Everything posted by The_Hammer

-

Straightening out wiring harness.

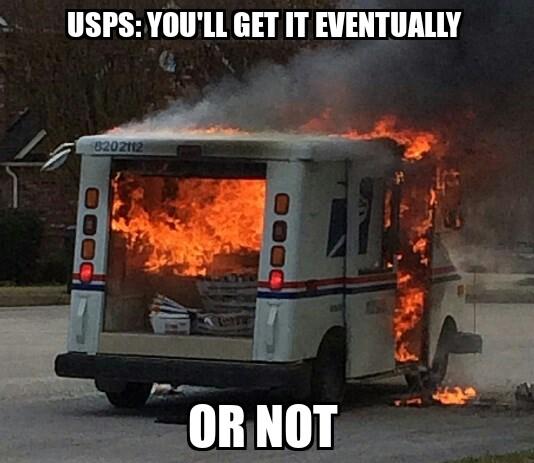

Taking off all the old, cracked up and baked on electrical tape was tedious. Wrapping up a section of harness just to realize you left out one wire sucks too . It's not horrible by any means, but I can't say I'm having a blast doing it. No. Apparently USPS has found me unworthy of receiving it, judging from the fact that it's been sitting in GA for 4 business days.

-

Straightening out wiring harness.

Thanks. You know how sometimes doing repairs and fixing up your truck is fun and enjoyable? Well this ain't one of those times lol.

-

Straightening out wiring harness.

-

Straightening out wiring harness.

That's the complete harness from the PCM, to the engine, and transmission. I'm getting rid of random plugs that aren't used for this truck, replacing all the brittle tape and loom, as well as cleaning up old splices. That just literally made me lol! All the loom and tape were falling to pieces, which ended up with random wires floating around just waiting to short out. I also wanted to get rid of all the unused connectors and their wiring. All of the plastic wiring holders are broken as well, which I'm going to replace. Basically just preventive maintenance.

-

Straightening out wiring harness.

-

Transmission issue now

I went through 9 kinds of hell with my 47RE after I had it "built" by a somewhat local trans shop. It's a frustrating thing to deal with if you don't have a decent understanding of how it all works. I talked to reputable trans builders, searched forums, and read through the ATSG service manual a few times before I got a solid handle on these things. One of the big issues with my trans was that the shop didn't a have a clue how to rebuild a VB. I ended up buying a fully built one from HTS which eliminated my transmission woes. When starting your truck, are you immediately putting it in drive, or waiting a bit? There is a check valve in one of the lines coming from the heat exchanger that if removed, will allow the trans to loose prime. With a stock VB there is no fluid flow in park, so you must put it neutral for a few seconds to allow the system to prime up. With a built VB there should be fluid flow in park, so all you have to do is wait a bit before putting it in drive. This is a good read for helping to diagnose trans issues http://www.cumminsforum.com/forum/94-98-drivetrain-except-engine/578420-47re-transmission-troubleshooting-chart.html

-

Transmission issue now

Are you checking the fluid with the trans warm and in N?

-

Tutorial: How to crimp connectors, strip wire and use heat shrink.

I happened to come across this video on YouTube and found it very informative. I'm guilty of some of the mistakes show in the video, I never gave it much thought before.

-

Would You Invest in My Truck or A Newer Truck

I specifically steered clear of the 2nd gen 24v trucks because of the vp44. I wouldn't trade my 12v for anything.

-

Teardown and Rebuild

I envy guys with trucks that look as good as yours

-

Wiring harness tape

That's the plan. I want to make it look clean and organized, and the rats nest it has become lol.

-

Wiring harness tape

Will do. It's funny how that works out sometimes. It was probably a fraction of the cost compared to the dealer.

-

Wiring harness tape

I was doing some electrical work under the hood today when I realized just how ratty my wiring looks. Loose wires floating around, electrical tape peeling off, plastic loom cracking and breaking, just a mess of problems waiting to happen. I didn't want to wrap it all up in regular electrical tape, which will end up peeling off and making a mess, so I started looking for actual wiring harness tape. During my search I came across this company http://www.tesatape.com/industry/automotive/electrical_systems/wire_harnessing-abrasion_protection. I was a tech at a John Deere construction equipment dealer for awhile and I'm almost positive this is the same tape that was used on all of Deere's wiring harnesses. It's though stuff that handled high heat and abrasion VERY well. I've found it on Ebay for $15 per 3/4" x 27.34 yard roll, free shipping. I'm going to order a roll and see how it works. If it is in fact the same stuff Deere uses, it's leaps and bounds ahead of using regular electrical tape.

