Everything posted by Tractorman

-

WOW

Wonder if the VP44 was replaced yet. - John

-

VP 44 voltage issue

Pin #15 and #35 provide power to the transfer pump. One is for run mode and the other is for crank mode - not sure which is which, but it doesn't really matter. The wires are both connected at splice #160. That splice is a potential problem area, but I don't think it is your problem because you are having two problems simultaneously - no fuel pump operation in bump start and a delayed wait-to-start light. It could be that your delayed wait-to-start light is not allowing the ECM to trigger the bump start fuel pump operation. Ditto on what @Great work!says. - John s

-

VP 44 voltage issue

Did these two situations resolve themselves? Things must be looking much better now that you have a truck that you can drive again. - John

-

VP 44 voltage issue

Before installing the 140 amp fuse, connect an incandescent test tight - one end on the alternator output and the other end on the battery side of the 140 amp fuse holder. If all the diodes in the alternator are okay, the test light should not light because there will be no path to ground. If all is well, install the 140 amp fuse. The 140 amp fuse is not there to protect the alternator - it is there in case a direct short to ground should occur in the alternator or the alternator output wiring. If that fuse was not there, an engine fire could easily start from the heat generated by the overloaded circuit from a seemingly endless supply of energy from two large batteries. - John

-

VP 44 voltage issue

Part of your statement here is normal. What is not normal is the blown 140 amp fuse. Need to find out what caused that right away. It is not likely that the alternator caused that fuse to blow. The maximum output of the alternator is about 130 amps. One thing that can and has happened to people is accidental momentary grounding of the alternator output terminal. The 140 amp fuse instantly blows. You have been doing a lot of electrical work on your truck. The 140 amp fuse could have been accidentally shorted to ground right at the PDC location. Because the 140 amp fuse is blown, It is now normal for the alternator output voltage to be higher than normal (22 volts) because the current has no where to go (the 140 amp blown fuse}. The internal regulator (inside the PCM) is sensing that battery voltage is low (which it is) and it is telling the alternator to increase output. That 140 amp fuse is how the current gets from the alternator output to the driver side battery. So, things may not be as bad as they seem. The alternator may be fine. Congratulations on your success with getting the engine running without codes!! - John

-

VP 44 voltage issue

A big thank you to @IBMobilefor answering the question about wiring harnesses. - John

-

VP 44 voltage issue

I am sorry, but I don't know how to help you acquire the correct part number for a wiring harness. But, I would like to back track just a bit. Are you using a FSM for a '99 year model truck? If so, can you post a photo similar to the one below. The diagram in the photo below is from my 2002 FSM. The wire (BR/WT wire) from Pin 36 goes through Connector 125 (pin 8) and Connector 130 (pin 9) and arrives at pin 86 on the fuel pump relay. The color of the wire stays the same from beginning to end. What does your diagram show? It does sound like you have a wiring harness issue. - John

-

VP 44 voltage issue

You would have everything connected so that the electrical system is fully operational. You would find the most accessible test points along the circuit to be tested. In your case the circuit will start at Fuse #3 (20 amp) in the PDC. The next item downstream in the circuit is Joint Connector #2, also in the PDC. One wire leaves Joint Connector #2 and goes to pin 30 of the fuel pump relay. The other wire continues to Splice #161. One wire leaves Splice #161 to an unknown location, the other wire continues to Splice #167. Three wires leave Splice #167, one to an unknown location, and the other two terminate at pin 48 and 50 on the ECM. You would have the ignition switched on and have your voltmeter hooked up to pin 86 on the fuel pump relay to continuously observe the low voltage you have mentioned. With a test light clipped to the negative driver side battery terminal, you would begin probing any accessible place starting at Fuse #3. If the light burns brightly, then you have eliminated that part of the circuit as a problem. If along the way you suddenly find the light burning dimly, then you have located a general area of where the problem is. As you proceed, you are not proving where the problem lies, but you are proving what is working properly - a process of elimination that will lead you to where the problem lies. But, before doing all of that, have you verified that no pins have been pushed back into the wiring connector at the ECM? If everything is good there, then try the following: Disconnect the wiring connector from the ECM. Using a jumper wire protected with a 1 amp fuse, jumper pin #36 (brown wire with a white tracer that leads to pin 86 on the fuel pump relay) in the wiring harness side (not the ECM side). If the fuel pump relay activates and voltage stays high and the test light burns brightly on pin 86 of the fuel pump relay, then you know the wire is good between the ECM and the fuel pump relay. If the voltage remains low and the test light burns dimly, then you know there is a wiring problem between the two location. Please verify the pin numbers that I have given are correct and that my instructions make sense to you before you do any testing. - John

-

VP 44 voltage issue

You just gave an excellent example of how using an ohmmeter can lead you astray. One good method for finding poor connections in a 12 volt circuit is to use a test light with an incandescent bulb. The bulb will impose a small load in the circuit and the bulb will glow dimly when there is a voltage drop present. Your "barely touching fuse" would have been much easier to find with the test light approach. I am very interested to see what you find. - John

