Everything posted by the7t7

-

Fried ECM from lift pump wiring? Also ECM pin 44?

ACS as most here suggest Can’t check at the moment but when I checked before I did the mod, it wasn’t too bad, I think around 20 mV. Testing my alternator is on the list. Does anyone know the answers to the last part of my post? Why my 98 doesn’t have a vp44 connector going to ecm pin 44 and what that pin does? It’s labeled as “datalink shield injector pump” Could this be an issue?

-

Fried ECM from lift pump wiring? Also ECM pin 44?

I recently fried my second ECM. It died in the same way as the last one. Stumbled will cruising around town and then died completely. It felt like the lift pump failed but the VP44 kept trying for a bit and then it stopped too. After getting it towed home I could get both the Fass lift pump and the injection pump to run (and the truck to idle) by bypassing the ecm but got no voltage signals from ecm to either lift pump or injection pump when trying to start the truck with e dry thing wired normally. After reading the article here by IBM mobile about proper lift pump wiring, I believe the ecm failed because the relay that was used in the lift pump wiring didn’t have a diode which allowed the relay coil to back feed to the ecm and fry the lift pump circuit in the ecm. I believe I’m in the same boat as another thread’s poster as my instructions from Fass had me using the ecm lift pump feed as the trigger for the relay, but now Fass recommends using an ignition switched trigger instead. I will probably not use the ecm to trigger the lift pump with the next ecm (even with a diode relay) as I just don’t want to take the chance. I want to really be as sure as can that this is really the cause because if I fry another ecm, I’ll probably drive the truck off a cliff. I have done the W-T mod and am in the process of upgrading all my battery cables and grounds, though they weren’t in that bad of shape. I have ohm tested the ecm’s power leads and grounds as well as the injectin pump’s ecm power and ground wires. All wire runs read less than 0.5 ohms. Anyone have any more suggestions to check? Also, while testing the vp44 connector’s wires back to the ecm and pdc, I noticed that my truck is missing one vp44 connector pin that goes to ecm pin 44. I am using the wiring diagram from here that is I believe either for a 1999 or 2000. My truck is a 1998. A pin out that I have describes the pin as “datalink shield injector pump”. Anyone know what this wire/pin is for? It doesn’t look like my truck ever had this pin as there are no extra wires in the harness. Thanks for any help anyone can give me.

