Everything posted by AH64ID

-

Weird cooling system problems HELP?

Your motor was built on my wife's 19th birthday. My guess is the thermostat is the same, but its represented a little different here.. instead of the crack/full open numbers in other places. [TABLE=class: box] [TR] [TD]Coolant Capacity (engine only)[/TD] [TD]9.0 liters [9.5 qt][/TD] [/TR] [TR] [TD]Standard Modulating Thermostat - Range[/TD] [TD]84 to 91°C [184 to 195°F][/TD] [/TR] [TR] [TD]Maximum Allowed Operating Temperature[/TD] [TD]100°C [212°F][/TD] [/TR] [TR] [TD]Minimum Recommended Operating Temperature[/TD] [TD]71°C [160°F][/TD] [/TR] [TR] [TD]Minimum Recommended Pressure Cap[/TD] [TD]48 kPa [7 psi][/TD] [/TR] [/TABLE]

-

Weird cooling system problems HELP?

180°'s go full open at 198°, max allowed operating temp is 212° 190°'s go full open at 207°, max allowed operating temp is 225° What's your engine serial number?

-

Weird cooling system problems HELP?

You have to drive it more with a big load to fully exercise the stat. I watch my coolant temps via OBDII and this year about 60% of my miles were towing and I bet I only went full open on the thermostat 10 times, if that. It takes a lot of heat!

-

What oil filter do you use?

The FAQ section listed it as 35um absolute.

-

Weird cooling system problems HELP?

I agree with everyone on the tstat... Go to the local Cummins shop and pick one up, cheaper than Mopar. Thermostats fail at a higher rate on these motors than other rigs due to the huge cooling capacity. It take a lot of load to get the thermostat to hit full open and stay there so its always modulating. It's not uncommon to see a 15° swing while towing, or even driving around a city on a hot day. The 180° thermostat cracks at 180°, but isn't full open until 198°.

-

Timing Effects

Ah yes, I know that name... I'll see if I can hit him up.

-

What oil filter do you use?

Looks like its absolute at 35um, not worth it.

-

Ran Away From Home And Got Into Hot water!

But still above average, which was what I was getting at... Unfortunately they don't have any meters on most the rivers we camp on... This is the closest, but we haven't camped there since April.

-

Been a good couple years of camping...

This is all the places my wife and I have camped from the summer of 03 until now, at least in the home region. We did some camping in Alabama too.. We did miss a few trips thanks to the Army, Summer of 04, spring of 05, and all but one trip in 06. Really can't complain too much.. we have hit some of these sites 5+ times.

-

Ran Away From Home And Got Into Hot water!

Water flow is down? It's only been a month since I have been in the hills, but I thought it was quite high all summer?