-

VP 44 voltage issue

You are doing some good troubleshooting here. Just for clarification (you probably already know this), the fuel pump relay is for the VP44 power supply, not the lift pump. You are correct in that pin 86 should receive 12 volts from pin 35 on the ECM. That fact that voltage at pin 86 falls to almost ground potential when you ground pin 85 tells me that there likely is a poor connection somewhere in the supply circuit. Using a ohmmeter to check continuity is not always conclusive. For example, 12 volts can be present under no electrical load, but can fall dramatically when a load is applied due to a poor connection. A test with an ohmmeter may not show this. The fuel pump relay coil gets supply voltage from pin 35 on the ECM and the ECM gets its supply voltage from pins 48 and 50 at the ECM connections. Those connections get their supply voltage from Fuse #3 in the PDC (which also supplies voltage to pin 30 on the fuel pump relay). There are splices along the way. John

-

Options to Trigger Relay

Are you saying that when you activate the OD switch on the shift lever to shift into fourth gear that you want to turn on the transmission cooler fan? I am not sure what your objective is here. If this is what you are trying to do, then I don't think wiring it this way is beneficial. Shortly after selecting fourth gear, the torque converter will lock up. When that happens, virtually all heat that was being generated by a slipping torque converter ceases. If I am misunderstanding what you are trying accomplish, then please disregard the above. - John

-

W T mod ciruit breaker

I used the 150 amp fuse shown below. Comes as a two-pack. I mounted it to the outside of my OEM air filter box. I have only had mine in operation since last October (about 4,000 miles), but no issues so far. Some say that the lid comes off easily - I have not had that problem yet. - John

-

New IAT, temp goes above 293, watch it drop on the code reader

Try not to jump to conclusions. @Great work!said, "burned up number 5." He did not say what was burned - piston, valve, cylinder, etc. Your engine had flame going back into the intake manifold through the intake valve while the valve was closed. Your situation is unique. As I mentioned before, intake valves don't burn. Something had to hold that valve open - possibly it was adjusted to tight, or foreign matter passed through the valve which could damage the valve face or valve seat or cause the valve to leak, or possibly the valve was struck and bent by the piston while the valve was in a forced open position. A properly operating intake valve will not burn, even if combustion temperatures are excessive. Again, I recommend that you have the shop collect and save the failed parts for analysis. @Mopar1973Manhas suggested to post some photos of the failed parts. I, too, would be interested in seeing photos. The photos may tell the story. - John

-

New IAT, temp goes above 293, watch it drop on the code reader

I don't know the answer regarding prices. I have never had the need to replace a diesel engine - long or short block. Maybe @Mopar1973Manwill respond here. He is much more familiar with labor and parts cost for major engine work. What about an available used engine from a reputable source? Not sure of what stage of tear down your shop has done on your engine, but I recommend that all parts related to the failure are collected and saved for you. - John

-

New IAT, temp goes above 293, watch it drop on the code reader

If this were my truck, I would want to see the failed parts. A failure analysis will usually tell the story as to what caused the failure. "Cylinder 5 had burnt valve." This is a very general statement. Was this an intake valve? I've never seen any burnt intake valves - burnt exhaust valves, yes. If the intake valve was held open by a foreign object, then there should be witness marks on the valve or in the piston head if the the piston made contact with the valve. I could understand an intake valve being burnt if something damaged the valve first. Then combustion gases could starting eating away at the valve after the damage occurred. However, a normal operating intake valve always has air flowing across its surface, unlike an exhaust valve that has hot combustion gases flowing across its surface. - John

-

Spring Camp trip Dates set in Concrete

-

New IAT, temp goes above 293, watch it drop on the code reader

I know it will be awhile before your truck is fixed, but don't forget to let us know the exact cause. We are all interested in knowing. - John

-

New IAT, temp goes above 293, watch it drop on the code reader

I wondered the same, but I can't imagine that even if both grid heaters were activated how the air temperature could rise from ambient to 300°F with the engine idling. However, it would certainly be easy enough to remove them from the equation. - John

