Everything posted by Bafazane

-

Camper Tie Downs

Thanks @JAG1. I know moving the pump to behind the transfer case is the better set up, just haven’t gotten around to it. I’m never in that cold of weather so it’s a low priority. I’m away at work for a while so it’s making the planning for the camper a little harder with not being able to look at the truck.

-

Camper Tie Downs

Hi Folks, I’ve been thinking about it for a long while and have decided I’m going to purchase a slide in camper for my truck. I’ve been looking at tie downs and like the idea of frame mounted tie downs (like the Tork Lift version). The one issue I see with the Tork Lift tie downs is the fronts use the bed bolt which is where my Fass is mounted. Is there anybody around that has a Fass or Airdog lift pump that also uses Tork Lift tie downs? If so, how did you accomplish it? If anybody wants to chime in with their other tie down recommendations for these trucks, I’m all ears. Thanks

-

Nv5600 clutch time

The new flywheel I installed with the Southbend kit came with new bolts.

-

W-T ground mod

Ah! I like that idea. Will incorporate that into the operation. And I know what you mean about coffee, I get this light until I have some...

-

W-T ground mod

I'm finally getting around to taking care of this project but I have a question (please pardon my complete lack of knowledge of anything electrical, it's certainly my weakest area). As IBMobile listed above: we unplug ground wire from grey plug from aux. battery and cut that wire at the splice near VP44 to make our new ground connection to the gear case. What have people been doing with the piece of ground wire from the grey plug to the aux. battery negative terminal that is now dangling around doing nothing?

-

NV5600 Clutch Not Disengaging

@Dieselfuture I have tried the shift into third a few times under different conditions and the crunchiness that made me start double clutching is still there. Would be excited if the new clutch fixed that too, but it doesn't appear so.

-

NV5600 Clutch Not Disengaging

@Tractorman Yep, nice and smooth. Now on to the next projects... Those are some good recommendations for keeping the clutch and transmission happy on these trucks and ones that I've followed since I've owned it. Not much sense beating on a truck I intend to keep for a long time. I wish I knew more of the history of the truck but the dealer I bought it from (at 156,000 miles) didn't get any of it from the prior owner. All I know is that he was the original owner was local and had a fifth wheel hitch mounted.

-

NV5600 Clutch Not Disengaging

Well, everything is back together and I took the truck for a substantial test drive. What a difference the new clutch makes! The pedal is unbelievably light, engagement is smooth with no chatter. I might be sensing barely more rollover noise but if so, it's a very faint increase. I went with the South Bend OHD as I do plan on putting bigger injectors on soon and potentially going the Quad route for tuning at some point. I'm happy with that decision as it feels like a stock clutch, only with lighter pedal feel. The pilot bearing needles had partially disintegrated but luckily the input shaft snout had only very minor scarring that I was able to smooth off with 2000 grit. The new ball bearing will be riding fully on the input shaft. I want to note as I think back on how I could have detected the issue sooner, there was a very slow, steady increase in vibration at idle with the clutch pedal out over the past months. It wasn't very noticeable at all, even at the end, but it's gone now so I feel confident the pilot bearing slowly self destructing was the cause. Something for others to watch out for I guess. The clutch plate and the pilot bearing must have using the same clock because the friction surface was worn to just barely above the rivets. It was definitely time for a clutch! The pressure plate was pretty worn but no bent or broken fingers and the release bearing was pretty haggard but not totally dead. It's nice to have a new one in there. As always, I appreciate the help from all who contributed and thank you Mike for creating such a helpful forum!

-

NV5600 Clutch Not Disengaging

Yesterday was a long day and I'm about to head back out to the truck to keep putting stuff back together, but I wanted to post a quick note to say that @Tractorman was dead on (thanks!) and the pilot bearing had disintegrated. Luckily the input shaft was in pretty good shape (just needed a quick buff with 2000 grit) so was able to get the new clutch kit installed and the transmission bolted back up yesterday.

-

NV5600 Clutch Not Disengaging

I've got a new clutch and flywheel on the way, and will be dropping (or attempting to) the transmission tomorrow. Hoping for a straightforward parts replacement job. Tractorman, you mentioned the pilot bearing damaging the snout of the input shaft when it failed; what would you suggest is the damage threshold before you would without question replace the input shaft?

-

NV5600 Clutch Not Disengaging

I pulled the slave off and didn't find any weeping oil or anything that looked out of place. I had forgotten that the plunger extends itself as you remove it (hence those plastic tabs when installing a new slave), so I don't really see a way to measure the amount of extension you're getting by depressing the clutch pedal. If anybody has any ideas on testing functionality of the clutch hydraulics I'm all ears. Did I see something about using a steering wheel puller in place of the slave cylinder to determine if it's a hydraulic issue or not? Also while outside with the truck, I started it up in neutral then depressed the clutch and slipped it into second no problem. I shifted back to neutral, the depressed the pedal again and couldn't get it into any gear. I tried pumping the clutch multiple times before holding the pedal down and noted no improvement in condition. The truck had been parked for approximately 7 hours.