-

Would You Invest in My Truck or A Newer Truck

That's what I've been dealing with on my truck. The previous owner didn't do much besides just drive it, what repairs he did do were completely half assed, making things even MORE fun. One thing that helps me get caught up on all of this, is that I don't put many miles on my vehicles. I don't even log 25k miles a year these days.

-

Normal day...

Since my whole truck is bedlined and the only salt it sees is at the beach, it doesn't get washed all that often. Once I get a nice paint job on it though, it will definitely get the wash and wax treatment on a regular basis.

-

Finding & Fixing your Air Leak

Nicely done!

-

This is fixable, right?

That's my fuel shutoff solenoid relay lol. I've a got a couple new ones on the way from Larry B, until then it's the ol' "pop the hood and push the rod" routine.

-

Dana 60/248 Intermediate Shaft Seal Replacement Made Easy

This is how I replaced the intermediate shaft (passenger side) seal without having to remove the differential carrier from the axle. You will need to make a tool to press the new seal in to the axle tube. There are a few ways to go about doing this, below is just one example. I used some 1/4” plate for the cap, sanded down sch 40 PVC pipe that just fit the inside diameter of the seal, a couple feet of 3/8” all thread, and the top piece of a steering wheel puller as a crossbar. If a picture is worth a thousand words, then you have some serious reading to do! I was replacing ball joints at the same time as I did the seal, which is why the knuckle was removed. As you can see, my gear oil had water contamination due to the leaking seal. If gear oil can make it out, you can bet water will find it's way in. Hopefully this little trick will save you some effort when the time comes to the intermediate shaft seal.

-

98-99 HD steering upgrade

Thanks! The only issue I had was trying to create columns for the "Tools Needed" section, as the formatting wouldn't transfer over from LibreOffice correctly. Michael suggested taking a screen shot of the "Tools Needed" part in LibreOffice, then inserting it as an image in to the article. That's what I did and it worked great.

-

98-99 HD steering upgrade

That sounds like plan. The steering article is now up: http://forum.mopar1973man.com/cummins/articles.html/12-valve-2nd-generation/axles-suspension-brakes/98-99-hd-steering-conversion-r188/

-

Would You Invest in My Truck or A Newer Truck

This may sound silly, but there is NOTHING short of a big rig that sounds like a 12v cummins. That's reason enough for me to want to keep my truck for the long haul

-

98-99 HD steering upgrade

A lot of it was due to stricter EPA regulations. AFM got GM the fuel economy numbers required to please the EPA. Besides causing reliability issues, the improved fuel economy results could only be reproduced under VERY specific conditions, none of which are applicable to the typical consumer.