-

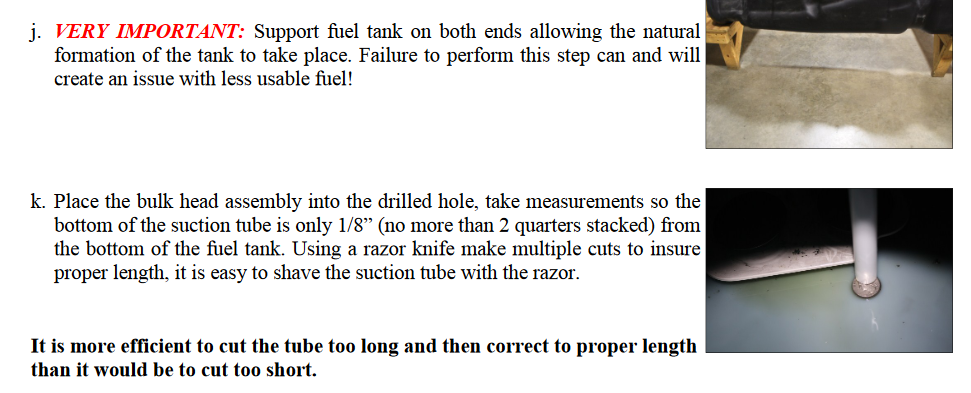

Draw straw install

Your memory is still good. About 18 gph fuel returned from the VP44 (including fuel injectors) at engine idle - about 28 gph at 2,000 engine rpm. Now we will see if my memory is correct. I think @Mopar1973Mansaid to make a straight cut on the fuel line as in the example from FASS instructions. If I am wrong, he will let me know. - John

-

New IAT, temp goes above 293, watch it drop on the code reader

Tim, I reviewed that same post yesterday. I am glad you decided to inspect the IAT sensor. I certainly think you now have proven the source for the damaged IAT sensor is from a source of high heat. And, since it appears to happen right away with no load on the engine, the only thing I can think of that could generate that much heat in a such short period of time would be a nearby cylinder with an intake valve that is leaking - not a large leak, but enough of a leak to allow combustion gases (a flame) to enter the intake manifold. The leak would have to be small, otherwise there would not be enough compression to ignite the fuel. Possible causes: * an intake valve adjusted too tight * foreign material passed through an intake valve and is still lodged there or has damaged the intake valve or valve seat. Is it correct in assuming that the intake manifold was opened for replacement of the VP44? Not sure how hard it is to remove the intake manifold. You might try barring the engine over to see if you can feel a cylinder with less resistance on the compression stroke. It would help determine which cylinder is the problem. - John

-

New IAT, temp goes above 293, watch it drop on the code reader

I have looked at the photo. It looks as you described. If I am understanding correctly, the sensor in the photo had been in operation since 2008. According to the title of this thread, you installed a new sensor and observed a very high temperature reading (above 293°). You also noted that the temperature dropped off slowly after turning off the vehicle. My previous response was based on this information regarding the new sensor - not the old damaged one. So, I am thinking that there are two possible problem areas: * One - the temperature reading (over 293°) is real and the previous IAT sensor was overheated by excessive of heat of an unknown source. This source of heat, if not found, will damage the new sensor. * The other - the high temperature is false and the false reading is caused by a wiring issue or an improper signal. The temperature slowly dropping off after turning the vehicle off could naturally happen because the signal voltage to the sensor would have been switched off at the same time. The cause of the previous melted IAT sensor would be difficult to determine because it had been in the truck for years without observation of condition (assuming it had never been removed and inspected). It may be worth pulling the IAT sensor for inspection to see if it is being exposed to excessive heat. I think you have a unique and a difficult problem to solve here, but the folks here will help you through the process. If I have misunderstood anything you have said, please disregard the above. - John

-

New IAT, temp goes above 293, watch it drop on the code reader

Anytime poor wiring connections are a possibility, the symptoms may or may not be predictable as the resistance value can change at any time for no apparent reason. The only time an electrical connection will have resistance stability is when the connection is good electrically - which means virtually no electrical resistance. - John

-

Here Kitty Kitty Kitty...

When the deer come back, you will know the cat has moved on. I lived above Scotts Mills for twenty years and occasionally a cougar would be around for awhile - most of the time unseen, just tracks and an absence of deer. You knew the cat was gone when you saw deer munching on your favorite plants again. - John

-

Death wobble issue rears it ugly head again

I am also running the Centramatics - installed one year ago (10,000 miles ago) this month. I installed them for a particular reason. I had purchased a set of four commercial winter tires for a good price. It turned out that they are excellent rock pickers (probably why the good price). I live on a 1/2 mile long gravel road and those tires load up with rocks. After two hours of freeway driving, there are still lots of rocks in the tread. Of course, this affected tire balance dramatically. The Centramatics have worked well for the fix. The wheel balancer compensates for rocks leaving the tread, thus making the ride smooth again. The steel balls are enclosed in a circular tube filled with synthetic oil. This allows them to work well in cold weather. I think they are available for a dual rear wheel truck. - John

-

Spring Camp trip Dates set in Concrete

So far, we are on track for a late spring. The 10 day extended forecast is still showing below normal temperatures and snow showers for my location about 10 miles northwest of Baker City. Then it is forecast to switch gears for warmer, more seasonal temperatures. The photos below taken on 3-10-2023 (bottom) and 3-28-2023 (top) at my place (3,800' elevation). This is only my fourth winter here, but normally the snow is gone by the middle of March. There is still plenty of time for the snow to melt in the high country and (as @JAG1mentions), I will check out the area around Magone Lake early enough to make a decision on camping there. I am looking forward to seeing everyone wherever "there" ends up being. Just for information, Prairie CIty is at 3,500' elevation and Dayville is at 2,400' elevation. Prairie City has by far the best view. - John