Everything posted by PilotHouse2500

-

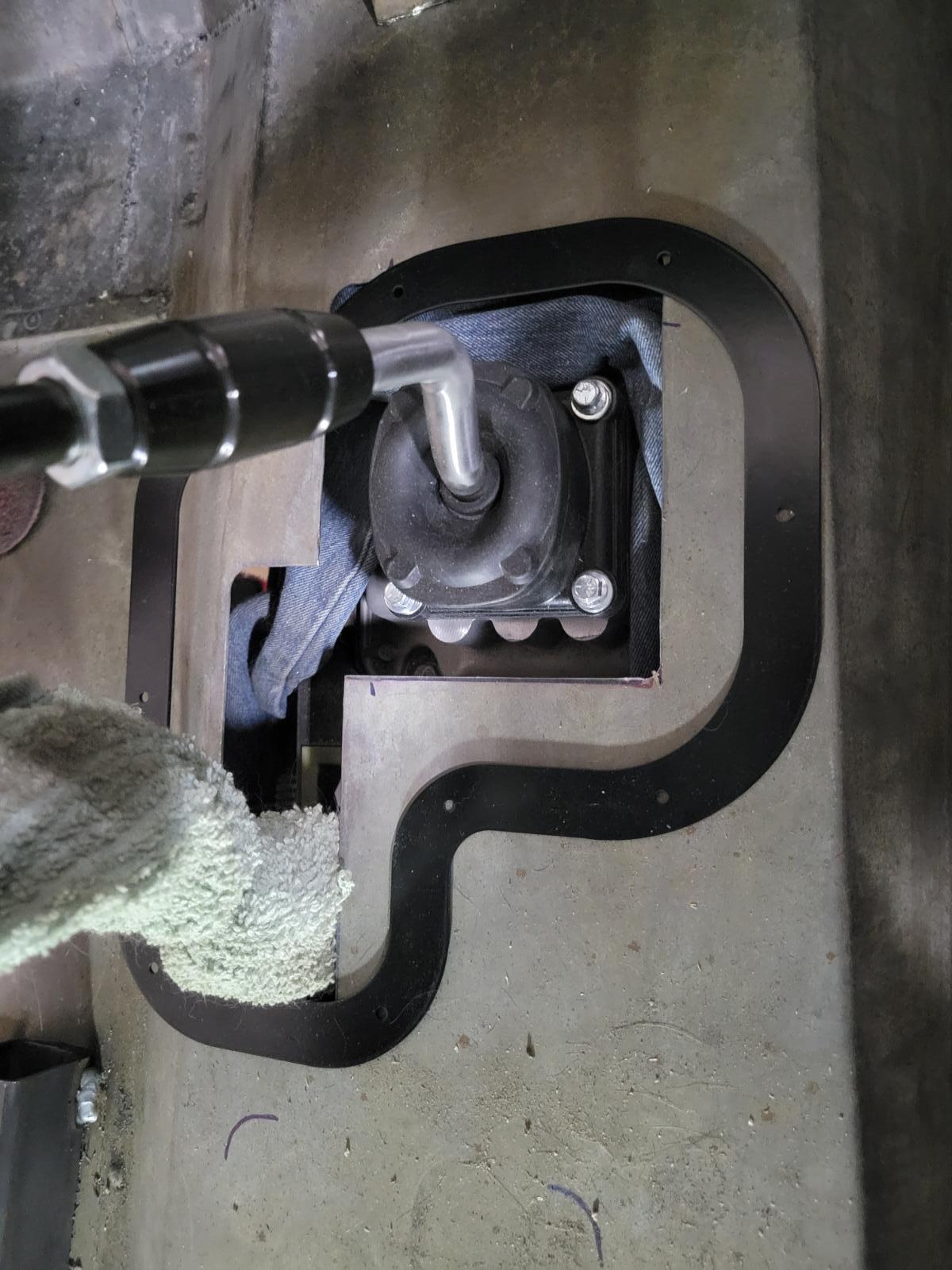

shift boot location on tunnel

That's ok, kinda figured right now it'd not be you. I don't know if it REALLY matters TOO much for overall location. I was planning on centering on the gear shift and let the TC fall where it may. I just don't know if that is a problem or not (cause I won't know untill stuff is welded up and painted), just hoping someone has a number/idea before I start making parts become one via MIG.