-

Timing Effects

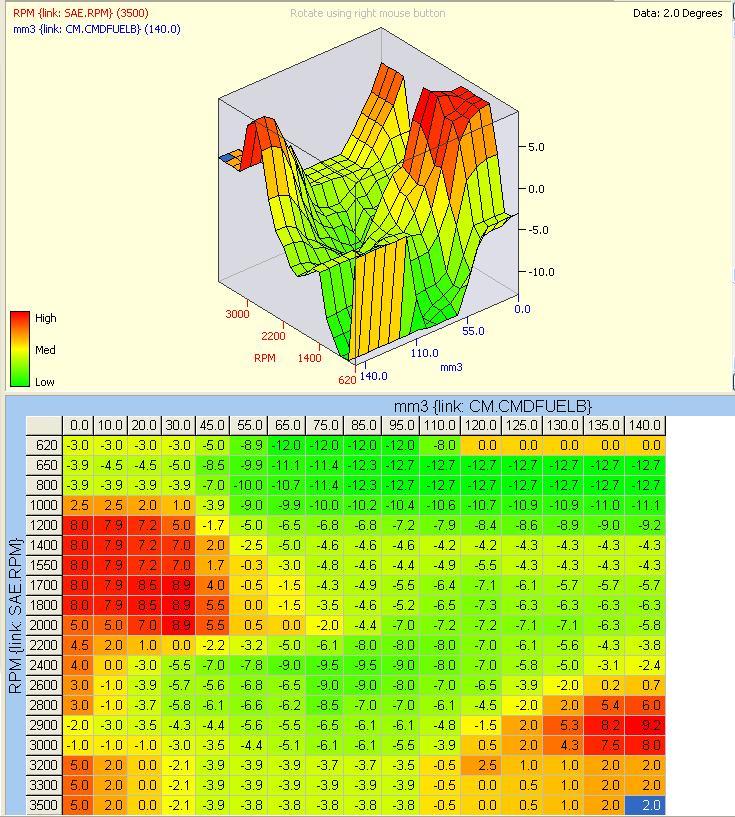

I can quite easily see the difference in boost/EGT when I change my timing parameters. It's most noticeable to me in acceleration, but cruise/towing is also noticeable. But what I don't know is the difference in timing from stock to max advance on my tuner, maybe its more than 5-7° and that's why the effects are more noticed. --- Update to the previous post... This is from the H&S 5.9 tuner, a tuner I have zero experience or knowledge about.. But as you can see the timing changes are not small! 0 - 18 degrees 1 - 24 degrees 2 - 26 degrees (Default) 3 - 28 degrees 4 - 32 degrees --- Update to the previous post... I have heard the stock tune refereed to as 12° max, but that EFI Live table disagrees. But I did some reading and think I run about 6° advanced, but that's on the 12° scale so it's really hard to say! --- Update to the previous post... That table I posted is a HPCR table, not a VP table. I can't read numbers on Mikes. Also those very advance numbers are above idle rpms... --- Update to the previous post... Even more reading show that this is what is thought to be factual on a stock tune. VERY retarded numbers, but there is a pre-event before this so it's not apples to apples... Testing is still being done to confirm/deny the theory.

-

Timing Effects

I still frequent that site, , what's his name? --- Update to the previous post... This is the stock base timing table... This is a 06-07 (really should be 04.5-07).

-

Timing Effects

Which is why you need to load the motor more to see the effects easier. Under normal driving the changes will be slight, but that increase in economy is from advanced timing which does the things I have stated. They are just that.. more aggressive. They are not making it static they are simply advanceing it for performance. Emissions does play a role in timing, but not the only role. The driveablilty and performance are huge in dynamic timing, its the main reason 98.5+ trucks are smoother. I am not saying it doesn't effect emissions, just that emissions is not the sole reason. Making a VP44 or CP3 have static timing is a step in the wrong direction.

