Everything posted by JP907ATB

-

2hi axel binding in reverse with wheel cranked to the right only? Dana 70 4x4

Is there a way to check spider gears without tearing down third member?

-

2hi axel binding in reverse with wheel cranked to the right only? Dana 70 4x4

Okay so i believe it’s coming from the rear, it’s like it’s in four wheel drive when in reverse with wheel cranked to right, it feels like my clutch’s slipping , but not as intense as 4wheel drive iwas wondering if it has anything to do with the driver side front always turning? Because i believe the 4x4 disconnect only disengages the passenger side, just a thought i had on why it only dose it with wheel cranked to the right in reverse. And to awnser your question, there was no water in my oil or differential, that must be a reflection from something inside the shop. Also my u joints are tight i can’t get any play from them with a pry bar, same with axel joints. i will try jack up front end and crank wheels and rotate and see if i can feel it there. But if it was a front axel joint why would it only do it in reverse and not going fwd?

-

2hi axel binding in reverse with wheel cranked to the right only? Dana 70 4x4

so i got something in my drivetrain kinda hooking up making a poping sound in 2high, It only dose it in reverse with the wheel cranked to the right.(in 2hi) i don’t feel it or hear it with the wheel cranked to the left. I also can’t make it pop going fed in either direction (in 2hi) In 4high I can make it pop going forward with the wheel either way, like barely half to 3/4 turn not even cranked. if i kept wheel straight in sounds fine but turning the wheel either way it was binding up hard. I was on dry pavement so i know it 4high this is somewhat normal. I am more concerned about the 2hi noise. I cant find any play in any axel joint or u joints. I just had the diff cover off and inspected the oil, was a little dark and there was a little fine metal on the magnet, but it didn’t look to bad, there’s 10k miles on it since i rebuilt it when the cone on passenger side where spider gear rides grenaded, and i had to dig out all kinds of metal. That being said i couldn’t feel any play in rear wheel bearing or rear pinnion, That would be the 3 gear oil change since the rebuild in 10k miles there’s a little more metal on the mag then i would like to see and the oil was a little darker then i like but i couldn’t find any chunks of metal in the housing and i rotated the axels and everything in the 3rd member that i could see looked fine. I checked backlash and it was right at .008, that’s where i remeber setting it when i rebuilt it 10k miles ago . Any input is appreciated as i am gearing up to two a 15k load this early spring and i would prefer not to be the guy on the side of the hwy!! thanks

-

2hi axel binding in reverse with wheel cranked to the right only? Dana 70 4x4

so i got something in my drivetrain kinda hooking up making a poping sound in 2high, It only dose it in reverse with the wheel cranked to the right.(in 2hi) i don’t feel it or hear it with the wheel cranked to the left. I also can’t make it pop going fed in either direction (in 2hi) In 4high I can make it pop going forward with the wheel either way, like barely half to 3/4 turn not even cranked. if i kept wheel straight in sounds fine but turning the wheel either way it was binding up hard. I was on dry pavement so i know it 4high this is somewhat normal. I am more concerned about the 2hi noise. I cant find any play in any axel joint or u joints. I just had the diff cover off and inspected the oil, was a little dark and there was a little fine metal on the magnet, but it didn’t look to bad, there’s 10k miles on it since i rebuilt it when the cone on passenger side where spider gear rides grenaded, and i had to dig out all kinds of metal. That being said i couldn’t feel any play in rear wheel bearing or rear pinnion, That would be the 3 gear oil change since the rebuild in 10k miles there’s a little more metal on the mag then i would like to see and the oil was a little darker then i like but i couldn’t find any chunks of metal in the housing and i rotated the axels and everything in the 3rd member that i could see looked fine. I checked backlash and it was right at .008, that’s where i remeber setting it when i rebuilt it 10k miles ago . Any input is appreciated as i am gearing up to two a 15k load this early spring and i would prefer not to be the guy on the side on the hwy!! thanks

-

Bottom of dipstick looks melted?

The bottom of my dip stick looks like someone put a tack weld on the end. I haven’t seen any signs of overheating. Haven’t noticed it before, is there something going on?

-

Electrical bug! Bad ECM

I don’t understand what your asking? I don’t know about quadzilla but i know with smarty if you program a tube, and then program back to stock it unlocks high idle(6cyl) and 3cyl high idle. I haven’t done that to my new ecm yet, but i have a little switch wires to a little deal under the throttle body that will hold the throttle open at set amount rpm. It is not strong enough to push the throttle by itself, so i have to flip the switch and tap the throttle and it will then Hold at 1200rpm

-

Electrical bug! Bad ECM

Okay thanks, yeah i haven’t unlocked 3cyl on my new ecm yet, with smarty. I’m just staying stock right now to make sure all my bugs are gone before i mess with ecm programming. And regular high idle Dosent seem to do much as far as getting up to operating temp and staying there.

