Everything posted by Tractorman

-

How hot are you?

Overnight low of 43° here in Baker City. Also, the coldest night for over two months. - John

-

Traction Bars for short box 2wd

Under what conditions is your axle wrap occurring? and which gear? Details matter. What clutch did you install when you swapped to the G-56? Why not go back to the OEM rear spring setup? There are plenty of OEM 2WD pickup trucks with 6 speed manual transmissions out there that don't have any drive-ability problems. - John

-

thermostat help !!!

@Nekkedbob, I apologize for my part in hijacking your thread. - John

-

thermostat help !!!

@JAG1, I appreciate your response. I strongly agree with most of what you are saying. But, I am not challenging any of those things. In fact, I have done some of the things that you mention - mounting my lift pump on the frame rail, modifying the suction line inside the fuel tank, adding a serviceable coarse suction strainer just upstream of the the lift pump, and rerouting the return fuel flow to the fuel tank filler tube. What I am challenging is the long-lived belief that somehow the lift pump pressure determines how much return fuel (cooling for the VP44) comes from the VP44 via the 14 psi overflow valve. Over the years I have read many posts from the leader / leaders of this site who have referenced that if lift pump pressure is less than 14 psi, then there is no return fuel flowing over the 14 psi overflow valve, thus no cooling for the VP44 injection pump. I have also read many posts that say the VP44 will be damaged if the if lift pump pressure is less than 14 psi. It is my opinion that this is simply not true. I have never seen any documentation to support these beliefs. I have performed fuel return flow tests that dispute this concept. Others have also performed this same test using flowmeters and driving their trucks for real-time documentation. Some of the tests were performed and results were posted over 15 years ago. In fact, one of the testing events involved a vendor that was going to market improved lift pump systems, but dropped the idea when the fuel return flow test results were documented. One of my goals for posting this information is to help the readers decide what fuel system is best for their truck and to help the readers diagnose any fuel related problems. Years ago I attended a truck driving school. The school was taught by veteran truck drivers, each with over 30 years of safe driving experience. Toward the end of the training I was talking with one of the instructors. I was thanking him for the knowledge he shared. One thing that stuck in my mind was something that he said. It was something to the effect of, "You can learn a lot from a veteran truck driver - including any bad habits or misconceptions of the trade. So, don't be afraid to challenge what you hear" That has always stuck with me. I am hoping that my challenge will be addressed. - John

-

thermostat help !!!

