Everything posted by Tractorman

-

Headlights, tail lights, and turn signals blink

Thanks for the clarification. I should have figured out that you are familiar with these trucks, just reading your signature. My brother-in-law owns a 2003 truck and I recall that he had a control module that operated his headlights. I looked on-line and found this "In a 2002 – 2005 Dodge Ram, the Front Control Module (FCM) is responsible for managing and controlling various electrical components and systems in the vehicle. Its functions typically include: Exterior Lighting Control: The FCM manages the operation of the headlights, turn signals and other exterior lights." I would start my trouble shooting in the this area since your symptoms involve multiple lighting circuits. - John

-

Headlights, tail lights, and turn signals blink

Define "blink" with more detail. If you are meaning that the lights dim and brighten in a cycling manner after a cold engine start, then this is normal. What you are witnessing is the post-cycling of the intake manifold heaters until the truck is driven or the engine reaches a specific operating temperature. When the intake manifold heaters are post-cycling with an idling engine, the current draw is greater than the alternator output when the heaters cycle to "on", consequently, the lights will dim. - John

-

2001 24v Cummins High Idle Issue

I watched your video. Are you confident that you ran the engine long enough in the jumpered mode to conclude the VP44 is good? You could jumper the lift pump to perform a longer test. In my mind I would want to be absolutely sure that the VP44 is not the problem. You are definitely right about checking out your wiring mess before you condemn the ECM. Very interested to know what the solution is going to be. Hopefully, you will succeed - I think you will. - John

-

2001 24v Cummins High Idle Issue

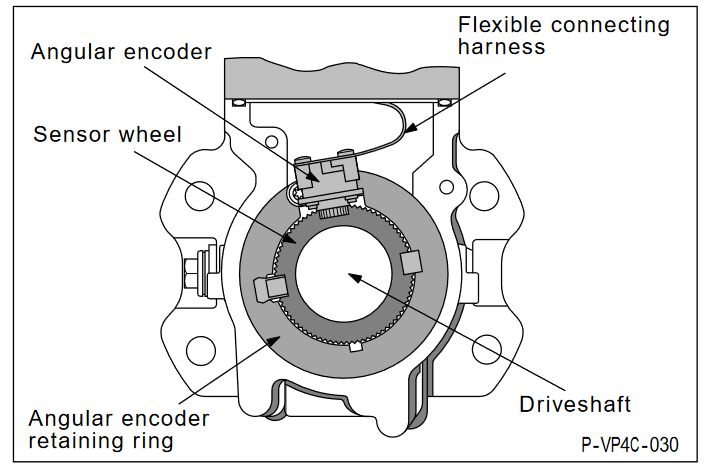

There is an angular encoder inside the VP44. It provides many features, but one feature is a redundant camshaft position sensor. This is probably why the engine ran for 15 seconds during your test. I am guessing that when the VP44 is reconnected, the ECM is picking up the signal from the angular encoder and consequently turns on the lift pump. - John

-

2001 24v Cummins High Idle Issue

The ECM controls lift pump operation. When the engine starts, I THINK the ECM gets a continuous input signal from the cam position sensor and then the ECM commands the lift pump to turn on. I don't think a disconnected VP44 would affect that operation - but, I don't know that for sure. Are you saying that your current condition is that the VP44 is jumpered, there is no lift pump operation, and the engine won't start? If so, does the lift pump perform correctly when you re-connect the VP44? There is an internal fixed displacement vane pump (Bosch calls it a feed pump) inside the VP44. This pump will keep the engine running (even without a lift pump) unless there are sources for air to get into the fuel lines - especially between the fuel filter housing and the VP44. When you had the engine running for 15 seconds or so with the jumpered VP44, was the engine already warmed up and displaying the high idle issue prior to jumpering the VP44? - John

-

2001 24v Cummins High Idle Issue

Each to his own on going with stock injectors or RV275 injectors, or injectors from DAP. I ran my my original injectors to 303,000 miles and replaced them with new Bosch RV275 hp injectors. The original injectors were performing just fine - good fuel economy, good power, no smoking, smooth idle, no rpm increase at idle, easy starting, etc. I replaced them only because I thought it was time. A friend of mine is the original owner of a 1999 truck at 293,000 miles, still with original injectors. His engine performance is the same as mine. Sometime in the next year or so he will replace his injectors - probably with stock or RV275's. - John I am very interested in hearing the results of this test. ....., - John

