Everything posted by Tractorman

-

No low beams

Since it has been modified, you are on your own here. I would verify whether the relays are using positive or negative switching (both on the coil part of the relay as well as the switch part of the relay). Then troubleshoot the lighting circuit from there. - John

-

No low beams

Is it a factory 4 bulb system (Sport Package) or a modified 4 bulb system (after market)? - John

-

Inconvenience of EVs

I agree. There are other areas for electric vehicles that are not being talked about much - small off road equipment, such as a mini-excavator. One of the most undesirable aspects of an electric vehicle is the large amount fixed weight (the batteries) the vehicle must carry around all of the time. In a mini-excavator, the weight of lots of battery power would be an asset. The heavy weight of these batteries would be part of the needed counterweight. There are already a few manufacturers of EV excavators. I have a Takeuchi TB016 mini-excavator. It weighs about 3500 lbs. It is powered by a 3 cylinder 14 hp Yanmar diesel engine. It would be an excellent candidate to be powered by a large battery pack. The high starting torque of DC electric motors would easily propel the tracks - no hydraulics. The volume of oil needed for the electric powered on-demand hydraulic pumps used for the auxiliary hydraulic circuits would be significantly reduced. A lot of pluses. - John

-

Is there a foolproof way to tell if I need a heater treater?

All of the air that leaves the blower chamber immediately flows through the evaporator core. If the evaporator core is partially blocked, then you will have reduced air flow from the vents - not reduced air temperature. In fact, the air temperature from the vents would probably slightly higher because of the longer saturation time while flowing through the heater core. You have not mentioned anything about low air flow - you have only mentioned low air temperature. It is possible the thermostat could be a problem, but I don't think so. I run a 180° thermostat in my truck and my heater works fine. I think that you are down to a partially plugged heater core, or the blend door actuator is not indexed correctly, or the blend door itself is damaged / not sealing. I think it would be worth a try to remove the blend door actuator again and rig something to prop the blend door in the correct position to ensure that all air is flowing through the heater core. If nothing changes, then you can rule out a blend door actuator problem. I know you will get it figured out. - John

-

Is there a foolproof way to tell if I need a heater treater?

To make the rear screw installation easier, I used a longer screw with a spacer (can't remember the length). This made the head of the screw more accessible for starting the threads and for keeping the tool driver on the screw. I don't think I would worry about the actual temperature coming from the vents. You will know if it is fixed. - John

-

Clutch Safety Switch

Thanks for sharing your experience. Your story has well demonstrated how quickly things can get out of hand. Many times a safety device, such as a clutch safety switch, is mandated, but the reason is not thoroughly explained, even though the reason may seem obvious. Then, as time goes by, the value of that safety device changes even though the device itself hasn't changed. Let me explain (using the clutch safety switch as an example). In 1984, I purchased a new Ford E150 van with a 4 speed manual transmission. It had a clutch safety switch. I never modified it. But, if I would have modified it and activated the starter in gear while outside of the vehicle, the following could happen, even with the park brake set. * The engine could start before I let go of the key. That would be the worst case scenario, but probably would not happen. Why? Because back then most engines were gasoline engines and the engines were carbureted. Those engines would usually take a few revolutions of cranking before the engine would start. Plenty of time to let go of the key. Also, the resistance of cranking the engine in gear with park brake resistance would greatly reduce the chance of the engine starting. But the event would probably scare the heck out of me. So, fast forward a few years and you will find that the safety device has not changed, but the instant starting of a high torque, low RPM diesel engine has. Therefore, the risk of serious property damage or serious injury has greatly increased. @JAG1has illustrated this well. @JAG1has also made a good point regarding a tire shop employee starting the engine in his truck using poor safety habits - a risk that I did not think of. In this case the employee is relying on the operation of the safety switch and he is not placing himself in the driver seat every time he starts an engine. Over 50 years ago (before the addition of clutch safety switches), safety awareness regarding starting manual transmission engines was greater. Now, the safety awareness is posted within pages and pages of other safety awareness items. Not likely to be read. For all of these reasons, I think I will keep the clutch safety switches in my truck and my tractor fully operational. - John

-

Clutch Safety Switch

According to the wiring diagram, it should work without any side affects. If you decide to do it, just be sure you continue to practice your learned engine starting safety habits - no starting the engine without being fully seated in the driver seat. - John

-

EVENT.....May 2023 Magone Lake group Camp, Oregon

@JAG1, I am definitely interested. Three nights would be good. I would be willing to drive to the location in early May to check road conditions and report back. - John

-

Is there a foolproof way to tell if I need a heater treater?

