Everything posted by SVALIN

-

Dodge hub removal tool

@Mopar1973Man Happy friday! Good to know Delcos are a stand up oem alternative! For sure that is a downside for drilled and slots. Also, cannot machine true if warped! I think these arn’t overly aggressive, and the slots can be beneficial as ‘wipers’ on the pads. The power stop kit was fairly good bang for buck and powder coated. In terms of cracks.. Ive seen a set of rotors and pads gone in a weekend of scca. Street tires can be gone in day. Mostly found wear dependent on user and condition. Even with complete ‘spider cracks’ most rotors weren’t replaced till 50%+ of pad width. Not saying I recommend it though, especially towing with a rig.

-

Dodge hub removal tool

Wow, yikes. After grabbing tools, the second side took about 40 minutes.. leisurely. nickel anti seize was on the 4, 12 point bolts. The splines, and the hub to housing. Removal was easy with no downsides over its lifespan. Highly recommend. The axle nut gave me a bit of trouble though, 1-11/16 torqued tight, used a 3/4 4’ breaker bar. After reinstall, the ball joints are still giving me slight play, the dana spicers lasted 8 years. Any other brands recommended? Saw some Yukons looked ok. Pics of some of the 3rd gen brakes and shield. Shield, dorman p/n 924-228. Powerstop brake 2003 kit, unless heavy downhill towing, I dont think the slotted and drilled rotors give much performance.

-

Got my truck back yesterday.

Truck looks great. Mine will probably never look that clean. Whats the deal with the hood? Aftermarket?

-

Dodge hub removal tool

12pt 14mm? I just did it this afternoon to put on gen 3 dust shields. This is on a 01 3/4. Used regular sockets, hub was 8 years old, but assembled with anti-seize.

-

New Dash Now Won’t Start

I can try and take a pic tomorrow. But it should be fairly tucked up in there. The other connector doesn’t have much length. I think that ones for cruise control, all the SRS are yellow, so shouldn’t affect it anyways.. Im guessing you’ve tried bleeding it? Not sucking air from another source? Do you have a fuel pressure gauge?

-

New Dash Now Won’t Start

Up on the steering column. Attaches to clock-spring harness lead. Don’t know why would be no start though.. Truck will crank, no start?

-

16" Wheels suggestions?

Could consider sanding wheels a bit and rattle can black. I ran like that for a while and liked the look. Current wheels did the same to. the stock rims are weight rated and light. Forged? Hard to beat from a stock performance perspective. If you move to aftermarket steel, probably heavier, and not rated.. Pic of 4th gen? 18s with 3rd gen brakes

-

16" Wheels suggestions?

It should be noted that for 3rd gen conversion, 17” rims minimum required. I have 18” and its close. Some trimming of rod end threads may be required.

-

Angry & can't do it anymore, serious iQuad timing issues

These are the old rods I pulled from mine. Doesnt appear to have the mushrooming.. On some of larger cummins, says rods could crack and fill with oil. Didnt hear a response if anyones come accross that in the 5.9s..

-

Angry & can't do it anymore, serious iQuad timing issues

To me those look pretty stock.. the orange by the cup kinda tell tail.. My hamilton/mantons/whatever dont make any different noise than stock. Theyre 7/16 and its QUITE a visual difference. My OEM rods were weighing 103-4grams. 10mm? The 7/16s are 200grams each! BTW do you guys do dimples out or in, on the bridges?

-

Angry & can't do it anymore, serious iQuad timing issues

Whoops! Thought I saw one down there with mine, but could’ve gotten mixed up with another one. Guess Im half right, CMP has a ton more data to give than the crank! @Stanley For rods, usually roll them on flat surface to see if bent. Check for cracks or uneven wear on the ball. Standard stuff.. Quick google on some larger engines said they could crack and get filled with oil?? That would change mass of rod. I dont know if thats the case with our engines.. You can crank engine over by hand, with cover off, see if a valve is bent or sticking. Not many things jumping to mind though. Have you tried a stethoscope? Put it on each injection line to be sure its something there. Taking stuff apart can be fun, but not always productive. I had a loose exhaust brake support rattle, that for longest time thought was in tappets, even though on other side of engine!