-

NV5600 Clutch Not Disengaging

Thanks for the replies guys. I just crossed 200,000 miles and as far as I know it's the original clutch. I replaced the hydraulics because the original system failed on me. As far as I remember from that instance, the deterioration in shifting was a slower, steadier process than what I'm encountering now. But my memory isn't perfect... When I get a chance to pull the slave off, I'll post what I find.

-

NV5600 Clutch Not Disengaging

Hi Folks, I want to preface this by saying I searched this site and many others without finding satisfactory answers. The issue is that my clutch does not appear to be disengaging when I depress the pedal. The symptoms began yesterday with a sporadic increase in effort to get it into gear when shifting. Today, over the period of about an hour of mostly easy highway driving with a few of stops, the symptoms persisted and worsened until the clutch would no longer release and I had to start the truck in gear to get moving and float gears to shift to get the truck home. What was weird to me is that it was inconsistent in the behavior, mostly the clutch wouldn't disengage, but sometimes it seemed like it was releasing just fine. There is no new noise that I have identified. I took care to ensure I was fully depressing the clutch, and always shift slowly (including double clutching into 3rd for a weak syncro). I can't see any obvious leaks in the hydraulic system (South Bend that I installed 4 years and 43,000 miles ago) and the reservoir is full. From reading it appears likely to be either the hydraulics or the pilot bearing. I'm going to pull the slave cylinder off to see if it's leaking there. How far should the rod extend from the slave when I depress the clutch pedal? Is there anything else to check on the hydraulics? Is there any way to troubleshoot the pilot bearing or whatever this may be if the hydraulics check out without removing the clutch and transmission?

-

What is this?

I can't figure out if it was as you suggest (an attempt to limit sag when overloaded), a scabbed together fifth wheel hitch mount, or a combination of both. In any case: people are...creative.

-

What is this?

You can see the overload perch block behind the angle in both pictures. The location of that one agrees with the other one on the passenger side. I'm just going to pull that piece of angle iron off and call it good. I'm just curious if anybody has seen anything like this on a fifth wheel hitch setup before.

-

What is this?

I've been tracking down a noise from the rear end of my truck. It seems like it gets worse the heavier I load the bed. I don't know how it took me this long to find this, but I'm guessing it's a redneck modification on a fifth wheel hitch mount. I'm assuming my "squeak" is the upper spring hitting the piece of angle iron. The other side is NOT like this. Has anyone else seen anything like this? Pictures are drivers side, looking aft.

-

Installed a Nations alternator - results

I haven't made the W-T ground mod yet, it's in the works though. As far as how this played out: I tested the AC noise immediately upon installation of the new alternator. The readings were fluctuating between .036-.042. That was in February, and I did immediately contact Nations. The AC reading in September had crept to .037-.047. The OE Bosch alternator was reading a steady .035 when I removed it. I suppose I should just swap the Bosch back in and try again with Nations.

-

Installed a Nations alternator - results

I don't want to piss on anyone's parade, but my experience differs from that of others here. In fact, I purchased and installed a Nations alternator due to the positive reputation they had via this thread and others. Unfortunately, the Nations alternator had higher AC noise than the 175,000 mile stock alternator when installed. I attempted to contact Adam Nations repeatedly over the two month period post installation regarding this, via email, voicemail, and messages left with other employees of the company. At no time did anyone from Nations ever respond to my inqueries in a way other than "Adam will get back with you". I never heard back once. The AC noise has slowly crept up, not down, as some members here would have you believe happens with new alternators.

-

Mobil 50 SAE Transmission Fluid used in NV4500

I've got just under 30,000 miles on my truck after I drained whatever was in there when I bought the truck and refilled with Redline MTL. Shifting performance improved substantially and has remained that way. Certainly not as comprehensive a test as Mike's, but it seems promising.

-

Would You Reuse an A/C Evaporator?

Well, it looked fine other than a little forest detritus built up against one side, but I replaced it anyway. It would be great if that did fix the leak! Many thanks to Mike for his article on HVAC case R and R, it made a project I was dreading into a smooth, less fearsome process.

-

Would You Reuse an A/C Evaporator?

I'm in the process of replacing a leaky heater core. My A/C system has a slow leak, and I'm wondering whether or not to re-use my existing evaporator core. I'm curious if there would be any outward signs of it being leaky. Or would you folks just replace because you're in there anyway?

-

VP44 Keyway Dropped into Gear Case

I skipped a tooth when I reinstalled the gear into the case with the timing cover off. I don't see any way for that gear to skip a tooth with the cover on, VP shaft present or not.

