All Activity

- Today

-

Problem with idle cut off

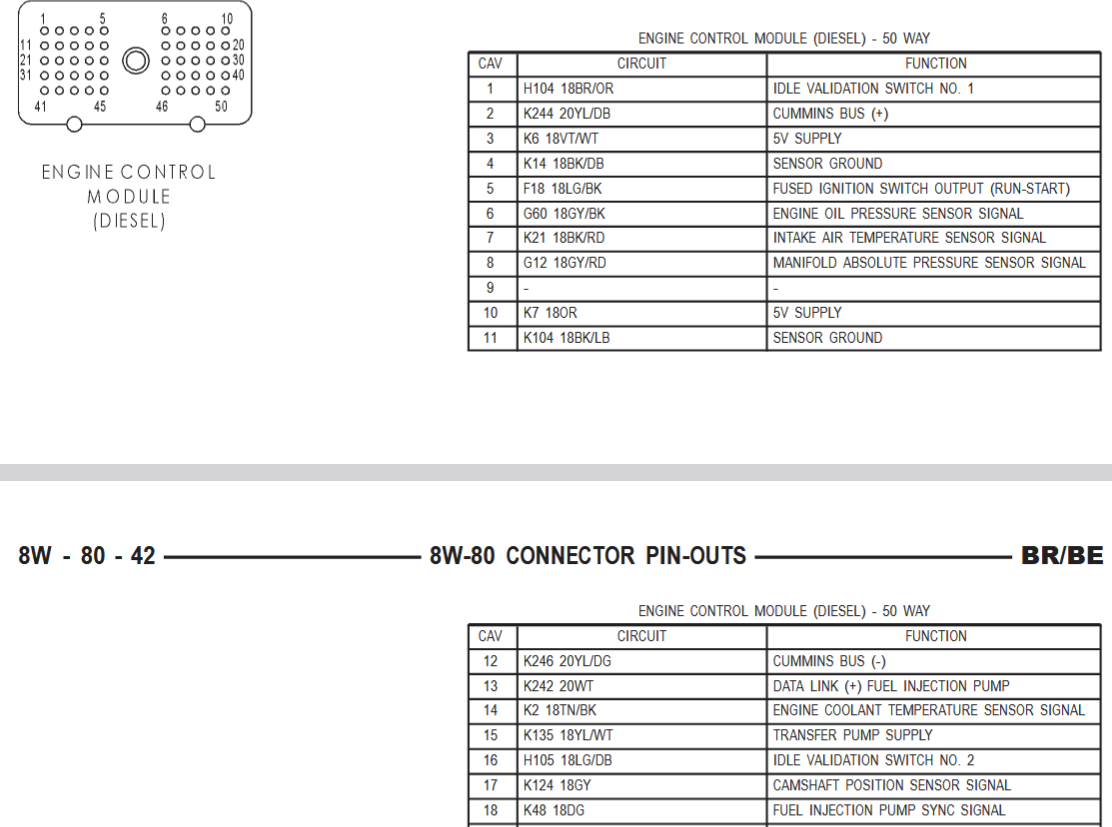

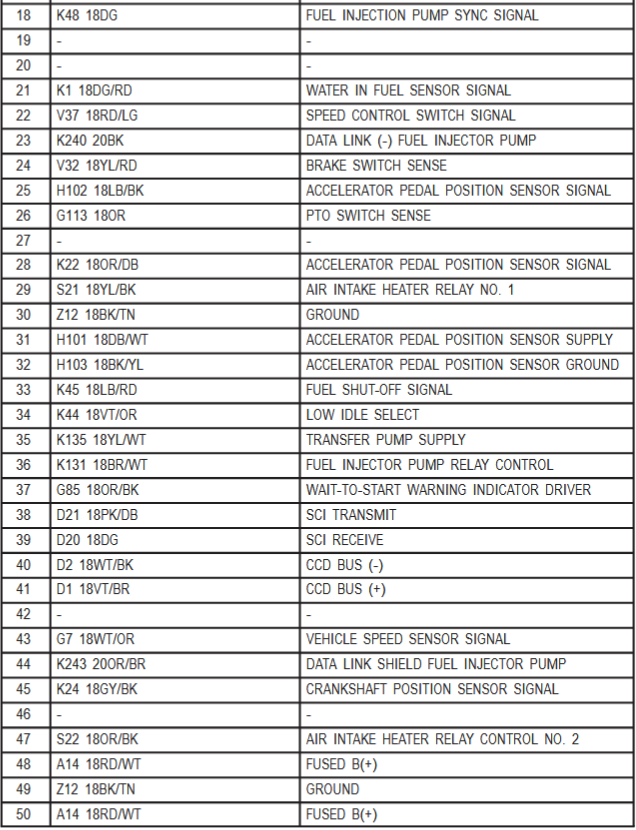

On the diagram sensor"signal" or sensor "supply" is it a positive wire ( + 5 volt)?Because I imagine there is no 12v on ecm or only at pin 48 and 50 it s write fused B+ .

-

Problem with idle cut off

OK. Thank you very much

-

Mopar1973Man started following Clean Up Day and some Seat Repair and Looking for members that wish to help!

-

Looking for members that wish to help!

Hey there gang, I'm looking for people who truly want to get involved with the website. I'm adding functions like the Gallery so people can place there truck photos up and show them off to the rest of the world. The Event Calendar is going to be set up for the idea that we might plan travel trip to places and share our location so people can meet up with me. I also want to bring the Zoom meetings together too. I'm going to be building articles on Thor here shortly we are going to have more information on 3rd Gen Trucks soon. I'm serious I'm looking for people who want to get involved in building up this website. I'm willing to teach and show you around. Most of the stuff you would be handling is from the front end and no code knowledge is required. Anyone wishing to become part of the staff please contact either @Mopar1973Man or @Tweety Bird and we will interview you and see what you have to offer the website.

-

Thor

Thor is my 2006 Dodge Ram with 5.9L Cummins Diesel. 5 speed G56, 4WD, 3.73 gears

-

20250521_201853.jpg

20250521_201853.jpg

-

20250521_182653.jpg

20250521_182653.jpg

-

20250521_182554.jpg

20250521_182554.jpg

-

20250521_182544.jpg

20250521_182544.jpg

-

20250521_182537.jpg

20250521_182537.jpg

-

20250521_182511.jpg

20250521_182511.jpg

-

20250521_182432.jpg

20250521_182432.jpg

-

20250521_150756.jpg

20250521_150756.jpg

-

20250521_150737.jpg

20250521_150737.jpg

-

20250521_150707.jpg