-

Max boost only with WG hose pinched

@Tractorman All very good information, paper calculations with BP are matching up closely with the WG numbers. This should be fairly true across the board, Even with units that have a lot less BP. I guess not many complaints though if say gate is set to 40 and getting 38. @Mopar1973Man Pray tell more about this fingertrap invention. Having a constant boost leak isn’t ideal. I found a PPE 116030000 Boost valve that looks like what your describing. Its preset though much lower, 25 psi, and designed for a LB7. Ebay search resulted in nil.

-

Max boost only with WG hose pinched

So I made my own adjustable elbow. Im noticing from online photos that there seems to be a vent drilled into it? Or atmosphere pressure? The one I made just put an allen to block off/restrict pathway. So if im missing something may have to try again. it made no difference, several attempts at different amounts. I readjusted waste gate to open at 45 lbs, which has netted me 33 or so boost. I installed a boost reference gauge, very similar to my back pressure setup. It showed the same pressure as my MAP sensor. No higher than 34. 1160 egt. So I guess that sorta settles it. Drive pressure has to be assisting the wastegate opening. When I adjust the arm all the way in, im getting more boost from preload, but also limiting how far the door can open, increasing Egt and drive pressure, and cant seem to get enough before running into choke point. Another note about this/these turbos. Ive seen a lot of similar/close 64s on the market, spoologic, cheetah, stealth. So sorta bizzarre I seem to be only one running into this, but not seeing many other conclusions. If Im missing something, let me know. Otherwise I hope I collected some useful data for spinning my wheels for a week.

-

Angry & can't do it anymore, serious iQuad timing issues

@Stanley Someone more familiar with the VP will have to chime in, Im only speaking from my case example. I would GUESS, that the cam sensor has more influence over the pump then the crank. Although the 2 sensor definitely work hand in hand, so cant hurt. The CMP is a lot harder to change. I think its a single 5 mm allen holding it in place, but you need a long wobble allen and wobble socket and really contorted arms. reaching behind the inj lines, On timing case hidden behind the pump. I dont have an idea about the line sounds. Also if @Me78569 thinks the data isnt abnormal, probably right. Again Im just throwing shot in dark, so no promises on what helped me.

-

Angry & can't do it anymore, serious iQuad timing issues

Shot in the dark. How old is the Cam sensor? I had a serious case of Murphy law when I put in my 150s. No codes or anything, finally showed itself when the tac went haywire and dropped off. Finally a P0341. Needless to say it was very difficult to tune. Unless you were looking for smoke, high load, egt, and low power.

-

Max boost only with WG hose pinched

….So, no. Definitely bad to have it plugged. 45 boost, 80 BP (high mark, usually 70 or 60) only 1260 egt though. This was on the smaller 0-100 gauge though, so thats 2 different variables. I feel its pretty accurate though. This makes some sense finally. Above 40s gotta be the near choke point. Definitely want the wastegate to be functional. So next test is reset actuator to 40 lbs and boost adjustable elbow.

-

Max boost only with WG hose pinched

Appreciate the head scratching. Center wall is drilled, 1”ish port right after bolts to manifold. the drive pressure tests were with it “functioning” adjusted to open at 60 psi boost reference. Drive pressure gauge hooked to bank 2. But can do either or. With the dual volute wall drilled, not sure it matters much. Think thats what you’re getting at. I guess I can do another drive pressure test after work today with it plugged off. See if I do get 44 boost/ <50 BP.

-

Max boost only with WG hose pinched

@dieselautopower Thanks for joining! For sure, thats almost 2:1. I mentioned I was purposely over fueling for data. Its closer to 36:50, still not optimal. The actuator rod is almost all the way in, so gate isnt far open.. When Im running up at 40-44, the EGTs are a lot lower, so wouldn’t be surprised if staying at 50 BP still. Around 20 boost was closer to 20ish BP. So thats where Im getting confused at setting. When I make 40-44 boost, EGTs are good, BP prolly closer.. But only can happen when I plug the boost reference hose. But wheel wants to overspeed..(hits defuel setting). When I leave hose unplugged and adjusted in, Im only making 36 PSI at max adjust, with 300+ Higher egts. So a plugged off wastegate gives me LESS Egt??? Next step theory I think is to bring actuator rod back to 50 lbs, and close off most of the reference air with the adjustable elbow.

