Everything posted by PilotHouse2500

-

New Life and New Body with issues...

-

Pilothouse/RAM3500 build

I'm guessing it'll be in Jan when he can start. He needs to get his building finsihed and inspected prior to starting to actually work in it.

-

Pilothouse/RAM3500 build

-

A little Dodge horse tradin'

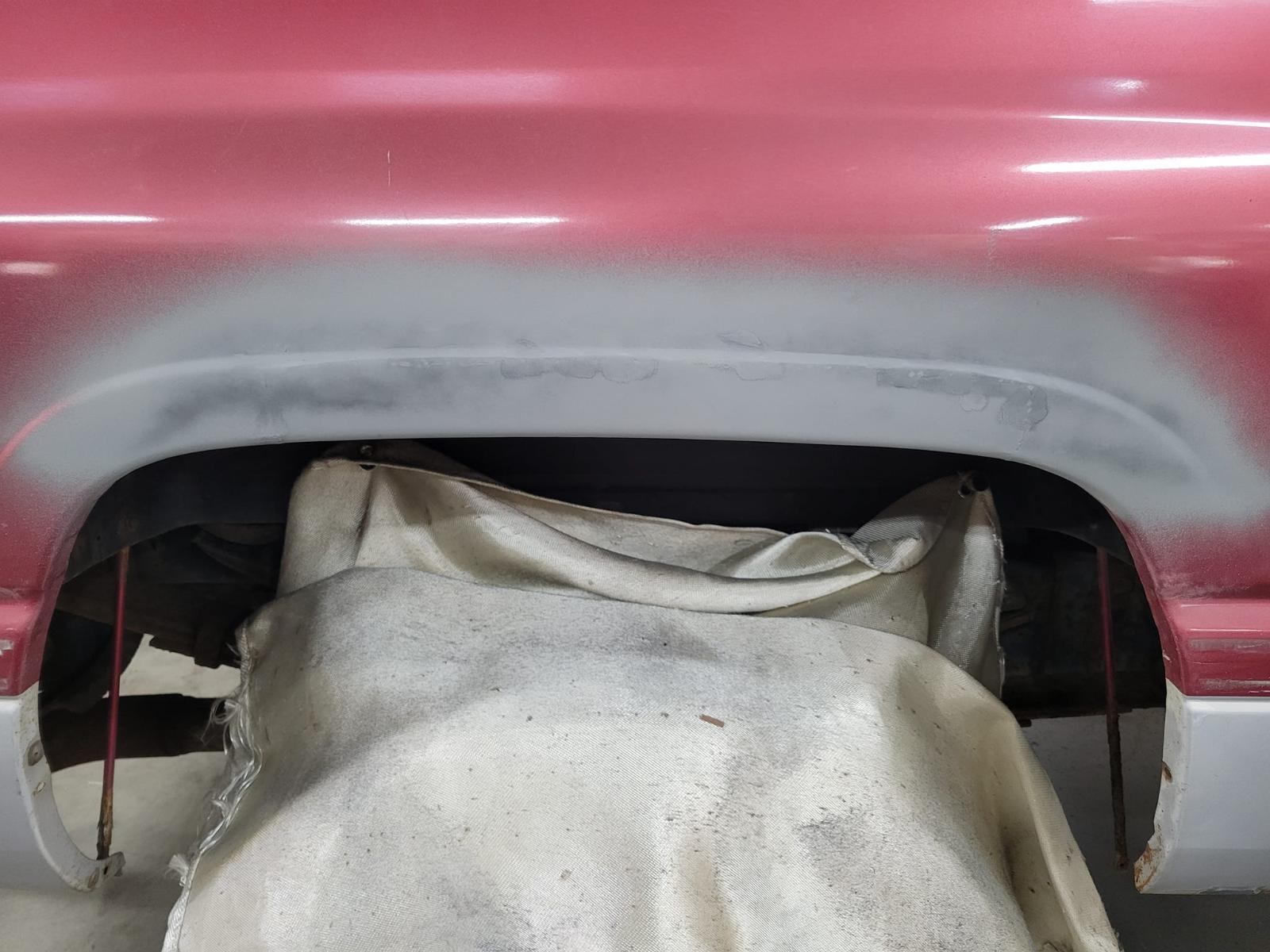

My buddy traded me a first gen 6bt to do some body work for him on his truck. So several patch panels later I got a "free" engine.

