Everything posted by rogerash0

-

Lockup bog/timing torque/general q's

Damn, them spider gears? Guess I'll continue not to do any boosted launches. Something will give way.. lol. I figured u joints and transfer case would be first. Not rly worth it. Any advice on when to engage lockup switch? Before big power, not under big power, in the meat of the power around 2k rpms, or? It had just rained when I test drove it and I could tell it instantly put down big power as the rears lit up spinning. The anti torque management mod is next, but they say 98.5-99 don't have Tm? Not sure exactly....

-

Lockup bog/timing torque/general q's

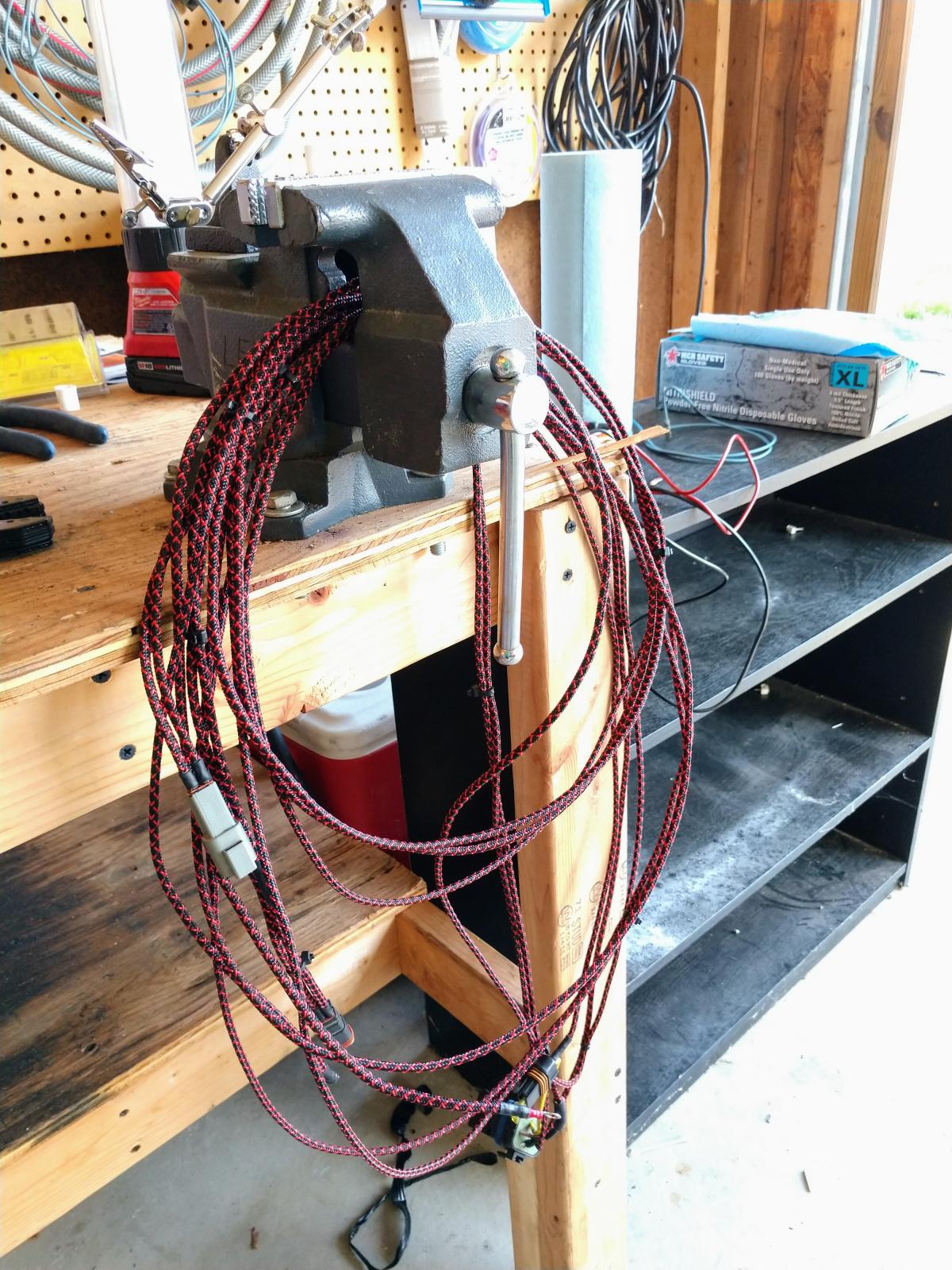

That does sound really good, but the truck really shutters way too bad as it stands to justify the three pole switch. Plus my wife is a smart cookie and can understand the current problem at ease when she drives my drunk *** around (not often). Hopefully the added torque from higher timing helps, but I doubt it. I added another half degree of timing because I can feel a big difference going just half a degree at a time, which I'll test drive tmrw on the way to work. It's also got an auxiliary trans cooler on it now, so even if you drove around with lockup off it would take quite awhile to overheat. Any status on the alternative od off switch? I've been working on my crimps and wiring skills, even purchased a nice Weller soldering iron. Reworked airdog harness pictured. Putting down 600-700hp, do you think a 4x4 boosted launch at say 3-4psi would blow my truck up? Armet billet input and billet output. Dana 60/70 with 35 spline front axles and Yukon hubs. I feel like it would wreck the transfer case, driveline, and differentials after not too many. Good assumption?