20250521_150707.jpg

-

20250428_111253.jpg

20250428_111253.jpg

-

20250428_111231.jpg

20250428_111231.jpg

-

20250428_103841.jpg

20250428_103841.jpg

-

20250428_103021.jpg

20250428_103021.jpg

-

20250428_103011.jpg

20250428_103011.jpg

-

20250428_102954.jpg

20250428_102954.jpg

-

20250319_180649.jpg

20250319_180649.jpg

-

20250420_131649.jpg

20250420_131649.jpg

-

20250420_111535.jpg

20250420_111535.jpg

-

20250419_193259.jpg

20250419_193259.jpg

-

-

Clean Up Day and some Seat Repair

Today I bounced outside, and it was warm and sunny. I wanted to get busy trying to make Thor cleaner and comfortable. Yeah, grab the power washer and nearly a gallon of degreaser and give Thor a good washing down on the engine so I can hunt oil leaks and other things. Don't need a greasy engine. I sprayed down the door jams and hinges so I can lube them back up and get the creaky door hinges to stop. The driver seat was pretty bad I peeled the seat bases out of both sides. Not really hard, just need to be sure to unhook each hook on the frame of the seat. You'll see in my photos I took an old 2nd Gen Seat and chopped up a chunk of foam from the 2nd Gen passenger seat (salvaged truck). Now I slowly pieced the seat foam back together with Gorilla Spray Contact Cement. This worked out great for binding foam together. I also cut a chunk of fabric out of that old 2nd Gen seat and used it to fill it. When funds are available I'm planning on purchasing the new seat skin and the foam pad both... SEAT CUSHION - DRIVER SIDE - CLOTH, VINYL & LEATHER ('06-'09, 2500/3500 ALL CABS & '06-'08, 1500 MEGA CAB ONLY) https://www.genosgarage.com/product/seat-cushion-gg-sc0609cl/seat-cushions FACTORY-MATCH BOTTOM SEAT COVER (MEDIUM SLATE) - CLOTH - DRIVER SIDE 40/20/40 & BUCKETS ('06-'09, 2500/3500 SLT, ALL CABS & 1500, MEGA-CAB) https://www.genosgarage.com/product/ram-cummins-seat-covers-dr-slt-08-ms-p1-dc/seat-covers-oem-material