If you have never changed out the plastic interposer that connects the blend door motor to the blend door, I would just do it. When I replaced mine several years ago, I could not see a crack in the interposer, but it was worn and it was the problem. Trying to diagnose a cabin heater problem by checking the temperature of the heater hoses is not a conclusive solution. If the blend door is stuck in a mid-range position, the symptoms will be the same as a partially plugged heater core. - John

-

Rear Trans Seal NV5600

@jlwelding, just curious, how many mile are on the transmission. I presume that the transmission is the original. - John

-

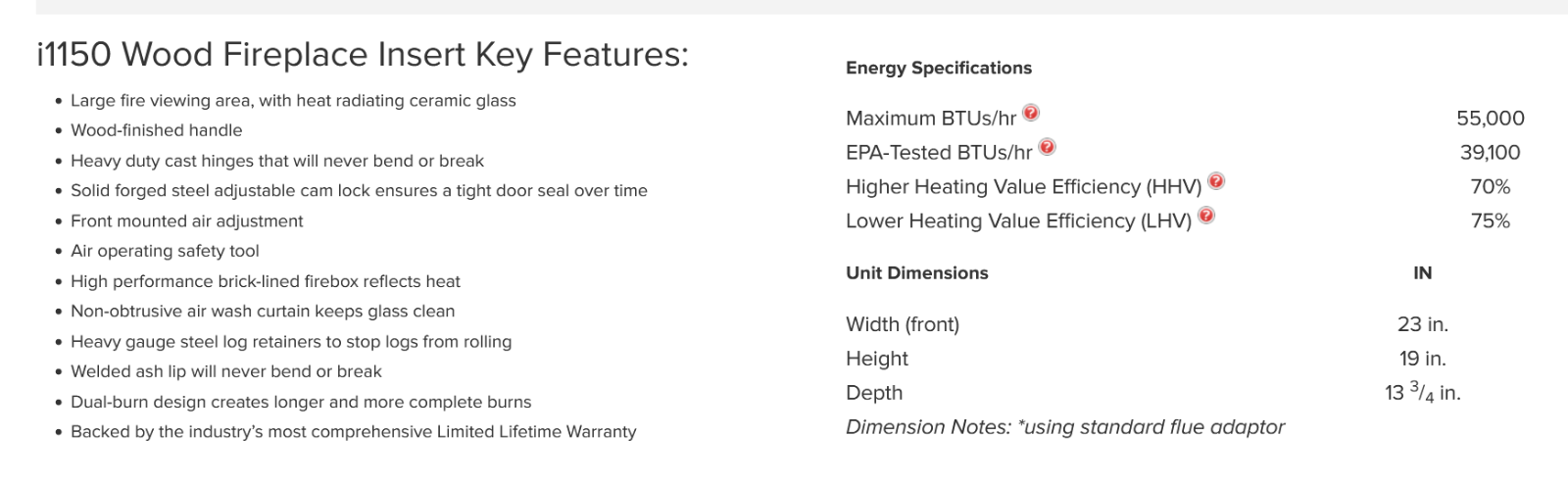

replacing 1980's heatilator fireplace insert with a new wood stove.

Have your checked Regency for fireplace insert. It looks like these dimensions would possibly fit. They are made in Canada. You can still get non-catalytic wood stoves and fireplace inserts that pass the 2020 EPA emissions. I have been using Regency wood stoves ( the free standing FS2400 wood stove with glass door) for years, using it for the main source of heat every winter in the Portland, Or area. One of them I used for twenty years with no problems. Glass always stays clean. In my opinion, the Regency stoves are excellent quality. I have since moved to Baker City, Or (much colder winters) and built a 2250 sq ft house in 2020. Purchased a new Regency FS2400 non-catalytic wood stove and I am heating the whole house with that stove - I only cycle the furnace once a month or two for exercise. Going into the third winter now. I would talk to the pros about whether or not to use a chimney liner. I do know that old chimney flus can be a fire hazard risk. - John