-

Lockup bog/timing torque/general q's

14mm 625's ;) Blowing the head off isnt a concern (obviously), its hurting something else like the rods or bearings. I adjusted the TV cable relentlessly with nill results. I then took it to Firepunk where they had to bend the TV bracket. It now shifts at much higher RPMs (2k ish), and shifts right, thank goodness. I havnt played with it since. So your saying to cut the same wire I tapped my lockup switch into, albeit after the switch, right? Also, is there an easy way to wire in another OD OFF switch? Mine is getting worn out and I typically have to press it numerous times unless I get lucky. Thank you!!!!!!!!!!

-

Lockup bog/timing torque/general q's

My 98.5 auto bogs when the TCC locks up at light throttle. With OD off it locks up at 35mph, otherwise it locks up at 50mph. However my speedo is roughly 5mph fast compared to actual, so subtract those readings by 5. After running custom tunes off this board, it seems like timing of 17/20/25/28 on the Quadzilla makes more lowend torque than my previous timing of 16/19/24/26, and when the TCC locks up its not as prone to bogging and shaking the entire truck to bits. I am confident I have no boost leaks based on the great off idle torque my truck makes, and the supreme lack of smoke (also thanks to going back to a stock stall torque converter). This takes us to my questions: 1) With ARP 625 studs and o-rings like I have, can I throw all the timing in the world at the motor, or will I hurt it at some point? I ask becasue perhaps I can keep increasing lowend timing and gaining power, hopefully to negate my problem all together with another degree or two of timing. 2) I just installed a lockup switch. My problem is lockup is occuring about 10mph too soon. Well, the lockup switch didnt stop the truck from locking the TCC, it just enabled me to lock it even sooner. Not exactly solving my problems here. This leads to 3... 3) Is there a way for me to disable TCC lockup, so I can have the truck only lockup when I command it? This is not practical, but the alternative solution I have been employing is pressing OD off just before 50mph so lockup in 3rd gear is smooth. But then I have to disable OD off at every stop light, because if I leave it on and take off again when it locks at 35mph its ultra harsh. Worse than 4th gear 50mph OD lockup. Not practical at all. Thanks. Edit; these lockup conditions I speak of, bogging the truck, shaking and rattling the entire drivetrain and cab, happens only at light throttle. If Im wide open or even accelerating hard, the truck will lockup 10mph later or more, and lockup will be perfect. Problem is, most the time daily driving I am at 10-20% throttle whilst crusing. And the roads here are commonly 50mph, so I have that harsh terrible lockup at normal cruising speeds, aka every street, every day. Drives me nuts.

-

Dropping the transmission, tips n tricks

I torqued them to 48ft/lbs with a brand new 3/8" Craftsman digital torque wrench from sears.com. I know it's not the best torque wrench but at least it's new and probably not too far out of calibration. It would keep rattling when dropped in drive and reverse, if the bolts were the problem, right?

-

Ground Reference VP44,ECM,PCM,PDC plus TC lock/unlock

My tests were done on a brand new alternator. Before and after. Its just an AutoZone special. I just took the grids off as well.

-

Ground Reference VP44,ECM,PCM,PDC plus TC lock/unlock

I did, but I didn't write it down is the problem. My instincts tell me the ac is less because the highest reading I got with the stereo on, becsuse I can't turn it off, measured at the back of the alt was .012vac. Before I tested it off the back of the alt and I got .040vac, I remember that now because it matched what the sticker spec'd out as ac ripple exactly. Only thing is I can't remember if .040vac was measured with a hot hot engine like the .012vac reading was read just now. And my batteries read the same voltage at rest in the winter and summer here. It's just when it's real cold I see up to 14.3v charging rates whilst driving. They still don't read 13v+ while at rest with the truck off. (They shouldn't, but they are now). Previous to running the new charging line they read a perfect 12.8v. I will go re-measure again now just to be sure.

