Everything posted by Mopar1973Man

-

Angry & can't do it anymore, serious iQuad timing issues

If you look at the Dodge FSM it does list out lash limits for the 24V engines. You should see 3rd Gen lash numbers. IIRC it's 0.026 for exhaust.

-

Ok this is starting to make me mad

Donaldson is a good filter but I've been using NAPA for years. For the AirDog I've been getting Donaldson from @dieselautopower. For oil just a NAPA Gold. Stock fuel filter I've been using NAPA Extra Guard (7um filter). Air Filter I get BHAF from @dieselautopower.

-

16" Wheels suggestions?

I've seen even aftermarket wheels crack and fail. Aluminum wheels are not very strong when dealing with lots of weight and rough roughs like out here the back country roads will beat up wheels quickly. Steel wheel hold up much much long without bead leaks and cracking issues. You might add a few pounds of rotational mass but over all life span will out run any aluminum wheels. @JAG1 I'm sorry you have a problem with color... If you look at the animal kingdom the males always have the flashy colors and females are typically rather plain. So why is it that humans woman are flashy and males are bland? Hmmm... Just think about it...

-

16" Wheels suggestions?

I'm running the stock steel/chrome wheels from factory and fit the 245/75 R16 like a glove. No outward offset to sling mud and slush on the side windows. As seen in my signature pic. MUCH stronger that alloy wheels which my factory wheels cracked after 200k miles. The other problem was road salt ate into the aluminum as well. Aluminum wheels out here are very known for bead leaks and the local tires shop deals with way too much. Steel wheels no issues and seem to hold up MUCH longer without issues.

-

TC not fully unlocking on 1998.5

Jumping out of gear is because of bad bearings on the main shaft. As torque is applied to the shaft it moves and kicks the stick out of gear. Basically most likely using too thin of fluid and allowing it to overheat. Max trans temp should be no higher than 220°F. Yes you should install a trans temp gauge but do not install fast coolers because it moves the temp sensor too far from the gears and will show cooler. But the fluid around the gears is still hot.Temp sensor must be as close as possible to the gear teeth for proper temp measurement. Mine I bung close as possible to the PTO gear. I've seen my last trans over 240°F towing my RV to Pittsburg Landing near Oregon. I was only running 15 MPH on dirt road running 7% grade. Even my heat shield in place. Even running downhill didn't cool because of reverse torque running down hill. This is why trans temp is required and why fast cooler should not be used.

-

Angry & can't do it anymore, serious iQuad timing issues

You could just check it in a week or so. Remember... Intake set to 0.010 (0.006 to 0.015 allowed) Exhaust set to 0.020 (0.015 to 0.030 allowed) So quick check is pretty fast.

-

New Turbo

Thanks for the chat on the phone hopefully it answers your questions.

-

16" Wheels suggestions?

Biggest thing is finding the right offset. I did modular mags but the offset was wrong so about 1 inch of tire hung out of the wheel wells. This is bad being driving in snow or rain it slung mud and debris up the side window to the point you can't see the mirror any more. Be aware most cool looking aluminum wheels are typically for wide tires. My problem is trying to find wheels that look cool but keep my 245/75 R16 I'm using a narrow stock steel wheels. Bit heavier but not likely to crack like aluminum wheels did to me.

-

Turbo/Injector balance for towing/EGT control

Yea... too low of ratio for sure. Gotta remember I talk to so many people no way to remember and yeah I don't re-read the whole thread every time.. sorry about that.

-

Turbo/Injector balance for towing/EGT control

What is your RPM in top gear at 65 MPH? What sized tires are you running?

-

TC not fully unlocking on 1998.5

Yup good man for the job. @Dynamic did all the upgrades and beefed it up good.

-

Angry & can't do it anymore, serious iQuad timing issues

@dripley did the rocker change IIRC.

