Everything posted by Tractorman

-

2006 Dodge Ram 3500 - Thor Project

Pretty much the same as our VP44 engines. When my VP44 replacement and in-tank lift pump mod was done by the dealer under warranty, it was replaced with the same in-tank pump that was used for the common rail system. I agree - that's why I am recommending temporarily plumbing the lift pump to a remote fuel container and then going for a test drive. - John

-

2006 Dodge Ram 3500 - Thor Project

The lift pump pressure falling to zero at WOT may be trying to tell you something. I think it is time for a different approach. I would rig a five gallon container with fuel supply and return. I would anchor the container in the bed of the truck and go for a test drive and document the results. - John

-

47RE kicking out of O/D

@TCMagnum, Good job determining that that it is actually downshifting to 3rd gear. I don't think you have an AC noise issue, although performing the W-T ground reference mod would be a good idea, if you haven't done that already. Usually, AC noise affects torque converter lockup stability which is the problem most people have. When the transmission does an unwanted downshift, does the torque converter lock up, or does it stay unlocked? What about the code - P0122 Accelerator Position Sensor (APPS) Signal Voltage Too Low, is it still there? If it is, I would get that cleared up first. - John

-

Pilothouse/RAM3500 build

I had a feeling that you would go back to the first running board after you had better results with the second running board. That's not "OCD" - that's a "good decision"! - John

-

Track Bar

You're welcome. I think you set your toe-in a bit aggressive. You will likely wear the outside edge of the front tires and the truck won't handle as well as it should, especially going into and coming out of curves. With the Y type steering linkage, the toe-in should very slightly inward - no more than 1/16th inch. With T-type steering the recommendation is zero toe-in. It appears that you have the Y-type steering. Good job marking the jam nut positions. - John

-

Track Bar

Let me know what you think of it. After I set the jam nuts, I marked the nut-to-sleeve and nut-to-track bar with bright orange torque seal. It makes for an easy quick visual inspection to know that the nuts are staying tight. - John

