Everything posted by LorenS

-

Getting back into the trucks

Yes! Welcome, That Guy, nice to have you join us.

-

Coronavirus; Is it hype, blown out of proportion?

Also of note is how differently the HVAC systems are designed in doctor offices, and ESPECIALLY in surgery rooms! I'm a member of ASHRAE, the engineering association that is referenced over and over and over in building codes of all kinds (International, Uniform, etc.). The monthly magazine has no shortage of articles on the topic. It bores me to tears because I'm in the meat-packing refrigeration industry and have no real interest in the topic, other than the fact I and others I know and love are sometimes in surgery rooms! Those rooms are relatively cool and dry with good air speed; they are nothing like a Costco or Wal-Mart! Twice sitting by my wife while I was masked and frocked, I wasn't uncomfortable in the surgery room, despite the (relatively) high stress environment of a child birth! I want to have these "I know everything" doctors who talk about wearing them every day come with me onto a slaughterhouse rooftop in Dodge City, KS where it's 110F and humid, then see if they understand why I complain about masks. Bright sunshine and 40 MPH wind, 200 feet from the nearest human being, and they say I am REQUIRED to wear a mask?! Who is the one "ignoring science"?

-

Normal Load % for Basically Stock Truck?

Yes, it has been while reading your posts that I noticed how low your engine load is. Knowing you had larger injectors I assumed that had a lot to do with it, wasn't sure about your hybrid turbo, dry climate, elevation, effect of different OD ratios, and also knew about our different final drive ratio due to tires. Your engine has a lot more miles, but we know are well maintained miles. I only know the history for the last 48k miles of my truck, no idea age or condition of lift pump. Kind of hoping SOMEONE out there has stock or close to stock injectors and can provide insight as to whether my engine load is reasonable, especially the 65% I saw this morning! Slight rolling terrain, not a 'hill', by any means. Should I be setting my Low PSI Timing Reduct to something less than 5 PSI? Light throttle load limit to more than 30%?

-

Second Fuel gauge sender to replace...

Ah yes, I was using incorrect terminology. Thank you, Dripley!

-

Second Fuel gauge sender to replace...

Oh my! So does a guy have to remove the whole hub, like doing ball joints?!

-

Normal Load % for Basically Stock Truck?