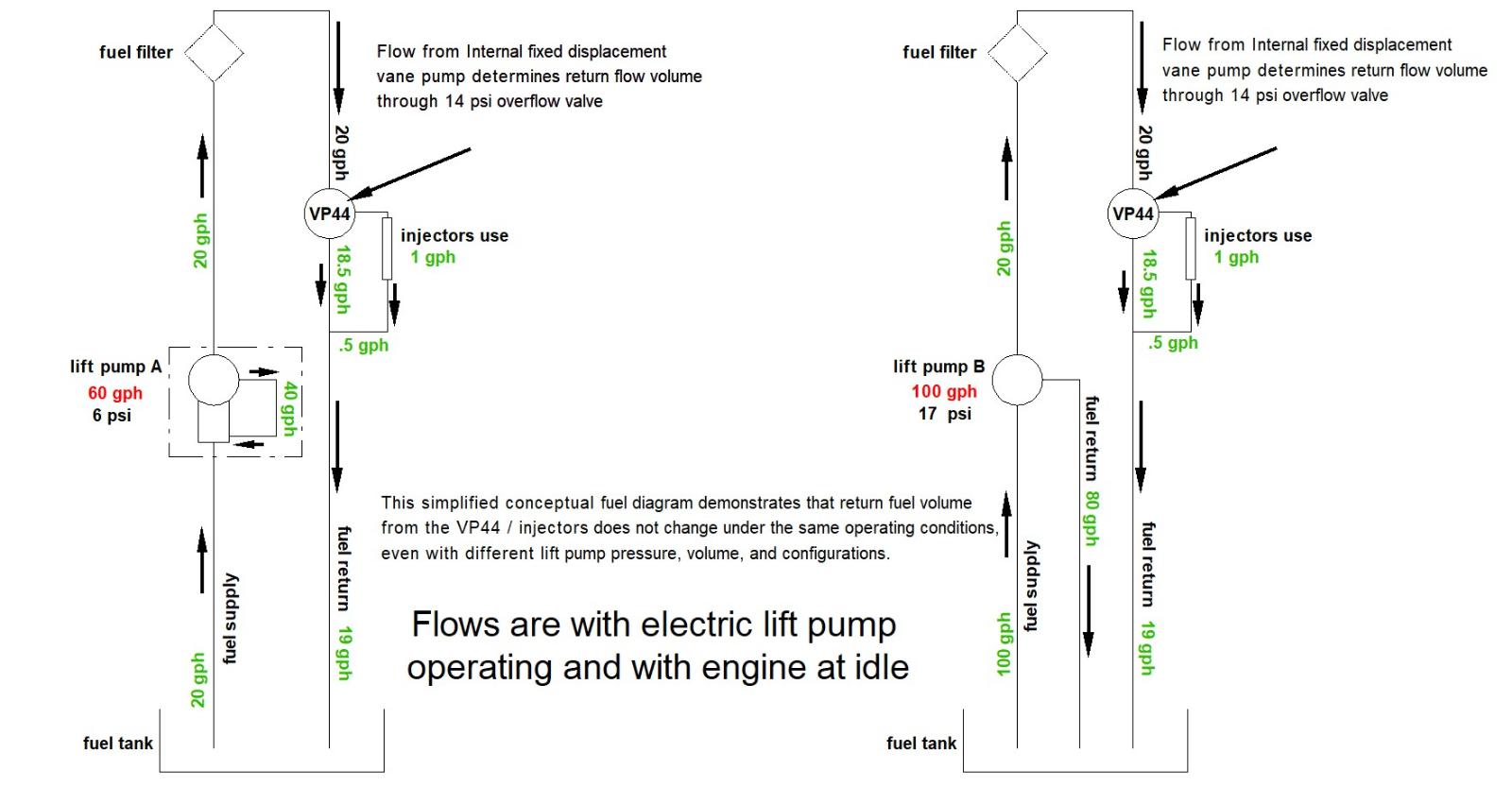

In my opinion, there is a lot of incorrect information being posted here. I am assuming you are referring to the 14 psi overflow valve in the VP44, The moment the engine starts and idles, there is approximately 19 gph of fuel instantly flowing through the 14 psi overflow valve and returning to the fuel tank. This flow is provided by the VP44 internal fixed displacement vane pump - NOT the lift pump. If the lift pump pressure is 5 psi or 20 psi, the 19 gph return flow will remain the same while the engine idles. If there was no lift pump and the internal vane pump was drawing directly from the fuel tank, there will still be 19 gph fuel return flow from the VP44. The internal vane pump pressure regulator is set to around 135 psi - certainly more than enough pressure and flow to ensure that the high pressure pump chambers fill and that fuel flows through the 14 psi overflow valve. At 2000 rpm there will be about 28 gph of fuel returning to the fuel tank via the overflow valve. That is certainly much more than the 2.5 gph injector consumption. It is also likely that if the lift pump pressure is around 15 psi, then the lift pump flow will be much less than rated 150 gph. The lift pump manufacturers do not provide flow vs pressure performance charts. The most information that I could ever find was from FASS - which stated that the rated flow was at 0 psi. So, I would not be surprised if that 150 gph rated lift pump is only flowing half of that rating at 15 psi. If this were the case, 75 gph minus 2.5 gph minus 28 gph equals 44.5 gph returning from the lift pump to its own inlet, or returning to tank by separate line. Not true if you are referring to 10 psi lift pump pressure. At 10 psi (or 5 psi, or 20 psi), 19 gph of fuel will be passing through the 14 psi overflow valve and returning to tank with the engine at idle. The only time the 14 psi overflow valve is closed is when the engine is shut off. I made these charts below to illustrate the combined series and parallel fuel circuits involved in the VP44 fuel system. The 19 gallons / hour of fuel returning to the fuel tank from the VP44 is based on return flow tests that I and others have performed. The test is at engine idle. The circuit on the left uses a 60 gph / 6 psi lift pump that returns fuel to its own suction. The circuit on the right uses a 100 gph / 17 psi lift pump that uses a separate line to return fuel to the tank. Compare the different flow rates in some parts of the two circuits. Note that the return flow rate from the VP44 does not change in either circuit. - John