-

2000 Cummins Surge/Dead Pedal

This is one of the few reasons I would typically suggest to have the alternator bench tested for AC ripple at the time of the w-T ground wire mod install. Kind of hard to fix a noise issue if the alternator is still screaming into the charge wire. The ground mod helps with the noise not hoping back on the ground strap to the ECM and VP44.

-

2000 Cummins Surge/Dead Pedal

Talked to someone today at a alternator/starter rebuilder spot, and the guy makes wiring harnesses and rebuilds alternators and he said those values are fine but sounds like I have a wiring or ground issue, especially since after I did the WT ground mod it was better for a few weeks then came back. Was saying that sounds like when I did the ground mod I had “touched” whatever the problem was or affected circuit since it did get better for a short amount of time.

- Yesterday

-

Bad intermittent drive line vibration at highway speed

I think he said that he did a road force balance on all of the rear tires. John

-

Problem with idle cut off

The VP44 trucks were only made from '98.5 - '02. There could be a discrepancy in some wiring colors, but not likely. Just pick a row that looks like the colors match the pinout row and you will know right away whether or not you are on track. For example, if the LB/BK wire APPS signal from the ECM pin #25 was a different color than the diagram, then the wire will be the same color where it connects to pin #3 on APPS connector. Just be patient - it will begin to make sense. John

-

Sycostang67 started following Bad intermittent drive line vibration at highway speed

-

Bad intermittent drive line vibration at highway speed

Are the tires just being spin balanced? I had a similar random vibration that turned out to be a rear tire. I took the tire in and they did a road force balance that involves putting pressure on the tire. I’ve been vibration free ever since.

-

Chris76 joined the community

-

Problem with idle cut off

The little problem for me, Is this the right wire color for my 98.5 Dodge? Because I imagine that as time goes on they deliberately change the color and number... why make it simple when you can make it complicated...😁😁😁

-

Problem with idle cut off

That's always a bit confusing to me, as well. I verify by identifying some of the wire colors on the wire connector side to match them with the pin number. This will confirm the orientation for identifying the correct pin number. John

-

Problem with idle cut off

OK. Thank you very much. The photo of the ECM connector with the 50 ways is the photo of the connector as it is on the ECM from the front, wire side, or is it the photo of the connector turned inside out? I'm talking about the first little photo on the left.

-

Problem with idle cut off

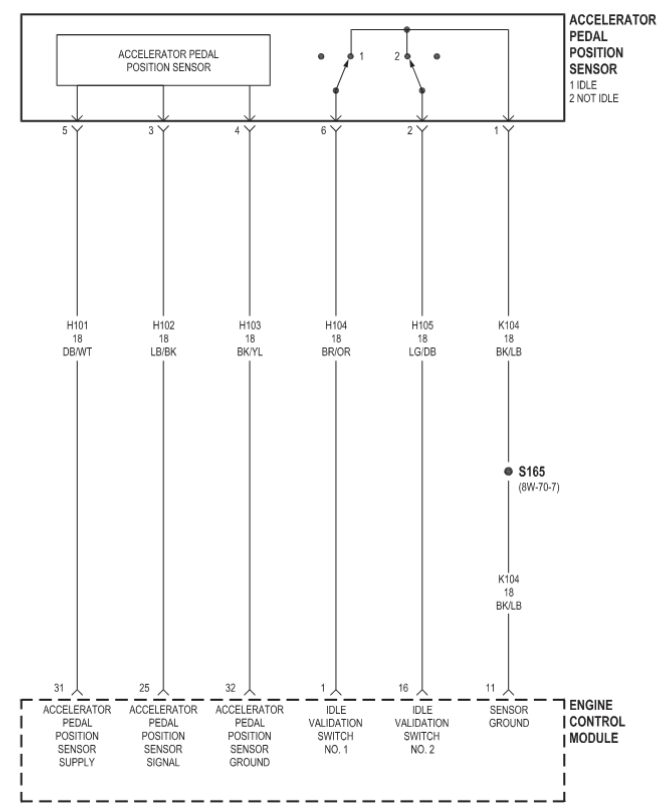

Shown below are the pinouts for the ECM. Perform continuity tests (using the ohmmeter setting) on circuits that you wish to check. Be sure there is NO POWER supplied to any circuit being tested. For example, the APPS communicates only with the ECM. You could perform continuity tests on all of the connecting wires (see bottom photo). John