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

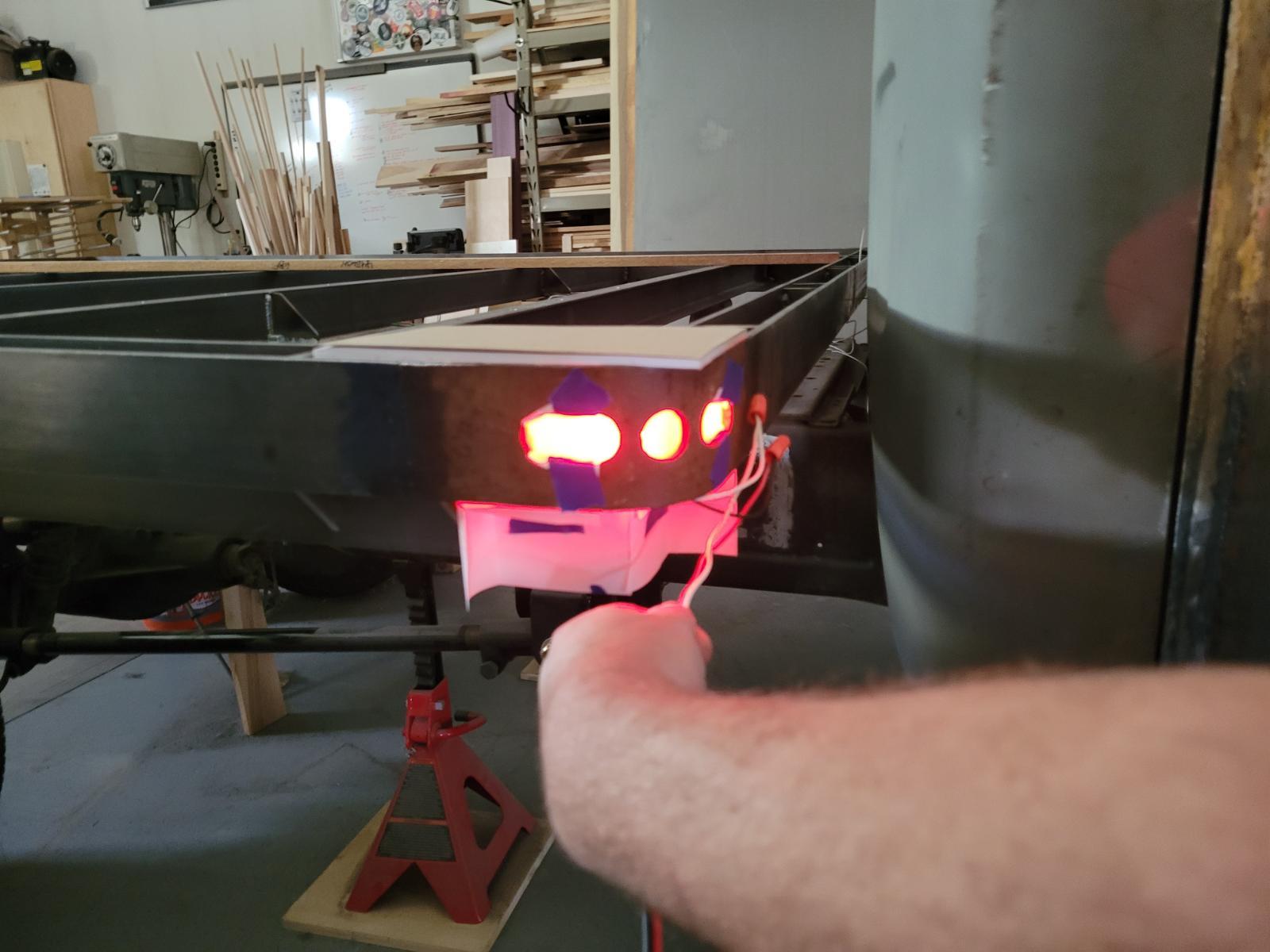

Ya, I just spaced out "evenly" the pockets...there will never be a stake panel in there and it's more for looks than anything. Center rear three will be on the "bumper", and I mocked up what I'm now going to do on the corners for marker lights. TBD if I will do side marker/turn signals....

-

Pilothouse/RAM3500 build

I did this to see how it looks. Use the corners to be the lights. or this: mod the lower corner to be 45° and mount a single light to be side AND rear.

-

Pilothouse/RAM3500 build

originally yes....now....I dont know...I'm waffeling on what to do and how to do it.

-

Pilothouse/RAM3500 build

Spent the day yesterday SLOWLY drilling the bed strip holes...60 in total thru structural U channel....all while under the influence of my shingles booster shot....but I got it done. Here is my "favorite" version of the back plate (for all intents and purposes legally read that as "bumper"). orange dot is camera, yellow is trailer connections. I just don't know if the marker lights are "out" far enough or not. I might need to trim my stake pocket bits a bit to push them out further.