-

VP44 Keyway Dropped into Gear Case

Several vendors, including sponsor DAP have KDP fix kits. This kit is from Geno's and has good instructions and is one of the cheaper kits.

-

VP44 Keyway Dropped into Gear Case

Update: I cleared the codes today and took the truck on a 20 mile or so drive, with a couple of stops. So far the code hasn't returned; it appears at this point that pump gear misalignment can cause a P0216 code. I'll be keeping an eye on it though. Again, thanks for the help, folks.

-

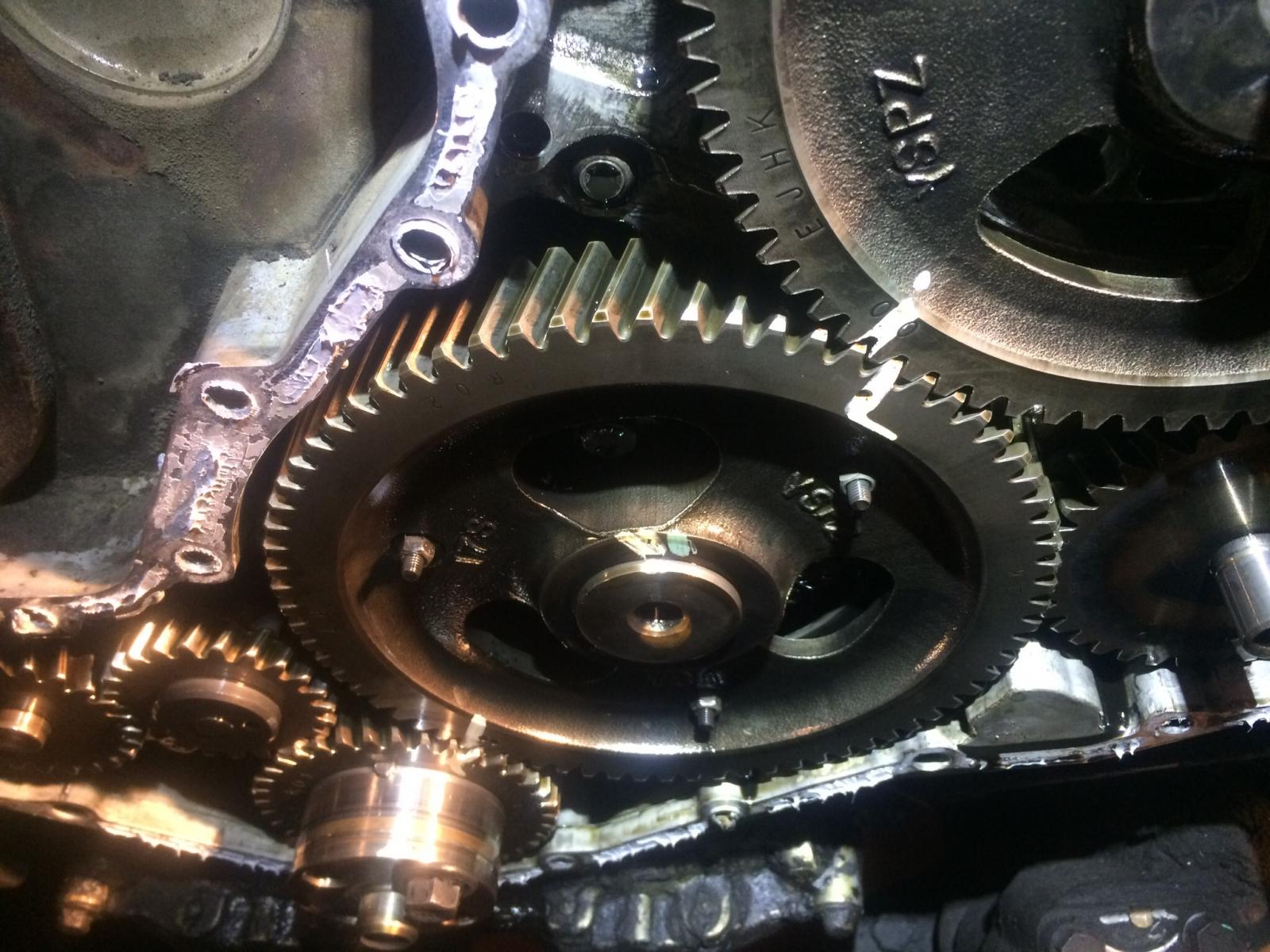

VP44 Keyway Dropped into Gear Case

The pump gear was off by one tooth. I've rectified that and am now buttoning the front back up. I really hope that was the issue, and will let you guys know how it goes tomorrow when I fire it back up.

.jpg.93fc54cbba597bab0b71ea7b893bc373.jpg)

.jpg.5d5960929a9b0cc9c53f0c3530de5dee.jpg)