-

High EGTs After Minor Upgrades

What are the EGT's running at now? I believe the 2004.5 through 2007 Cummins engines use the HE351CW turbo (waste-gated at 32 psi) as a stock turbo. These engines run stock 610 lb/ft torque and 325 HP. I recall from reading many posts on the Turbo Diesel Register that these truck owners were concerned about 1400° - 1450° egt's when towing. They were told that this is normal and not to worry about it. I also read that the injectors, head, and pistons for this era of engine are designed to handle the additional heat. It is my guess that you may not be able to achieve 1200° or less egt's with that turbo and the power you want from your engine. And, the 2nd generation 24 valve engine is not designed to handle the higher heat. I have RV275 hp injectors, stock HX35W turbo (393,000 miles now on the turbo), and a Smarty S03 set with a mild tune and stock timing. I can pull a 4 mile 6% grade at 50-55 mph (combined weight 20,000 - 21,000 lbs) and keep the egt's below 1200° - 5th gear 2,000 - 2,200 rpms. I hope that you can accomplish what you want with the tuner, but I am having doubts. - John

-

2001 24v Cummins High Idle Issue

I only mentioned it because you know absolutely nothing about the history of the injectors and the truck was behaving this way when you bought it. I really don't think it is the injectors, but in your case I wouldn't rule them out. Interesting regarding the your observations when revving the engine. I will be interested in hearing the results of your test. - John

-

2001 24v Cummins High Idle Issue

Your scanner certainly sounds more than adequate to pull codes. I would follow up with Blue Chips guidance to make the VP44 run as a stand-alone by supplying remote power and ground. Wait to do this until the engine is fully warmed and you are experiencing the idle issue. In my mind, if the engine idles fine while jumpered under these conditions, then I would say the VP44 is fine, and the injectors are fine, but you could have a problem with the ECM or wiring (I know, you have thoroughly checked out the wiring). The following is an excerpt from Blue Chip Diesel under "RPM takes off without throttle application". "If it revs up on its own from an idle, you can also do the “No Start” test three, and if it idles smoothly and at the same speed dependably, then it means the ECM is the cause of the problem." If the engine continues to run at a fast idle while jumpered, then I would say you could have a VP44 problem, or a problem with injectors. Normally, I would not think the injectors could be an issue, but you do not know anything about the injectors that are currently in the engine. It is possibly to have high mileage worn out, high horsepower injectors that could exceed the fuel rate control limits of the ECM when engine idle is commanded. If the ECM cannot pull back fueling enough, then engine rpm's could begin to creep up. Just a guess here. Let me know what you think. - John

-

5v reference circuit? Ecu? All of the problems!

Give these folks a call. They have a good reputation. https://mopar1973man.com/forum/210-auto-computer-specialist/ - John

-

2001 24v Cummins High Idle Issue

Sounds like the APPS is performing as it should. As far as reading codes, not all scanners are equal. See if you can borrow a better scanner, or maybe try your local auto parts store for a free scan. How many miles on the truck? When did you take ownership? Has the improper idle symptom been there sine you owned the truck? Do you know what injectors are in the engine and how many miles on them? I assume that there is no tuner hooked up. You mentioned that you think the engine has been replaced - any more information on that? - John

-

2001 24v Cummins High Idle Issue

I went back and re-read this thread. If I am understanding correctly, the only problem you are now having is that the engine won't return to a normal idle rpm after the engine has warmed up. Other than that, the engine is performing fine/ Is this correct? Is this still occurring. Have you driven the truck with a scanner monitoring the APPS at idle after the engine has warmed and the engine rpms won't drop back to idle? The scanner should read zero percent at idle, then start reading a small percentage just off idle. The APPS uses an internal idle validation switch that tells the ECM to let the engine idle. When the ECM commands "idle", all other inputs to the ECM are ignored. There is a procedure that involves disconnecting the electrical connector on the VP44's PSG and then jumpering a remote power and ground to the PSG. In your case, if the warm engine idles normally under the jumpered conditons, this would indicate that the VP44 is operating as it should. The link below is for Blue Chip Diesel. It shows various troubleshooting methods for diagnosing the VP44 fuel system. Carefully read steps #2 and #3 for a "No Start" situation. If you perform Step #3 and the engine idles fine after it has warmed, then I would think you can rule out the VP44 as the problem. https://www.bluechipdiesel.com/runningtests Have you checked for DTC's? I asked the question before, but I don't recall reading an answer. Don't give up! - John