-

shift boot location on tunnel

-

My Personal Opinion

Good to hear you are keeping up on things and a good attitude!

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

He's SUPPOSED to go in for paint this spring....frantically trying to find the energy/time to get everything done in time. The list keeps seems to keep growing sadly instead of shrinking! And I have a dockett already of woodworking projects I need to start on this spring as well (gotta pay for this all somehow as inflation is eating my main job check pretty efficiently). So figure about 1 year or so after I get parts back from paint I hope to have him on the road. And I AM planning a drive out to CA to visit my buddy for his car/truck show and hope to loop up thru the NW as part of the trip.

-

Pilothouse/RAM3500 build

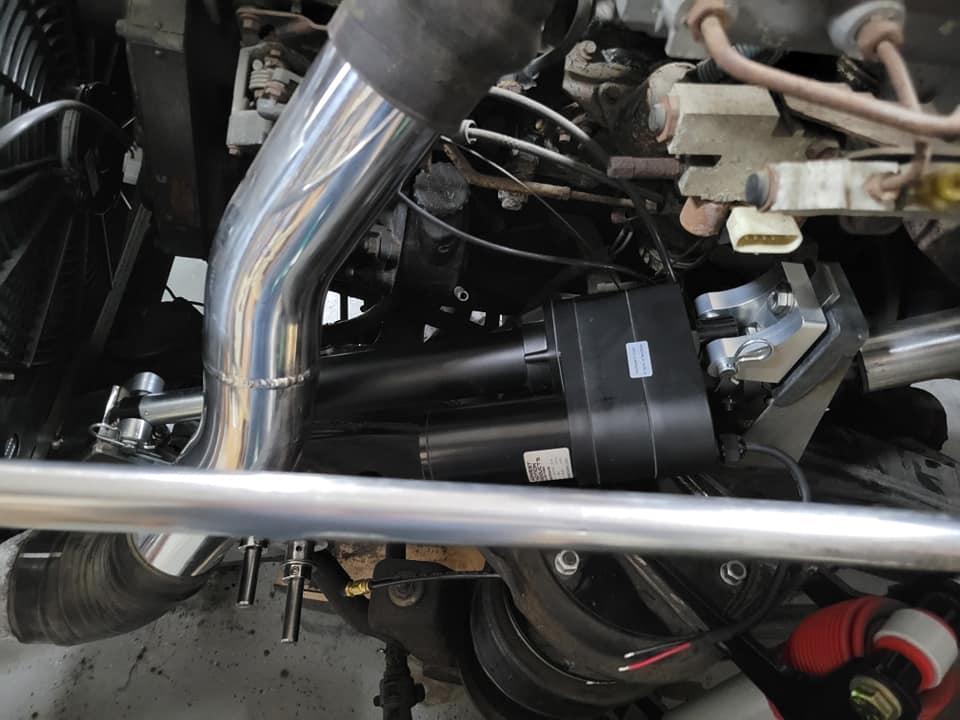

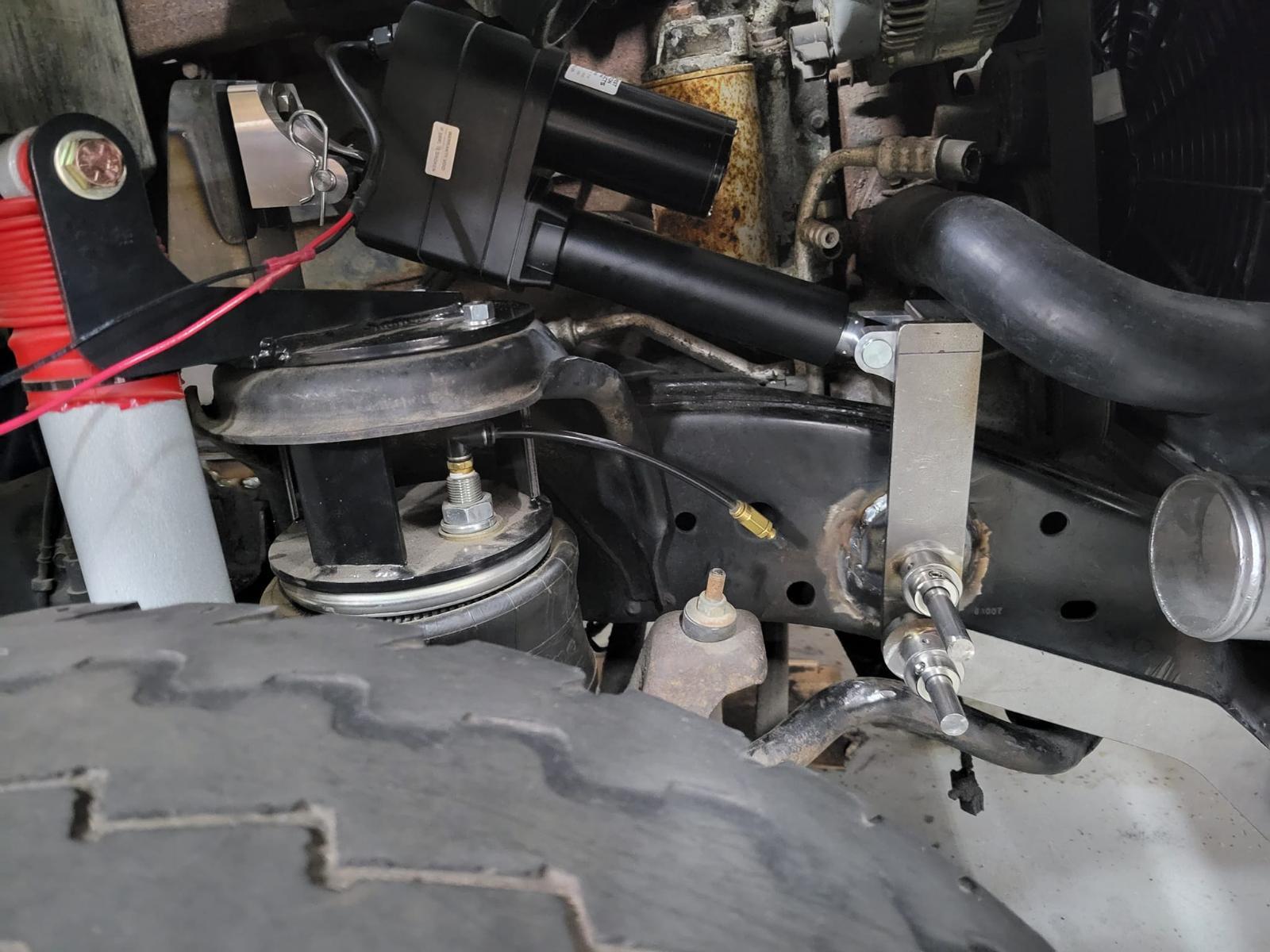

been a while for an update, so here you go: Power for front doors AC condensor rock gaurd foot pedal head light dimmer Turbo gauges holes punched in Cenrter console

-

My Personal Opinion

Glad you have a good team buddy! One of my old neighbor is going thru some C as well and a good support staff makes all the difference in the world. Sorry to hear the Neo isn't an option. Hang in there and do all you can, lean on those you can and keep as much smil eon your face as possible. I promise to hold a Zoom here to look over my project by the end of the month.

-

My Personal Opinion