-

Pilothouse/RAM3500 build

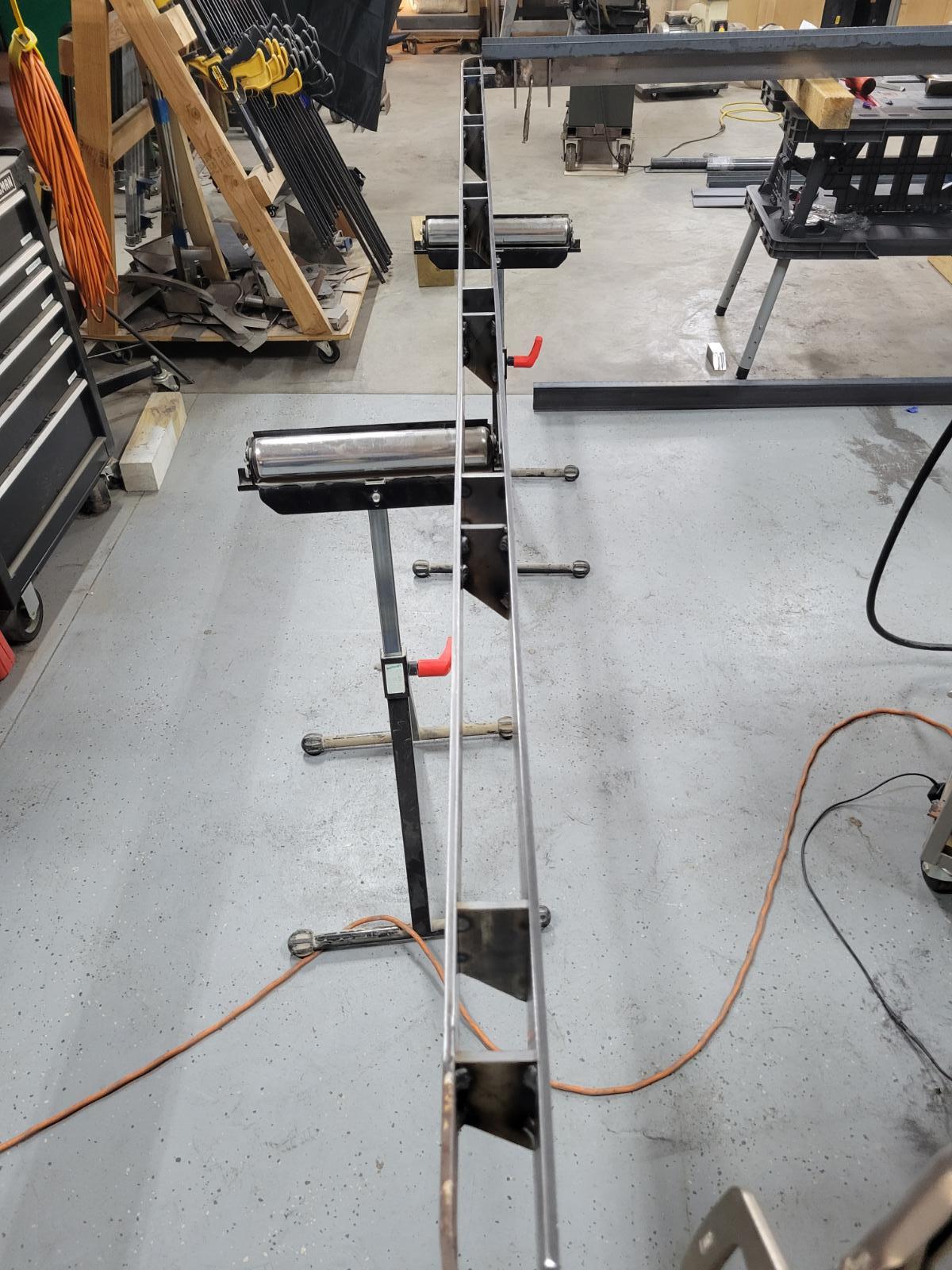

I have a bed... Things left: 1. Fuel fill bracket 2. Tie down backers 3. Drill holes for bed strips 4. Drill holes for marker lights 5. Make bed tail plate for turn, brake, back up, plates,back up camera and trailer power

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

Bed "on" the truck. Not at final height yet. Amazing what you can do by yourself with no ready hands to help.

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

broke the bed down to these 4 parts, with these and $1200 at CoreMark, I'll make a new bed with out all the "historical issues"

-

Pilothouse/RAM3500 build

Spent more time with the parts yesterday, a few cut off wheels and a few scary moments with large pieces by myself....I've secioned it into 4 pieces now, but have decided to just build a new one, these parts are just too beat up to match up to a nice clean cab and frame. So off to CoreMark I go to spend unplanned $$.

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

I've been helping the painter build his new 5000sqft building to knock some of the cost off the project. He THINKS he'll be all buttoned up here in early Oct. So we'll trailer him over in early Oct and he'll "start". No idea how long he'll be working on it....but needless to say I HAD orginally hoped to be reeassembling by Oct....so a few months behind. Money will be the big driver on my side now. Meanwhile I'll start working on the bed frame.