-

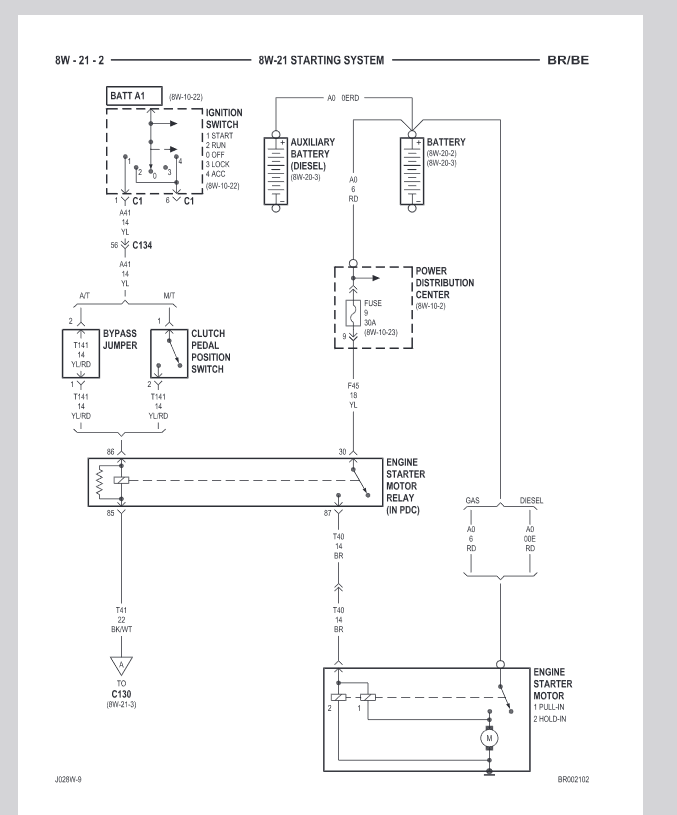

starter motor and ignition issue

Your signature says that your truck is a '99. The wiring diagram that I posted is from my 2002 FSM, but I believe the diagram is correct for a '99. Maybe you can verify. When you used the jumper from the positive battery post to terminal #87 in the relay base, you bypassed the ignition switch, clutch safety switch, starter relay, and the 30 amp fuse in the PDC. Since the symptom remained the same (a single click), you have essentially eliminated all of those components and associated wiring from being the problem. Continue with testing in the manner recommended in my previous post and you will narrow down the problem area even further. - John

-

starter motor and ignition issue

Bypass the #87 pin and jumper directly from the battery positive post to the "S" terminal on the starter. If the symptom remains the same, then there can be only one of three potential issues. This is assuming that your batteries are fully charged and are in good operating condition (which they should be). 1. Poor connection / cable from the battery positive post to the starter. 2. Poor connection / cable from the engine block to negative post of battery. 3. There is an internal problem with the replacement starter. - John

-

starter motor and ignition issue

I don't know how you are using your meter to check continuity for grounds, but if you are testing using the ohmmeter, then the test results will never be conclusive. All it takes is the connection of one strand of a wire to show good continuity. Performing voltage drop tests under load would provide much better information. You sound like you are comfortable using a multi-meter. Many people that I know who have used multi-meters for a long time have drawn wrong conclusions when using the ohmmeter for testing, or using the voltmeter without an electrical load being applied. Again, it only takes a single wire strand to read continuity or 12 volts. This is one reason I use an incandescent bulb test light for testing circuits - the bulb imposes a small electrical load and will readily dim if the circuit being tested has a fault. Have you tried the jumper test that I recommended? I think this test would be the fastest and most conclusive test to perform. - John