-

Common Sense Obituary

According to a post from a TDR member GAmes, this obituary was printed in the London Times. It seems there are many truths here. I thought I would pass it along. Enjoy, - John Today we mourn the passing of a beloved old friend, Common Sense, who has been with us for many years. No one knows for sure how old he was, since his birth records were long ago lost in bureaucratic red tape. He will be remembered as having cultivated such valuable lessons as: - Knowing when to come in out of the rain; - Why the early bird gets the worm; - Life isn't always fair; - And maybe it was my fault. Common Sense lived by simple, sound financial policies (don't spend more than you can earn) and reliable strategies (adults, not children, are in charge). His health began to deteriorate rapidly when well-intentioned but overbearing regulations were set in place. Reports of a 6-year-old boy charged with sexual harassment for kissing a classmate; teens suspended from school for using mouthwash after lunch; and a teacher fired for reprimanding an unruly student, only worsened his condition. Common Sense lost ground when parents attacked teachers for doing the job that they themselves had failed to do in disciplining their unruly children. It declined even further when schools were required to get parental consent to administer sun lotion or an aspirin to a student; but could not inform parents when a student became pregnant and wanted to have an abortion. Common Sense lost the will to live as the churches became businesses; and criminals received better treatment than their victims. Common Sense took a beating when you couldn't defend yourself from a burglar in your own home and the burglar could sue you for assault. Common Sense finally gave up the will to live, after a woman failed to realize that a steaming cup of coffee was hot . She spilled a little in her lap, and was promptly awarded a huge settlement. Common Sense was preceded in death, -by his parents, Truth and Trust, -by his wife, Discretion, -by his daughter, Responsibility, -and by his son, Reason. He is survived by his 5 stepchildren; - I Know My Rights - I Want It Now - Someone Else Is To Blame - I'm A Victim - Pay me for Doing Nothing Not many attended his funeral because so few realized he was gone. If you still remember him, pass this on. If not, join the majority and do nothing

-

New theme for Mopar1973Man

I went back to the old theme as well. Not just because it is easier to read, but also the notification icon (a bell) and the email icon (an envelope) are good visuals for the action you would expect when they are clicked on. - John

-

Lifter Access Panel

I don't have the answers, but I will be following this thread as I want to do the same repair on my truck this winter. - John

-

Pilothouse/RAM3500 build

Looks like the original oil filter is still installed. Now I see how you are saving money! Nice job with your plumbing skills. - John

-

Compound Turbo install complete

Push on the steering wheel. - John

-

Redhead steering box leaking, Pitman arm nut loose again

That would be a good way to make sure the nut is tight. If it passes the test, it might be worth loosening the nut and then retorquing the nut. Static torque is always higher that dynamic torque. If you choose to re-torque the nut, make sure the nut is still in motion when the desired torque value is reached. Since you said the popping noise has returned, checking the pitman arm nut would be the first thing I would do. Nothing else. Drive the truck to see if anything has changed. Have you ever checked the condition of the track bar? A steel bushing moving around in the axle end of the track bar could make a popping sound. In this case the fastener could appear to be tight, but the flanges may not be clamping the steel bushing with enough force which could cause movement. Have you checked the condition of the anti-sway bar rubber bushings? There can be metal to metal contact if the bushings are badly worn or split. Keep in mind that when you have the truck parked and you turn the steering wheel from one stop to the other, there is more going on than just loading the steering components. By design (positive caster. kingpin angle and angle of inclination) steering geometry will lift one side of the vehicle - left side when turning left and right side when turning right - every time you turn the steering wheel. The further you turn the steering wheel, the higher one side of the truck is lifted. This is to promote quicker straight ahead steering when coming out of a curve by using the weight of one side of the truck to assist in re-centering the steering gear box. It also loads suspension components, which could contribute to unusual sounds if something is loose, worn, or broken. Just take it one step at a time. Troubleshooting is nothing more than a process of elimination. Sometimes you will have trouble proving what isn't working properly, so, switch gears and prove what is working properly. - John

