Everything posted by Mopar1973Man

-

Upgrades

For sure not going to with 44 inch tires. Even with 37 inch these trucks suck for braking, suspension, and acceleration and MPG. Most foul the ratio and then have huge issues.

-

Upgrades

Already there and can compete with that currently. I'm already 500 HP and solid to tow anything I wish no issues (EGTs, etc.). Biggest thing for towing is make sure you in a 3.73 realm this will remove a ton of stress off the axles and transmission hence why I registered already for the maximum of 26,000 pound commercial plates. My problem is with my amount of power I can hitch up my 31 foot RV (8,500 pounds) and fry the tires while towing. Why I opted for the 245/75 R16 tires I can have the 3.69 ratio without the cost of axle swaps.

-

My personal network

Mopar1973Man replied to Mopar1973Man's topic in Linux Computers, Networks, and Servers's Linux Computer SupportMany improvements to this network since this post. IPv6 and IPv4 addresses are available for all my network. WiFi access points include a firewalled Guest WiFi limited to 10Mbit down and 5 MBit up speeds and has zero access inside my network. WiFi range is enhanced being it covers 4 properties and cross the highway still have signal for broke down people. Within the network I can share my Printer to all internal users. Starlink is 200 MBit down and 50 Mbit up with current conditions. Changed my DNS server to Cloudflare giving more privacy. Enhanced WiFi priority so less lag hopefully for cellphone users. Going to be adding... Smaller 10 port switch down in the shop so I can add a few more cameras. Adding hard line RJ45 ports in select rooms. Currently, my server machine is going to relocate into the server cabinet and use use Reminia Remote Desktop which is easier to use than Windows versions. This way I can clear the second position of my deskop and not have a entire station choked with just a server machine that is holding desktop. My cameras record to the server automagically and over write older files. I've got a few weird issues currently where my cloud management of the network is goofy.

-

Upgrades

Running 3.69 final ratio after tires which is easy just drop to 245/75 R16 tire on 3.55 and close enough without huge cost of gear swap. Being I'm the MPG king with solid axle no CAD and no free spin kit I've past the 30 MPG mark by crossing the entire state of Washington on a 1/4 tank of fuel. Low rotational mass (smaller is better), good final ratio after tires (245/75 R16), good tuner with timing settings (Quadzilla) you can do the same without the huge cost. Let me know when you can top 30 MPG.

-

New Life and New Body with issues...

You would be surprised there is better content on tiktok. For the EmoGoth or Goth there is quite a few people doing this style and makeup work. Great way to ask a fellow artist questions on make up and other things. Slowly I'm over 350 followers and always on the hunt for a new video to upload. Like Suzanna took me out for my birthday dinner and ending up with a Tiktok in the restaurant. Cook bought me an ice cream cone her treat. Why would you stop? I'm not I'm enjoying the smiles I created.

-

2001 24v Cummins High Idle Issue

12V series block had a mechanical lift pump rode on the cam lobe. 24V they used a L shaped bracket to mount the lift pump from those bolt holes. So it was dual purpose block off plate and a mount for the electric pump. Sadly, some dummy pulled the plate and used cardboard and silicone to keep the oil from running out. Part #1 - You can see the bracket and how it held the stock lift pump. Auto Computer Specialists can do harness rebuilding too. https://mopar1973man.com/vendor.htm/vendor/auto-computer-specialist-r5/?do=getLastComment&d=7&id=5 Dielectric grease will seal water and road salts out keeping the contacts clean and functional. Use some contact cleaner then use the dielectric grease. Forward... Just consider I've managed to build a 492k mile truck up to about 500 HP now, 30+ MPG and enough power to tow, drag, or just haul. Once you get the other stuff fixed then we can start optimizing the rest of the truck. https://www.tiktok.com/t/ZTF3eREgC/ <- Beast out in the snow a year or so ago.