-

98-99 Heavy Duty Steering Conversion

If you own a 94-97 Ram 2500/3500 4x4 then your probably aware of the steering related issues these trucks can have, most notably the dreaded “death wobble” and steering wander. You may have replaced all the ball joints, tie rod ends, track bar, and even the control arm bushings on your truck but still have wandering or death wobble issues. Before you set your truck on fire and/or pull your hair out, you may want to consider upgrading from the factory Y style steering to the later T style. How will converting from an inverted Y setup to a T setup improve the steering you may ask? It's simple really. Notice that the tie rod on the light duty inverted Y steering (94-97) does not directly connect both wheels together. Instead it connects to the drag link which is then connected to the knuckle. This setup allows the tie rod to pivot as the axle moves up and down during normal suspension travel, which is exaggerated even more when traveling down very bumpy roads. The problem is that as the tie rod pivots it also changes the toe-in/toe-out of the alignment, which in turn causes the front end to “walk around” or “wander”. This design can also cause death wobble, even when all new parts are installed. The heavy duty T style steering eliminates the pivot point by utilizing a one-piece tie rod which is unaffected by suspension movement. If you do a Google search on the subject you're likely to come across numerous discussions of using the T style steering from a 4th Gen Ram for the conversion. The problem here is that the tapered holes in the knuckles will have to be enlarged in order for the 4th Gen parts to fit. As a note you can't simply drill out the tapered holes, they require a larger diameter TAPERED hole and NOT a straight diameter hole. So, besides dropping big money on a custom steering setup what other options do you have? Why converting to the 98-99 HD steering of course! 98-99 Ram 2500/3500 trucks came with either the light duty inverted Y steering or the optional heavy duty T steering. The drawing below shows the 94-97 light duty inverted Y steering and the 98-99 heavy duty T steering. The HD steering option was only available for the 98-99 model trucks. One of the best parts of this conversion is that it is a direct bolt-on for the 94-97 trucks. However, there is one catch, in order to retain the steering dampener you will need a universal style bolt-on mount. I currently do not have a dampener installed and to be honest I really don't feel the need to use one with this steering. Here are the parts you will need for the conversion. All part numbers are AC Delco Professional. These AC Delco Pro parts are actually re-branded Raybestos Pro parts. AC Delco Pro parts are easier to locate than Raybestos, which is I why I used them. To complicate things a bit more, these same parts are offered by NAPA under their own name for about 60% more than AC Delco Pro from RockAuto. CarQuest offers these parts under Raybestos Pro and are also about 60% higher than RockAuto. They are also available in Moog. PN: 45A3074 Inner TieRod Rockauto Link PN: 45A6011 Small Collar RockAuto Link PN: 45A0811 TieRod End RockAuto Link PN: 45A3073 Passenger Side Tierod RockAuto Link PN: 45A6058 Large Collar amazon Link PN: 45A0871 Drivers Side TieRod RockAuto link You can do this conversion with the truck on the ground, in fact it makes keeping the alignment correct easier. Start off by making sure you're parked on level ground, wheels pointed straight ahead and the steering wheel straight. It would also be a good idea to chock the wheels as an added safety precaution. NOTE: I had the passenger side knuckle apart because I was replacing the ball joints when this picture was taken. This is NOT required for the steering conversion so please disregard. First step is to remove the steering dampener bolts located at the arrows along with the dampener. The frame side bolt head is 15mm and the nut 18mm. The drag link side nut is 18mm. Using needle nose pliers; remove the cotter pins from the driver, passenger, and pitman arm rod ends. Once the cotter pins are out, remove the nuts. Passenger and pitman arm nuts are 21mm, driver side is 22mm. This image shows a pitman arm puller installed. It's a straight forward tool to use, just tighten down on the bolt head until the rod end pops out. I was unable to use this puller as it was damaged while removing a stubborn pitman arm. This image shows a pickle fork being used. You wedge it flat side down in between the knuckle and rod end, then drive it in with a large hammer. The process is the same for the pitman arm rod end as well. A pickle fork works great for removing rod ends that will not be reused. You do NOT want to use them on rod ends that WILL be reused as they tend to destroy the rubber grease boots. With all three rod ends popped free, remove the old steering assembly from the truck. Below is a comparison shot of the old inverted Y steering to the 98-99 HD T steering. The old tie rod measures out to 1.000” while the new one is 1.250”. Both drag links measure out the same at 1.125”. Assembling the new steering is pretty self explanatory by looking at the above picture. One thing worth noting is that when assembling the new steering, make sure that there is an equal amount of thread showing between the rod ends as shown below. There is an alignment bar (red arrow) attached to the old drag link that needs to be removed and installed on the new piece. Loosen the 15mm alignment bar nut and slide it forward out of the way of the adjuster sleeve. Loosen the first adjuster sleeve screw, leaving the other tight. Unscrew the adjuster sleeve and short rod end together and remove them. Tap the alignment bar off of the old drag link and install it on the new one as shown below. Screw the new adjuster sleeve and rod end on and you're almost ready to install everything. This would be a good time to install the grease zerks. The tie rod end zerks are 8mm and the drag link ends are 7mm. Now you're going to adjust the tie rod adjuster sleeve until the tie rod fits into the knuckles WITHOUT moving the tires. Moving the tires will throw your alignment off which is what you're trying to avoid. Once the tie rod is bolted on, install the new supplied cotter pins. Next you're going to loosely mount the drag link to the pitman arm being careful not to move it. Then adjust the drag link adjuster sleeve until the drag link reaches the mounting hole in the tie rod, again being careful not to move anything. You do NOT want your tires OR pitman arm to move. If either move, it will throw off your steering wheel alignment. Once the drag link is tightened up at both the pitman arm AND tie rod mounting points, install the new supplied cotter pins. Here's everything all bolted up. I'm not running a steering dampener but they are easy enough to install if you so desire. All that is needed is a universal mounting kit and a new dampener. You can also weld on some mounting tabs as well. A couple notes: Even though you were careful to not move anything during the install you will still more than likely need to fine tune your alignment and steering wheel center. My alignment was darn close but my steering wheel was about a ¼ turn off. I wasn't done centering my steering wheel yet when the picture was taken so the alignment bar was still slid down out of the way of the adjuster sleeve.

-

98-99 HD steering upgrade

.....................

-

98-99 HD steering upgrade

I'll give it a shot. I know my box has some play and will need to be rebuilt, which I plan on doing around spring.