-

Redhead steering box leaking, Pitman arm nut loose again

First, I would like to say that I feel your frustration. I had a clunk / pop in my steering for over 25,000 miles. It affected steering performance for the duration, not all of the time, but most of the time. Fortunately, I didn't throw a lot of money at it, but I did install the Rock Solid bushing that supports the lower steering column. The problem went away for about a thousand miles, like it did many other times when I was trying to diagnose the steering / suspension system. I would have to repeatedly retighten set screws on the steering shaft. So, each time that I did something that made the symptoms go away, I thought I had found the cause and effect and the problem was fixed. But, each time I was wrong. The symptoms always returned within a thousand miles or so. In my case the problem turned out to be something that I would have never considered - a sticking slip joint in the new Borgeson steering shaft that I purchased to supposedly improve steering. The problem first occurred after driving the truck at least a couple of thousand miles after installing the Borgeson steering shaft. I had to modify the slip yoke operation for it to slide friction free. After that repair the truck drove so much better immediately. No more loose set screws. But, it took me 25,000 miles to figure that out. That was 95,000 miles ago. I am not suggesting that this is what is wrong with your truck. What I am suggesting is for you to start over from scratch with your troubleshooting. There are many things that can make the suspension or steering "pop". And, when you are taking things apart, or tightening fasteners while you are trying to figure this out, you can unwittingly change the operation of something that might be the actual cause of the problem. But, because you changed it (not fixed it) the problem comes back. Always. It is not uncommon to have to retorque the pitman arm nut. If it is not lubed or checked for burrs before torqueing the nut, the clamping force can be compromised. Need to conclusive here. Is the shaft leaking? Clean the area thoroughly and make sure that fluid is not leaking from somewhere else and just collecting around the shaft seal. I am not sure that you have found the real issue. You haven't proved a cause and effect relationship. You only mentioned that you tightened the nut one time. Have you checked to see if it is loose again? You are focusing on the steering gearbox, but your post starts out with a "popping noise when turning". So, the popping noise is still occurring with three different steering boxes (the original and two replacements). I don't think the steering boxes are you problem. This is why I think you need to clear you mind and start from fresh from scratch. When the steering wheel is rotated, a lot of multi-directional force is placed on all steering linkages, all front suspension components, and all nearby frame attachment areas. - John - John

-

Delayed start - longer turnover.

Thanks for checking back. We are always interested in the outcome as to what exactly is the cause of your symptoms. - John

-

Delayed start - longer turnover.

@DrJekyll86, any progress with the long crank time diagnosis? - John

-

Idle at 750 rpm-normal?

I have never quite understood that relationship. I ran my original injectors for 303,000 miles - performance was still fine, fuel economy still very good, and idle speed the same (right at 800 rpm) throughout the life of the injectors. - John

-

99’ 24v Alternator Went Bad, Possibly Fried PCM/ECM/VP44?

W-T, I can't believe it! You took the words right out of my mouth! What are the odds!? BUFFOONERY - Good word. As always, an excellent post.... - John

-

99’ 24v Alternator Went Bad, Possibly Fried PCM/ECM/VP44?

I don't believe the PCM can be involved. The communication for fueling and timing (the P2016 code) is between the ECM and the PSG mounted on top of the VP44. The P0216 code could be caused mechanically (binding timing piston, for example) or by an issue with communication between the ECM and the PSG which can include wiring. I still bothers me about the timing of getting the P0216 code the while the charging system was mal-functioning. How often does the dead pedal occur? If it is infrequent, it may be worth driving the truck for awhile as it is. At least it would give you time to make sure that you have covered all bases. I don't know if I would be ready to give up on the VP44 just yet. - John

-

02 Intermittent dead pedal

After listening to your video, I think you described the issue very well as an engine miss. In fact, I would have called it a direct engine miss - just like a gasoline engine with a misfiring sparkplug / plugs. I am glad to hear you solved the problem and it wasn't expensive. Also, thank you for reporting the final outcome back to us. - John

-

99’ 24v Alternator Went Bad, Possibly Fried PCM/ECM/VP44?

The P0216 code coming back with the dead pedal is of concern. If I am understanding correctly, you did not have any driveability problems prior the the charging system problem. Is this correct? In my opinion, over the years there has been too much emphasis placed on the role of lift pump performance related to VP44 needs. If you are seeing a positive fuel pressure at the inlet of the VP44 under all driving conditions, then the VP44 is operating and cooling itself as it should. It is possible that the remanufactured VP44 from Thoroughbred Diesel is not remanufactured to Bosch's standards - not all remanufactured pumps are treated the same. My original VP44 failed at 64,000 miles - replaced at 87,000 miles. I now have over 280,000 on the remanufactured VP44 and this VP44 has never seen any lift pump pressure higher than 12 psi - and that's at idle. Normal driving it is around 6 psi. If the P0216 code and dead pedal issue did not happen until after the charging system problem began, then I would try to rule out all other possibilities before replacing the VP44. - John