Everything posted by notlimah

-

Fuel return line

Thanks Hag, that's what I was thinking, glad someone else thinks the same so I know I'm not crazy! hahah For now, I'm just going to deal with it since it's been getting pretty chilly around these parts, I don't feel like dropping the tank so I'll wait until things get warmed up. Plus, I want to see about finding an OEM style return tube so I can avoid running regular rubber fuel line.

-

Fuel return line

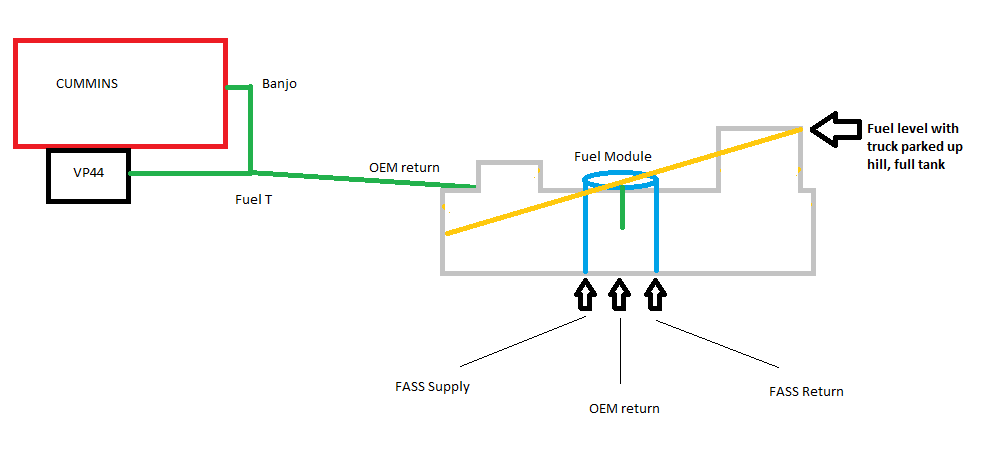

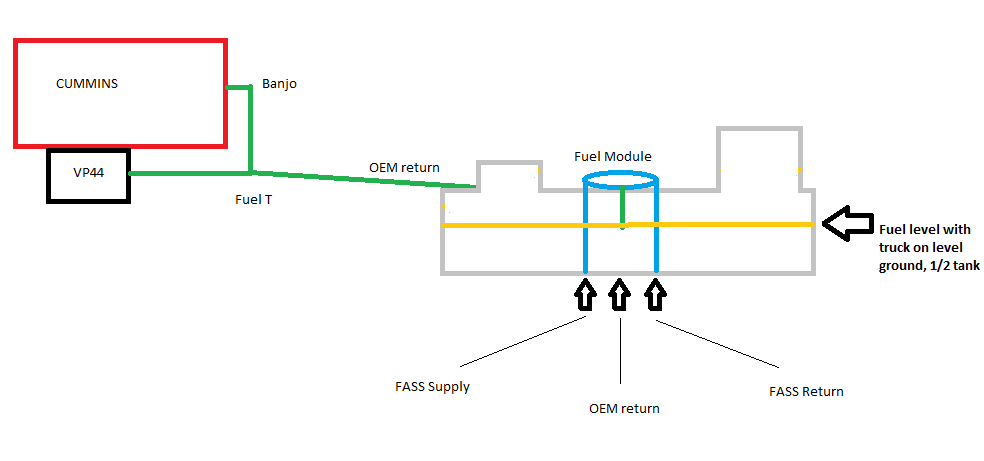

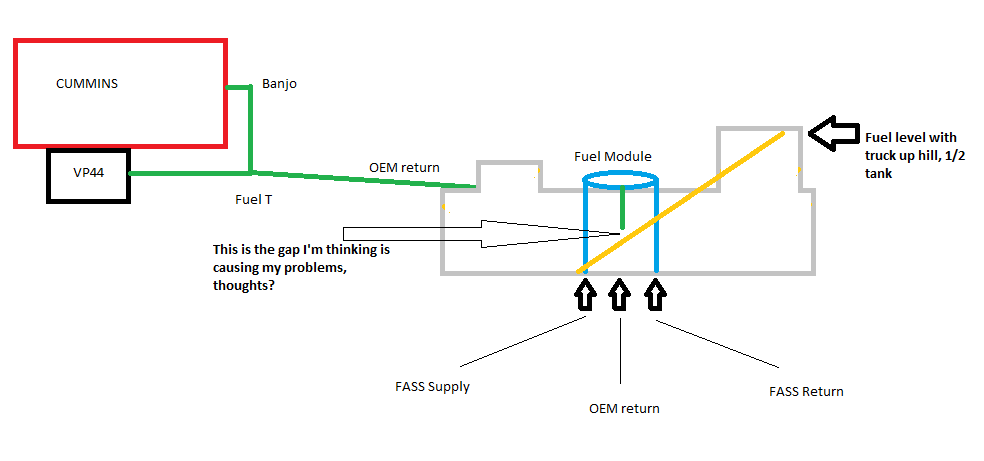

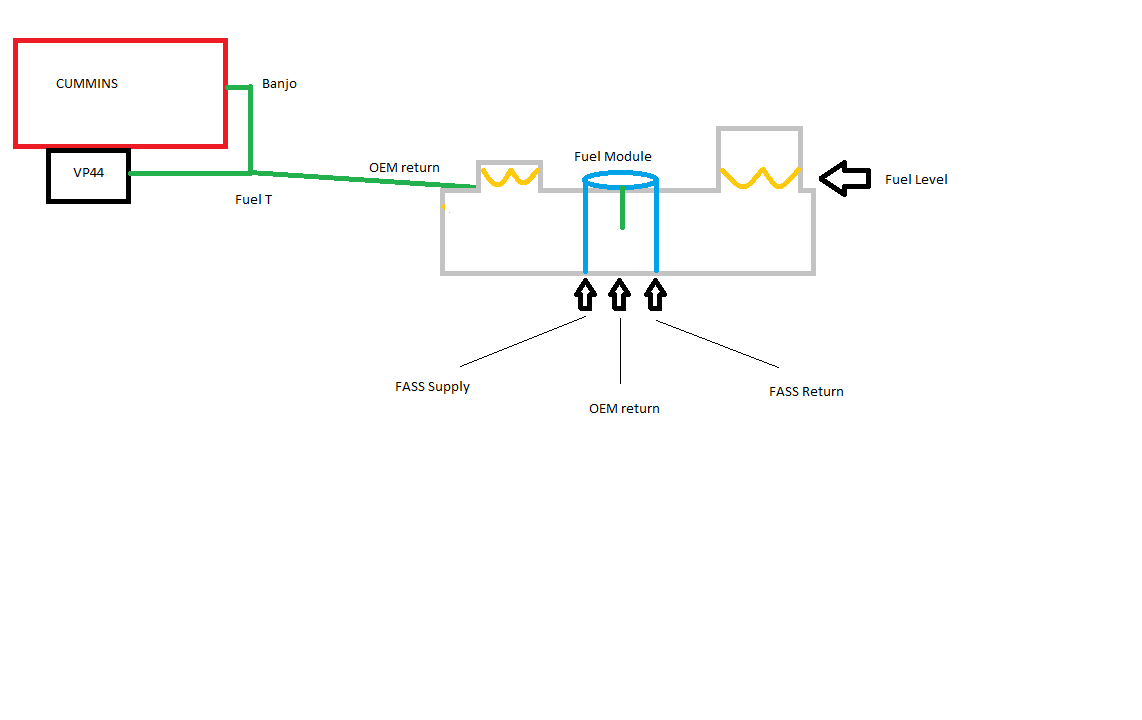

Alright guys, I just spent way more time in paint then I'd like to admit, but I think it shows what I'm thinking COULD be the issue here. ***images not drawn to scale *** This image shows what the fuel system would look like with the tank pretty full, on level ground. The fuel module is completely submersed and in this state I don't have any issues starting. In this image (and this is where things get to be a bit more crude drawing wise) you can get an idea of what the fuel would look like in the tank if the tank were full, but parked uphill. Again, every hose on the fuel module is submerged in fuel even though fuel is sloshed more towards the rear of the tank. No problems with starting in this situation. This image shows what things look like once fuel levels start getting lower. I'm saying this is 1/2 a tank and you can see that even though it's only at 1/2 tank, all of the fuel module hoses are still submerged. I don't have issues with starting in this position either. I can let my truck sit at work for 8 hours on level-ish ground (more level then my driveway at home) and it'll fire right up, no problem. Finally in this pic, it illustrates what I think is causing my problem. With fuel levels staying at 1/2 a tank BUT changing the slope of the truck to being parked up hill (in this case my driveway) you can see that now when the fuel sloshes to the back of the tank, it now exposes my much shorter OEM fuel return line to open air. What I'm thinking will solve this issue is simply extending my OEM fuel return line to a similar length as my FASS supply and return lines so that way it should never be exposed to open air in the fuel tank unless I was at an extreme angle with really low fuel in the tank. Thoughts?

