Everything posted by Tractorman

-

Problem with idle cut off

They are stock OEM injectors - correct? John

-

BAM, VP44 may have bit the dust.

Only 128,000 miles on the truck? What year is the truck? The fuel pump relay that I am referring to is for the VP44 injection pump. It supplies power directly to the fuel solenoid inside the VP44. It is labeled "Fuel Pump" or "Fuel Pump Relay" and it is located in the PDC. The OEM lift pumps are not relayed - they receive power directly from the ECM. I am the original owner of my truck. I started having problems with the VP44 (P2016 code) at 65,000 miles. A year later at 87,000 miles, I had the VP44 replaced under warranty. Additionally, a relayed lift pump was fitted into the fuel tank, also covered under warranty. I have since logged over 310,000 miles on the re-manufactured VP44. Also, worth mentioning is that for the last 310,000 miles, lift pump pressure has never been over 12 psi and usually averages about 5-6 psi, so lift pump pressure really has never been causing the problems with the VP44. Assuming your VP44 has failed and you are running the original VP44, there really is / was nothing you were going to be able to do to make your VP44 last longer. There was a lot of misconceptions regarding the VP44 injection pump failures in the early years and those misconceptions have carried on through the years. The lift pump was the least of the problems, or not even a problem at all. Bosch recognized that there were issues with the early VP44's. Some of those were: rotors not de-burred properly during manufacturing resulting in rotor seizure, poor solder connections in the PSG, under-designed diaphragm for absorbing high frequency pulses, metallurgy problems with timing piston / bore, to name a few. The good part is that Bosch corrected all of those issues with many revisions during their VP44 re-manufacturing process. Unfortunately, other re-builders became involved, but did not necessarily follow through with the Bosch updates. That resulted in casting a continued dark shadow over the VP44 injection pump reliability. From an authorized Bosch re-builder, the Bosch re-manufactured pump comes with a new PSG calibrated to the pump. The combined unit is operated on the Bosch 815 test stand for three or four hours of rigorous testing. This is the pump you want to buy. They have proven to be reliable. John

-

BAM, VP44 may have bit the dust.

Well, dang! Did you get good life out of the pump? Those three codes narrow things down a bit. By chance, did you try swapping the VP44 pump relay with another like relay? Doesn't cost anything to check. John