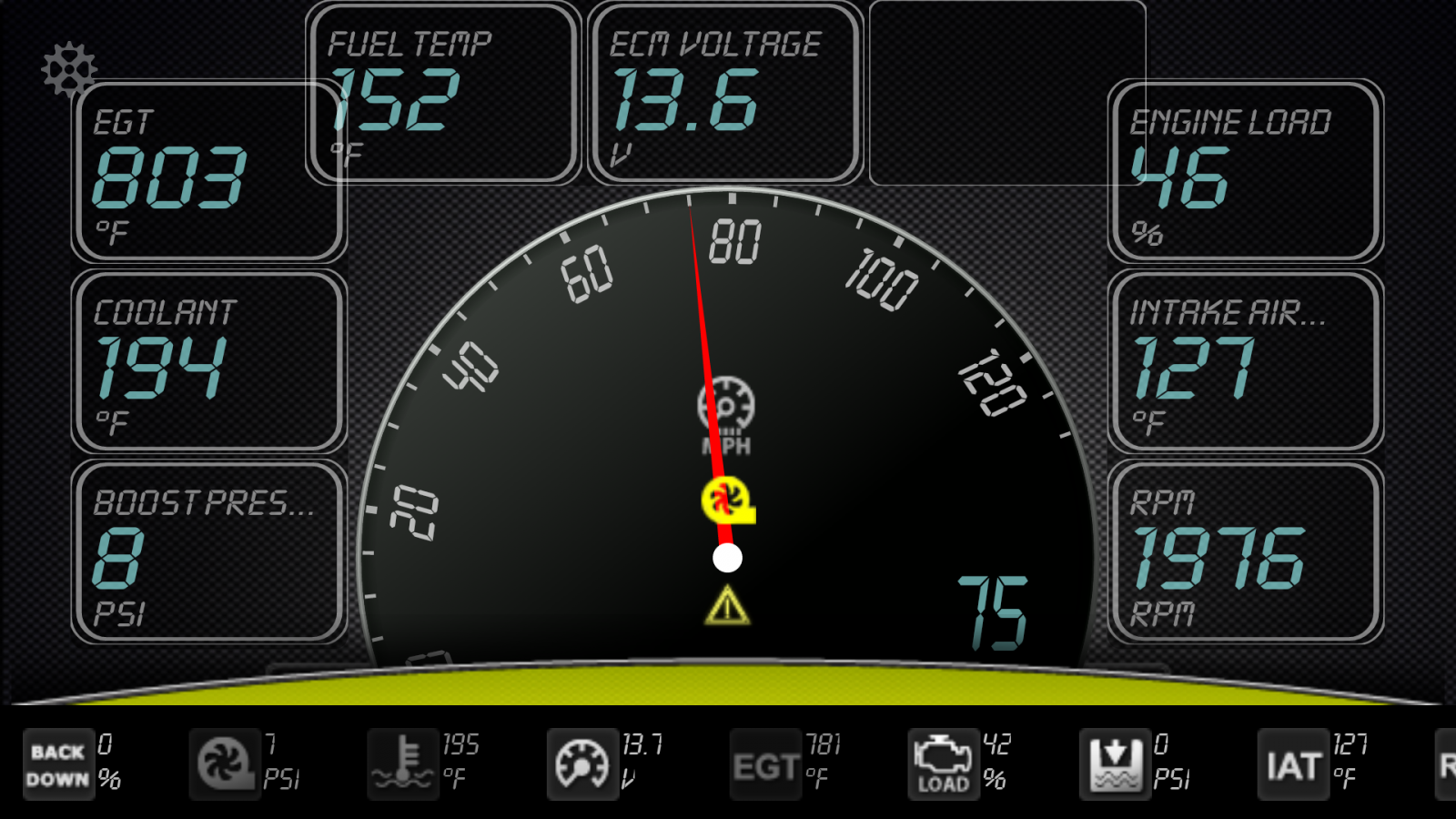

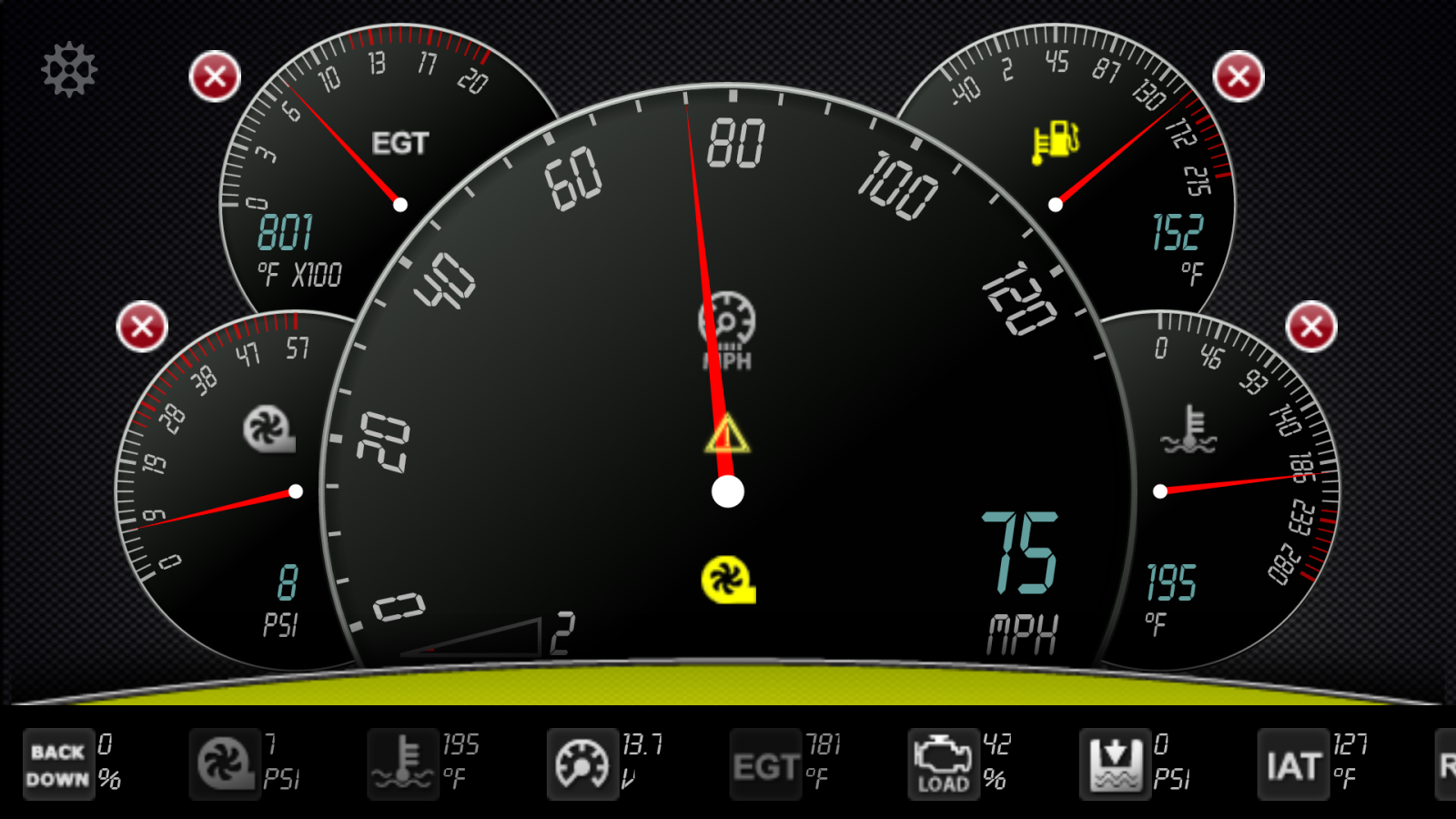

Now that I have a Quad (and now set to the correct V2 tuning!) I can see my timing, engine load, etc. When I look around this site I see all kinds of ranges for normal timing and load percentage for various driving conditions, but most folks have larger injectors, higher pop pressures, etc. I have reman Bosch injectors with about 30k miles on them. I still have the HY35 turbo. I roll down the road at about 7,800 pounds, with camper shell. Attached photos are flat Iowa interstate driving, from 10 days ago. The Engine Load seems high; I often see 65% on even a mild rise, such as this morning on my way to work +10 miles into the interstate trip. At idle, my load percentage is 6-8%. 1. What is normal engine load percentage for a basically stock truck? 2. If my values aren't normal, is it indicative of a VP44 with lots of internal wear/tolerance? Other cause? 3. What does the yellow Turbo warning indicate? It's almost ALWAYS present on my screen, but I see it on Mopar1973Man's screenshots, too. Since my truck is stock, does this mean I may have a boost leak, or...? No codes shown on my OBDLink. The photos are from before I knew to change my vehicle to "V2 Dodge...", so Timing wasn't available. My timing at these speeds varies from about 15 to almost 20 degrees, never 20 or above that I've witnessed. My low load advance limit may need to be raised to enable advance during flat ground traveling, but I do not want to do so until I'm comfortable it is not likely to cause damage. Any and all advice is appreciated. I have not installed my temp sensor in the engine oil at this time, as with an auto transmission it's not the easiest access on the filter housing. Has anyone put a tee in the turbo feed line to measure temp? I put an oil sampling port in the "extra" port, but will remove for the sensor if the tee is a bad idea. No, none of this is in the 16 page installation manual for the Quad. While I concede this information may be in some of the tuning write ups, I missed it numerous times if it is.