-

Swapped out some 50hp injectors for some 100's today

@Caleb Hardy, I like what you wrote. I think the words "effective ratio" are a better choice of words to present a case of how different tire diameters affect engine performance. Earlier today I was writing about this subject, but I wasn't ready to post. I am now posting below what my thoughts are. I changed the words "final drive ratio" to "effective ratio" as a result of reading your post. Thank you. I think the intent is to say, for example, "When a smaller diameter tire is installed on a truck with a 3.55:1 rear axle ratio, then the "effective ratio" at the ground would make the truck behave like it was closer to a 3.73:1 rear axle ratio." I think that in order to make a fair comparison, the only time "effective ratios" should be compared between different vehicles is when the vehicles that are being compared are using a transmission gear that provides a direct 1:1 gear ratio. There is only one gear in each of the three available transmissions for 2nd generation trucks that meets this requirement and that gear is a different gear in each transmission. Direct 1:1 ratio gear are: * 5th gear (NV5600) * 4lth gear (NV4500) * 3rd gear (47RE) Over drive gears ore: * 6th gear (NV5600) 0.73:1 * 5th gear (NV4500) 0.75:1 * 4th gear (47RE) 0.69:1 - John

-

Swapped out some 50hp injectors for some 100's today

For your truck, tire size, transmission, and 3.55 gears - sounds like you are right where you should be to me. - John

-

Any helpful tips on doing injectors / valve lash adjustment?

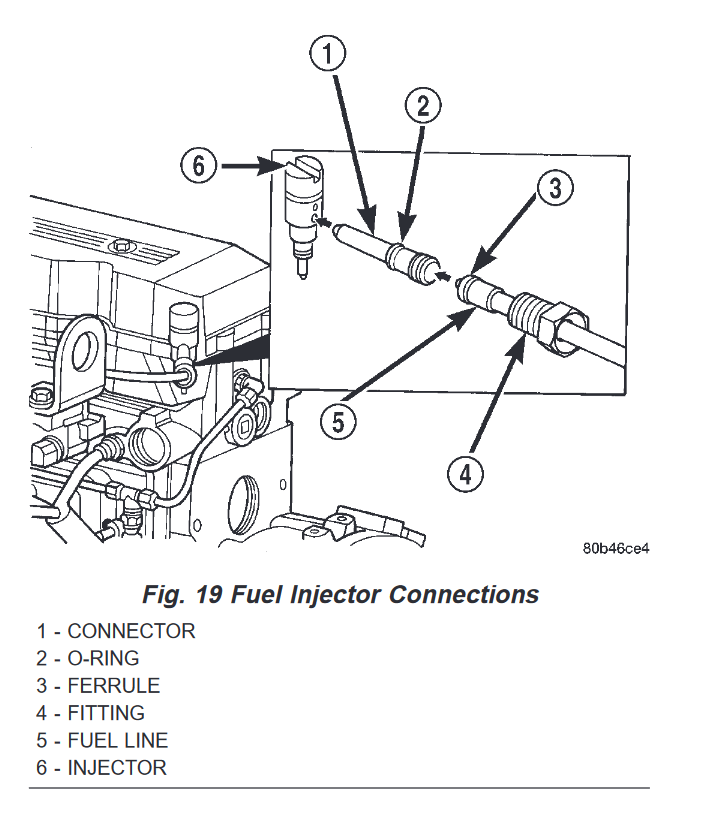

I apologize for any confusion with my instructions. Please disregard my initial instructions. As I recall now, I used the method for installing injectors from the service manual for a common rail fuel system. I have more confidence that this method will provide a more reliable leak-free connection at the intersection of the connector tube and the injector opening. The injector hold down torque is the same for both fuel systems. It's just how you get there is different. The connector tube nut torque is 28 ft/lb on the VP44 fuel system, versus 37 ft/lb on the common rail fuel system. While I am writing this, I see that @Doubletroublehas posted. His explanation works well, too. From the 2004 FSM (installing injectors): (a) Install fuel injector holdown clamp (mount- ing flange) bolts. Do a preliminary tightening of these bolts to 5 N·m (44 in. lbs.) torque. This preliminary tightening insures the fuel injector is seated and centered. (b) After tightening, relieve bolt torque, but leave both bolts threaded in place. (c) Install high-pressure connector and retaining nut. Do a preliminary tightening to 15 N·m (11 ft. lbs.) torque. (d) Alternately tighten injector holdown bolts to 10 N·m (89 in. lbs.) torque. (e) Do a final tightening of the high-pressure connector and retaining nut. Tighten to 50 N·m (37 ft. lbs.) torque (28 ft/lb for VP44 injectors). - John

-

Any helpful tips on doing injectors / valve lash adjustment?

