Everything posted by jordan

-

Electrical options

Well knowing that now, i think i will just stick to playing around with the smoke screw! I'm going to have to make some sort of solenoid however (I do most of my driving in Guelph one of the "greenest" cities in Ontario, I get dirty looks for just idling there ) also where might i get one of these EGT gauges? The more the merrier as they say, and i love a full dash!P.S. I'm not a stack man myself i like running board exhaust, more so when it's aimed at the sidewalk:evilgrin:

-

Electrical options

Ok well maybe I'm thinking of adjusting the wrong screw then. I want to be able to have liquid black smoke poor out on the side walk for as long as i want it too, from idle to full throttle (remember not just low boost), is this done with the smoke screw or main fuel screw ? and idle shouldn't be a big issue, i'm going to put an idle adjustment cable in the cab, kinda like the old school buses have (I have a thing for low idling engines, a little problem when it's cold out)

-

Electrical options

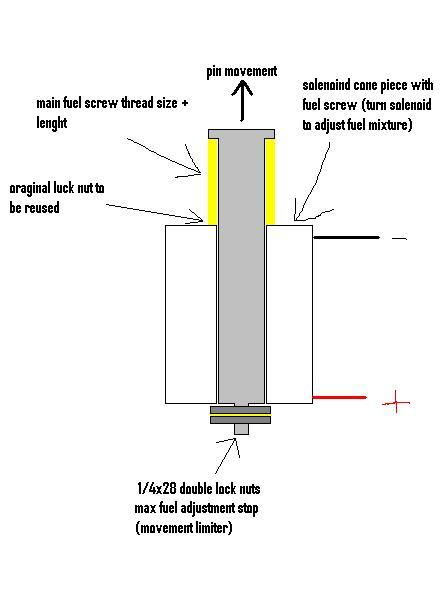

considering it's snowed in April up here before, i think i would rather a switch (which looks pretty strait forward) then trying to hook up my grid at 6am when it's 20F out lol and i took a couple of minutes and drew up a very basic example of what i was describing about that pin idea.

-

Electrical options

Although i am in Canada i do like the sound of that grid heater override "see how cold, before the old girl wont start" ;) I started working on the wiring diagram today with my brother and we decided to use relay banks close to the high amperage components to minimize heavy wire gage lengths. All the banks will be connected using CAT. 5e ethernet cable at very low amperage, and a 6 AWG positive supply. Both wires will be encased in heat shrink tubing. I'm going to try to make all electrical components military grade, hopefully this will make them last longer. I came up with a crazy idea today, as i was wishing my truck smoked more. My thought is to put a mechanically adjustable (min/max) solenoid over a custom made main fuel screw that would have a sliding pin in the middle (of the screw) for the solenoid to actuate. i would love to hear so input on these idea's. thanks guys:thumb1:

-

Electrical options

Ok guys here's the deal I'm rewiring my whole truck and would like to know what kind of extras you guys would like to inter graded into the harness. I'm going to put extras such as power window locks, TC lock up by pass, inter lamp over ride, and more stupid little options. I don't care how useless or impractical they are, i just want to be able cover all extra items that can be thought of.

-

What are you guys getting for oil pressure?

I just installed a mechanical oil pressure gauge i picked up for about $15 Canadian at the auto parts store. When i first start my truck it goes to 80psi then as it warms it drops to about 40psi at idle. For normal driving it stays at about 65psi with my truck.

-

overdrive problem

I may consider the wreckers idea, although i do enjoy doing the work. and I will know all my work is new and done right. as-well the same brother that fried my multimeter, is almost done school for an electrical engineer, hopefully he learned something and can help me. Either way i think there will be a wiring diagram by the end of this for others to use!

-

Custom made compound turbo set up (turbo sizing question)

I acquired a Holset turbo off of a 3 cylinder Cummins. the assy. # is 3524121 and the serial # is 1401616. Is this a suitable size turbo to be combined with my stalk turbo on my 92' w250? I took a very close look at my spare turbo and was barely able to make out the model # but it said type-H1C i believe it is the 72mm model, I'm still looking for any info on it's max CFM. In the process i found some very useful info that Holset owners should enjoy (service, repair, and a pocket guide for every Holeset turbo!) http://www.holset.co.uk/mainsite/files/4_4-service%20literature.php

-

overdrive problem

Thanks for the insight, i will defiantly take those points into consideration when it comes time to do the swap And as far as the 12 speed is concerned i would agree that it's totally useless, but i love shifting gear in standards, (for now) I'll let you guys know what becomes of it, when i get around to changing it! thanks again for all the help guys! ---------- Post added at 07:20 PM ---------- Previous post was at 02:30 PM ---------- So i took a look at the wiring and it's all sh!t, there's only about 1" of uncut wire loom! so i think i need to re-wire the entire truck. who ever had it before me used house wire in some spots! as-well the transmission cable going to the VE pump is loose and sticky (probably not adjusted) I haven't checked the CPS yet (my brother recked my multimeter) Does anyone have a full wiring diagram i will be documenting all my work and posting it for others including wire lengths, colors, and possible improvements to the system.

-

overdrive problem

Is it passable or even practical to put a 6 speed manual with high/low O.D i would love to have a 12 speed

-

overdrive problem

I'm new to this truck so i hope this isn't too stupid a question, but is the CPS off of the harmonic balancer? I also found a link off of this site, I hope it can help other people that might have transmission problems. P.S. what type of transmission do have? http://www.dens-site.net/Dodge_CTD/overdrive_lockout.jpg

-

overdrive problem

it works better when it's dry out. If i floor it to about 60MPH+ and let off it will shift but then kick out when i barely step on the throttle again. also my tach will jump all over the place sometimes staying at the 4,000rpm mark. This problem happens everyday and I'm really hoping i can fix it soon. I'm going to take a look under the truck at the transmission harness, and also look at the crank sensor. If anyone has ohm specs, or any info at all, it would of great help to me. Thanks again for all your help guys! hopefully i can fix this

-

overdrive problem

Thank you so much, that wiring diagram will be a life saver! one thing i noticed as well just today is that behind my glove box there was some sort of computer box looking thing that was not connected (i left it that way, don't want to fry it) I'm hoping someone will be able to tell me what it does. and if i should re connect it. thank you too all the people that make this site happen, it is an amazing resource (as soon as i'm old enough to get a credit card, I'm donating!)

-

overdrive problem

I have a 92' power wagon 250 with the 5.9L 12V intercooled, A/C, power windows, locks, and lots of electrical problems! My biggest problem right now however is that my over drive will disengage at speeds of 75MPH or not engage at all. I noticed that the problem happens when it's moist or wet out although it still occurs when everything is bone dry, also the tachometer will not read true or not give a reading at all while the problem is happening. But if i step on the brakes the tachometer will work but it still wont shift. my battery voltage drops a considerable amount as well sometimes down to 10V, all these problems come and go at the same time. please help!! I bought a book for the truck but it's useless. (no diesel info at all)