-

starter motor and ignition issue

Have you checked the condition of the 30 amp fuse in the PDC? I would make a 10 gauge jumper wire with a terminal connector on one end that will fit into terminal #87 relay base in the PDC. Place the transmission into neutral and set the park brake before doing the next step. Insert that connector into #87 (relay base in PDC) and touch the other end of the jumper wire to the positive post of the battery. If the starter cranks, then you have narrowed down the problem area to be somewhere between the battery connection and the terminal #30 of the starter relay, which would include the 30 amp fuse in the PDC and associated wiring. If it still doesn't crank, I would be looking for a ground issue between the engine block and the battery. - John

-

5v reference circuit? Ecu? All of the problems!

-

5v reference circuit? Ecu? All of the problems!

I think you are on the right path. Something worth checking. Is the stock engine block-mounted lift pump still being used? If so, the lift pump will get its power directly from the ECM, not the best decision from an electrical engineering standpoint. Many people have relayed the lift pump using the ECM to trigger the coil of the relay - a much better operation and the relay greatly reduces the electrical load on the ECM. - John

-

4.11 Rear end

I'll bet that is a powerhouse! - John

-

2001 24v Cummins High Idle Issue

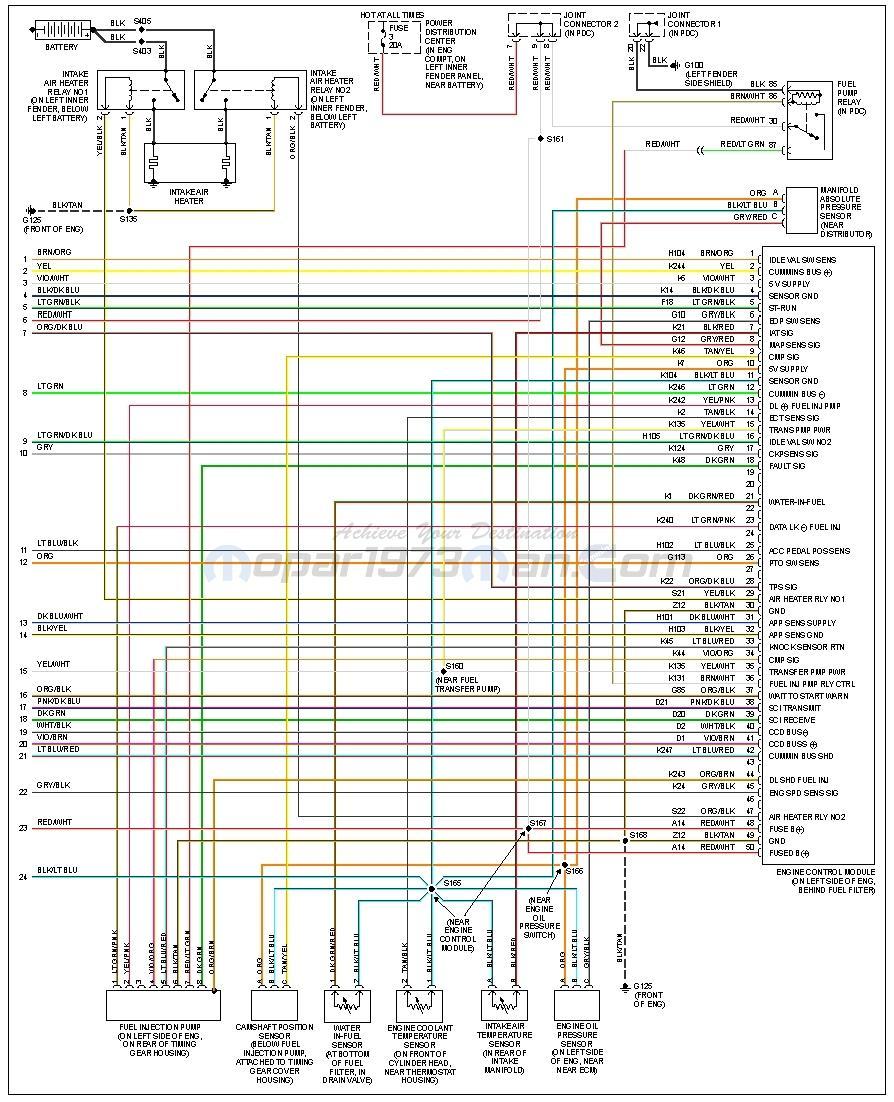

Splice #165 is a crimped affair - not the best idea for a quality electrical connection. It is located near the timing gear case on the driver side of the engine. Below is a link to the W-T ground reference mod that would be in your interest to perform. - John