It has been awhile since that repair, but if I recall correctly, the nut that is torqued for the fuel line connection is also the same nut that pushes the crossover tube (connector tube) into the injector inlet port, so, yes, it is necessary to torque all of the fuel lines. If there is a leak at a fuel line connection, it is usually because there is a small piece of foreign material or a scratch / burr on the mating surfaces. This is a fairly common problem, but usually loosening the fitting and slightly moving the tubing as the fitting is retightened usually will stop the leak. If a leak occurs, it is likely to be just a weep. Sometimes, the weep will disappear on its own. - John

-

Any helpful tips on doing injectors / valve lash adjustment?

This link should get you to the procedure for injector R&R. https://mopar1973man.com/cummins/articles.html/24-valve-2nd-generation_50/51_engine/59_fuel/fuel-injector-install-removal-r5/?do=getLastComment&d=4&id=5 My OEM injectors came out easily - even with 303,000 miles logged on them. The washers stayed on the injector. I think I used a flat blade screwdriver to break them loose and then they basically came out by hand. It is very easy to bar the engine over using the alternator pulley. I believe a 15/16" socket works well. Be careful to not bend any fuel lines. Loosen or remove fuel line brackets beforehand. Remove crossovers tubes before lifting out an injector. The crossover tubes use a steel to steel compression contact that fits into a machined slot in the side of the injector. If the crossover tubes are not pulled back or removed, the injector will not come out. When installing the new injector and new / used crossover tube, the tightening sequence is very important. Be sure to understand the method, otherwise you are likely to have a high pressure fuel leak. Basically, install the injector with the fuel entry port aligning to the crossover tube entry. Slide the crossover tube into its bore and ensure the tip engages into the injector fuel entry port. Tighten the injector bolts to a low torque value, then install and tighten the associated crossover tube to its torque value. This will force the injector to rotate and center the compression connection at the injector fuel entry port. Then perform the final torque on the injector. Just take your time, so you don't miss any steps. - John

-

APPS sensor adjustment and reset difficulties.

Here is another link. This one is W-T's version. I like his - he uses bigger words. - John

-

APPS sensor adjustment and reset difficulties.

I think this will link you to the Mopar1973Man's version of the W-T wiring modification. https://mopar1973man.com/cummins/articles.html/24-valve-2nd-generation_50/51_engine/electrical/w-t-ground-wire-mod-simplified-r574/?do=getLastComment&d=4&id=574 The alternator output wire is in a loom that crosses in front of the engine eventually arriving at its connection at the power distribution center. It is a large gauge wire connected to a 140 amp fuse at the entry of the PDC. Remove this wire from the fuse and connect the wire to the positive terminal on the passenger side battery. I recommended installing a 150 amp fuse in-line near the passenger side battery. This fuse will prevent a fire should the the alternator ever have a serious short ciruit to ground. I left my alternator output lead long until I establish a permanent mount for the in-line fuse. - John

-

APPS sensor adjustment and reset difficulties.

@Zach B, just FYI, note the ND emblem in the center of your first photo. That stands for Nippondenso. - John

-

Vacuum pump issue I think

That sounds more like it since you are located near sea level. The vanes in those pumps are lubed with a dedicated engine oil line. This is why those vacuum pumps are so efficient and why they rarely fail. Good to hear you have it fixed and the solution was simple. - John

-

Vacuum pump issue I think

@leety, I checked the on-line Banks vacuum operated exhaust brake owner's manual for 98.5-02 trucks. Unfortunately, there is no information for testing the vacuum source in the troubleshooting section. However, there is information for the 04.5-07 trucks where a vacuum pump is provided by Banks. Here is part of what is stated, "Connect this hose to a vacuum gauge while keeping the other end connected to the Vacuum Pump. Make sure the truck is in park and start the engine. Measure the vacuum at 1900 RPM. The Pump should generate a minimum of 10 psi (20.4”Hg) of vacuum." I think your vacuum pump is fine. - John