-

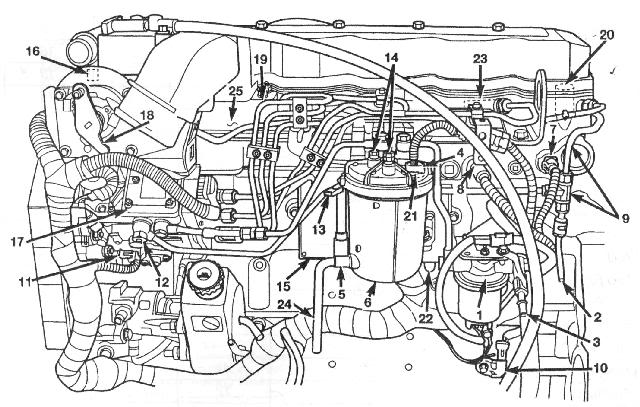

2001 24v Cummins High Idle Issue

Lift pump plate. You can use a Chevy fuel pump block off plate to cover. IAT only controls grid heater functions mostly. Below 80°F it will advance timing about 3 to 4 degrees. Then above 80°F the ECM uses normal timing.

-

New Life and New Body with issues...

So my life continues... As for the makeup work and my appearance, I'm not going to stop. Everywhere I go now is a very enjoyable experience. I was just in Home Depot and one of the employees started asking about my appearance and I told people this is my normal daily appearance. I was typically told I looked like a rock star like Alice Cooper or similar. Even this morning I got up and showered and shaved and as down and did my makeup art. I'm 3 months cancer-free and clean but still having issues with my kidney functions. As for returning to my normal life is still very limiting being I've still got to watch my pain by checking my blood pressure throughout the day. Some days I do great and other days I get the BP up and have to go chill out and smoke a bit to calm it back down. Even trying to do minor repairs on Beast sure put a beating on me. I'm still fairly weak yet and still working to gain that back., My days are getting longer on how much I can do. I'm healing for sure. My current problem is my stoma has shrunk a bit more and I've been having issues with my wafer starting to leak fairly quickly a times. The last few days feel like every day I've had a leak and changing clothes and washing my belly off to verify if it is the sealant leaking or did it was pushed around the seal between the bag and the wafer. Sucks because one day I bought a brand new shirt and put it on and just bent over and grab my boots then I managed to squeeze pee on the new shirt that I barely wore for 15 minutes. Yeah it's a back-and-forth battle some days and difficult to handle and just makes me wanna cry. So aggravating! I would rather be pissed OFF than pissed ON! Just for even more fun... I just broke the camera on my phone so my forward face camera lens is shattered. I've gotta make time and go buy a new cellphone now so I can continue with work here and even some of my video work on TikTok.

-

2001 24v Cummins High Idle Issue

Auto Computer Specialist will rebuild wiring for you.

-

2001 24v Cummins High Idle Issue

Could be fly by wire like Beast. There is no vacuum motor to pull the throttle. Manual trucks in the later series 2nd Gen had fly by wire cruise supplied by the PCM. Swapping you'll lose cruise functions. Most likely you have a bad switch on the steering wheel.

-

2001 24v Cummins High Idle Issue

I'd never do a P-pump swap. Horrid idea being 100% of all my member that did this swap ended up buying a newer truck or just parking it. Unreliable, too smokey and a cop magnet, or the fuel milage drops off, worst case was one member sold because he had troubles keeping it running at all. Got rid of the truck. So your willing to ditch dynamic timing for fixed timing? Then willing to lose cruise control? Talk to Auto Computer Specialist and a rebuild is better price than a p-pump swap.

-

Turbo actuator

I'm going to bet its a heat issue being the turbo is buried down low on the frame and relies on coolant to cool the turbo and the electronics.

-

New Battery Cables

Be aware running parallel ground leads is difficult to diagnose. Being it's possible to have one ground fail and the parallel lead will cover up the failure and hard starts. This is why I do not suggest this. Factory lead position is fine and diagnosing is simple being there is no bridge cable. Just be aware.