-

Max boost only with WG hose pinched

@Silverwolf2691 No need for white flag brother, Im not married to this thing, just having trouble running in circles trying to get it to work properly. Achieve, 1) max efficiency out of the unit, its supposed to get or be at 40, and I see good performance when tweaking to get those numbers. 2) Understand/trouble shooting wastegate actuator settings and effects. Appreciate all going after my specific issue, but I feel theres a lot of generic info to be learned here too.

-

Max boost only with WG hose pinched

Turbo is a P1 64/64 from puredieselpower. Sorry, wasnt trying to be obscure. Im doing this for generic data, and concepts too. It was the gauge I had laying around for the afternoon. Lets say within 5 psi accuracy, maybe better. Wastegate unplugged, but max adjust in. Also near 60 psi open with reference hose. So doesn't open very much. The 60 back pressure was with known overfueling for available boost. After 36 boost, ~50 BP, fuel just turns to egt and BP. About 10 psi for every 200 EGT is what Im calculating. So most accurate reasonable ratio is 36/50, maybe less. I plugged it and ran for one more run home at 44 boost, unknown BP, but only 1120EGT.

-

Max boost only with WG hose pinched

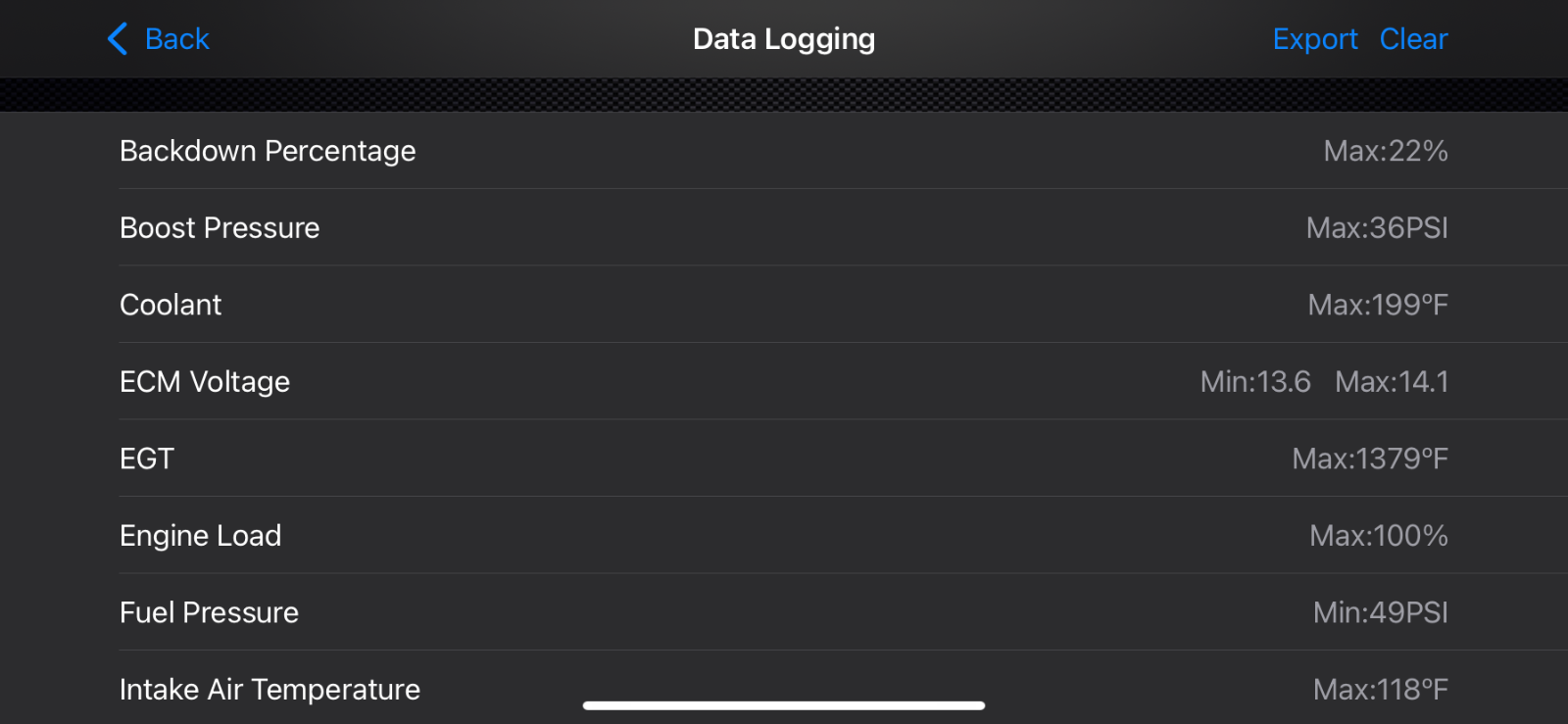

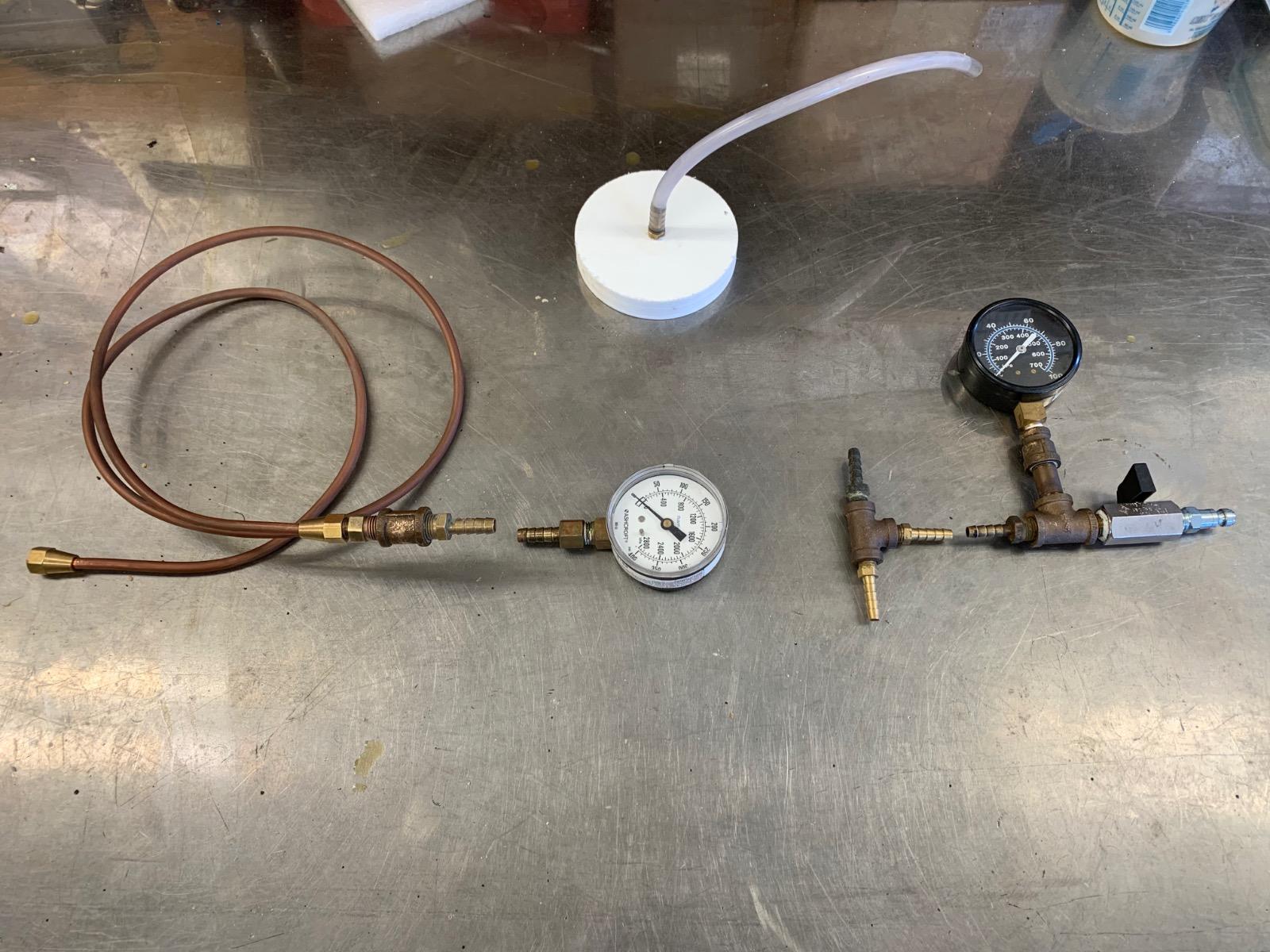

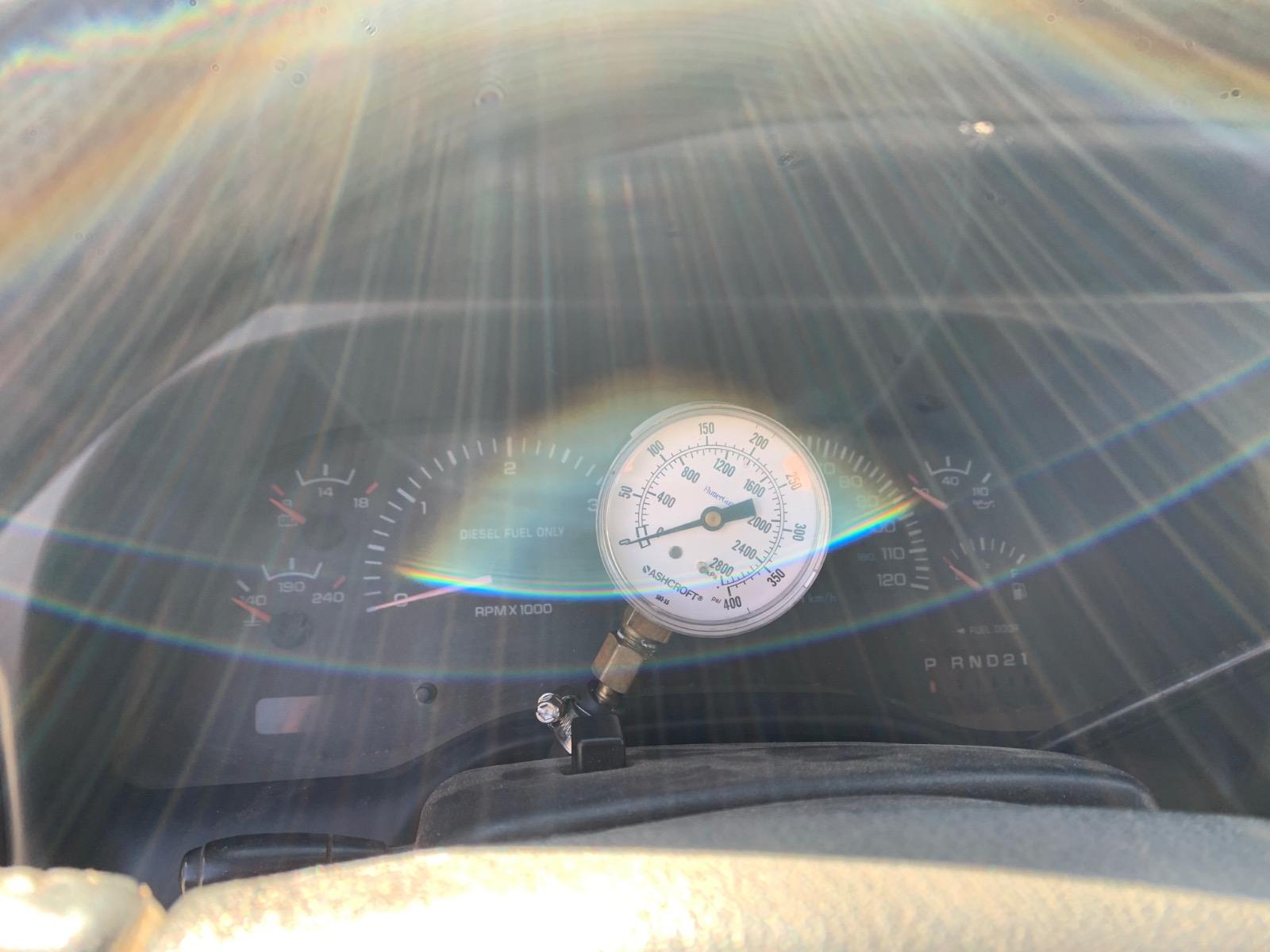

I did order an adjustable elbow, but for science, wasn't too hard to run back/drive pressure test. All these gauges/equipment are pretty rudimentary, but does decent job, and illustrates concept. Let me know if I missed a step. So Quad screen