-

Bad intermittent drive line vibration at highway speed

I think he said that he did a road force balance on all of the rear tires. John

-

Problem with idle cut off

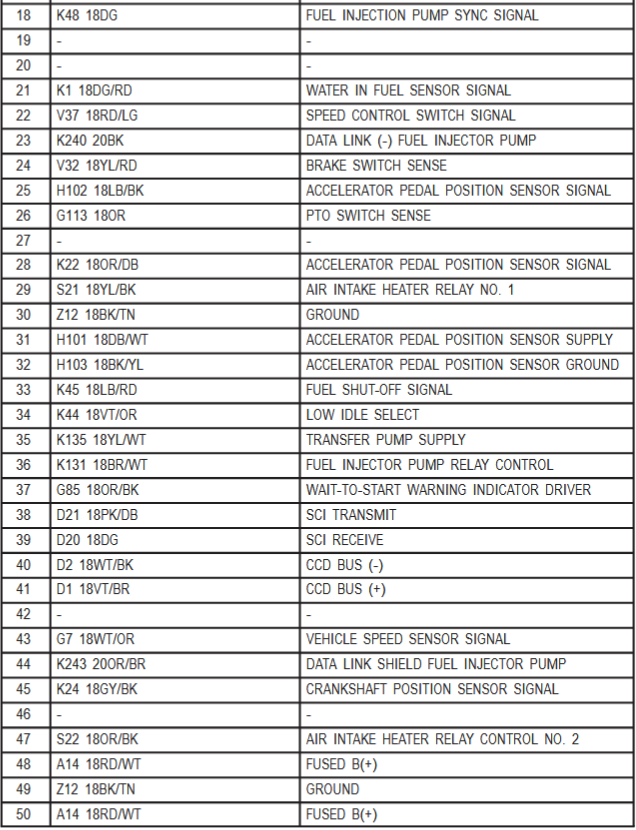

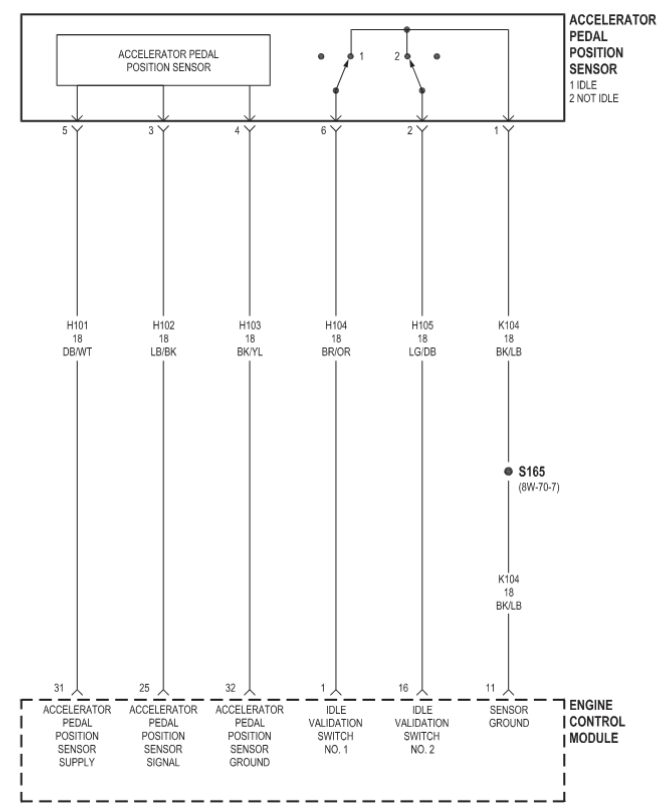

The VP44 trucks were only made from '98.5 - '02. There could be a discrepancy in some wiring colors, but not likely. Just pick a row that looks like the colors match the pinout row and you will know right away whether or not you are on track. For example, if the LB/BK wire APPS signal from the ECM pin #25 was a different color than the diagram, then the wire will be the same color where it connects to pin #3 on APPS connector. Just be patient - it will begin to make sense. John

-

Problem with idle cut off

That's always a bit confusing to me, as well. I verify by identifying some of the wire colors on the wire connector side to match them with the pin number. This will confirm the orientation for identifying the correct pin number. John

