Everything posted by notlimah

-

Longer cranking...

Hey any input is good input! I'm not sure if there is some sort of pressure sensor built into the system that tells the lift pump to run for a split second or not. I'm going to see if I can find anything. Other then that though I couldn't think of any other reasonable explanation. What's weird is that the truck starts almost instantly while parked nose down over night and any time during the day. I can typically leave my truck parked 6-8 hours or more at work and walk out and she'll fire right up, no problems.

-

Front axle alignment

Ok so if I get it to center off the body/frame and my end links end up being crooked again, how do I get those straight?

-

Ham radio operators

Man you got a lot going on in there!

-

Longer cranking...

So just something I noticed that I wanted to bring up here so see if you guys have the same thing happen. Since I've been dealing with this leak I've been parking nose down in my driveway to avoid the harder starting until I get parts in and I noticed this morning that when I park nose down, when I turn my key and get the WTS light, my lift pump doesn't prime like it does when parked uphill. It's not much of a prime, just a quick buzz and that's it. But now parked downhill it won't prime at all but the truck fires up almost instantly.

-

Front axle alignment

Ok so basically it should be centered via the frame not the body? Ill get get out and take better measurements and see where I'm at based off that.

-

Front axle alignment

So I've had the DOR track bar on for almost 2 weeks now and it's been great having the extra strength up there and it's keeping everything in line much better when truckin down the road. When my brother and I originally put the track bar on we basically used the stock end links as visual cues as to where the 'center' would be. Well going solely on that, I think things turned out pretty good. Truck drives straighter then it ever has and has little to no wonder now and I haven't even gotten a proper alignment yet. Needless to say I was taking out the trash and just happen to glance over and saw that my passenger side tire is sticking out noticeably further then my drivers side. Now I'm not 100% sure if it's because of my driveway angle and the wheels weren't perfectly straight but it's quite noticeable. I plan on checking it again when on level ground and wheels straight. Either way, how do you center this out? Do you use tires as a reference? Somewhere on the frame or axle? I thought I had it good to go but being this far off can't be right, can it?!

-

Ham radio operators

I've been looking at getting a ham radio for the truck. You should post a pic of your setups too so for those of us who don't have setups can scheme/dream!

-

TFaoro how is this possible???

Image just has to be flipped for whatever reason.

-

Running a bit warm

That's weird, I'm going to check mine now.

-

Running a bit warm

So a connector that was hooked up to the VP was loose and causing coolant temp swings?!

-

Running a bit warm

All my numbers are straight from the in dash gauge so I may be a little off on my numbers. I'm going to start driving with my tablet so I can get more accurate numbers.

-

Running a bit warm

I'll have to start driving around with the ODB hooked up so I can get a good log going on. The truck has a brand new radiator on it and since the radiator is overkill for these trucks it seems like the truck just can't always make fine tune adjustments. Like it'll get a little over 190 then it'll cool it down, but it can't cool down to precisely 190 so it goes a little under then the truck tries to compensate and it just turns into a game of over/under compensation until you get back on normal, level driving. That's my logic on it. I don't see how a temperature fluctuation of 185-195 is that bad on these older trucks. But please, someone school me up if I'm wrong!

-

Injector line threads

For our trucks I've used Loctite 545 on just about everything except standard bolts which I would use red or blue Loctite on. It's worked fine for me.

-

Running a bit warm

MIne will do something similar. My temp when fully warm usually stays right at 190 (according to dash gauge) and here and there it'll climb to 195-200 depending on how hard I'm driving and then the fan will kick on and it'll drop down to 185ish range and then slowly climb back to 190 depending on how I'm driving. Seems normal to be, unless those sort of fluctuation while empty or not driving grades is no good then maybe mine is jacked up too!

-

Injector line threads

@Hawkez I appreciate all the info, that helps out a lot! Do you put any sort or thread lock or anything to help seal it and prevent leaks? @Dieselfuture Thanks man, puts my mind at ease!

-

Injector line threads

Would you mind grabbing those part numbers when you do? My local shops aren't the brightest so it makes it easier when I can just give them a part # for them to look up haha

-

Injector line threads

Gotcha, I'm assuming those are just napa parts? Happen to have part numbers?

-

Injector line threads

Thanks guys, I'll leave them be. Mike so you get a 3/4in plug to what diameter for the boost fitting? 1/8th?

-

Injector line threads

Thanks, I'd appreciate it!