was with max, 1500ms pump. Previous test said wouldnt add more boost but thought Id try. That run almost went to 60 back pressure, also egt defuel, with 36 boost. Wiretap at 1000ms would’t go higher than 50 back, 36 boost. Normal driving was about 10 back, 7 boost. Accuracy of gauge isn't awesome though. Its 0-400 psi, with me driving and trying to watch it. Im trying to be as honest as possible about this for sciences sake. Picture of the exhaust port tap, run to a hose, going to cab. Also In pic are boost reference pressure/ wastegate actuator setting. And turbo cap attached for boost leak testing. Obviously only one hooked up at a time. Though about adding a mechanical gauge to reference to compare to MAP, but not tonight. Bench pic of equipment. And gauge in cab. Im still leaning towards back pressure helping opening the wastegate. The adjustable elbow should help confirm that.

-

Max boost only with WG hose pinched

Thanks for responding more ideas the better! 6x6 Blade Billet Compressor Wheel (Inducer 63.5mm Exducer 86mm) 10 Blade Turbine Wheel (Inducer 76mm Exducer 64mm), 12 Cm housing I needed direct bolt on and stock appearing. I thought 60/60 hybrids were fairly common, low issues. Thought be happier with slightly bigger. I have the actuator rod adjusted all way in, about 60 psi to crack. Earns me 34 boost. EGTs on whole run never go over 1200, so when the boost is there, stays cool. I got parts and gauges laying around, so rigging together backpressure test after work. Can drive pressure help pop the wastegate open, along from my reference actuator? As in both sides added together make the 60 psi? Im having a heck of a time too, compiling graphs with a MAC version of excel (all I got). The secondary axis is all messed up. Any help with that? Already read and tried to follow Me(Nicks) guide.