-

Fuel return line

I'm pretty sure there's not a check valve or anything in the OEM return side of things which is why it's so important to have good seals and such. I've read that people have solved OEM return line leaks by adding a check valve, but that was really only a band aid fix. I'll try and draw something up tonight

-

Fuel return line

From my understanding of it, there shouldn't be much pressure coming from the VP/injectors. It's really just an overflow of un-used fuel that's making it back to the tank, unpressurized, which would explain why it doesn't pulse and is low flowing. That also explains why when you have a leak at the fuel T or banjo on the back of the head, there are no visible leaks because of the lack of pressure. I'll try and draw up a pic of how I'm imagining it in my head to maybe explain it better. I think me and @dripley are on the same page, but then again, I think that with my wife and I still get yelled at!

-

Fuel return line

No worries about thread jacking, it's all relevant anyways! Only reason for me to not suspect it's a suction side problem is my fuel pressures are solid. Nothing more then 1-2psi fluctuation. If air was getting into that line in sure it's show on the gauge. With the amount of time this tanks spent on my garage floor, that idea gets more and more temping! Haha

-

Fuel return line

That's half my struggle. I don't even know if this will get rid of my issue, or if this is even really an issue to begin with. If if this were to fix it then great. If it doesn't, then the only other things I can think of that could cause this issue would be my cross over tubes or injectors, but that really doesn't make sense with this only happening below half tank parked uphill. So we'll see!

-

Fuel return line

I hear ya! It's a bit irritating dealing with things that you'd think would be easy decisions to avoid when you're engineering a vehicle!

-

Fuel return line

Hmm that's interesting jag. I wonder if your truck would do the same as mine?

-

Fuel return line

I suppose I could, would just need to figure out what fitting is used on the bottom there. I would prefer a flexible tube though, just so the fuel module wouldn't get held up when it flexes.

-

Fuel return line

Jag I'd be willing to bet that's you're return for your lift pump and not the return line from the VP and injectors. Unless of course you're joking! I agree as well. I think us Cummins guys have got that figured out as well! Makes sense that it affects different engines the same. Thanks for passing it along!

-

Fuel return line

I asked Eric, he said he didn't have any. He has to buy in bulk, like 15k worth of bulk so sorta hard to get onesie/twosies! Lol Ok, I think it'll be fine but I'm going to do it anyways. This line is biodiesel compatable which apparently is harder on fuel line then straight diesel. I'm a little more concerned about the diesel mixed with opti-lube additives o recently started using.

-

Fuel return line

Not really, but since I'm looking at using the hose in a non-standard way, and in my fuel system, I'm just being extra careful. Eric suggested doing the same as well so that's reason enough to at least see what happens. I plan on leaving them submerged for quite a while, more then a month at least. I don't see dropping the tank to install this anytime soon. At least not until it gets a bit warmer. I'd still prefer to find something OEM style so I'm going to keep an eye out. Nice! Was it the Parker super flex? At just over 2 bucks a foot, I imagine it's high quality line.

-

Fuel return line

I thought about that, but my problem with that is finding a fuel hose that's diesel compatible inside and out since this will be completely submerged, I need to make sure the outside doesn't degrade over time. That's why I figured just going with something as close to OEM as possible would be easiest. I ordered up some superflex from Vulcan and I plan on dunking it in some diesel and letting it sit for a while and see how it looks. It's supposed to be compatible inside and out, but I want to double check. I don't need anything coming apart in there, that'd be no good! lol

-

Fuel return line

Yea well whether I'm right or wrong will never come about if I can't find a stinkin' 5/16 flex tube! Any ideas?

-

Fuel return line

Yea, it's the only thing I can think of that it could be. I've talked with Eric a few times about this and he doesn't seem to think its the issue. He thinks that it would drain fuel back regardless as long as I was pointed uphill. I respectfully disagree to the point that I'll try and install a longer hose and if it doesn't fix it, I'll admit he was right and just live with it haha. Heres how short mine is and why I think it's causing the problem. It's probabaly about 6in above where the suction and return line from the FASS are.