-

Problem with idle cut off

Could you tell me wich wires at the ecm May I test . Because I remember when I unplugged it , there are so many wires .... I don't know if I should leave the connector in its position to find the numbers, or if I should turn the connector over? Then I don't know which wires I should test. Should I disconnect the 2 batteries to do these tests? These may be stupid questions, but when you don't know, when you're going on an adventure, it's better to ask before blowing everything up. Thank you very much for these clarifications. I remember it s a connector with 50 pins, but the job is really big ! When you talk about ohm test, is it really a continuity test? I remember only cleaning the ECM connector and its plug with an electronics cleaner. I didn't disconnect anything from it. It wasn't dirty, but since I'm a bit of a neat freak, I like to have clean connectors. Also, when removing the VP44, I had to remove the apps block and push it near the hydraulic booster. I disconnected the apps sensor so I could put it to the side. That's all.

-

lew28 joined the community

-

Problem with idle cut off

OK thank you very much.

-

Problem with idle cut off

Also, unplug the ECM and check for any pins that may be pushed back. John

- Last week

-

Problem with idle cut off

Basic wire test is to ohm from end to end (unplugged) you should see less than 5 ohms for good wire. Above 5 ohms there is a problem. Another test. Still both ends unplugged then measure connector pin to ground. This should show OL or infinite resistance. This means no wire shorted to ground. If any ohms show then it could have a rubbed jacket or wire damage. Remember both ends need to be unplugged or unhooked.

-

Problem with idle cut off

Friday I m going to replace the apps. And I will see. When I pull the vp44, I decided to change the cam sensor, the tappet cover gasket too, and I must unpluged the ecm and I ve cleaned the connector and pins of the ecm with electrical product. Do you think a wire of ecm could be disconnected when I reinstalled it. And how do I test it without scanner ? I need to tell I ve no trouble code..... it s really strange or maybe my obd tool can t read some code ....

-

Problem with idle cut off

Remember Bosch stock injectors are NOT made as a set. You could have low end of 293 bar you the high end of 327 bar. This can affect idle performance. I high suggest AGAINST using stock injectors. Buy +50 HP from any good injector shop and they are balanced as a set within 2% of flow rate. Like my custom 7 x 0.010 is popped at 320 bar and custom tuned by the Quadzilla. Remember low pop will advance timing, high pop will retard timing.