-

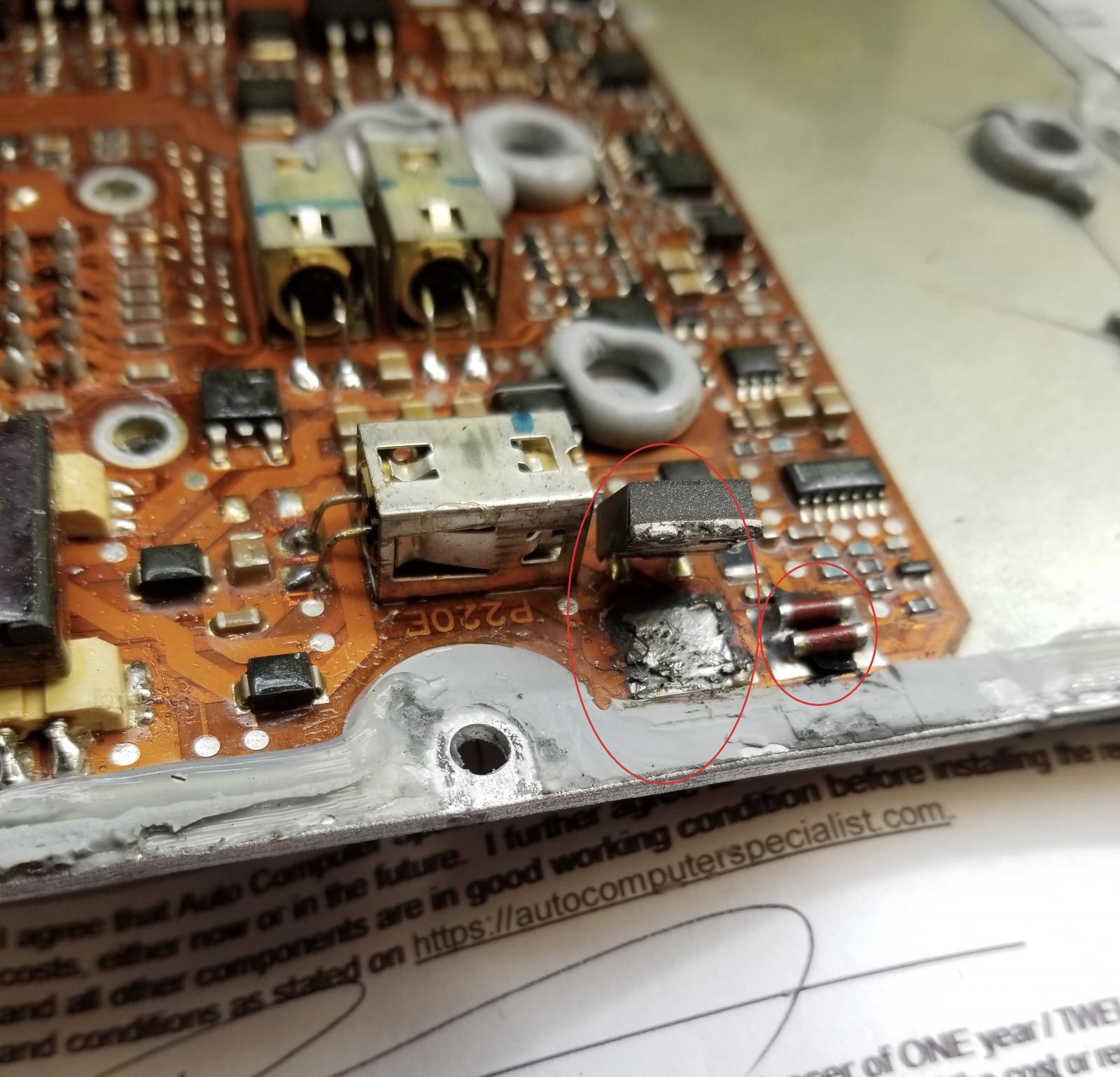

No fuel pressure but Fass pump is working.

I finaly got my ECM back from ACS and it was fried. They replaced it under warranty even though they determined I had a tuner which was nice of them because I didn’t say I had one. Here is the report: Notes:your warranty has been completed (please note: your are a valued customer we have informed that shorts, tuner and no communication & tampering of our factory programming is not covered under warranty) we have covered all warranties & shipping which is not part of policy and procedure, this is our last warranty being issued. Unfortunately your module communication was killed from you trying to program injectors into the module & low voltage from trying to program the module and once recovered all data was corrupted and unable to save the module, they are very delicate units. Unfortunately you have voilated warranty policy by altering of our factory programming & are NO Longer covered under warranty,charges will apply should you need our assistance moving forward. How ever we stand behind our products and have sent you a completely different module programming has been done completely.. Our findings: ECM(engine control module).. unit was DOA (dead on arrival), based on recovery file from cummin they units communication was taken out by altering of our factory programming & low voltage from trying to program.. upon recovery data info was corrupt unit unable to save. Prior to installing repaired unit: a problem still lies in vehicle (it keeps taking out the injectors ). Battery & terminal must be changed. Make sure all parts replaced are OEM (mopar) parts are a MUST! All Problem in truck must be tended to prior to installing repaired unit ( failing to do so will result in shorting out the unit and it will not be covered under warranty.) please refer to website for warranty coverage policy and procedures. ———————— Attached are the photos they sent. As for the their report, they determined that the unit wasn’t getting enough voltage. However when I tested resistance on the supply leads and the grounds of the ecm they were fine. I had also replaced both batteries recently with AGM units. I guess I can power probe the ecm supply as Alterego says below but not sure what that means. Is this just putting 12v to the wires without the ecm hooked and checking voltage drop up or is there more to it? They also recommended that I replace the Battery terminals. Mine don’t seem to be corroded or anything. Any suggestions here?

-

No fuel pressure but Fass pump is working.

I have good power and grounds to the ECM. Less than 0.3 ohms through both power (R/wht) and ground wires (blk/tan). I did the alternator ground wire mod anyway and fused the blue wire. I’m sending my ecm back to ACS to check out. Maybe more evidence that I have a weird early 24v unless it’s specific to 98/99. My wiring is different than what was described in the ground mod articles. The B+ lead for the alternator went down through the big bundle under the injection pump back to the starter and then up the fender well to the pdc. I just cut it back at those points so I wouldn’t have to undo the whole large bundle where I can’t reach it and then ran a new wire to the aux battery. I also had a large plastic block with the alternator ground, green and blue wires molded into it. I cut that off, elongated the wires and added new terminals.