-

2001 24v Cummins High Idle Issue

I pulled my Bosch out at 140k miles they still ran well but won't idle at specified RPM because they popped 260 bar after 140k miles thanks to Diesel Auto Power showing me injectors do not last beyond 100k miles in normal use. The bottom end spec is 293 bar according to the Dodge FSM book. For every 10 bar drop is a 1-degree advancement. Just because it's running doesn't mean it's still in tune. My Bosch stocks didn't last very long really. My RV275s even used barely lasted one year. Now Vulcan Performance +75 HP injectors barely lasted 90k miles stilled misfiring and popped at 250 bar. Now the custom-built 7x0.010 injectors popped at 320 bar huge difference in lifespan and performance. Injectors will not last very far past 100k miles without being out of specification on pop pressure. Being Bosch could release a set of injectors between 293 and 327 bar and be OK. But the performance on the engine is going to be subpar once you experienced good balanced injectors (within 2%) vs 293 to 327 bar Bosch injectors you'll never go back to a Bosch.

-

2001 24v Cummins High Idle Issue

I will not suggest Bosch stock or RV275 injectors. Bosch injectors are NOT pop tested as a set so they are not balanced as a set. This will void the warranty if you opt for pop testing. I typically suggest a +50HP injectors from @dieselautopower which are pop tested as a set.

-

High EGTs After Minor Upgrades

Typically advancing timing makes the EGT's cooler but the boost will disappear. The more retard the more boost and EGTs. I'm running on my 2002 Dodge Cummins 26 to 27 degrees for timing at 2,000 RPM (66 MPH) under 20% engine load. The boost is typically under 5 PSI in this mode. Now drop out of cruise timing (performance timing will engine load above 20%) I'll see about 19 degrees and an increase in EGTs and boost together being you need expanding/burning gases to spin the turbine on the turbo.

-

High EGTs After Minor Upgrades

In cylinder EGR event is made possible by a shorter duration cam lobe for exhaust. This could be fixed by changing the cam out for a performance cam and ditch the in cylinder EGR event and then get a tuner to ditch the retarded timing.

-

2001 24v Cummins High Idle Issue

Two things 1. Bad APPS idle validation switch. 2. Worn out injectors. Replace if over 100k miles. As injectors wear out you will see engine load drop to zero and then the ECM can't cut fuel any deeper and idle starts to increase as they wear. For every 10 bar lost is roughly 1 degrees advanced in timing. Like my oem injectors idled at 850 RPM and popped to 260 bar which is a long ways below 293 bar which is lower limit.

-

24 Valve Swap

No problem. Makes it a lot faster to hash out details.

-

High EGTs After Minor Upgrades

Boost leaks are not a cause for high EGTs. I've pull the boost hose off the wastegate and one bolt from the manifold still reached 43 PSI and EGTs still below 1200°F. Excessive advancement of timing will create high EGTs especially if your final ratio is less than 3.55 calculating oversized tires.

-

4.11 Rear end

Correct. 3.55 and 245s is 2k RPM at 66 MPH for my setup. Which is 3.69 final ratio.

-

New Life and New Body with issues...