-

Problem with idle cut off

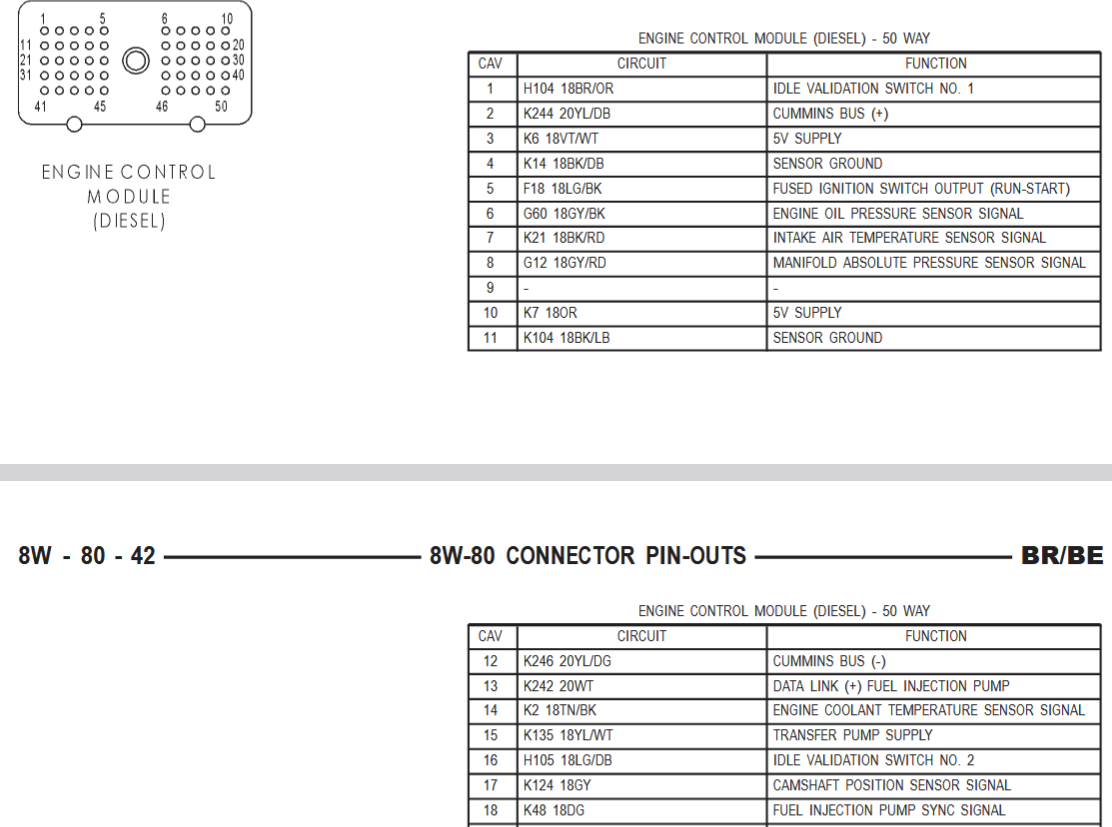

Shown below are the pinouts for the ECM. Perform continuity tests (using the ohmmeter setting) on circuits that you wish to check. Be sure there is NO POWER supplied to any circuit being tested. For example, the APPS communicates only with the ECM. You could perform continuity tests on all of the connecting wires (see bottom photo). John

-

Problem with idle cut off

Also, unplug the ECM and check for any pins that may be pushed back. John

-

Problem with idle cut off

Ok, I understand. That should rule out a torque converter issue. It does make sense that something changed during the replacement of parts. If I recall, you have to move the throttle assembly to the side in order to access all of the injector lines. Is it possible that the throttle is binding and not letting the throttle fully return? If the throttle does not fully return every time, it is possible that the idle validation switch is not activated in the APPS circuit. It must be activated for the ECM to know to take over idling the engine. Engine idle is controlled by the ECM only - no other inputs. John

-

Problem with idle cut off

Don't focus on this. You could be right, but you also could be wrong. Another scenario (mentioned by @Mopar1973Man ) that could cause your issue is a low stall speed transmission torque converter. Larger injectors allow much more fuel to flow, so when the engine comes to idle, the ECM has to cut way back on fuel delivery (not so much with stock injectors). So, things like a low stall speed converter, or engaging the clutch with a manual transmission, can cause idle fluctuations while the ECM tries to correct. John