Good people seem to have bad things happen...it sucks, but I am glad you are finding a way thru it as best you can. While not everyone will appreciate, do what YOU gotta do for YOU. Per request I suspended my donations and will watch for when we can start to help out again, websites aren't cheap and I fully want to help support this community. Drop me a PM if you ever wanna set up a call and check out my old dodge insanity stuff.

-

I know this is sudden but...

I'm heading "up north" near the Canaukastan border this week later to hang with some friends in their shack to have some fun w/o power or running water.....always a blast, so I won't be around till next week for any zoomy calls. If, after that, as I said anyone wants to zoom my shop and do a walk around my project I'd be willing. Glad to hear you in better spirits. I can sympathize your situation to a degree. My wife was in 4 accidents about 2.5 years ago. We count one accident as 3 because it was multi car and she took 3 impacts. She now has TBI and her (and my) life has changed dramatically. She's luckily still "there" but physically she can't do her old job, do house chores, drive at night etc. Severe concussions suck. It can wear on me as well with all the extra duties and understanding it takes now repeating some things as she doens't remember everything as she should. So I totally get where you are, just know people care about ya, are really hoping that you can find a new "normal" and keep a smile on your face as you move forward. Depression is insideous and remember there are help lines available if no one is around in your personal life to talk to in a dark hour.