-

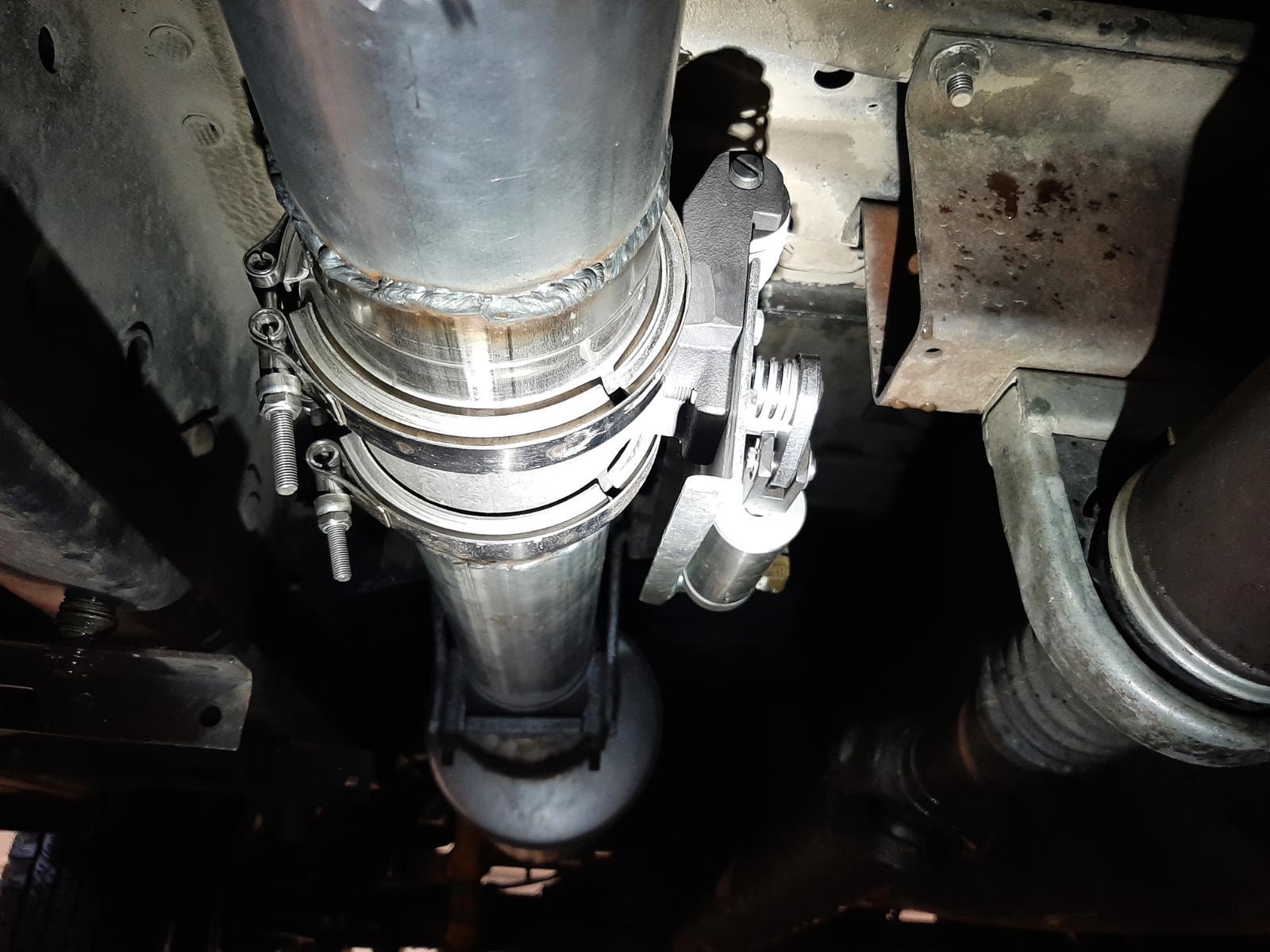

Staying With OEM 3" Exhaust System

A while back I posted some concerns about how long an OEM muffler would last on the OEM exhaust system. I was mainly concerned if back pressure could be an issue as the muffler aged. I never really did get a definitive answer, probably because most people had moved up to 4" and 5" exhaust systems from the turbo back with either an aftermarket muffler, or no muffler at all. So, I decided to do a little research on my own. I found a general statement that indicates Cummins does not want to see any exhaust back pressure above 3 psi. I connected a gauge to the 1/8" port on the exhaust elbow and strapped the gauge onto my windshield wipers and then went on a test drive. I made a few tests in which the engine was under full power (30 psi boost) at 2,000 rpm. The back pressure averaged 3.5 psi - not terribly high, but higher than the 3 psi limit. So, I knew I was going to get a new muffler - but which one? This was back in November when I was contemplating all of this. What muffler to buy? Should I go to a 4 inch exhaust? What about the resonator? I really wanted to keep the truck exhaust system quiet. Then I ran across a Black Friday special where PacBrake was offering a 4" in-line PRXB exhaust brake complete with an air compressor kit for $850. They never had sales like that before. I already had a vacuum operated PacBrake that has logged over 460,000 miles - 70,000 miles on my previously owned '99 truck and the rest on my current truck. But, the PRXB exhaust brake has much better performance below 1500 rpm due to a design change. Well, I bought it. Now – what to do with the exhaust system? One thing for sure, I wanted the system to be quiet. I finally decided to remove my vacuum operated exhaust brake, keep the three inch OEM exhaust system, remove the resonator permanently, install the PRXB 4 inch in-line exhaust brake, and replace the muffler. The decision as to which muffler to install was made easy through a fellow Turbo Diesel Register member who installed a Walker SoundFX 18853 Direct Fit Exhaust Muffler on his ’99 truck with high mileage. It turned out to be an excellent choice. Since the OEM exhaust system runs a short piece of 4” exhaust pipe between the removed resonator and the muffler, this is where I installed the in-line PRXB – just upstream of the muffler. The end result…, even quieter inside the cab under all engine rpms (with or without use of exhaust brake), much better exhaust braking below 1500 rpm, and 2 psi exhaust back pressure compared to the previous 3.5 psi. Plus, the turbo now spools about 100 rpm earlier in the rpm range. I am glad that I stayed with the OEM 3 inch exhaust and an OEM style muffler. I am hoping that this post may help anyone who wants to stay with the OEM exhaust system, but still get a little better performance without the additional noise. - John