-

Timing Effects

It says below peak torque becuase its a wastegated scenario. Above peak torque you get into wastegate operation and the wastegate controls boost, not timing. To see the effects of timing on boost in the upper rpms you have to remove the wastegate from the scenario. I would not say the burn is inefficient, it's actually very efficient in terms of emissions if its retarded a little. That is the reason the 04.5+ motors run retarded timing, it improves the emissions. EGT's go up because the burn happens later and the combustion is much hotter when the exhaust valve opens. To make 10 psi with advanced timing takes more fuel than 10 psi with retarded timing. You keep talking about the same amount of fuel being equal. But if you inject 100 mm3 of fuel at 14° it will have lower EGT's, lower boost, and more hp than injecting 100 mm3 of fuel at 12°. EGT is not related to boost, not 100%. I am running 30 more hp at 3-7 psi less boost with my new turbo and run 50-100° cooler. I have run several different timings on my truck over the years, they all made very noticeable differences in EGT's, so much that max continuous EGT and max EGT's vary with each timing setting. As the EGT drops for the same amount of fuel you put more heat into the cylinder, and will melt a piston sooner. It's hard to quantify as I don't know timing number, but here is what I use. TM1 is stock, TM4 is the most advanced. In order of retarded to advanced is TM1, 3, 2, 4. IMO this creates similar piston temps. TM1: 1400 max cont, 1450 momentary TM2: 1300 max cont, 1350 momentary TM3: 1350 max cont, 1400 momentary TM4: 1250 max cont, 1300 momentary --- Update to the previous post... Take a look at the points/dyno about timing in this.. http://www.madselectronics.com/downloadfiles/SSR_Tuning_Instructions.pdf --- Update to the previous post... I spent some more time thinking about this topic this morning.. I know Mike believes that dynamic timing was a function of emissions but I don't beleive so. It is also a big factor in the very flat torque curve that 98.5+ trucks have. With dynamic timing you can vary the timing based on fuel flow and boost to get the most power out of the motor. Now as emissions have evolved timing has been used to manipulate emissions along with power. As boost increases you need to back off the timing, one of the reasons the useful rpms vary so much on the P7100 trucks, you are timed for a certain rpm and/or load. Consider the 06-07 trucks that can utilize EFI Live. In low rpm, low boost, high power demand instances the timing can be retarded to help spool the turbo. As boost and rpms increase the timing is advanced to get the most power out of the motor thru efficiency. At cruise boost, rpm, and load the timing can be advanced to improve economy becuase we are not worried about acceleration spool. What Mike did with his fixed IAT sensor would be a good basis for proving the EGT, power, efficiency change. If there were a potentiometer in the system, vs a resistor, you could watch everything change using a boost, EGT, and Scan Gauge. Set the cruise at 75 mph on a long straight stretch of highway, or 55 while towing. You want the speed and/or trailer to put a load on the motor so the changes are more drastic. Once you have a stable med-high load adjust the potentiometer. At IAT increases the timing is advanced, this would generally make less boost, lower EGT's, lower GPH, but the power output is unchanged as the truck still requires "x" hp to move the weight at the set speed. Start decreasing the IAT and timing is retarded, more boost, more EGT's, higher GPH for the same rwhp. I really couldn't think of a better way to test it.. --- Update to the previous post... This is not quite how the mechanical pumped engines I have messed with work. Not saying it's not how the P7100 works, just not how I have seen it. The engine I have the most experience with is a 3406C marine motor. It's a good example as prop demand is pretty constant per rpm. 1" of throttle lever movement would produce the same rpm in neutral as in gear, thus the throttle doesn't apply "x" fuel, but looks for a specific govern point. Now in a truck it would still apply to a point. If "y" throttle is looking for "x" rpm but the load it too great for the amount of fuel at "y" throttle you will end up with lower rpms. My HPCR still works this way, it takes a TPS near 70-80% to get to 3000 in N, and the same in lower gears, in higher gears it fully depends on the load as now your torque demand exceeds what your pedal position can call for. Hopefully that makes sense and you could test it very easy. If the pedal position only dictates fuel flow (like a carbed gas motor) then it takes very little pedal to hit rated rpm, but if its like the other mechanical and electronic diesels I have experience with then it will take a lot of pedal to get to rated rpm. Ever drive a skid steer? You can go WOT without moving the skid or hydraulics and not over rev the motor, you couldn't do that on a gasser you would go well above redline. Diesel pumps govern fuel differently.

-

Ever wonder what a AirDog filter looks like inside...

I recall talking to Donaldson about that filter, but I don't recall the specs.. I do remember I wasn't impressed with them and I am guessing it was the flow rating not being sufficient for the AD pump.

-

Timing Effects

If I run my Smarty Jr on SW1 it's stock fueling with only advanced timing. It is dynamic, but advanced across the board. Reading many posts on the P pump timing effects EGT's pretty noticeably. I really wonder why yours didn't. It also should have taken a lot less fuel to make 30 psi. If you look at fuel to make 30 psi on advanced timing its a bit more than fuel to make 30 psi on retarded timing. On my model motor its quite easy to hit 40 psi on the stock turbo if you disabled the WG, but advance the timing and run the same fueling and you peak at 33-35, but the EGT's are 200-250° cooler.

-

Ditching the overloads for airbags, maybe, need input..

My dad and I have been using firestone bags on at least 4 rigs for the last 10-15 years and not one has ever leaked.

-

Ever wonder what a AirDog filter looks like inside...

I presume a P551315 on the final, but what for the f/w sep? The Baldwin BF1275 is the best you can get for the f/w sep.

-

Ever wonder what a AirDog filter looks like inside...

FASS are even worse. The OEM FASS 150 f/w sep isn't even rated by Fleetguard as a F/W sep.. hard to stop water if thats not what it's designed for!Put a Baldwin BF1212 on there, the HF6604 is the best you can do on the final filtration. FASS and AD really screwed up when they picked their filters and thread/gasket sizes.

-

Ditching the overloads for airbags, maybe, need input..

My truck has the OEM overloads and they are never used. I would like to add some taller bumpstops to them, at least the front perches, to help with axle wrap.