-

Vacuum pump issue I think

It is too bad Banks didn't say what the minimum required vacuum is for the exhaust brake actuator cylinder. That would have been most informative. I think it would be a lot closer to around 15"HG. A faulty vacuum pump could be be a possibility for your problem, but I am inclined to think the problem is elsewhere - such as a vacuum leak or a faulty actuator seal (even though it supposedly tested okay). For example, the actuator seal may perform fine when cold and then start leaking when ambient temperature rises around the actuator. Or, vice versa. Also, the FSM really is not that clear as to what vacuum pressure should be at engine idle. The FSM states, "With the engine running, vacuum output should be a minimum of 25 inches, depending on engine speed." It is that clause, "depending on engine speed" that leaves me wondering what the real value should be at idle. If it is believed that at least 25"HG is required to make the exhaust brake fully operational, then vacuum operated exhaust brakes would not work in high altitude locations. Example: Leadville Colorado at just under 10,000 ft elevation - current barometric reading is 30.53"HG. Station pressure (the absolute pressure) is currently just under 21.00"HG. According to Banks the exhaust brake would not perform properly. I disagree - I believe it would perform fine. I have personally driven my truck over many 11,000 ft mountain passes and my vacuum operated exhaust brake (although a PacBrake) operated just fine. The vacuum pumps on our trucks may need a seal replacement or a coupler replacement, but the vacuum pump portion of the pump is pretty bullet proof. I have been using a vacuum operated PacBrake actuator cylinder for well over 400,000 miles on my truck (70,0000 while installed on a '99 truck and 367,000 on my current truck). I have gone through two actuator cylinders in which the seals were slowly destroyed by heat from the exhaust system. The early symptoms were always intermittent and / or sluggish operation. When I tested the cylinder using a vacuum hand pump, they would sometimes pass the test and sometimes not. Also, I recommend to not use worm-drive hose clamps on the rubber lines. They tend to distort and cut the lines they intended to seal, sometimes creating leaks. I recommend properly sized spring tension clamps - they handle vibration and thermal expansion / contraction very well. So, after saying all of this, I would make absolutely sure there are no vacuum leaks on your truck and I would get a second opinion on the performance of the vacuum operated cylinder. - John

-

4" resonators/mufflers to quieten down exhaust

In late October of 2015, my wife and I were finishing an East Coast Fall Colors Trip with our travel trailer in tow. We traveled though some southern states on the return portion of the trip. While we were passing through Arizona, I told my wife that I would like to stop at ATP in Irvine, CA to check out the engine thermal blanket kit available for our slightly noisy Cummins 2nd generation 24 valve engine. We arrived at ATP about mid-morning and I met the owner Tim Thompson and, as @Hutch24vstated - he is a great guy. He gave us a tour of his shop and introduced some of his employees. The shop is hard to describe. Basically, it is filled with employees operating commercial sewing machines (like long arm quilting machines, except heavier duty). He said he got the thermal blanket part of the business going because of the need for it in the car racing circuit. Now he does custom fitting on engine exhaust systems on the Coast Guard fleet of boats and ships. He also insulates engine compartments on high end motor homes - such as ones that celebrities drive to his shop and visit with him while his crew install the material. He said that Ernest Borgnine would stop in with a new motorhome every couple of years to have the engine compartment insulated and while he waited, he would visit with the crew for a couple of hours and telling jokes. The crew loved him. Anyway, Tim offered to make and install the whole kit (except for under hood) for $1,000 while we waited. We agreed. When the job was complete, we test drove the truck. We were only able to attain about 30 mph in the neighborhood. We left the windows down while we drove around, it was definitely quieter. I was trying to not be overly optimistic about the sound difference, after all, Tim told me the product is primarily used to minimize heat transfer. When we returned to ATP, TIm asked how we liked it. I told him that we didn't have the opportunity to do try it on the freeway, but it is a bit quieter in town. Here's the part that impressed me. He said it will be noticeably quieter on the freeway, but if I have doubts or I am not satisfied with the product, he would happily have his crew remove it and refund the money. He said he was serious about that statement and that there would be no hard feelings. My wife said, "NO! We are keeping it!" And that was that. On our trip back to Oregon, it was definitely quieter in the cab and as a bonus, my wife said the floor stays cool now when going up those long hills. One of the benefits so far has been the durability of the product. It is not supposed to degrade, deform, or lose its effectiveness for up to well over 2,000° F. So far, it has done its job well. - John

-

4" resonators/mufflers to quieten down exhaust

That thermal blanket looks familiar. Did you get it from Advanced Thermal Products? They installed a 5-pieces set on my engine. Helps with engine noise abatement, but really keeps the engine bay and passenger side floor much cooler. The blankets have been installed for almost 7 years and over 120,000 miles now. There is no sign of degradation of the material or the components the material covers. The initial cost was high, but for me, it has been well worth the expense. - John