-

No fuel pressure but Fass pump is working.

Dang I wish I had seen this earlier. I spent the afternoon laying on top of the engine reworking those grounds (blk/wht). They probably aren’t the problem since they don’t ground the ecm but I thought I would do them anyway. I will be doing the Alt feed/ground mod tomorrow which I believe does ground the ecm. Removing the starter was a good idea.

-

No fuel pressure but Fass pump is working.

Thanks for the comments everyone! Looks like I will be feet up in the engine compartment today checking grounds and splices

-

No fuel pressure but Fass pump is working.

It’s probably a good idea for me to check the grounds just to be thorough. I had recently gotten both a new/reman ecm and pcm in an effort to get a Smarty with command module to work properly after having tested every wire between the pcm, ecm, and obd2 port. After getting new computers I still had the same smarty issues. My consolation for dumping so much money on computers is that at least I am starting fresh with new ones to match the mods and upgrades to my engine. Now I’m not so sure. After spending a couple months trying to sort out the smarty issue with experts on the the smarty support forum, I came to the conclusion that I had a really early 1998.5 24v that just wasn’t completely supported by smarty (which they would never admit). Both computers worked fine before I replaced them. It was just the only thing left to do. In the end, I switched to a Quadzilla setup which after switching from Dynomite injectors to DAP, worked fine until this issue. What I don’t understand is why the ecm is putting out sub optimal voltages to both the vp44 relay and the Fass lift pump relay. I’ll check as many grounds as I can find and reach but I’m not holding my breath. A bad ground it would seem to me to either cause intermittent problems or complete failure.

-

No fuel pressure but Fass pump is working.

I measured the voltage at the relay terminal in the pdc labeled “Fuel system relay”. I looked at the diagram on the relay and checked the voltage on terminals 85 and 86. 86 had continuity to ground so I assumed that 85 was the ecm signal wire. I’m assuming this relay is the injection pump relay because it’s the only one related to fuel in the pdc I could find. I had already measured the voltage on the lift pump trigger wire coming directly from the ecm earlier which was 6.5 volts. This is the wire pair that goes to the Fass relay. I swapped two other relays in this plug to check to see if it was the relay that was bad. Fass pump runs if I put 12 volts direct from battery to it (through relay plug terminal 87)

-

No fuel pressure but Fass pump is working.

Directly powering the fuel pump didn’t get the truck to start. So I hooked a tester to the fuel system relay signal wire (#1 or 85 lead) and I got 5.8 volts on key on and a little less running the starter. Shouldn’t that also be 12 volts to get the injection pump running? Does this confirm ecm as the problem? A thing else I can test?

-

No fuel pressure but Fass pump is working.

Yeah, I kind of think it may have been doing that all morning. It had trouble in the morning going into gear when it was cold. It kept cutting off so I let it warm up more than usual. I thought it was maybe my newish tune under fueling and/or not dialed in. I was just putting around town and it died once but started right up again. Now it won’t start. I’ll put some power to the pump and see if it starts tomorrow. If I have ecm issues then maybe other things will pop up when it’s running or it won’t even start with fuel pressure. I’m guessing ACS won’t warranty my ecm since I’m using a tuner?

-

No fuel pressure but Fass pump is working.

I get 6.5v no matter the ground on key on. It drops slightly as I bump the starter and then back to @6.5 v. Also no codes. I don’t even get the grid heater code I should be getting as I don’t have one. What about running a temporary relay to see if it runs? Isn’t there a relay mod for the fuel pump that doesn’t use the ecm. I remember seeing something about that in one forum or anothe.

-

No fuel pressure but Fass pump is working.

I don’t believe I have that connector. Maybe 1998 wiring harness is different than 2001. My fuel pump lead seems so come directly out of the ecm, down and then up by where the fuel filter was. When I measured the voltage at the plug, I measured the y/wh wire with the red probe and the black probe was grounded on the firewall dash metal. So I didn’t use the bl/wh wire at all. I’ll try it again with different grounding to double check.

-

No fuel pressure but Fass pump is working.

Thanks! I hope that’s all it is. I’ll have to do it tomorrow though.

-

No fuel pressure but Fass pump is working.