-

Timing Effects

Timing has a huge effect on EGT's, not because you make more power per gallon but becuase there is more work being done in the cylinder (same reason power goes up). With timing that retarded you should have seen a huge increase in EGT's. With timing alone I can see a 200° drop in my EGT's, or more.

-

Ditching the overloads for airbags, maybe, need input..

Airbags are great, I have the firestones on my truck. I don't think you will be sorry with your investment. I have never been a fan of the Timbrens, never made much sense to me. Nearly all of the cost and no adjustable. One of the best things about airbags is the ability to maintain a level stance when loaded which improves steering and headlight operation.

-

Ever wonder what a AirDog filter looks like inside...

Interesting... I hope you didn't use the same f/w sep again... its not really a very good filter. It's only rated at 50% free water sep at 20GPH, and 0% emulsified water sep.. The FF5613 is a good filter, but is 5um absolute not 3um.

-

Timing Effects

You certainly put your truck thru the settings dont you! [TABLE=align: center] [TR] [TD=bgcolor: #FFFFFF]Engine parameter:[/TD] [TD=bgcolor: #FFFFFF, colspan: 2] TIMING is: [/TD] [/TR] [TR] [TD=bgcolor: #FFFFFF]RETARDED ( - )[/TD] [TD=bgcolor: #FFFFFF]ADVANCED ( + )[/TD] [/TR] [TR] [TD]EXHAUST TEMP[/TD] [TD]increases[/TD] [TD]decreases[/TD] [/TR] [TR] [TD]CYLINDER PRESSURE[/TD] [TD]decreases[/TD] [TD]increases[/TD] [/TR] [TR] [TD]INTAKE MANIFOLD PRESSURE (BELOW P-TORQUE) WASTEGATED [/TD] [TD]increases[/TD] [TD]decreases[/TD] [/TR] [TR] [TD]BSFC (brake specific fuel consumption) [/TD] [TD]increases[/TD] [TD]decreases[/TD] [/TR] [TR] [TD]NOX (oxides of nitrogen)[/TD] [TD]decreases[/TD] [TD]increases[/TD] [/TR] [TR] [TD]HEAT REJECTION[/TD] [TD]increases[/TD] [TD]decreases[/TD] [/TR] [TR] [TD]HYDROCARBONS (HC) [/TD] [TD]increases[/TD] [TD]decreases[/TD] [/TR] [TR] [TD]BLACK SMOKE: 1000RPM[/TD] [TD]increases[/TD] [TD]decreases[/TD] [/TR] [TR] [TD]BLACK SMOKE: PEAK TORQUE[/TD] [TD]decreases[/TD] [TD]increases[/TD] [/TR] [TR] [TD]BLACK SMOKE: RATED[/TD] [TD]increases[/TD] [TD]decreases[/TD] [/TR] [TR] [TD]WHITE SMOKE: < 1000RPM[/TD] [TD]increases[/TD] [TD]decreases[/TD] [/TR] [TR] [TD]WHITE SMOKE: > 1000RPM[/TD] [TD]increases[/TD] [TD]decreases[/TD] [/TR] [/TABLE]

-

Trans Hunting?

I don't think there are any cables on an 05, other than gear select. --- Update to the previous post... On vehicles equipped with a Cummins diesel engine, the transmission throttle valve cable has been replace by the transmission throttle valve actuator (TTVA). The TTVA consists of an electric DC motor, two potentiometers, and a gear drive system. The TTVA is mechanically connected to the transmission throttle valve in the valve body by the “D” shaped opening in the bottom of the TTVA shaft. Changes in the TTVA position are therefore transferred to the throttle valve and cause changes in the transmission throttle pressure. --- Update to the previous post... ADJUSTMENT The Transmission Throttle Valve Actuator (TTVA) does not require any mechanical adjustments. All changes in throttle valve position are controlled by the Engine Control Module (ECM). The TTVA does require an initialization period after the actuator has been removed or replaced. After the actuator has been removed or replaced, move the iginition to the ON position for thirty (30) seconds. This will allow the ECM sufficient time to perform the internal calibration procedures to learn the TTVA’s current “zero” position. Once this is done, check the ECM for diagnostic trouble codes (DTCs). If no DTCs are set relating to the TTVA, the TTVA is fully calibrated and ready for use.