-

My rear end stinks

Just be sure no one is watching..., you know, sniffing your rear end. - John

-

Fuel Return To Tank (not basket) Question

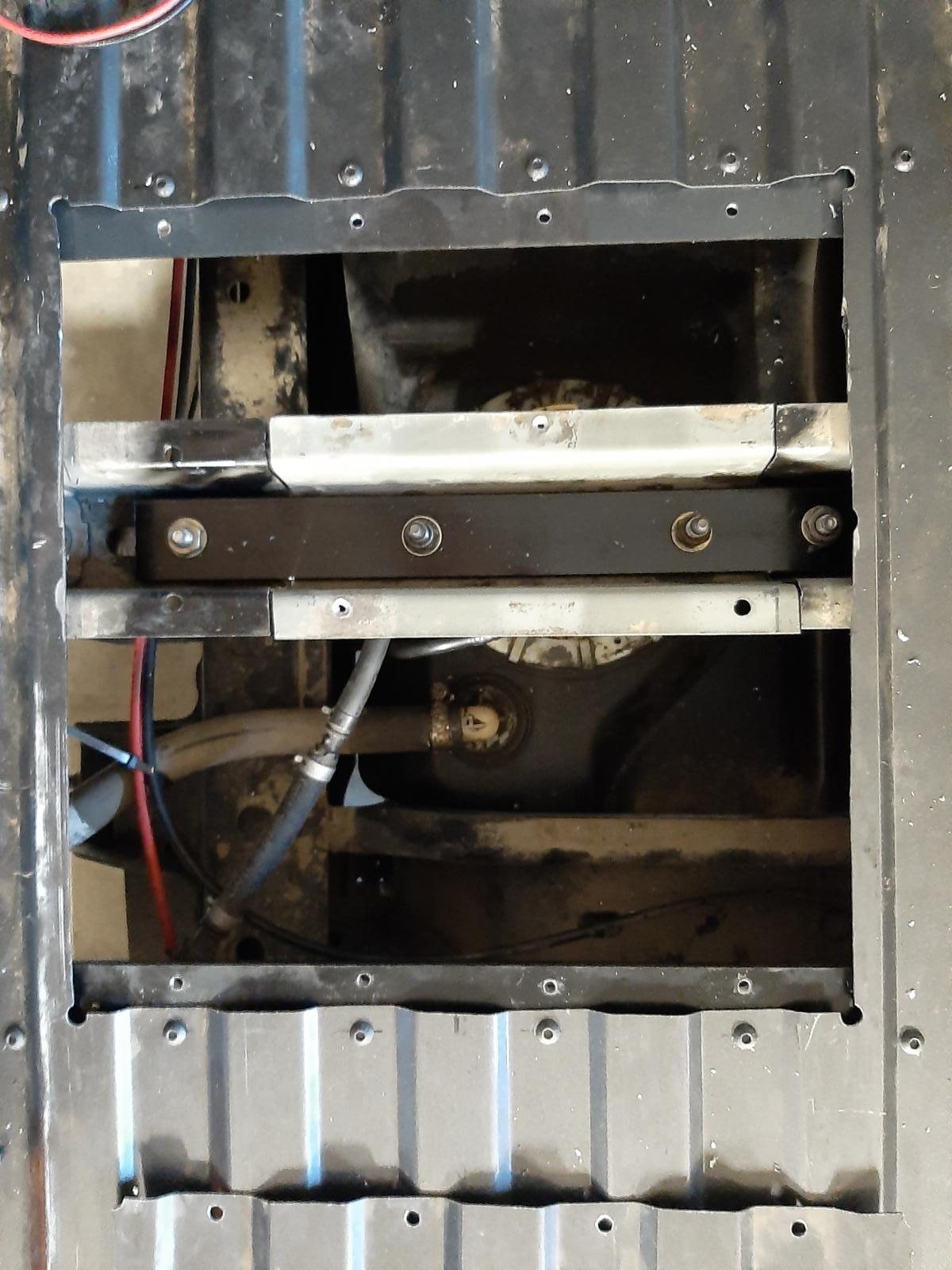

Yes. You will note the added flat bar to hold it into place in the second photo. As for drilling the pilot holes in the corners, I only drilled the easy one from the bottom - the other three were drilled from the top after some measuring. I spent some time figuring out which places I could use bolts and nuts for fasteners and which places I would drill and tap holes for easy fastener removal later. I need to extend the fuel suction line on my truck at some point. Now I don't dread doing the job - plus, the fuel tank can be full and it still will be an easy job to remove the fuel canister. I am considering writing an article for this modification, but it will be awhile before I can get to it. In the meantime if anyone has any questions about how to do the project, feel free to ask and I will assist as best as I can. - John