-

Ground Reference VP44,ECM,PCM,PDC plus TC lock/unlock

Did the ground mod this weekend, actually just now. Thanks a lot, I feel like it made a good difference. Lockup is a bit smoother now, but Im still getting some shuttering overall, unfortunately (even after a new TC). I put the 4 ground wires in a 6ga lug that I got at Lowes, put flux in there and used rosin core solder and a bit of map gas to solder it. That was after crimping it with a $37 hydraulic 10ton crimper from Amazon, delivered on Sunday. Then UL spec heat shrink to keep the moisture out. One thing I also did was put a 4ga cable from the alternator to the aux battery, as suggested in this write up. My stock charging cable looked fried. I noticed my batteries are now reading 13.2v on my Fluke, with the truck off at rest. The truck was driven for roughly 45 minutes with this new charging cable configuration. In the past its always sat at 12.7-12.8v at rest whilst off. I keep a keen eye on my batteries and charging rates after problems in the past. Its 13.6v-13.7v whilst driving on the quadzilla/ecm readout. Perhaps the batteries are being overcharged, now?

-

Derale Aux Trans Cooler

Ya I've given up on driving my truck off-road even with a Carli setup and 35s... It's just too hard on stuff. Unless your crawling, but when you have a dirt bike there's just no reason to do such thing.

-

Derale Aux Trans Cooler

Ya I like those setups a lot too but I could never justify losing the bed space, unfortuantly. I drive a lb so I can fit dirt bikes in there front to back. Salt will ruin aluminum too? Quicker than steel? I'm not sure if too much gets kicked up where my cooler is, since it's behind the cab it's pretty far from the front wheels. Also I didn't save the dimensions, I just cut up some cardboard, duct taped it together and knew my template was good.

-

Derale Aux Trans Cooler

I did the 15960 and made an alum bracket with drill bits/drill, bolts, grinder and a long stick of thick aluminum 90* angle stock from home Depot. Just made it first with cardboard and tape. Mounted it to the front left of the bed on the underside, in front of the fuel tanks fill neck. I wanted it to get some air flow. I haven't put the fan on yet but I've noticed it def helped the temps. Probably lowered temps 15deg on avg without a fan even.

-

Dropping the transmission, tips n tricks

The one I just took out started doing that at lockup a long time ago. The new one doesn't do it. Phil was saying you can modify the valve body with a Dremel to test the fluid in park, have more flow in park, and he said that would quiet the noise down, but I'm skeptical bc the noise is the same in N.

-

Quadzilla V2 Custom Tunes

Edge one reads around 70psi. That's why I had to buy yours which is no longer correct and changes it's reading by the day (keeps going up).

-

Dropping the transmission, tips n tricks

Rick at firepunk and Phil at dpc both said it's torque converter chatter from a few extra thou clearance. Hurts nothing, just annoying

-

Quadzilla V2 Custom Tunes

My quadzilla fuel pressure gauge showing 47-50psi when I have 18-20psi actual is the real fail..

-

Dropping the transmission, tips n tricks

Going from the 300rpm lower than stock stall to stock stall is a huge difference. Overall power feels down 20%, but Im in the meat of the rpms @ 2k-2100 off the line at lights so smoke is very minimal now, which was my goal. Its like I need to re-tune with my quadzilla, give it lots more fuel. I was test driving on "extreme" though, which normally lays down the law pretty good. I went to 95% throttle and it seemed like the quad was limiting rpms to a max of 3305....... thats all I saw out of it. It never locked up in fourth tho. 1105 EGTs is all I saw out of it. Normally I'd probably see 1200-1250 at that throttle, on that run, how I accelerated that time, on that tune, on that exact road, etc. I test drove my route to work which I drive both ways about 3x a day. So I know it well. I have a weird sound thats rpm dependent. Its very noticeable from the drivers side doors on either side, but not if your in front of the engine while its running. Also not super noticeable when I was playing with the tip of the exhaust, moving it around to see if that was what was vibrating. It sounds like a vibrating exhaust, quite frankly. I tightened the DP very well, touched it, put pressure on it, loosened where it mounts to the "mid-pipe". No difference. It sounds like when you push a kickstarter down on a dirt bike while its running. Its a metal sprag sound thats hardcore sounds like its coming from either my oil pan or TC when Im under the truck, while its idling. Its there in P or N. It also doesnt seem to be the fill tube. The sound also appears at random intervals whilst driving in gear, when Im dead pedal coasting. I cant make the sound repeatable though while driving, its like around 1100rpm or something whacky. Its got me feeling pretty uneasy about the whole thing. But I drove the truck 15 miles /w no problems. Engine turns over with the barring tool smooth and easy. I tightened the TC bolts to 50% torque, criss-crossing as I went, then to 100% torque of 45ft-lbs. Used red loctite. The bolts were grade 8, came with the TC, same length as I took out. Only 6 went in. I cleaned under the TC really well, and Im not seeing any shavings. The transfer case has fresh oil and the transmission is filled with oil to the proper level, 50-60% in the OK crosshatch @ 152*F. I did put a quart in the TC prior to installing it. Otherwise it runs well. It did take me four days to do. I cleaned every nut and bolt as I went, wire brushed lots of brackets, cleaned all the wires with electrical cleaner, greased them all up, etc. Took my time, trying not to make a mistake. I left the transfer case on and it shifted on the jack, that really hurt how things were going. Also my floor has big divets from how they poured it, which were my enemy. It took me 6 hours just to get it lined back up, 3 late at night with my wife and 3 hours the next day by myself after we both got really frustrated previously. Im still nervous and not sure how to feel about the whole thing. It was a lot of effort, but the first time doing anything normally its that way. Oh ya, my airdog went from 31-33psi at idle to 37-39psi at idle now. And the only thing I changed was my torque converter, period. I specifically didnt touch a single boot or anything, because I wanted one change at a time. The truck does sound a little quieter at idle like I can hear more engine hum now, feels a bit smoother at idle for sure, and no hard starts, but the grids did come on initially. Even after it got hot, no hard starts.