Made a trip to Fruitland ID to chase paperwork. I have to say I'm doing good. I totally missed the website's birthday which was October 4, 2007 website is 17 years old and still going. My birthday is coming up on the 26th. Yeah I'll be 54 years old. Thank you, Suzaanna for getting my birthday present for me. My idea is since I've got Halloween coming up I had my nails done but the crazy part is I did short stiletto nails with black on all nails but the ring fingers are blood-red metal flake. I'm getting ready to have fun on Halloween. The next step is to get my makeup artistry better. I was in Walmart and a gal just came to a sudden stop to wait patiently for the clerk to stop talking but she absolutely loved my appearance and gave me a high five. Even the clerk gave me a fist bump. It's truly amazing how many people love the makeup and cosplay work I do now. I more and more I continue to build on the look and appearance the more people keep coming to talk to me and request photos with me. On Tiktok even I've been building to 300 plus followers and still growing. I build in my own Emo(tional) Goth or Goth looks now. Like I said Emo is more Goth with color vs. Goth which is strictly black on white. As for Suzanna she has become a fixture in my life now. Yeah, it's been 3 months now and we are growing together. She is pushing to make sure I stay healthy. Continually after me to check my blood pressure being my pain scale is based on my blood pressure. For every 10 above 120 is +1 to my pain scale. I'm getting out working in the yard getting things put away for winter. , Mowed the lawn, drain hoses, trimmed trees, etc. Just that could raise my blood pressure and get my pain scale started. Don't worry about me she is right after me and keeping me out of trouble. Give me a bit I'll post pictures. https://www.tiktok.com/@titaniumgoth/photo/7426514592945212714?is_from_webapp=1&sender_device=pc&web_id=7426802226406147626

-

4.11 Rear end

Amazing how proper ratio really helps out.

-

New Life and New Body with issues...

https://www.tiktok.com/t/ZTFuhQynP/ Another run out to go shopping at Walmart and Winco. Suzanna and ended up skipping Walmart being ive gotta go back to Boise this week for medical with Suzanna. This time I did monochromemakeup and hair and even older folk would smile at me. Still enjoying mymakeup artistry and being out in public. This gal walked up to me and commented on my looks Suzanna got her to pose for a photo to add to tiktok. Sadly if you look on the left side of my belly you can see my ostomy starting to swell. Getting time to drain the bag.

-

New Life and New Body with issues...

I'm still here. I'm still waking up every morning ready to battle each day. Even though my body is not quite ready for the world of work but I'm trying to figure out how to work with my new body. I'm thankful I've got a few good friends that advocate for me and helped out. I need to call out Mark Hall thank you for being a close friend and helping out get my firewood for the winter. Then Dan Catherman for bringing his Datsun pickup with his fishing pole setup that loaded all the logs on my trailer. Then Einer for helping up in going out and doing the heavy work getting the firewood loaded. I'm even making attempts to see how much I can do. I had the driver's wheel joint fail last spring. I managed to change it out but took two days getting it done and still not quite right. The wheel joint is fine but my slide pins on the calipers need replacing and the kits were missing the rubber boots. Now to add a bit of good news. I had to endure hell to get to heaven. What do I mean by this. My hell was handling my mother's dialysis, my mother's death @MoparMom, 3 bad relationships. Then hit with bladder cancer both times on 2018 and 2023 Christmas. Then deal with 4 months of chemo. Then a 7-hour surgery to modify my body to no longer have a prostate or bladder which are gone! Now on my trip to Portico West medical building, I ran into Suzanna Lopez and had a few words and got called into my appointment. Now during my appointment, I rescheduled for 2 weeks not the 4 weeks that the doctor wanted. This lined me up to see Suzanna a second time and she came off the elevator and said "I remember you from the last time!" yes this was true. I was decked out in my Black and blue hair and makeup. She got in and sat down and the first thing she asked was for my phone number. Crazy fact Suzanna is the first woman to walk up to me in 53 years to ask me for my phone number. I asked why she was impressed with my makeup and appearance as well as some of my story about my cancer and taking care of my mother. Suzanna has more or less just stayed with me. She is attempting even right now to sort through all the Social Security documents and getting information dealt with. She has been there for all my medical appointments too. We have already been together already 2 months and have a difficult time when we are separated for a length of time. Suzanna issues are that she was injured in an accident that broke her left ankle and then had issues for most of her life. Now she had her ankle fused and now we are healing together attempting to support each other to work out and get back into shape. So there you go gang a tidbit of good news. I'm trying to get over the Social Security hurdles and she is being a huge help.