-

Turbo/Injector balance for towing/EGT control

Empty truck on flat ground at 55 MPH. Towing the RV at 55 MPH it only rises to 600*F on flat ground. Like I said final ratio is a huge factor in what EGT's are going to be. More I've played with other customers trucks and most having tires like 33 to 35 inch tirs they all have extremely high EGT's because of improper final ratio with tires. If you running above a 265/75 R16 you should be running 4.10 gears for the over sized tires. From 265/75 R16 and smaller you can keep the 3.55 gears but optimally the 245/75 R16 are the best combo for towing. That is a perfect 66 MPH at 2,000 RPM can't get any better. Even running empty at 80 MPH on the interstate I'm twisting 2,450 RPM at 80 MPH but still get close to 20 MPG. Again EGT's barely 700 degrees at 80 MPH. Even with 30 to 40 MPH head winds going across Nevada desert I was floating 800 to 1,000 degrees in EGT at 60 MPH. Yeah I'll admit the MPG was way lower but 10 to 11 MPG wasn't to shabby. Just look in my yard of the customers rigs I get to play with and see how different tires and power combo work. I still beat them all with Beast with that super low EGT's with a stock turbo, 150HP injectors, and Quadzilla with my Economy tune.

-

New Turbo

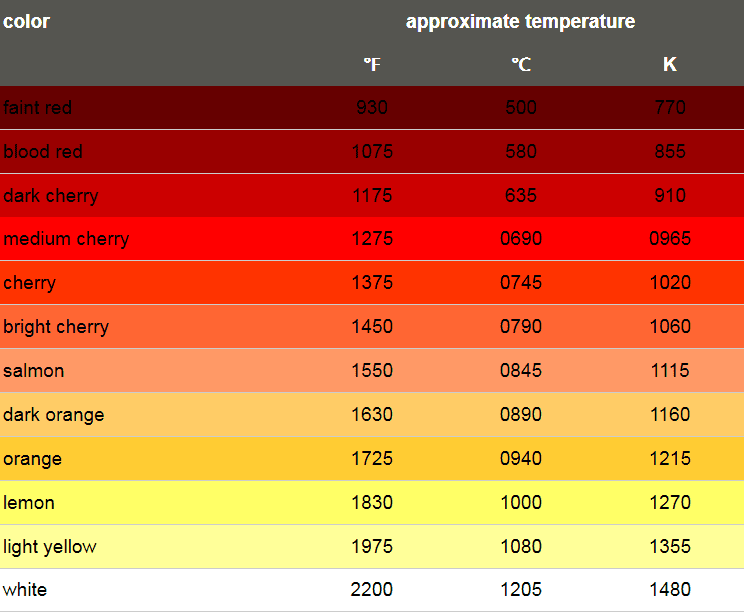

Hey I just seen a Ford V10 engine turn cast manifolds glowing red hot just barely getting to 55 MPH in a class A Bounder motorhome. Those manifold were blue before we even started. You could see it in normal daylight. It would not surprise me on a turbo being that is the narrowest flow spot and will convert heat energy to motion of spinning the turbo, it should turn that cast iron blue rapidly. Just figure 1,250°F will for sure get the color going.

-

Angry & can't do it anymore, serious iQuad timing issues

Just consider... im running the 7 x 0.010 injectors on a stock HX35W turbo (54/6012). Even towed my RV which tipped the scale at 8,100 pounds (17,500 Gross weight) all the way to Cally. No EGT issues. It has to be something about your selected turbo. I'm more stock than you are with no issues with EGTs so makes me think combination of addons are causing your issues.