-

Track Bar

@Threadzy, I just edited my post with some additional information on the track bar. - John

-

Track Bar

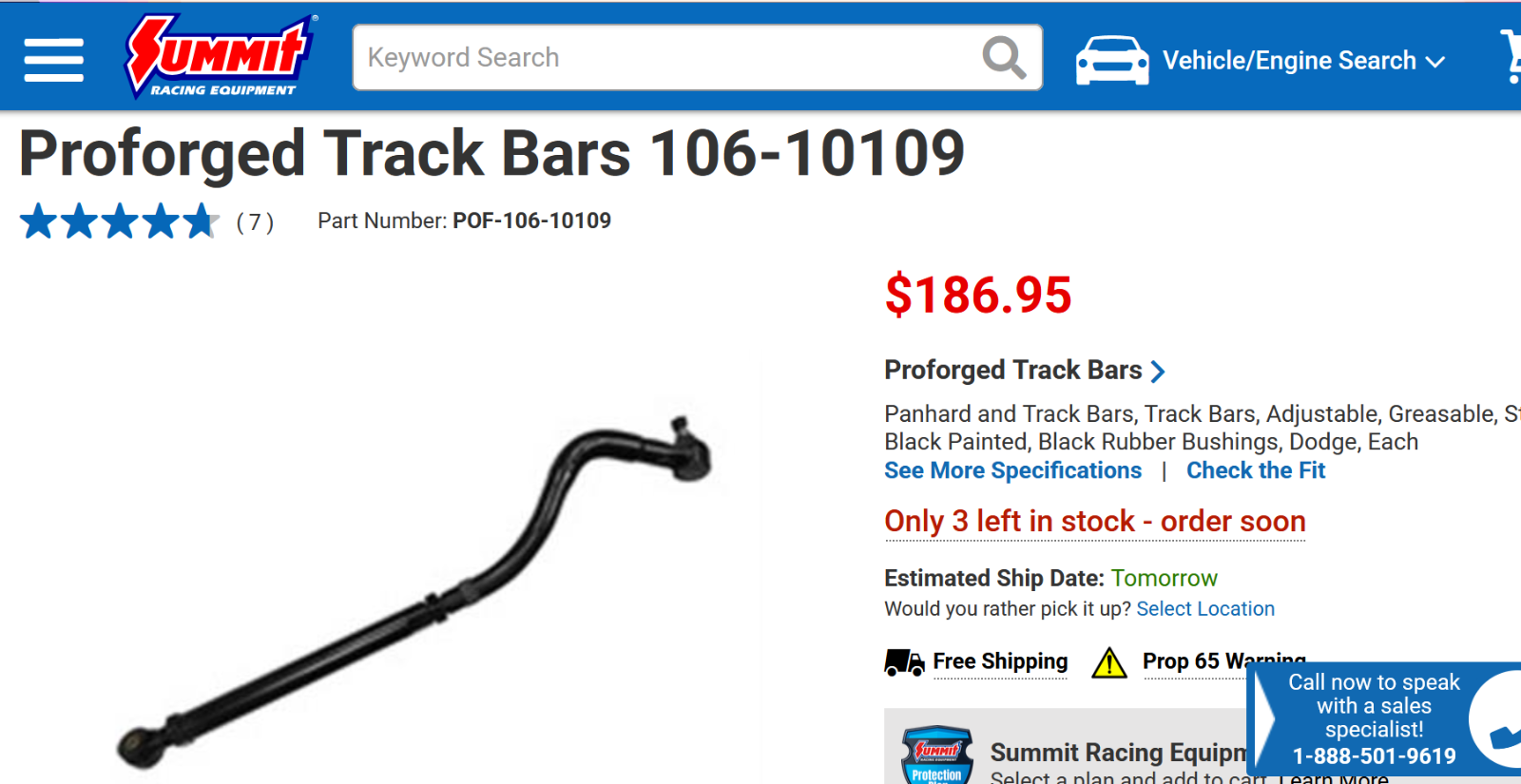

This is the track bar I just put on my truck - called Proforged. It is adjustable (after installation), heavy duty, and has an excellent seal on the ball joint, AND it's reasonably priced. I have only logged 22,000 miles on mine, but I think it is going to be a keeper. There are several sources to purchase them. - John