-

I know this is sudden but...

if you get despaerate, I could zoom a call and walk around my project truck and you all could laugh at my insanity.....beyond that, I'm not too deep into the engine (yet) to get into a 6bt discussion.

-

Pilothouse/RAM3500 build

It's been awhile since yu last visit here. Updates: outter body work all done as far as I can go. I have started interior work and figuring out how and what I want layed out in the cab. So some shots of the fender "rivets" which are now carriage bolts turned down to look like rivets, NOS arm rests for the people doors, and under dash panels built that will hold AC vents, AC controls and a radio.

-

I know this is sudden but...

Just saw this. Your attitude is a wonder to behold, too many would fold up and give up! Keep that attitude going and do all you can do in life!

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

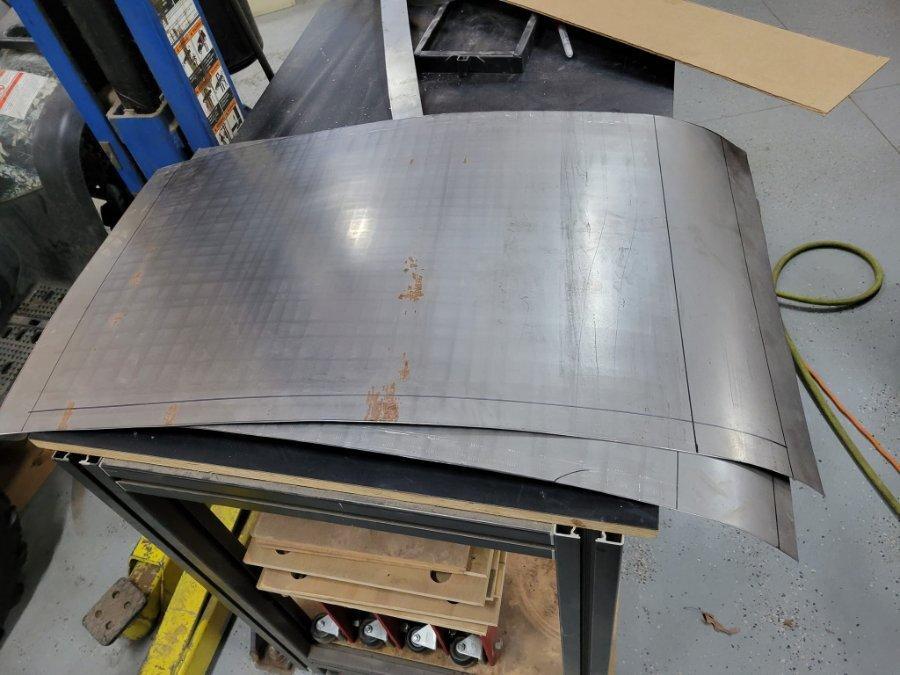

few days of work shown here: rear door skins made prepped rear doors for skin addition added power blocks for the rear window power rebuilt door side of the check arms replacing and re-enforcing the area

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

Well, short of a few things to tidy up, "Pa's Shed" is complete for the year and I plan next weekend geting back to the truck. Got lots to do, so hopefully I can keep motivated and start to wrap up all the loose ends there!

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

While waiting to get more work done on the new shed, I have time to work on some stuff on TODD. So, the rears were removed, cleaned up and I POR15'd the exposed work where I knew it'd be hard to get to for coverage from the door access panel area.

-

Pilothouse/RAM3500 build

Steel all around. Roof got weather tight this last Monday. Now I get to finish the steel siding (yes I paid for the roof steel to get put on).

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

Not much to report on the truck work. I've filled in some holes ands detented areas to smooth the jamb areas is about it. My painter will be ready in one year, so I HAVE to get things moving into high gear to hit those dates. Meanwhile, I'm spending a majority of my time building the new shed.

-

Pilothouse/RAM3500 build

Well, the weekend was busy! Running on 18V instead of 12V (wheeler battery had a bad cell) so its a bit FAST, and I need to figure out how to stiffen the whole thing so the bounce stops. But I'm happy! 38964.mp438965.mp4