-

Electrical bug! Bad ECM

Quick question... if i engage my manual high idle, it’s set just about 1200rpm would it be bad to turn on me pac brake to help warm up?

-

Electrical bug! Bad ECM

Once i changed my IAT sensor connector i was able to clear the po113 high input code with no return. But my old ecm was still acting funny engaging high idle when it was to warm for it. I am thinking between the bad sensor connector and all the electrical diag i did that i damaged the ecm somewhere along the line. I put in a different ecm and i hadn’t no codes and was idling properly. My smarty would not communicate with the new ecm though, so i emailed Bob Wagner @smarty power, and he sent me a recovery software, and i successfully recovered the new ecm and smarty will now communicate. So everything appears to be functioning normal now, headaches are gone for time being. The recovery file he sent me is equivalent to a stock dealer flash and will work on 98.5-01 trucks so I’m pretty stoked on that software! Also Bob informed me that the 98.8-99 trucks had a weak flash memory in the ecms and that if i have problems with this new ecm tonfind a 00-01 ecm which have stronger flash memory to my understanding. I would like to thank you Moparman and all the other members on this forum for helping me get to the bottom of my electrical bug! Thank you! Cummins is purring like a kitten!

-

Electrical bug! Bad ECM

Yeah my IAT was in the 40s and 3 cyl high idle was still engaged/engaging

-

Unidentified aftermarket transmission tuner boxes, with pics.

-

Unidentified aftermarket transmission tuner boxes, with pics.