-

Track Bar

Also, without a dense rubber bushing on one end of the track bar, every pulse of energy generated from the road will transfer through the track bar to the frame, then the body, then to you. I don't think you would like that. - John

-

Hi everyone

Welcome to the site! It's great to see someone having the insight to buy a troubled truck and turned it into an affordable, reliable work truck. - John

-

Is my grid heater dying?

Just curious, are you replacing the original OEM style, and what are you replacing them with? I just replaced uppers and lowers last week (395,000 on OEM arms). I replaced with OEM style complete arm assemblies. I put the old ones in a vise and one by one slipped a large pry bar into each of the holes to see how much flexing was going on. They were all tight, so I didn't expect to see much performance difference with the new ones. However, I was wrong, the new ones performed much better. Before I started the repair, I did notice on one of the lower bushings that one end of the outer steel cage was no longer pressed tight into the control arm. This is what triggered the idea of replacing all of the control arms. Using the same caster adjustment that I had previously used, I set the caster to maximum on the right control arm and then I set the caster to just slightly less than maximum on the left control arm. I did this cross caster adjustment to accommodate for road crown. It turned out great. Just did a 500 mile road trip and between @Mace's power steering pump mod and the new control arms, the truck handles excellent. Very stable, tracks straight, and tracks in and out of curves effortlessly. - John

-

ECM or something else?

Sorry, I missed that in your original post. That tells me that you are NOT having a fuel or air in the fuel issue, which is what you are already thinking. So, you could very well have an issue with the ECM / PCM as you stated, or you could be getting a severe voltage drop at the PCM, ECM, or PSG on the VP44 while the starter is cranking. I would think that a code would be set, but not necessarily. - John

-

ECM or something else?

When I am troubleshooting difficult issues, I try to eliminate things that may contribute making troubleshooting harder. For example: if your fuel tank is half full or less, then I would go fill the fuel tank. If the engine now starts easier, then you know that fuel has been draining back and drawing air into the system. The fuel can still drain back, just not as easily with a full tank. Since this is a new to you truck, have you checked to see if there are signs of fuel leaking on the banjo fitting and T-fitting on the back of the head? A leak here will definitely cause hard starts, especially if the nose of the truck is parked up hill. The used tubes will still be in a different rotational position than when you removed them. Did you try my suggestion? - John

-

ECM or something else?

Have you push-started the truck with the same results BEFORE you tried starting the engine with the starting motor? If not, the engine may have coincidentally been ready to start during the push-start. After a night of setting, try doing a push-start without use of the starter beforehand. If the engine starts right away, this could indicate that there is an excessive voltage drop to the ECM or to the VP44 solenoid valve when the starter motor is cranking the engine, consequently, no fuel. If the engine still doesn't start right away, then this is not likely a cause. As far as the one injector line that is leaking, it is not unusual a line to leak at that connection point with new crossover tubes. Each injector line seals as a metal to metal sealing connection at the crossover tube. The new crossover tubes may have a slightly different surface sealing area shape than the old crossover tubes. Try loosening nearby clamps and then loosen the offending injector fitting. As you are re-tightening the nut, try rotating the line back and forth slightly while maintaining some friction using the nut. The objective is to grind the two mating surfaces together to smooth out any surface irregularities. Don't be aggressive. - John

-

ECM failure

I believe that should be below .050 volts AC, or below 50 milli-volts AC. From Moparman's video: - John - John

