- Replies 5

- Views 103

- Created

- Last Reply

Top Posters In This Topic

-

Tractorman 2 posts

-

Jordan_ 2 posts

-

Mopar1973Man 1 post

Popular Days

Most Popular Posts

-

Good information on your first post; however, I am not sure what a "hiccup" means - could you elaborate on that description a bit more? In the meantime I will refer to "hiccup" as a symptom. If I

-

Good idea posting the video. I listened to it several times. To me, it sounds as if the engine fueling is being momentarily switched off (no fueling, falling rpm) and then a split second later switc

Need some help. I have an issue with my truck where it will progressively hiccup then stall. Truck is a 99' 2500 auto 4wd shortbed

If I start the truck and change to gear, after 4 minutes truck will start hiccupping and it will hiccup in intervals of exactly 5.4 seconds where they progressively get worse. After about a dozen or so it's bad enough that it's able to stall.

If I start and stay in idle, wait 5 minutes, change to gear, it will immediately stall.

The predictability is truck start -> 5 minutes pass -> will stall.

However:

I can circumvent it by applying and holding throttle for about 5-10 seconds. If I do this before, during, or after that hiccupping cycle starts, I can drive like normal for however long I want with no issues. But once the truck is shut off, depending how long I wait to start the truck again, it will either immediately stall or go back to square one. The sooner I start the truck, the sooner the cycle starts. Overnight, the hiccupping will start after 4 minutes.

So, this issue happened 3 years ago as well. Now is the time to mention I had, and have again, a P0216 code. Last time, after I changed the factory APPS sensor to the WELLS, everything ran smoothly and the code went away and all issues went away for over 2 years.

Currently, the WELLS APPS is set to .533v. The original was labeled .536v before being replaced.

Fass lift pump steady at 14-15psi.

Restarts immediately after stall.

Alternator outputs 13.5-14v.

Potential issues:

Live throttle reading is between 10.2% and 73%

Truck will not reset APPS. Remains 10.2%-73% after multiple attempts.

While live throttle reading is stable with key on, engine off, with the truck on it oscillates ~9.8%-10.2%

Troubleshooting so far:

-I've tested the APPS sensor voltage while the truck is on and off with a multimeter and it remains stable, even during the hiccups/stalls. While all measures don't point to it being the cause again, a replacement is on the way just to rule it out completely.

-I've tested the idle at 6v and 5v. Symptoms change a little but remain.

-I've done the W-T mod. Nothing changed.

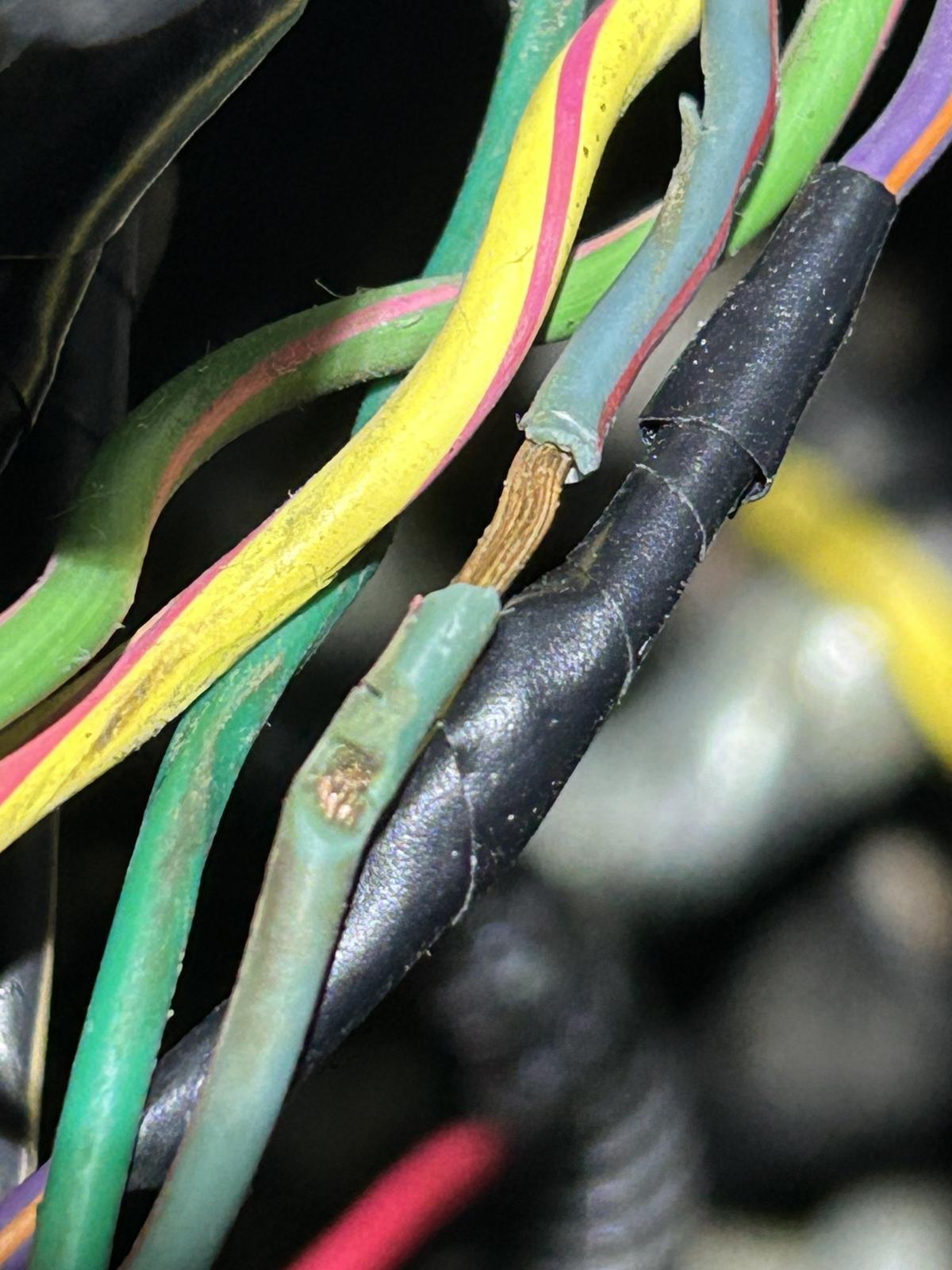

-I've re-cleaned each and every ground cable and terminal. Nothing changed.

-I've wiggled the cables while measuring, APPS voltage remained steady.

Does anything immediately ring a bell and sound like something you think you know what it is?

If not, where do I go from here?

Thanks for all the help.