-

Fuel return line

Hey guys, looking to get a new, or at least longer, fuel return line for my fuel module. I installed Vulcan's drawstraw 5 that includes modifying my existing fuel modules so my fuel return from the FASS and VP/INJ all go back into the fuel basket. I had to cut out a couple of the old stock lines to eliminate some unnecessary parts, but now it's extra short and I think may be causing my 'hard start' issue. Problem is, it seems that when my fuel level gets below a 1/2 tank, I start having issues similar to having a leak in the return line, but I've fixed all those and problem is still there. So this is my last ditch attempt to fix this before I just say screw it and know that if I'm below 1/2 tank parked on a slight up hill for a while that my truck will crank a second or two longer then normal before starting.

-

Issue that has everyone stumped!! Rough Running truck

That sounds like a cold engine on high idle to me Tyler, is it not?

-

Fan Clutch

I was nervous for your fingers!

-

Because, Roadkill. If you like wrenching for the sake of wrenching, come on in.

I've been looking forward to this one for a while!!

-

Teardown and Rebuild

Oh so it's just sitting in that little plastic piece that surrounds the fan?

-

Teardown and Rebuild

Doesn't the above method in theory completely eliminate the radiator? With carboard right there in front of it there's no possible way for wind to pass through or the fan to do its job. With just the front grill mesh area I'm sure there still plenty of air getting through. No where near air tight but even if it was, ambient air would be abundant enough inside the engine bay and the fan could still pull air through and do its job. Right?! This is what mine look like just for reference. They're just held in my washers and wing nuts

-

Teardown and Rebuild

Yes I agree! I put together a make shift winter front. It's just 1/16th in plastic cut outs to fit into the grill area, much like many others have done. I can tell it's working because the my hood has a bigger dry spot on it the mornings I plug in.

-

Rear view camera and head unit options

I really like what you got going on here. I'd like to do something similar, except I don't need a screen as big as that. I really just want something big enough so I can know if/when I'm going to hit something, and to make hitching up easier. My wife's 2014 GMC has the camera and it's great, but you can see behind that fairly easily even without the camera. The Dodge on the other hand?!

-

Cummins additives

I tend to think the same @leathermaneod but I think as long as you can get EGTs up to around 1000* here and there you'll be fine. Remember, the flash point on 2stroke is fairly low, even below idling EGT temps so it's burning, and it's ashless so no residue. I think what it really is, is just using the truck hard in general, not even using it hard while using 2stroke. I think I read somewhere that a guy took in a gummed up VP or LP and they diagnosed it as 'under used' and advised getting over 2k rpms on every drive. Lugging around under that seemed to cause that in their opinion, I think lol

-

Teardown and Rebuild

Definitely agree that plugging in for an hour or even 2 isn't going to do you as good. I'd suggest using 3 hours if using a timer. Some data that Dauntless found is that over 3 hours, the gains are marginal at best and really not worth it. From his thread... "At first glance, it looks pretty impressive. The block heater can get temps up to nearly 140? Sweet! Not quite. It was nearly 55 degrees out by the end of the test, hardly block heater weather. We have to remove the ambient temperature from the equation to get a real idea of heater performance. This the same data, reformatted to show coolant temperature rise relative to ambient temperature instead of the absolute values. Looking at the numbers this way, we see the heater is capable of raising coolant temp by about 85 degrees above ambient, What's interesting is half of that temp rise occurs in the first 45 minutes of operation. Common sense would suggest the heater's temp rise is a diminishing returns scenario, and this both confirms and defines those diminishing returns. A couple years ago, I had settled on a 3-hour prewarm period. I chose this amount of time because that was where I could no longer perceive changes in starting behavior or time-to-operating-temp in my normal operation of the truck. While my heater's effectiveness was compromised by a defective thermostat, allowing convection currents to move the warm coolant into the radiator while the heater was running, a 3-hour prewarm period looks to be about ideal, in my opinion. It gives you about 85% of the total temperature rise, where a 4-hour prewarm only brings you to 89%. 5 hours will get you to 93%, and starting at hour 6, we can see the delta drop radically down to a virtually non-existant 1 degree per hour until it drops to zero after 7.5 hours of runtime. Alternatively, a 2-hour prewarm period would give you 75% of the temp rise, and even a 1-hour prewarm period will still give you nearly 60%. Use this information to tailor your prewarm period to your specific needs. If you're out in BFE in the Klondike and it's -60F, you probably want the full 8 hours even though the last 4 are pretty inefficient, from a dollars-to-degrees perspective."