-

Second Fuel gauge sender to replace...

That job was handled 50k miles ago, with much anti-sieze applied, so hopefully that won't be a bear. To change the seal you have to pull the whole carrier from the the housing, right? To change u-joints the axle shaft just needs to be released and slid out through the hub to work at the vice/bench, or do guys somehow change the joints in place?

-

Second Fuel gauge sender to replace...

Is changing a front u-joint as much work as I think it is? I rarely use 4WD but think at least one is giving me popping as I make the rare tight turn. And driver's seal is leaking pretty good. Not looking forward to that job, but don't want to pay what I think it would cost at a shop. Not many independents around here.

-

Bosch VP44 Injection Pump Overflow Valve

Is the bleed hole in the relief valve to allow air to leave the system, for instance when priming? Wouldn't need to be very big to flow a significant amount of air. I would find it very interesting to set up a test of how much diesel goes through that hole during normal operation, and the temperature change, to calculate the amount of heat being removed. Also, to see effects on fuel pressure and heat removal by drilling out a little larger. Alas, I now have two young kids and a non-understanding wife... Someday maybe I will be allowed to conduct such experiments in the name of "science experiments" for the kids!

- 1 comment

- 3 reviews

-

-

- 1

-

-

Fuel Temperature

I understand that's the consensus. However, if your truck requires less pulse-width of the solenoid, then that should reduce the average amperage through the computer, thus reducing heat load. That's all I meant. Kind of like the logic of take lift pump power draw away from the ECM by use of a relay, thus reducing heat in the ECM and hopefully extending its life.

-

Fuel Temperature

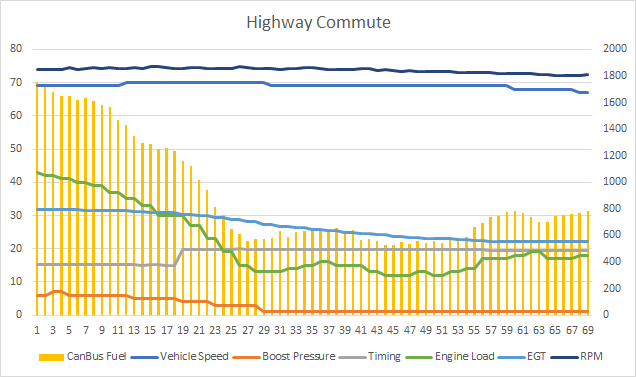

I understand the fuel temps are high. Plan to change "screen" filter ahead of lift pump and the fuel filter. I unhooked the fuel heater as you suggested, made no difference on my 350 mile trip home yesterday. I know you've got much larger and higher pop injectors than my stock remans. That should reduce the VP44 computer heat, right? I must be getting some decent flow through my VP44 because it took 200 miles for the fuel temps to rise after fueling up; it was a slow climb from ~85 to 142. Nice, cool, fuel from underground tanks sure helped! But if there was very limited flow through VP, that shouldn't take nearly 3 hours for the fuel to get hot. Is it possible my VP44 is so worn that it's "churning" the fuel, causing substantial heat and possibly also has (for lack of a better term) "blowby"? My EGTs on flat, Iowa interstate with no head wind just seemed very high yesterday. Side note, why does the yellow turbo warning symbol show up almost every time? When I restarted the app after filling up, I drove the remaining 250 miles without that symbol popping back up. Here is part of my datalog graph from this morning after I discovered the correct V2 vehicle setting; yellow turbo warning popped up this morning, too! I don't have NEAR as much timing as you do. Fuel temp here as already to 128 about 15 minutes into the drive. Low-80s this morning when I drove in. The weather here is awful...