-

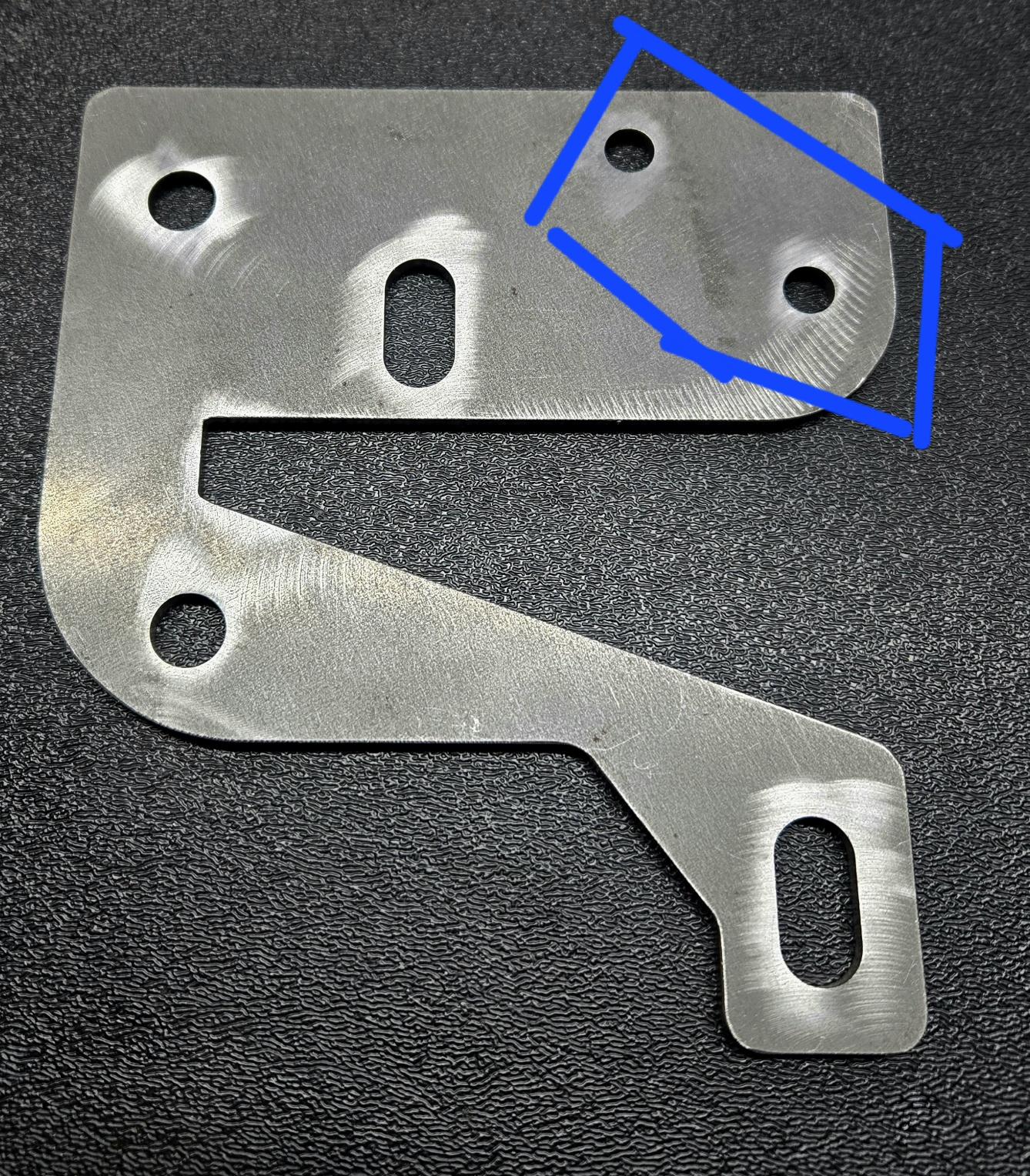

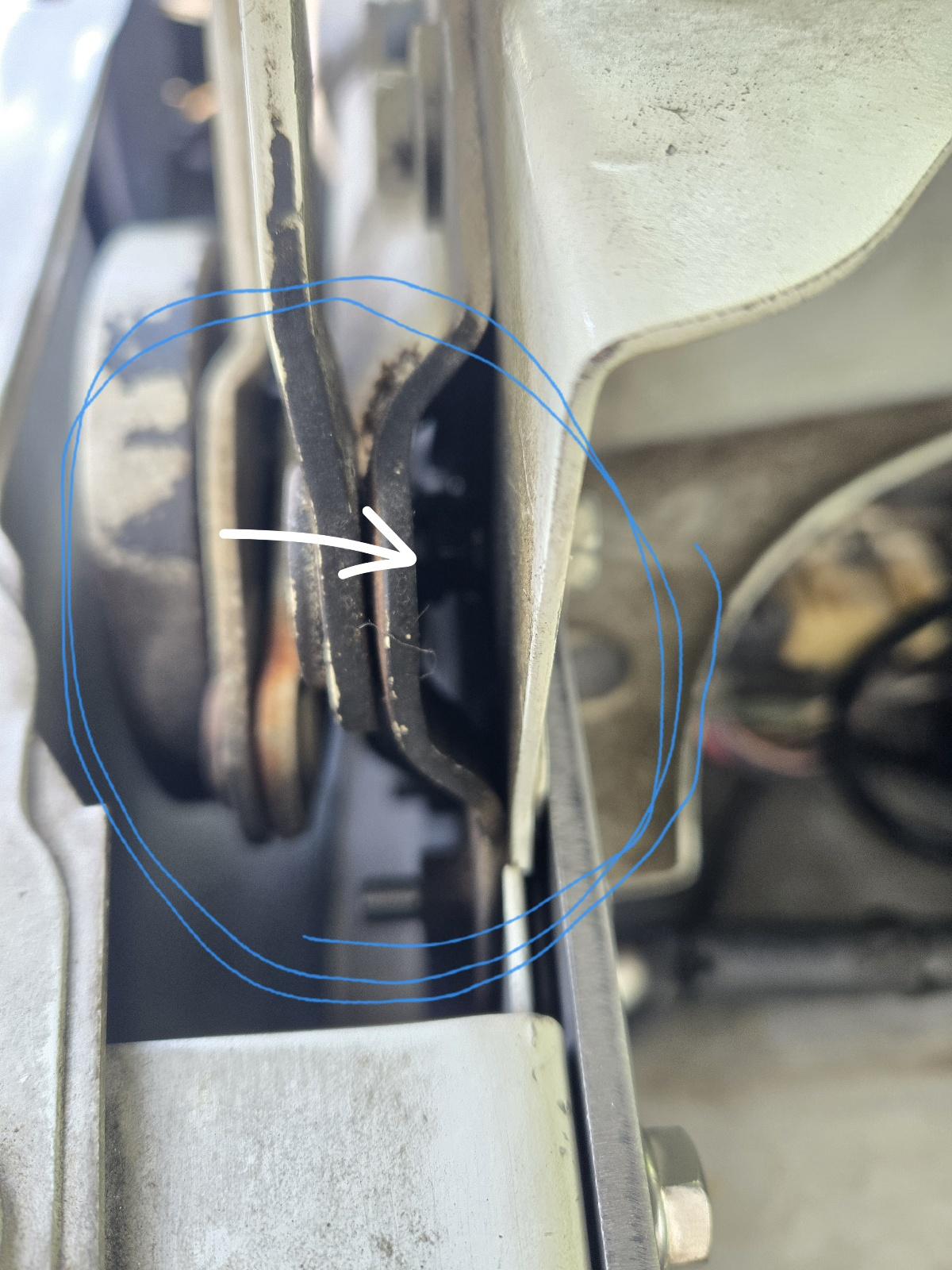

Cracked bodywork at hood hinge

For installation, 2 new holes have to be drilled. They need to align with the "channel" in the hinge. The bracket is used as a drill guide. It will fit a 3/8 drill perfect. Reuse the one long bolt in the lower hole and a shorter bolt in the upper. A piece of masking tape works good to hold the nut on an open end wrench when installing the bolts in your drilled holes.

-

Problem with idle cut off

Ok, I understand. That should rule out a torque converter issue. It does make sense that something changed during the replacement of parts. If I recall, you have to move the throttle assembly to the side in order to access all of the injector lines. Is it possible that the throttle is binding and not letting the throttle fully return? If the throttle does not fully return every time, it is possible that the idle validation switch is not activated in the APPS circuit. It must be activated for the ECM to know to take over idling the engine. Engine idle is controlled by the ECM only - no other inputs. John

-

Problem with idle cut off

OK. But I put new oem injectors. These are originals not modified. I think too at the ecm . But there would be normally a dtc if there is a problem with it. I dont know if it s possible to test ecm without scanner. I will see friday. I will make an other vidéo too. Thank you for your help again.

-

Problem with idle cut off

Don't focus on this. You could be right, but you also could be wrong. Another scenario (mentioned by @Mopar1973Man ) that could cause your issue is a low stall speed transmission torque converter. Larger injectors allow much more fuel to flow, so when the engine comes to idle, the ECM has to cut way back on fuel delivery (not so much with stock injectors). So, things like a low stall speed converter, or engaging the clutch with a manual transmission, can cause idle fluctuations while the ECM tries to correct. John

-

JohnJohnson27 joined the community

-

StackAttack90 started following Ground Reference VP44,ECM,PCM,PDC plus TC lock/unlock