-

High idle when hot out

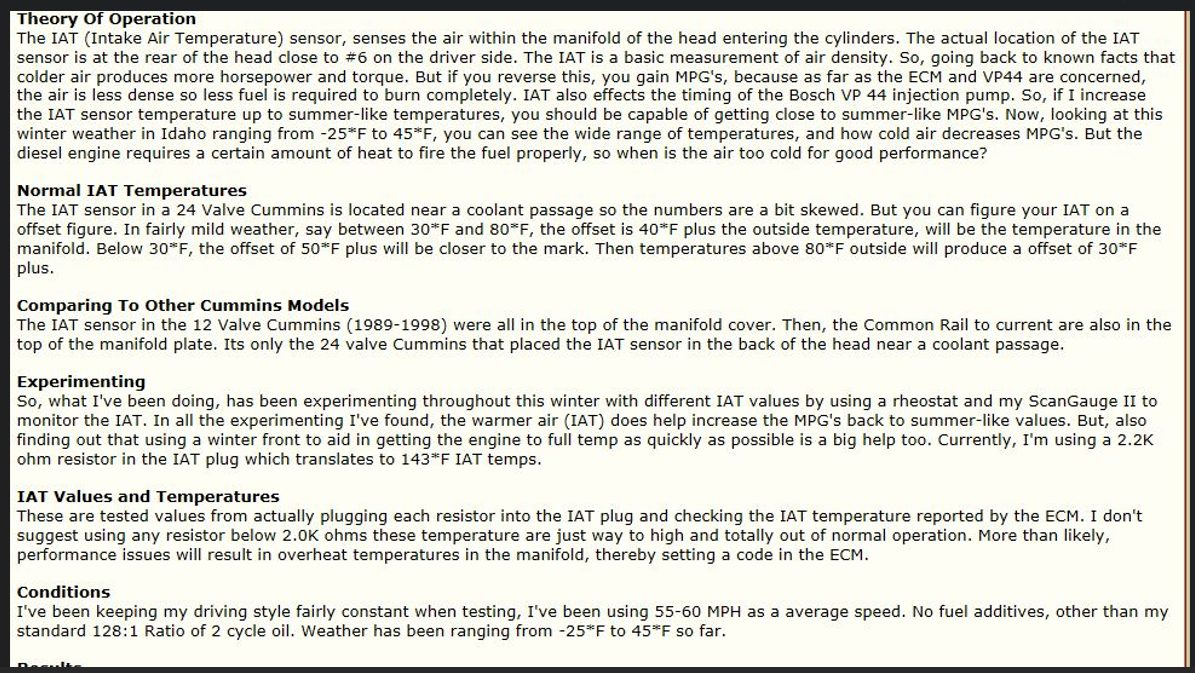

You asked, "What are the values of the potentiometer that you use? I like that idea quite a bit." Back in 2016, I tried a fixed output resistor of abut 2,200 ohms, but it set a code and I didn't have a scanner at the time to read the fooled temperature. So, I just bought a variable resistor and installed it (trial and error) and it worked. Later I purchased an OBDLink and dialed in the temperature of 143°. It is easy to make the modification - just buy a couple of Deutsch 2-pin connectors with pigtails from Amazon for the wiring. John Here are @Mopar1973Man 's observations.

-

High idle when hot out

I think you are correct. I am basing this on the fact that I am using an IAT fooler (potentiometer) that is adjusted to keep the IAT reading at a constant 143°F. I can tell the ECM responds to the setting because it does not advance the timing aggressively, as it does without the IAT fooler. I don't have the high idle switch on my truck. Maybe it would be worth completely removing the high idle switch to see if the symptoms change. John

-

Different thickness injector washers?

This photo is of a typical 12 valve engine. No crossover tubes. Fuel line are connected directly to the injectors, so injectors can be shimmed. John

-

Different thickness injector washers?

My guess is that if you change the height of an injector on a 24 valve engine, the connection point of the crossover tube to injector will be misaligned. John

-

Intermitten P1689

That's good news, as well as an inexpensive fix. I should replace my fuel pump relay just because it is the original and has logged almost 400,000 miles. No sense of waiting for it to become a problem - especially, an intermittent problem. Thanks for posting the fix. John

-

Problem with idle cut off

Glad to hear that everything worked out and thank you for reporting back. John

-

Bad intermittent drive line vibration at highway speed

It may seem like there is no interest here because you are not getting any more responses, but I think that we are at a loss of how to fix the problem. I would focus on the above paragraph since the truck was fine before the tire change. Did you replace all six tires, or just the four on the rear? Did you replace tires and wheels, or just the tires? Did you do any other repairs at the same time? Are the wheels centered on the hubs? John

-

Pilothouse/RAM3500 build

You certainly do good work!! John

-

1689 with HVAC

Were these readings with the P1689 code set or cleared? Were the readings different with the code set and with the code cleared? John