-

Milestone

I get a lot of comments about my 300,000 badge, you guys with way more miles may need to print "FAQ" fliers you can just hand out, to give your gums a rest.

-

Fuel Temperature

Thanks, I found that late last night when I returned home. Didn't know to scroll down past the Ford listings to find V2 listings. The gauges were there for my drive in this morning! I did some data logging this morning now need to make a spreadsheet to plot it all, I guess. My EGTs seem high for flat ground, wondering if my timing needs to be adjusted to compensate for possible wear in my VP44 (previous owned had 36k pound license plates and scrapped heavy iron).

-

Replaced lift pump and injection pump, still losing all fuel pressure

-

Fuel Temperature

I made sure. Unless there's something else to do besides check the 01-02 Dodge option. Still no Timing. Nor ECO, for that matter.

-

Fuel Temperature

Looked last night, I have 1.9.45 and that was the latest update shown. May uninstall and reinstall.

-

Fuel Temperature

This is the issue for me now. I guess Timing is not an available parameter on my 2001. Or, I've overlooked it a lot.

-

Fuel Temperature

The answer is "swipe left". Whoops... Follow-up question @Mopar1973Man, how does one get the Timing gauge? Is that something you programmed yourself? Now that I'm home from months on the road I'd like to start making small changes to get my timing right. Will move transmission temp sender to oil, I suppose, to follow your recommendations.

-

Fuel Temperature

Your results may (should) prompt me to find 30.5" tires for my 17" wheels. I'm at 31.8" now - or was 50k miles ago.

-

Fuel Temperature

@Mopar1973ManHoly smokes how do you get more gauges to show up?! Also, can't even imagine blowing down the road over 2,500 RPM. Is there any chance my fuel heater would be stuck on? I didn't mention it, but my voltage was 13.6, which is atypical for my truck. Normally in the 14.4 vicinity.

-

Fuel Temperature

It's the stock style, but moved to frame rail. The fuel that's used to cool is after the positive displacement rotary vane pump, right? It could be that fuel return is not occurring as you say, but it'll take some real solid explanation to convince me 12 PSI at the VP inlet isn't sufficient. The stock return flow is into the same vicinity as the fuel pickup, nice in winter, maybe not so nice in summer.

-

Replaced lift pump and injection pump, still losing all fuel pressure

The two 01s I've been involved with had the pumps on the engine block and still had a screen "sock" as shown above. Mine had over half a beer can full of trash coating it. Removed that, added draw straw and inline screen (think old truck fuel filter), moved lift pump to frame and gained back 7 PSI.

-

Fuel Temperature

What is a normal fuel temp rolling down the interstate at 75, unloaded? Quad showing 140! Full tank of fuel, 84 outside. Lift pump at 11 psi. IAT 122. Quad on fuel economy level 2.

-

Forewarning of doom, paranoia, or...?

@dripley you were on to something with the needle valve! At least that's where I needed to look more closely. Turns out the fitting tapped into the elbow at the VP44 had finally shaken loose and was letting in air while the truck was off, and letting out fuel while the grid heaters were on. I tightened it while the truck was on high idle, and the difference in engine noise was quite noticeable! Doubt that has much to do with my strange EGTs, but who knows. At least now it should start better in the morning.

-

Forewarning of doom, paranoia, or...?

Fuel pressure is same as it's been for tens of thousands of miles, 10-14 PSI. If air is leaking in through the fitting at the back of the head, could that screw up my starts? I sure wouldn't think so, but I'm not 100% versed on how Dodge engineers (or summer intern, Rube Goldberg disciples?) thought the system should work. Dripley, I suppose you're right that it could be the needle valve has just worked out of adjustment, it just seems very suspicious th pressure drop coincided with the rough starts. Could the VP44 pressure relief valve be weak, or a piece of trash stuck in it? I run Donaldson fuel filters, but don't remember the exact part number or specs. The relief valve has been externally dry every time I've looked at it.