-

Power Steering Pump / Vacuum pump Conversion

I purchased the Standard Motor Products vacuum pump - not sure about the quality. While performing these modifications, I also replaced my original vacuum operated exhaust brake (PacBrake) with an in-line PacBrake PRXB for better performance at low engine rpm. It uses an air cylinder, so the only vacuum load I have now is HVAC and the CAD unit on the front axle. The old vacuum operated exhaust brake served me well - 70,000 miles on my old '99 truck and an additional 393,000 miles on my current '02 truck. It will begin a new life on a site member's 2002 truck next summer. Is the Dorman vacuum pump any quieter? What brand was you original vacuum pump. - John

-

4.11 Rear end

Since it is not in his signature, I will add that Moparman's transmission is a NV4500. I believe he is in 5th gear and running 245/75R16 tires in his photo. - John

-

4.11 Rear end

The stock tire (listed in the driver side door jamb) is 245/75R16. The trucks were actually sold with 265/75R16's. Your tire is slightly larger diameter than stock. Trucks came with either 3.55's or 4.10's. My truck has 3.55 gears and 245/75R16 tires. In direct 1:1 gear ratio (5th gear with my NV5600) , my tach reads about 2000 rpm at 50 mph. If I had 4.10's, the tach would probably read about 2200 rpm. Since you have an NV4500, you would need to use 4th gear (1:1 ratio) to make the same comparison. Include a minor adjustment for your slightly larger tire diameter. - John