-

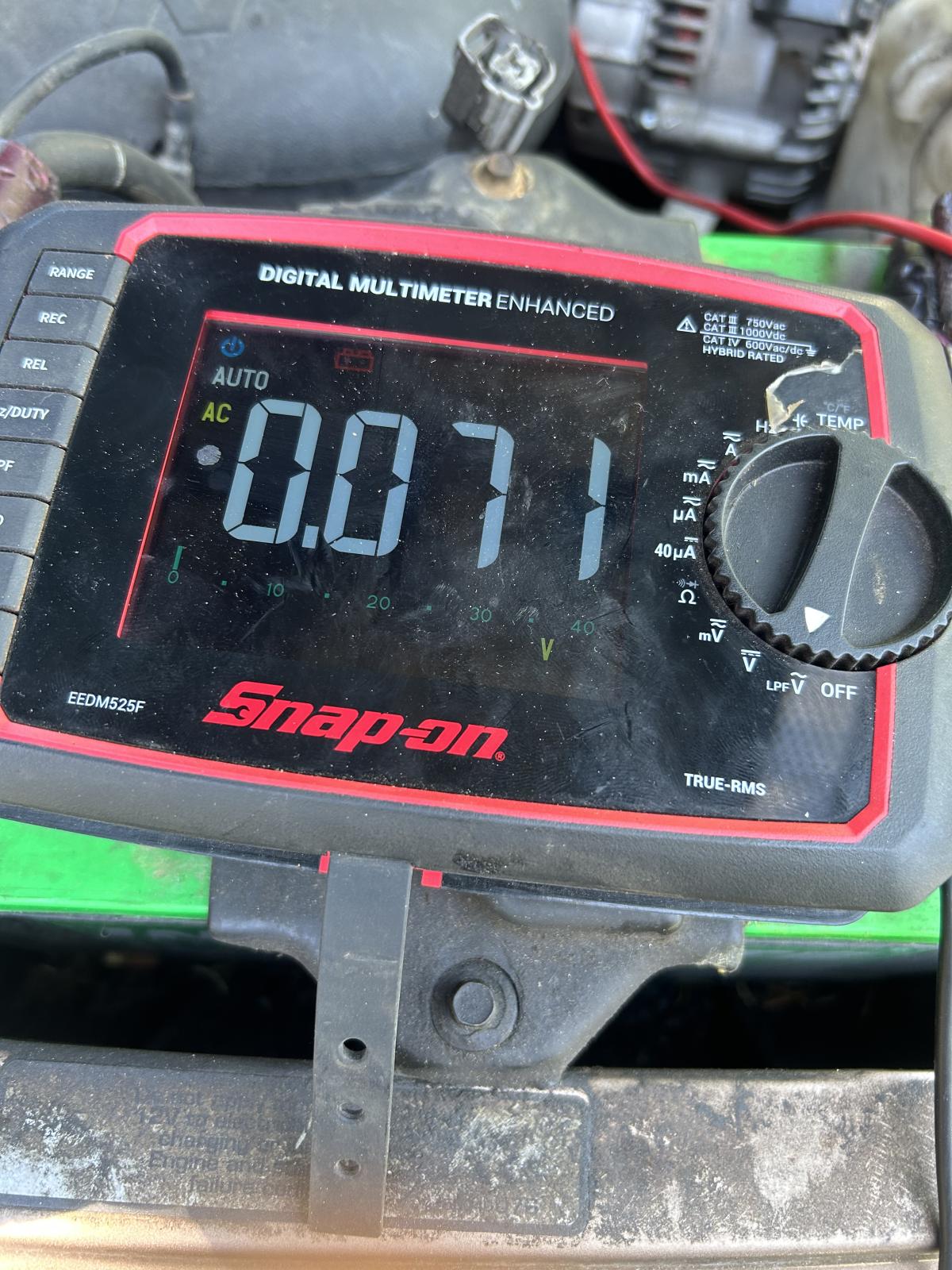

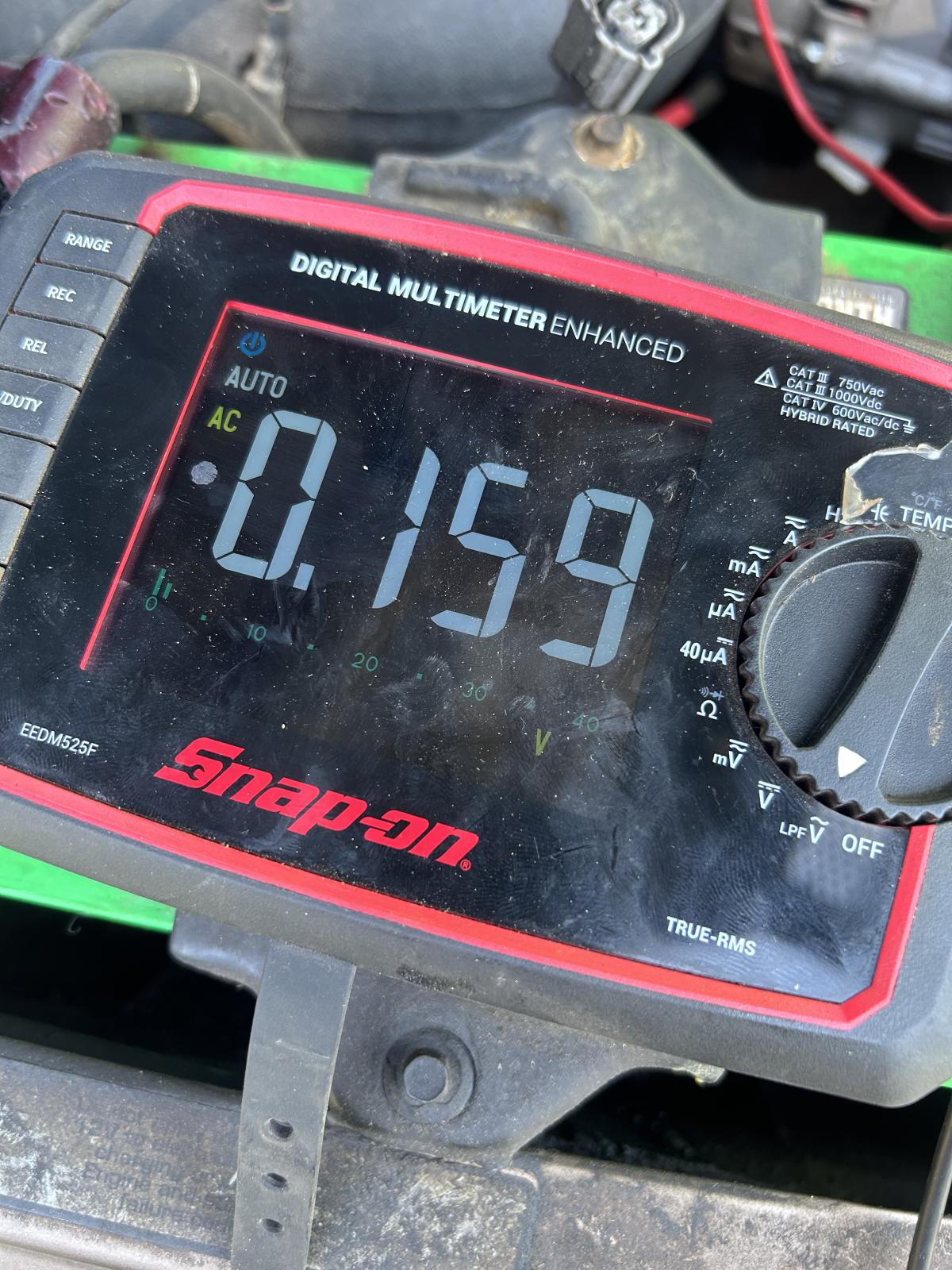

2000 Cummins Surge/Dead Pedal

Hey guys, been a bit since I last posted. I didn’t drive the truck much over the winter but when I did zero issues. Now it’s warming up outside here and starting to have problems. Drove it last weekend and took me 20 minutes to do a 10 minute drive. Dead pedal and revving up on its own. Sometimes it would dead pedal and id pull over, wait a minute and then the throttle would be back without clearing the codes. It would happen again and sometimes I would restart it and it would start revving high right away at the same high RPM like when I shut it off. Eventually I left the code and kept trying to get where I was going and it surged a bit while I was driving but eventually ended up being okay. I brought my multi meter home from work and checked for AC noise because I’ve been suspect of the alternator. With the truck running right away with lights, radio, defrost heat, grid heaters, etc. I was reading .112-.185 depending if heaters or compressor clutch was cycling. With heat shut off I was reading about .071 and seemed to be coming down as truck ran longer but I usually have problems when I first start driving. From what I’ve read these readings are way to high? Am I looking at a new alternator here? If so what’s the go to? Looking at getting a 170 amp and have looked at nation and mechman. Thanks!