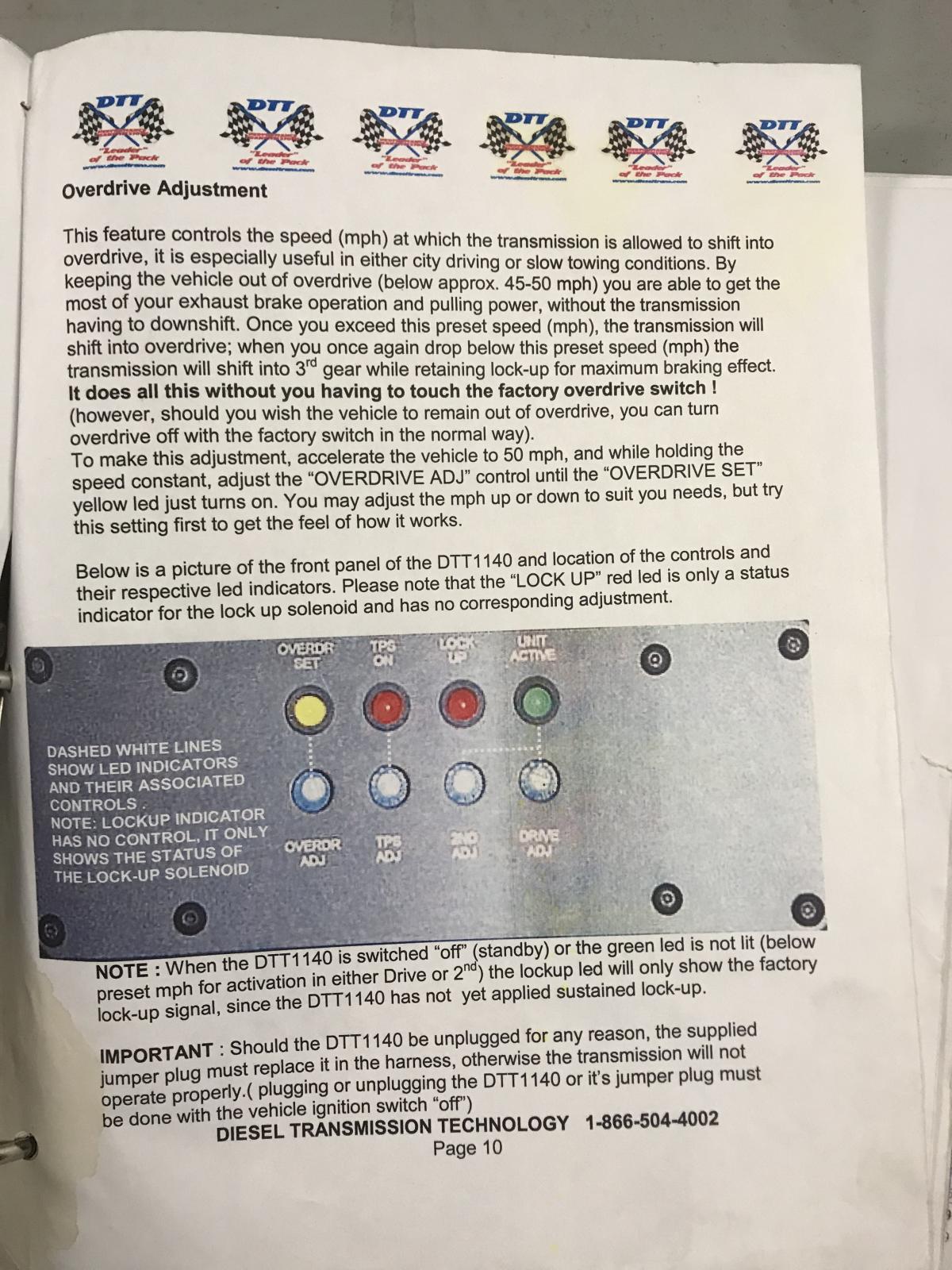

I have the manual for my ats co pilot it looks similar, but i think i have one more setting on mine , i only see 3 settings on yours. When i get back out to my shop i will snap some pics for you, you tune it with a small screw driver, and make adjustments according to speed and when you want lock up and overdrive to engage. To adjust mine you need to be able to see the lights come on and off to know where your at, I’m not sure how you will do that with it being under the hood. Is there enough wiring on the harness where you could get it in the cab to adjust? I’m working nights this week will try to get pics of my manual up for you sometime tomorrow.

-

Unidentified aftermarket transmission tuner boxes, with pics.

Looks my ats copilot but mines mounted under passenger dash

-

Electrical bug! Bad ECM

Oops i meant check engine light stays off with my old Ecm after clearing codes, but i think the 3cyl high idle is engaging when it shouldn’t be

-

Purpose of lockup switch

Yes, however i think you need at least custom valve body to lock up in 2nd, when i lock up going down hill and hit the engine brake at the same time i wouldn’t even have to use the trucks brakes.

-

Electrical bug! Bad ECM

Alright so you guys are gonna shake your heads... I put in my new ECM, and no change in my high volt code to IAT... so i decided to cut plug off IAT connector and wire in a new one.... that cured my po113 code... now i have taken new ecm out and put my old one back in, and the check engine light stays on however something fishy going on... truck was sitting in my shop at 45 degrees and when i fires off and backed it out the door, it sat at idle for moment before kicking into 3cyl high idle, with both ECT and IAT in the 40s. It stayed in high idle welll above 120 degrees on Coolant temp... i don’t think that it should be going into 3cyl mode being this warm.... the outside temp was zero, but everything was warm from being inside shop. I am thinking the bad IAT connector shorted out and damaged the ecm some how, but Its not throwing any codes. When i had the new ecm in, it did not go into high idle at all even with the Po113 code... what do you guys think? I am also wondering at what temp 3cyl high idle will engage and at what temp will it disengage when working properly?

-

4x4 won’t work! Help

My actuator down on axel froze up, instead of ordering a new vacuum actuator, I ordered the posi lock cable from summit racing. It replaces the vacuum actuator with a mechanical cable. It’s much more reliable in my opinion, it’s not as user friendly as i have to put it in neutral or reverse even to get it to disengage. Also have to be rolling a little to get the collar to slip over the passenger axel when you first engage, but it works for me.

-

Electrical bug! Bad ECM

400 shipped, how much was your remanded one?

-

Electrical bug! Bad ECM

The one I’m getting isn’t rebuilt, it came off a cracked 53 block, i was just wondering if i could get the one i have repaired if it turn out to be the culprit

-

Electrical bug! Bad ECM

well after triple checking all my wiring to all sensor connectors back through ecm plug, testing alternator, replacing batteries, cleaning grounds, and various other electrical tests. I have pulled the trigger on a used know good ecm, same year truck, and part numbers match, hoping for the best. Will let you guys know of it cures my headaches. Also is anyone taking faulty ecms and repairing them?

-

"New" ECM Works Good

Glad you got your rig back up and running! and thanks for the review and recommendation on ECM supplier

-

Electrical bug! Bad ECM

Okay, I have ohm checked all wires to all sensors on the IAT circuit.( CTS, IAT, CPS,MAP, and oil pressure sensor) they all ohm check good through sensor connectors back through ecm plug. I have new CTS, MAP, and IAT. Going to put new oil pressure sensor in before i reinstall starter, thinking about putting in a new crankshaft sensor to. Is there a way to test these two sensors?(OPS and CPS) just trying to eliminate last few ideas before going after new ecm...

-

Electrical bug! Bad ECM

Do the wires in this diagram for crankshaft position sensor go to ecm or pcm? I thought that the crankshaft sensor was on the same circuit as; Oil pleasure, coolant temp, map and iat sensors. Am i wrong?

-

Electrical bug! Bad ECM

So i just checked wiring to the oil pressure sensor and it ohm test good, I’m wondering if there is a way to test the sensor itself, or of i should just replace it now while it’s easy to get at before i put starter back in

-

Electrical bug! Bad ECM

What is normal Oil pressure @ start up and @ operating temp??