-

Thinking I have a boost leak

Breather tube? Thatd be crankcase pressure Id think. Quick google ‘cummins boost leak tester’ I made mine out of 4.5” hole saw plastic part. Put a fitting where the drill bit went. Regulated shop air to it and spray hoses, intercooler, etc with soapy water. No codes? Air filter clean? If getting at least 19# from MAP?, may be fueling related.

-

What shocks are you running and why?

Depending on material of bushing, I don't think they should be ‘squished’ much. Snug is good. Sort of like sidewall for tire? If they wanted it designed super tight would come with a rod end. So when my shocks failed, truck would bounce down the road after small bump for 1/4 mile (springs return, no dampeners). Fairly easy test, if they're really shot. Jump on bumper and see how many times it bounces. More than 2 small probably shot. When I removed the shocks you could compress them all the way by one hand in a second, and would maybe regain length in a minute. Another test, high speed up and down (only)bounce/death wobble/ reverberation. Best I can explain, thats before complete failure though. I always wanted Fox shocks, and there was already a sticker on my window, so thats what I got. 2.0 IFP. 650$~ for 4. Not too bad for some stickers. The next step up with reservoirs would have been like 2k. Not for my application. I like them, they work well for me. Fairly stiff/responsive and effective. Have hit bump stop with only minor front end pavement contact loss however. Not for Baja superman stuff. About 10k miles on them. My peev with the expensive reservoirs is that they’re rarely adjusted after, used for looks mostly. If going that route, get a hose extension and mount them inside the cab for on the fly tuning.

-

Max boost only with WG hose pinched

So I did 3 runs, have 2 data files. Theyre small, someone maybe can make sense before I can figure out how to excel graph them. On the run I dont have data for was canbus only. And that only pegged 36 psi with it closed, so Plugged off and no wire tap could be a ‘safeish’ way to run. On the open run I had wiretap at 5 instead of 6, and was going up slight grade. Only hit like 12xx EGT, Around 31 psi. So 5 of 6 of 1500 Wiretap is max. Well explained John for the marine use, they're constant use, constant conditions and ratings. Ex 24kw@3500 all day. The turbo is a 12cm. The 62/xx are all the s300? This unit was more of a direct bolt on. have an exhaust brake. Was told the 7x.009 would be a better match, but read a lot about the .010 being good, so thought id go bigger, than not big enough and wonder more later. Thoughts on matching? With fuel prices I’m real tempted to swap my 275s back in. Although was seeing over 20 on the lie o meter. So far pretty happy with it, just stumped about this setting. Actually having issues tuning the down low power load egt and smoke, but that should be in a different thread. Back to basic questions for laymen help. Anything Im missing in diagnosing low boost or leak? SV WG Closed.csv SV WG Open.csv