So I was driving around testing my new 7x.012 injectors and new quadzilla and my truck died. I tried restarting and it started right back up. Fuel pressure from my Fass seemed a little low (around 12 or or 13 psi) but otherwise everything seemed like it was working ok. I made a stop for about 20 min and when I got going again the truck died again 100 yards down the road and wouldn’t start. I noticed that the pump wasn’t cycling on key on/ starter bump so I had the truck towed back to my shop. When I tested the pump by putting 12v to it, it worked, so I replaced the relay with another but couldn’t get the pump to cycle. I then tested the ecm signal lead and I was only getting 6v at key on and nothing higher when I bumped the starter. I did notice that when I bumped the starter the voltage went to open line and then back to 6v. I don’t think 6v is enough to trip the relay. So do I have a bad ecm now? This would really suck since I just replaced it with a reman from ACS. Any thoughts?

-

Quad over fueling even starting at 60%

Well I installed the injectors and used your 7x012 daily tune and it worked great. Much better smoke control down low. I couldn’t really test it much as we’ve been getting dumped on here in Bend. Also can’t test it now because it died on me and I has to have it towed back to my shop. No fuel pressure. After some testing, I think it’s signal from the ecm. Fuel pump works with power and 3 different relays didn’t work so I tested the ecm lead going to the relay. It’s putting out 6v when the key is turned on so I think that’s the problem. I’m going to make another post in the 2nd gen Powertrain section.

-

Quad over fueling even starting at 60%

Thanks! That’s the first thing I’m going to try.

-

Quad over fueling even starting at 60%

I just spoke to Matt at DAP and who just sold me some 7x..012 voc injectors. He felt confident I could build a clean tune with those and my compound set up. The learning curve on building this truck has been steep. I wish I had known everything I know now before I tried to build this “sleeper shop truck”. I could have saved myself some time and money.

-

Quad over fueling even starting at 60%

Ah! Now it makes sense. Thanks! Sucky news about injectors. If I were to get new ones, what do you guys recommend for clean tunes? Local guy didn’t recommend Industrial Injection. He said he would go with Haley Speed.

-

Quad over fueling even starting at 60%

I've read both you and mike's tuning guides cover to cover (both very helpful BTW!) but still don't really understand that explanation. Part of it seems contradictory. In one place it says that "scaling function will limit max timing" and then later says "it will effectively allow for you to reach your max sooner". Sorry I know I'm being dense On another note I found out I have Dynamite diesel's DDP150 injectors with pop pressure set at 290 Bar. They said the don't really recommend setting them more than 5 Bar more but I could have a local shop do it if I wanted. You guys have any recommendations there?

-

Quad over fueling even starting at 60%

Yes, I think you're right about my injectors. I paid attention to the engine load at idle and its around 7% which would suggest I have a lower pop pressure? I did some testing yesterday and moved timing around quite a bit and could not really get rid of the smoke in the lower (<17psi) high load situation i.e. when I give it 3/4 to full throttle and the load goes up to 75% there is a cloud of dark grey smoke that doesn't clear up until psi gets over 26 or so. What I need is for my turbos to spool up very quickly. I'm a little confused about reduct scaling. If this is the steepness of the timing reduct, then as values decrease from 100% does reduct happen quicker or slower. And do you still get the full reduct if scaling is less that 100? Thanks for the help!

-

Quad over fueling even starting at 60%

I'm not sure on POP pressure. I had a local shop install them when they did the headwork. I will get with them on Monday to see if they kept any info. It might end up I have to pull them and have them tested just if I can't get it cleaned up any better. I'll try some of your settings today or tomorrow. Do you have any advice on the load/throttle/boost timing settings to reduce smoke when the pressure is low.