-

Dropping the transmission, tips n tricks

Does the tranny fill line pull right up and out? Also does anyone use loctite on the comverter bolts, and what torque? I think it's 45ft lbs, perhaps a bit on the high end. Or we can just go hella tight.

-

No name

Any advantage to 14mm studs and do all blocks need machine work to run em?

-

Dropping the transmission, tips n tricks

Dave I just tend to think statically, and I tell myself the odds of the ECM being slow to boot on a 60 degree morning but not on a 50 or 45 degree morning are low. Odds of my phone's temp being a bit off, or the truck picking up a different temp than the exact air temp, are greater. I cant recall the exact cut off air temp for the grids, but I want to say its 62 degrees or so. Could be 65.. Not out of the factory manual, but from dodgeram.org I get the bulb check for aprox 2 sec /w key on. Read that article some years ago, and have given it some thought previously, that's why I've already got my mind made up the ECM aint bad. See the grid heater temp chart here: http://dodgeram.org/tech/dsl/troubleshooting/Maniford_htr.htm

-

Dropping the transmission, tips n tricks

Ya, my phone said 59 but maybe it was 62 or what not. I like the grids for that reason too, (fast starts,) but it seems wonky it would need them at all on a morning that warm. I guess the test will be mid-summer on a real warm morning, does she crank right up or are the grids that big of a bandaid. Dave I mostly lol'd because we are so used to everything being broken or breaking on these trucks. So right away you point to an ecm failing. I feel like it's a second gen thing haha

-

Dropping the transmission, tips n tricks

Lol I'm pretty sure my ecm is just fine Dave. It just didn't get Cold enough . Thx guys. Maybe it's something I can achieve sure enough

-

Dropping the transmission, tips n tricks

Sounds good lads. It's a 59 degree morning and my truck had to crank for 5 sec to start. I promise u if the grids came on it would have started up in a second. I've noticed this habit from the truck for some time, but this am it seemed worse than usual. I parked it at 4pm yesterday and got in it at 0620 this am. Slight downward angle towards the front of the truck. Any thoughts? Also are 47 and 48re torque converters the same? The box my dpc converter came in has no documentation besides my name and "3000 replacement". I didn't even realize he was sending me one, if that tells you anything. I like that idea Mopar!!! Thanks. That thing I had no idea about it on my first rodeo, the beating it requires I mean, and I have some really bad memories of having to get the truck together to get to work at 6pm on a Sunday night and the beating that thing took. Edit; wow it's $200. Yikes. Atleast it ought to work then

-

Dropping the transmission, tips n tricks

That two by six idea sounds amazing. I had battled with that member in the past, and holy **** my mind was blown, lollol. Thanks for the suggestions & positive vibes, lads.

-

Dropping the transmission, tips n tricks

Anyone have good advice for dropping the trans? Ive read the truck needs to be on jack stands to fit the tranny out. Some guys say seperate the transfer case, other guys say not to. My thoughts are keep them together, get the truck up a few inches on jack stands, get a harbor freight transmission jack because I can get it here & now, and go to town. It's the little details like a double click of the converter, not hurting any seals as I slide it on, and/or anything else I may not know about. I'd rather not mess anything up. I do have the big factory service manuals here I will read first, but I thought maybe someone here could share some insight. I've never dropped a trans before. Im planning on swapping converters. Also, my thoughts are doing it at home because all my tools are here. But for about $8/hr on the air force base I can have a proper stall with the truck in the air and work under it, and use their transmission jack instead. Do you guys think that's worthwhile? My thoughts are have the truck at home in case I run into any issues, plus I can make lunch here, take my time, work at night outside their hours, etc,etc. thanks edit; would jlbayes or Dynamic know of a spring I could put in my valve body to make first gear shift higher? Lavon said I should have green springs in there (tv,1-2 and 2-3), which are already the higher rpm shifting springs, so am I SOL?

-

47RE

Thanks for the good advice. I'll be sure to do that soon enough.