-

1689 with HVAC

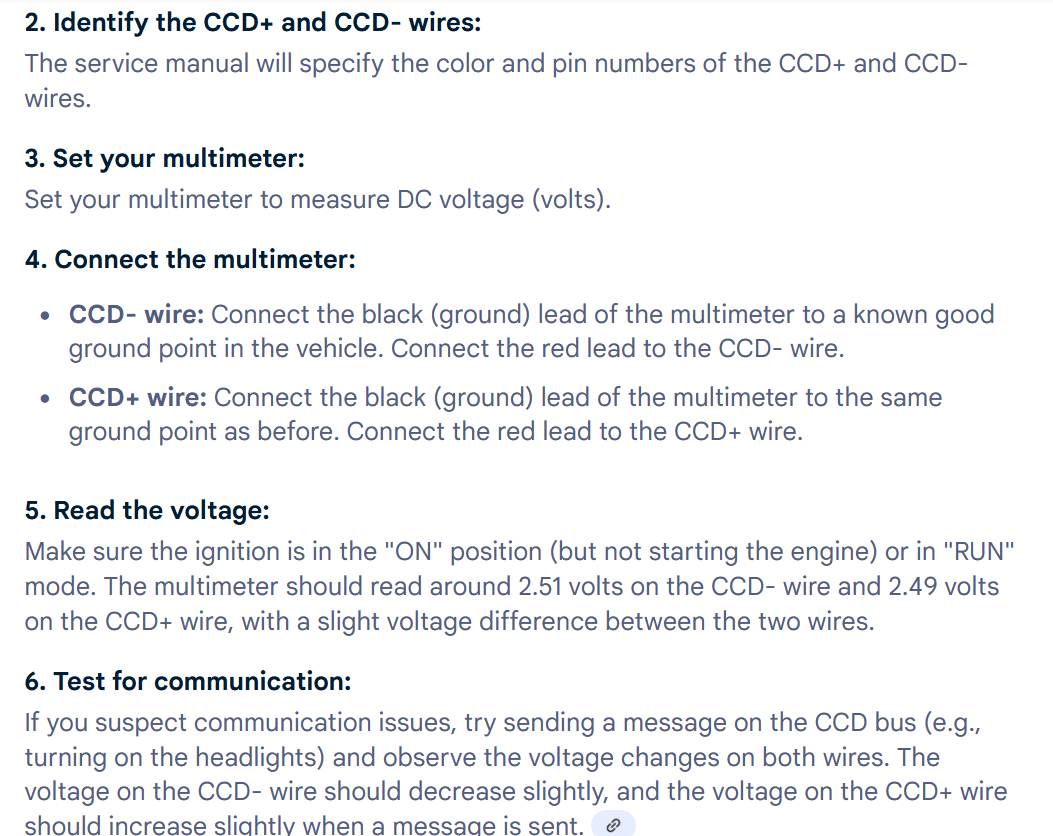

I tend to agree with that conclusion, but I wouldn't rule out a ground issue. Poor grounds can cause irrational behavior and can mess with your mind. Have you tested the CCD circuit (as described below) while you are making changes in the blower motor circuit? It would be interesting to see if CCD voltage readings reflected a change when the "no buss" message showed. John

-

1689 with HVAC

It is only the blower motor relay coil (#85 and #86) that draws from this fuse. That current draw is less than 200 milli-amps. The switch portion of the relay (#30 to #87) carries the full load for the blower motor - #12 40 amp fuse in the PDC. Most likely you have a short circuit to ground downstream of the mirror heater switch / relay that is causing the blown fuse when you activate the mirror heater switch. At least you now know where to begin looking for this problem. Back to the "no buss" message issue - I will have to think about that some more. John