-

Pilothouse/RAM3500 build

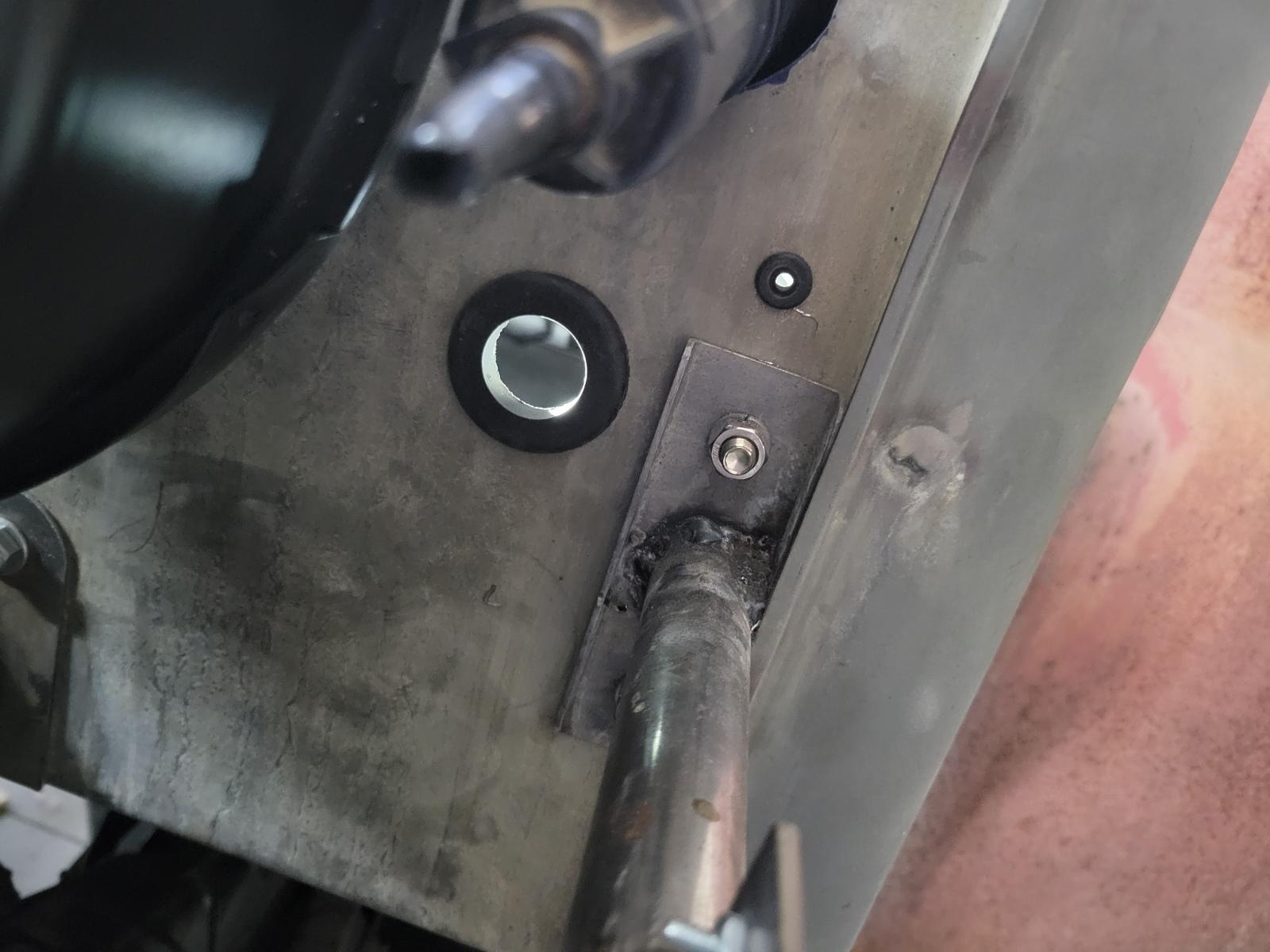

Pic of a full size mock up of the running board below. Meanwhile I've plugged unused holes, made ones needed, made a mount for the gauges computer, welded in place the wing handle mounts, welded on mounts for wiring and cable controls. At this point I'm pretty much ready for paint. Hard to believe.

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

been a while...but punching holes in the firewall for cable controls, wire harness and acc cable. Building running board mounts and frankensteining an acc pedal

-

Converting Auto to Manual

I THINK that is still needed to set idle....looking for confirmation is all.

-

Converting Auto to Manual

Are the circled parts needed when converting from Auto to Manual transmission on the throttle linkage?