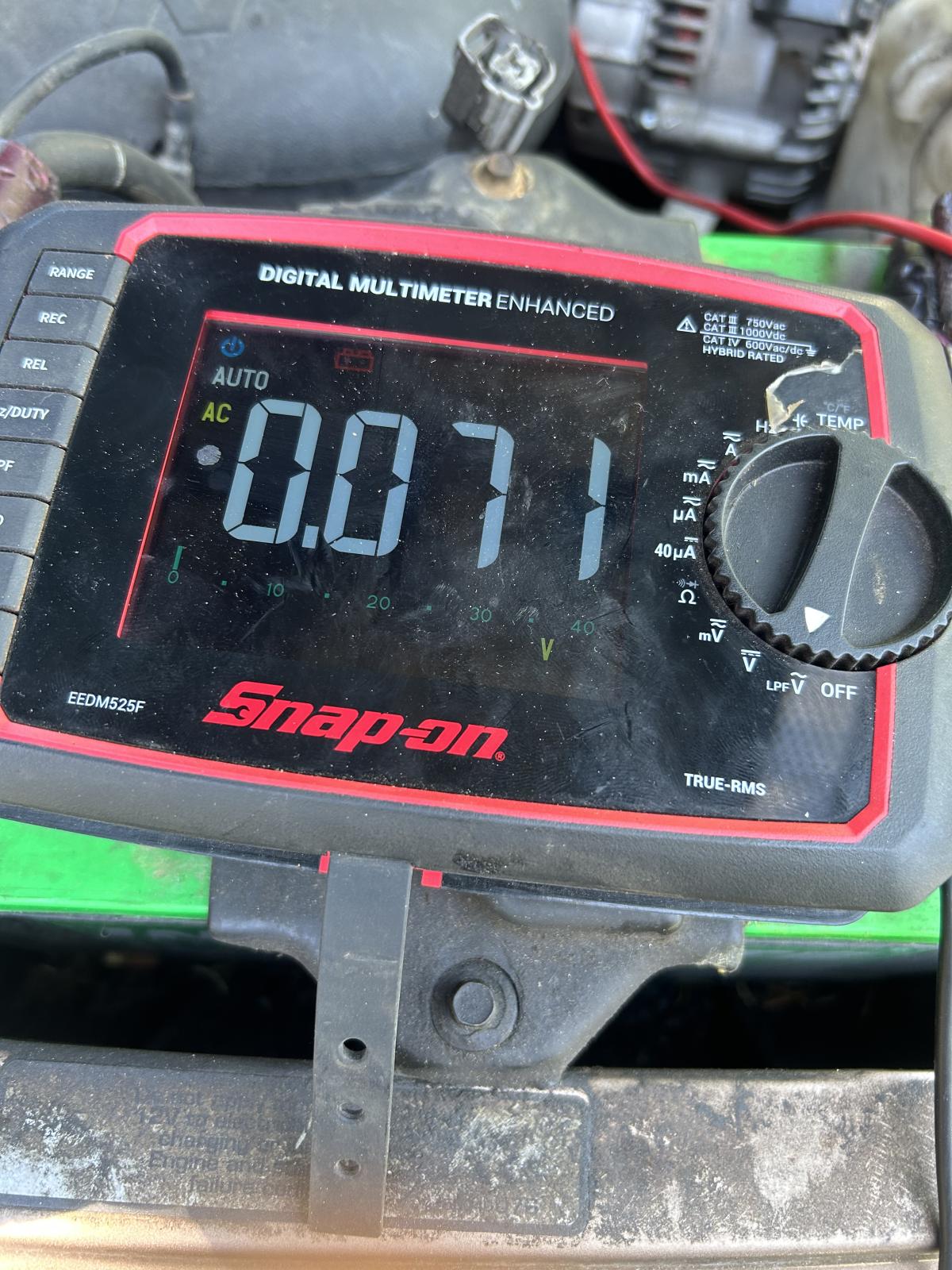

I checked for AC noise and am getting 0.127V, is this possibly an alternator gone bad? Like I said I replaced it last year with the timbo and was good for awhile but now a year later dealing with the same problems. Just want to make sure I’m not missing something here. Seems weird to me that it goes away when the truck warms up. Any insight would be greatly appreciated!