-

1689 with HVAC

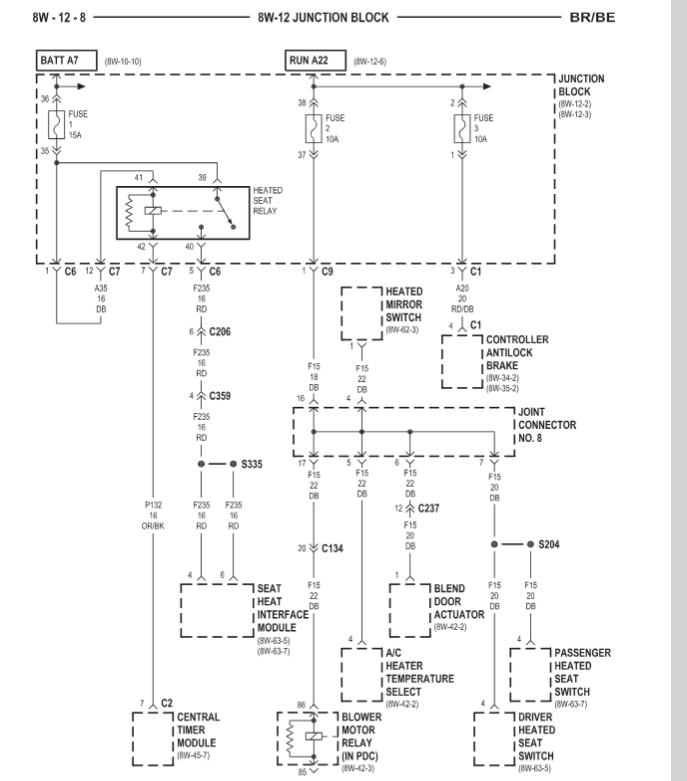

Since you mentioned this, I did find a correlation between the heated mirror switch and the blower motor circuit. The 10 amp fuse #2 in the junction block feeds Joint Connector #8 which connects to the mirror heater switch and some other components INCLUDING connection to the coil of the blower motor relay. Was it the #2 fuse in the junction block that blew? John

-

1689 with HVAC

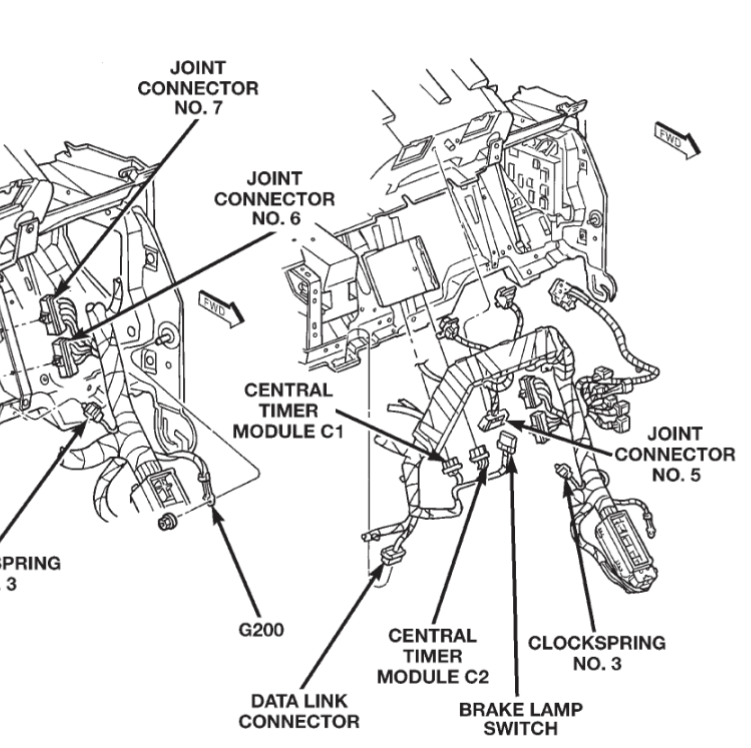

From the FSM, the blower motor and HVAC controls ground at G200 which looks like a stud behind the kick panel. Hopefully, this illustration can help (unless, of course, you have already seen it). John

-

1689 with HVAC

This is probably clear in your mind, but it is confusing to me. I am not quite sure of what you are saying. Can you write it differently? Example: Saying "no buss" message can mean something different than saying no buss message. Maybe you can say, "I am getting the P1689 code "no buss" message"; or "I am no longer getting the P1689 code, "no buss" message." Thanks, Edit: I reread your posts and I think I know what you are saying. John

-

1689 with HVAC

Sounds like you are on the right track! Keep us posted. John