-

Turbo/Injector balance for towing/EGT control

Huge problem you just made the ratio to tall and adding stress to the driveline and increasing EGTs. Smaller tires and proper final ratio between 3.55 to 3.73 is optimal. Your currently 3.42 final ratio with 285/75 R16 with 3.55 gears. Beast is currently 3.69 final ratio with 245/75 R16 with 3.55 gears. Then I made that trip to California hauling my 31 foot RV to 7,500 feet elevation never even worried about EGTs with 150 HP injectors and STOCK HX35W turbo. Thor is 3.73 final with 265/70 R17 with 3.73 gears. I left this truck pure stock because of optimal gear ratio for the weight roughly 9,000 pounds. Final ratio is huge impact on EGTs. Here is a example. Again I've got no EGT issues and super high MPG number at 28.04 MPG. Ratio does matter number 1 on my list.

-

Turbo/Injector balance for towing/EGT control

I just made a trip to Bridgeport, CA 1400 miles roughly. Climbing up to 7,500 feet. With my 31 foot RV, ATV in the bed I weighed out at 17,500 pounds. Now... the truck I'm running 150 HP injectors on stock HX35W turbo (54/60/12). No EGT issues at all using my towing tune on my Quadzilla. Biggest thing is final ratio. Mine is 3.69:1 after tires (245/75 R16). Running 2k at 66 MPH. Perfect towing setup.

-

New water pump for the RV?

Blue and black... You must be color blind...

-

Max boost only with WG hose pinched

Here you go... Inside is a check ball and spring but still has a small bleed hole to allow for the pressure to be released after the boost pressure falls. The check ball will close again keeping the boost going strong. Tested and proven at least on my truck. I pulled the wastegate hose loose and left it open not plugged. Then pulled 1 manifold bolt out as a open hole leak. As for max boost pressure was only down 5 PSI and had ZERO impact on EGT's on my truck made little to no different even while WOT operation. So as for the tiny pin hole boost leak has ZERO impat on performance nor will it change the EGT's when I've had a leak that was MASSIVE comparing it didn't run hot or smoke any differently.

-

New Turbo

-

Transmission Cooler Options

Biggest thing is getting the torque converter locked up as soon as possible. Proper final ratio of 3.55 to 3.73 is going to keep trans temp down more so. Trans temp is a sign of power loss by too much supplied power and/or working load.

-

Transmission Cooler Options

The ISSPro EV2 gauges can be programmed to control the fans. Basically have the Trans Temp gauge set for tripping the aux relay that plugs into the gauge and it can control the fan. Then you can also program the warning light for a higher temp. Being I've got manual trans I really don't need this function but... I might be designing a trans cooler set up.

-

Max boost only with WG hose pinched

Mine is way different its two body halves with a spring and check ball inside the unit. As you screw it together it increases the boost pressure, loosen then there is less boost pressure. I gave up on those boost elbows since its just a controlled boost leak and now a regulator for the wastegate. The check ball keeps the line closed till the boost pressure is enough to open and push the wastegate. This also has a small bleed hole too to release the waste gate after the pressure falls again but works way better than those boost elbows. I got mine off of eBay from a place in China it took awhile but it was a mere $15 bucks or so.

-

Wiper Motor Replacement

Wiper Motor Replacement The 3rd gen wiper system sadly is one piece. I lost one the joints to the passenger side wiper arm and fell off. Yeah I know the links could be replaced but the chances are the ball stud is going to be too worn out. https://www.napaonline.com/en/p/NOE81921851?impressionRank=5 You only need a torx screwdriver for the two screw on the edge of the cowl. Then there is a series of plastic fasteners along the engine edge of the cowl cover. Once loose at that point you need to release the wipe arms and blade assemblies. There is a little lever on the glass side of each arm pull it out and away from the arm and the wiper arm will lift right off. Now the cowl kind of push it forward towards the glass a bit and i will release the snaps and lift straight up. I just left the washer line hooked up on mine and just move the cowl forward on the engine. Just need a 10mm socket and remove the 3 bolts hold the assembly and unplug the motor. At this point just reverse the process to go back together.

-

2nd Brand New Redhead Popping

He basically is turning around so fast there is no stock. He will receive yours rebuild and send back out. takes just about a hour or two to go through and he'll have it sent back out the next day.