-

Power Steering Pump / Vacuum pump Conversion

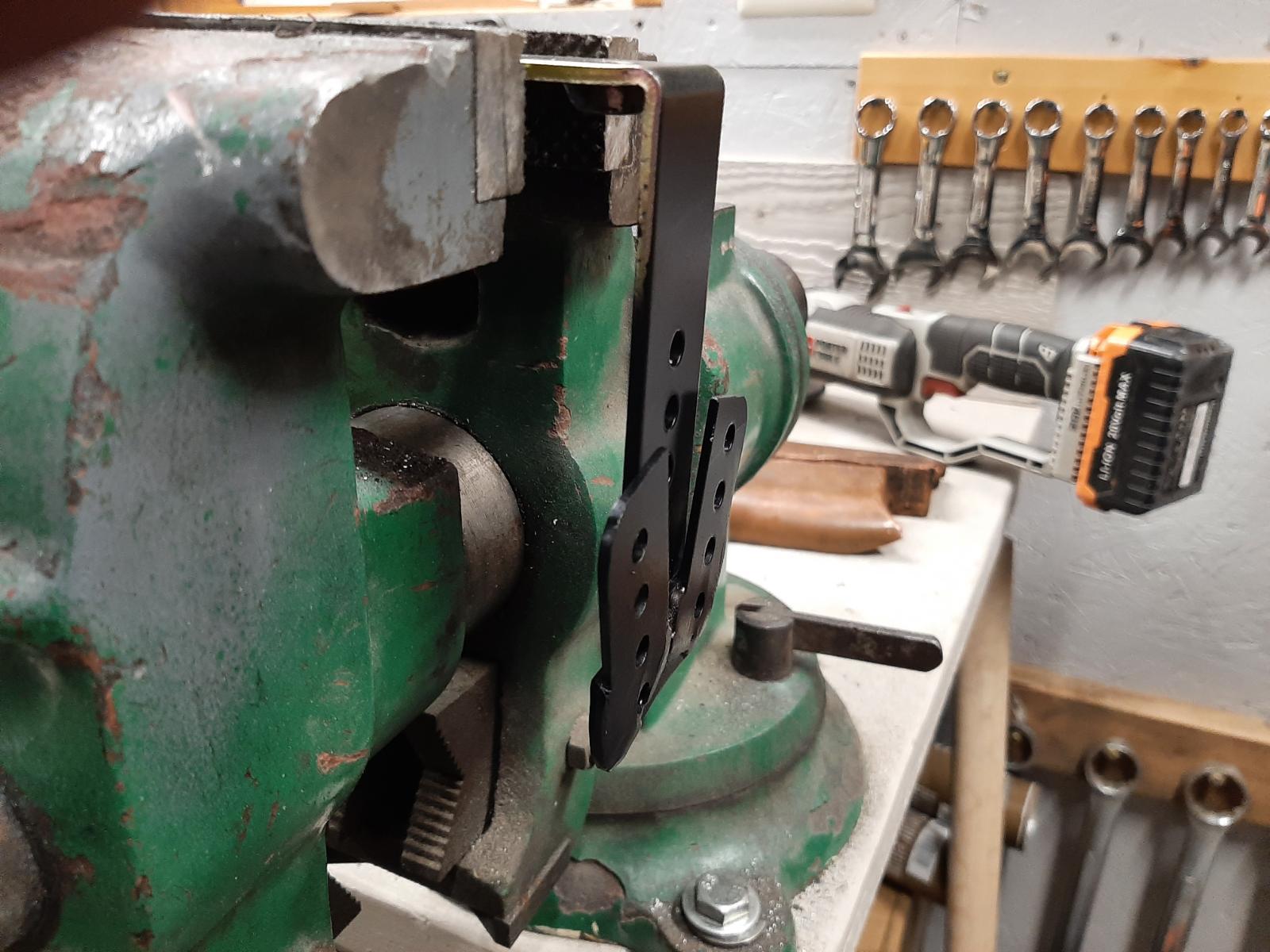

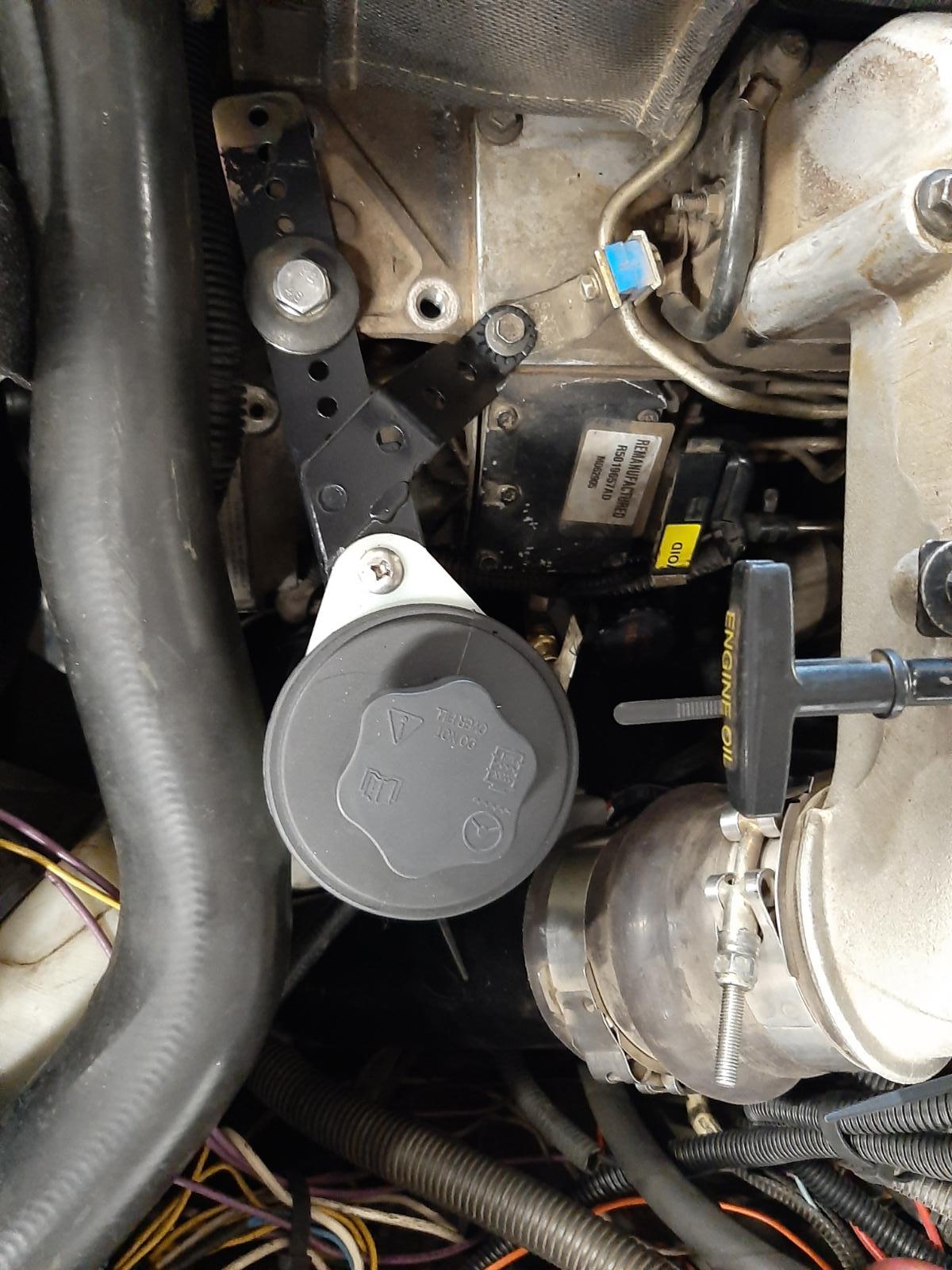

@mace, I have performed the power steering pump and vacuum pump conversion that you brought to this site. I hope you are still perusing the site and will see this. The time and effort spent on this project (and the APPS relocate) has been very worthwhile. Much engine space has been freed up and the power steering reservoir is right where it should be for easy fluid check / fill. The reservoir is like the brake master cylinder reservoir – you can see the fluid level through the reservoir. An unexpected benefit is that this direct mount power steering pump outperforms any previous power steering pump that has been on this truck. There is no more stopping of the steering wheel when the power steering is under high demand, such as when maneuvering in tight spaces, steering from stop to stop with little forward or backward movement of the truck. I started the project by finding a location for the new power steering reservoir, which was going to be right where the APPS assembly used to be. Then I built a mounting bracket for the reservoir (shown below). The first part of the bracket assembly is designed to let the weight of the oil and reservoir rest in the V slot. In the above photo, note the welded nut where the tab on the top of the reservoir is screwed into the bracket. In the photos below, more brackets are added to fasten the unit to the engine. Below is the new location for the reservoir in the engine compartment - lots of space available for mounting with the removal of the APPS and APPS mounting assembly. I don't have any photos of the actual pump mount, but the mounting is straight forward, especially with the addition of studs instead of bolts. Much easier installation the old vacuum pump / power steering pump combination was. I didn't use a gasket - just the grey Permatex RTV gasket maker. The one thing that Mace did that I should have done (which