-

Injector line threads

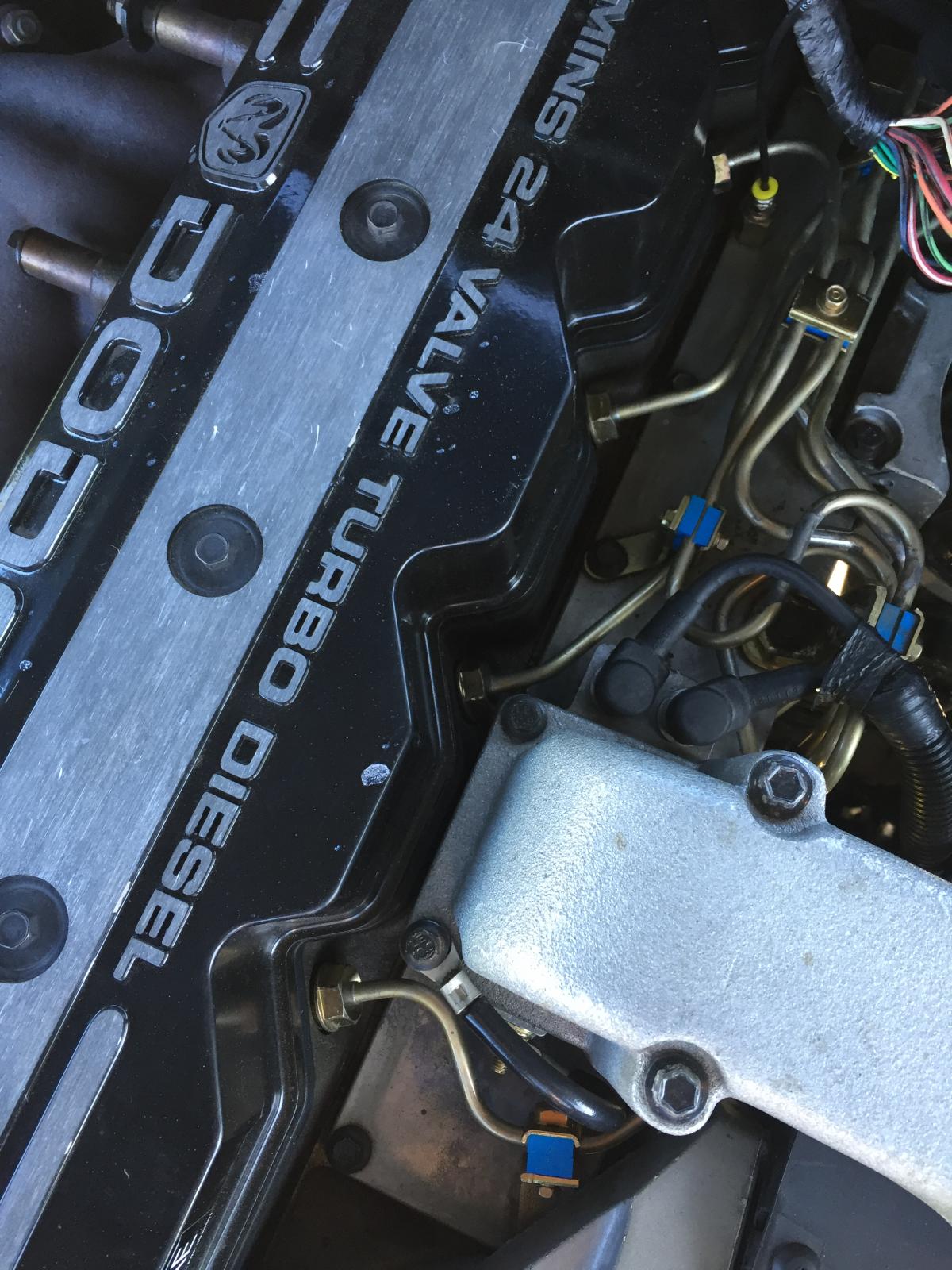

So as I'm chasing down this fuel leak, I was poking around under the hood just to make sure I didn't miss any obvious leaks or that nothing new happened. Well I got to looking more closely at the injector line bolts and it looks like some are threaded on more then others. Here's some pics theres not leaks or wetness anywhere and last I checked, they're pretty tight. Is this normal or should I pull them off and check for something? I don't really want to ignore this, but at the same time, I don't want create a new problem.

-

Longer cranking...

Ah ok, well that makes sense. I'm looking to eventually add a bigger turbo/inj/tuner and all that so that's why I wanting to hold off on injectors until I decided what exact power upgrades I wanted to go with so I could match everything up right ya know?

-

Longer cranking...

Yea I'm not planning on doing the connector tubes quite yet. I want to try and see if I can't get the O-rings for the T connector first, although I'm still trying to source a cheaper option then what I've seen. If that doesn't fix it in conjunction with new banjo return on the VP then I'll be looking at changing out connector tube O-rings and probably just look at putting new injectors in. I was hoping to wait on injectors because I'm not sure what size I'd want with the upgrades I'm looking to do in the future but I'll cross that bridge when it comes. Why are you looking to 'downgrade' your injector size?

-

Teardown and Rebuild

Jeeez! Glad you made it out with what you did! That sounds like it could've gone a lot worse! i really need to start a more consistent ritual of checking under the hood and things like that that typically go unnoticed until it's happening. Part of me couldn't help thinking while reading this . . . . roadkill

-

Longer cranking...

Thanks for those links, I have one of those sockets that's 19mm meant for the fuel lines at the head but I figure I can use those on the fuel lines at the vp as well. I just wasn't sure of the size. I'll get one of those connector tube pullers ordered though! Right now I'm planning on only replacing the connector tube o-rings. I'd like to avoid pulling injectors right now because if I did I'd have a hard time not putting new injectors in and the budget doesn't allow for that right now lol! Either way I appreciate the tips because those lines may have to come off regardless so nice to have an idea of what can happen.

-

Longer cranking...

No I haven't replaced either. This is all new territory for me. I've watched a couple YouTube videos and seen some write ups. Only thing I haven't seen in those is when removing the hoses from the VP (if needed in this case) do you need a crowfoot or will a regular wrench work?