-

Quad over fueling even starting at 60%

Im having trouble with my initial set up. I started with a mid hp injector tune from here and I believe I’m still too rich even with starting fueling at 60% (level 3, not even messing with pump tap). I don’t have big black smoke now but I have significant dark gray smoke under heavy throttle until 24 psi. Light to medium throttle is better and clears up at 17psi. Interestingly I’m coming from a smarty custom tune set up that also had the same issues which is one of the reasons I switched. This doesn’t seem right. Also wierd is I did the valet level 1 testing and I had trouble finding a starting point (even after I figured out that I needed to reload the tune after I changed anything that had a “save” buttton in the upper right”). 30 % behaved as it probably should, putting along. 100% seemed right too. But I was started getting light haze at 50%. Could I have bigger injectors than I thought or other issues? Light throttle cruising is fine, idle is fine, WO after 24psi and 2k is fast and clean Here’s my truck: 98.5 2500, 150hp DAP injectors, Head studs, heavier valve springs, DPP compound turbo s475/stock Holset, built AT, DPP intake horn, intake heater delete, FASS 150 Here’s the latest tune. I Started with 2 deg on the fuel load , low psi, and light throttle and made the current changes after lowering fuel but it didn’t do much. Power Levels: 6 Timing Fuel Load Timing: 3 Low PSI Timing Reduct: 3 Timing Reduct Scaling: 100 Light Throttle Timing Adv: 3 Light Throttle Timing Load Limit: 30 Timing vs rpm 1500: 14 2000:18 2500:22 3000: 25 Timing Max:26 Wiretap Pump Stretch:1600 TPS Pump max:100 TPS Pump Min0 Minimum Pump Tap Fueling Percentage:0 Pump Low Boost Scale PSI: 10 Boost Scaling:40 RPM Limit:3500 Power Reduction: 0 PSI %:60 1 PSI %:62 2 PSI %:63 3 PSI %:66 4 PSI %:70 5 PSI %:74 6 PSI %:78 7 PSI %:82 8 PSI %:86 9 PSI %:90 10 PSI %:94 11 PSI %:99 12 PSI %:103 13 PSI %:107 14 PSI %:111 15 PSI %:115 16 PSI %:119 18 PSI %:124 20 PSI %:129 22 PSI %:135 24 PSI %:139 26 PSI %:139 28 PSI %:139 30 PSI %:139 The low % start and steep ramp was a effort to cut back on smoke but still fuel at higher psi

-

No DTC codes through Smarty, other issues

This issue is still un resolved I'm hoping to bump it for more comments. Here's an update: So The tuner I am using for the smarty custom tunes wanted a High Speed data log. When I went to try that the smarty showed the same error (17143) as when I try to get DTC codes from it. I called smarty again and they said that error is related to the ECM communication to the PCM. I toned all the wires from the ECM to the PCM and from the OBDII port to the ECM an PCM. All the wires are good.I sent the smarty back again and they replaced the board for my piece of mind. It still won't read the DTC codes or do a HS data log. Everything else seems to work with regard to the ECM and PCM. I can read codes with an aftermarket code reader. The only codes I have are related to the intake heater which is removed on my truck. I am thinking that I have a weird very early 1998.5 truck with a pcm ecm combination that smarty didn't account for. I want to try a different ecm or pcm but don't know which to try first. At one point the pcm in the truck was updated to 56046355AE because there is a hand labeled dodge sticker over the original one. This comes up as a 1998 pcm when I google it. Could it be a 12v pcm? The ecm looks original. Any 24v ECM experts know what I should try next. I really need to get a data log from the smarty so I can have smoke free tunes for my compound turbo set up. Thanks!

-

No DTC codes through Smarty, other issues

Thanks for the reply. When I sent it back to smarty, they tried it on a 2001 and it read the codes. They also mentioned that the smarty might not read the dtcs from the same pin?/wire as the code reader which I don’t think is possible. I’ve read vague post in other forums that I interpreted to mean that the 98-99 ECMs aren’t as solid/sorted as the later years. I was wondering if maybe I had an ECM issue. I suppose the next step would be to try a different smarty on my truck and see if it could read them.

-

No DTC codes through Smarty, other issues

Hi, I thought I would post this on this forum because there seems to be a bunch of people here that are good with Cummins electronics. I have a couple issues. I have a smarty touch with the command module (essentially an MM3) on a new Diesel Power Sourse compound turbo setup. I can’t get the smarty to read DTC codes or the trans temp. Everything else seems to work ok. I sent the unit back to smarty and they were able to test it on a 2001 (mines a 1998.5) and it worked ok so they sent it back and said to check the OBD connector and wiring (which looks good). My generic code reader also works on the OBDII but not the smarty. Anyone have any thoughts on this or know what could be causing it. I’m also not seeing any trans temps when I set the Smarty to read the on board trans sensor. I just get a red hourglass. I’m currently sorting out custom tunes I’ve received from Calibrated Power and that’s not going too well, either. Everything they’re sending me really rich (smokey) on any significant throttle application. Are these problems related, what should I be checking etc. Thanks!