-

2001 24v Cummins High Idle Issue

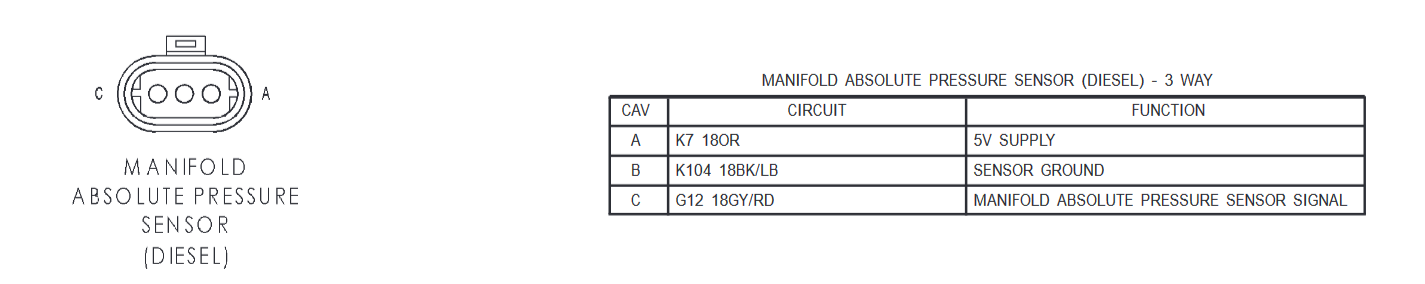

When you saw a consistent 5 volts at the IAT, were you using the black/tan wire for ground, or were providing a remote ground? - John

-

2001 24v Cummins High Idle Issue

I have never experienced this, but I have heard of it happening. The general consensus is that a strong static charge builds from the normal operation of the serpentine belt. That static charge discharges periodically near the crank pulley because the crank pulley has the shortest air gap distance to ground. Some have replaced the serpentine belt with a different brand and said that it cured the issue. Others have said that the sparking causes no harm and have done nothing to stop it. - John I don't think it is that simple. The ECM could be putting out a good 5 volt supply, but an erratic ground could make it look like an erratic 5 volt supply. I would try to figure it out - not bypass it. - John

-

2001 24v Cummins High Idle Issue

Have you checked for any trouble codes? The oil pressure switch, camshaft position sensor, and the manifold absolute pressure sensor all receive a 5 volt signal from the ECM. Splice #165 (S165) is a through connection for ground for all of these sensors and oil pressure switch. Since voltage is "all over the place" for some of these sensors, I would be checking the source and ground for the 5 volt supply. - John

-

Throttle stutter/truck jerks at highway speeds

Does your tuner read fuel pressure - commanded pressure and actual pressure? If so, what is happening with these pressures when the stutter issue occurs? Does the stutter between 1800 rpm and 2100 at any engine load, or a particular engine load? There are people on this site that know more about the common rail fuel system than I do - maybe you will hear from them. Sounds like you know your truck pretty well. Now that you mention operating the truck in the salt belt, I would definitely check wiring and wiring connections to sensors, ECM, frame grounds and body grounds, etc. How about the possibility of bad fuel? Might be worth a fuel filter change which would allow you to inspect the fuel passing through the filter, as well. - John

-

Throttle stutter/truck jerks at highway speeds

Have you checked for any DTC's? Is fuel pressure where should be (lift pump pressure)? What are the conditions of your battery cables (including the crossover cable) and battery connections - both positive and negative? You may want to get the tuner completely out of the system to help diagnose. Please give some history about the truck - miles and years you have owned it and what you have done to it, etc. - John