he clearly mentioned) is to have the pump suction fitting turned down on a lathe from 22 mm to 19 mm to match the 19 mm connection on the reservoir. Because I didn't do that, I have not-so-neat connections from the pump suction to the reservoir (another reason to not take a photo down there). @Mace, thank you again for making this possible. That’s all, folks! John

-

VP44 bracket and power steering pump

I understand why you would have been concerned. Sounds like everything went well. You will know everything is fine when that engine clatters to life and there is not a pool of oil on the floor. - John

-

VP44 bracket and power steering pump

Since I have never done what you are describing before, I would listen to hear if the VP44 gear dropped just a little as you remove the vacuum pump. The VP44 gear may have been resting on the vacuum pump gear. The VP44 gear should still remain timed, but you may have to lift the gear a tad when you re-insert the vacuum pump. Just speculation. More than likely the VP44 gear will be resting on a shoulder inside the case rather than the vacuum pump gear. I would rather approach this cautiously. - John

-

VP44 bracket and power steering pump

The VP44 is connected and timed off of the camshaft gear. The vacuum pump is connected to the camshaft gear, but not timed. There is no connection between the VP44 gear and the vacuum pump gear. You should be okay to remove the vacuum pump / power steering assembly. - John

-

Driving with 5th gear removed

Yesterday, I put your situation in the "911" section of the TDR, but so far no response - but, it was a weekend. Here is what I posted, "Trying to help someone out here. Fellow has a '99 2WD Dodge Cummins truck. He is 1100 miles from home and has lost 5th gear. He wants to know if he can remove 5th gear and drive home, or if anyone knows of a reliable manual transmission repair shop in the Fort Myers, Florida area. Thanks," I let you know if / when I hear anything. - John

-

Another APPS Problem

! - John