-

Fuel Return To Tank (not basket) Question

Since I figure I will have my truck forever, I just modified the bed to allow access. The top of the photo represents the front of the truck. Many holes are drilled and tapped for easy removal. So much easier to work with! - John

-

Lift pump shuts off after engine starts

Here is just one of many vacuum gauges that would be suitable. Just make a temporary tee fitting to work for your test. You don't necessarily have to drive the truck. Just bring the engine rpm up to 2,000 and hold. This will bring the tank return flow to about 28 gph via the internal vane pump. Observe the vacuum gage reading. As far as a permanent fuel pressure gauge setup, I have no recommendation. I use a warning light mounted in the dash. The warning light is triggered by a low fuel pressure switch under the hood. I have never felt a need for a fuel pressure gauge inside the cab. I have also added a fuel line with a check valve that loops around the lift pump. This means that fuel flow to the VP44 inlet will not be disrupted in the event of a lift pump failure. The VP44 internal vane pump will continue to draw fuel from the tank and around the disabled lift pump. There will be no disruption of engine performance or fuel return flow to the tank. I have proven this with my own truck on a 28 mile roundtrip to town with the electrical supply disconnected to the lift pump. During the trip I applied full throttle several times, set cruise control for a few miles, and stopped / started the engine several times. No change in performance. Of course, the low fuel pressure warning lamp stayed on the for the whole trip (no lift pump pressure), but there was no cause for concern. - John

-

Fuel Return To Tank (not basket) Question

I used the same as above. No need to drop the tank. - John

-

Lift pump shuts off after engine starts

The VP44 fixed displacement internal vane pump is the only pump that controls flow through the VP44 and over the 14 psi overflow valve returning fuel to the fuel tank. Because the vane pump is fixed displacement, it will always flow more fuel as engine rpms are increased, therefore more return fuel. None of the vane pump's operation has anything to do with the lift pump. The lift pump's only purpose is to supply more fuel to the VP44 inlet than the internal vane pump can use. That is all. Nothing else. Because the lift pump supplies more fuel than the internal vane pump can use and the internal vane pump is rpm dependent, there will always be a positive pressure at the VP44 fuel inlet. The fuel pressure at the VP44 inlet will be the highest when the engine is at idle and the lowest when engine is at full rpm under full throttle. I have logged similar miles on my truck (367,000) and over 270,000 miles on a replaced VP44. My frame-mounted FASS 65 gph lift pump pressure is the highest at idle - 12 psi. It is 6 psi at under near full power. The 6 psi is of no concern. It is a positive pressure at the VP44 inlet. I operated a OEM relayed in-tank lift pump (modified under warranty by Dodge) for over 150,000 miles on the replaced VP44 - that lift pump produced 6 psi at idle and 3 psi under near full power. Again, 3 psi is a positive pressure - no concerns. I think you are on the right track with getting a reliable gauge setup and installing a frame-mounted lift pump. The frame-mount pump will allow the lift pump to behave like a pusher pump instead of a puller. Most of the time the fuel level in the tank will be at or higher than the lift pump inlet. Lift pump pressure should be steady at any pressure reading. You mention you still have concerns with blockage. I think it would be worth installing a temporary vacuum gauge at the lift pump inlet (on your frame-mounted lift pump) to measure the pressure drop. If there is no blockage, I would expect to see a minimal vacuum reading (less than 5" hg) while driving the truck. I just noticed that you are reading the 14 psi overflow article. A good read, but in my opinion this valve is not your problem. The operation of this valve is largely misunderstood. It very rarely fails - if ever. - John

-

Squeak/Screech noise in reverse only

Sometime problems get figured out just by chance. If you would have kept track of which side the adjusters came from, then you would not have posted the above statement and you would have likely re-installed the adjusters on the same side from which you removed them. This, of course, would have been wrong and brake performance would have deteriorated over time as the lining wore. So, in this case, it turned out to be a good thing that you didn't keep track of which side the adjuster came from when you brought them into the garage for cleaning. Now you have good performing brakes and you did the work yourself and you probably learned a bit along the way. Good job. - John