Everything posted by rancherman

-

Found the perfect family car...

didn't they 'hellcat' the challenger too? or charger only? ....... knock off the 2 rear doors... and I'd buy one! (seems we had this discussion a couple years ago??)

-

Miss at all RPMs

Not real sure how this works: These 'plans' will have inputs for ComputerAidedMachining?? Local shop has a plasma table.. I'd buy your design... and all the little parts would be accurately cut on their table? Or is it something more simple... scan the plans in, and 'scale it up' to proper size? Their computer would do the rest? Dad used to have a shop with a simple 9 head pattern torch, which had a simple auto-trace feature.. As a kid, I'd sit there for hours watching that thing! Keep this project visible in the forum!

-

antifreeze... long and short

Think of the thousands and thousands of v-6's that had melted (not from heat either) plastic intake manifolds because of that stuff!

-

Miss at all RPMs

I like it! ... what program did you use for the drawing?... oh hell, just send me (or sell) the plans! I'd probably change the name tho... and use my cattle brand.

-

Crude oil prices!

Another consideration: Oil companies really don't appreciate ethanol. period. And since grain prices are at least half of what they were 2 years ago... the ethanol industry will be making money. (unless fuel prices drop) and they magically have! Seems like grain prices and fuel prices are almost parallel. We (farmers) have suspected this for many years!

-

Crude oil prices!

Nice 'end of summer' type reprieve on our fuel prices!! Gasoline is right at 3 bucks, E85 is about 2.35, and sigh, diesel is still 3.55. Oh well, it's better than it was! The 'new' oil coming from N Dakota, and Texas is reportedly pumping hard again... seem we have a glut! Of course, Russia, and other eastern oil producing nations are pissed!... too bad! My question is... Is this a natural swing in the cycle of oil prices... or is it because next week is election Tuesday?

-

MoparMello: Cooling problem

I actually found a tub (not the one in my bathroom)"This time".. that would hold the radiator (flatwise) and hose fittings pointed up.. and let her soak overnight. simple green, I believe. filled the tub with just enough so the soap wouldn't run down the hose fittings.

-

Oil smoke

"around here, when sumthin stops leakin... It means it's outta oil"..

-

Oil smoke

well, you did say it started smoking after a long idle period?? perhaps the guide seals just needing some exercise to kinda reseal... OH, btw, have you ever taken a sample of diesel w/ 2 stroke, and just let it set for a long time? "Mason jar type experiment".. any chance it may have settled, and you sucked up some pretty strong concentration of oil?

-

Flatbed pics! and dumbass question..

flatbed progress pics: http://forum.mopar1973man.com/index.php?/topic/9117-flatbed-is-bolted-down-getting-close/ And of course, when I took off the old box, I just cut the whole harness... figured I'd sort out the wires later! uggg. Anyone have the schematic of rear body wiring?

-

How to make an income and build your own house

What would your competition for the same services be? Lot of mills in your area? My experience with mill operators, is them finding the time to do work for me.. lol, I'm impatient. I'd say if you get this machine figured out, and dialed in, do quality work for a reasonable price, you'll be golden. (if not over run) The ability to 'go to the trees' has to be in your favor! tool purchases such as this can be looked at differently.. I'm looking at buying a hydraulic tree spade, for moving about 300 cedar trees into shelterbelts. (digging wild ones from rangeland, and moving them in ) I figure I'd pay around 7-8k for a good used 30 incher... use the crap out of it for a couple years, then re sell it. Cheaper than having the trees custom moved. You may be able to mill up a storm, (for your own use) and if the market doesn't knock your door down, resell the mill.. Then again, looking at the price of lumber, having your own mill 'out back' may pay for itself quite easily, especially if you get this one for a good price!

-

Miss at all RPMs

Oh MAN... fresh paint, and leaning over the fender to work on the engine!!! Wish you all the luck in the world!!!

-

Coil Springs

Correct. slightly different material, coil shape, etc... could make the 'free' height different. especially when dealing with the variable rate coil. They know what that spring does when loaded, and have adjusted the length accordingly. Not saying all replacement springs are like this, the few I've replaced all had the little 'warning' sticker in the box. "don't freak out when comparing springs" Rockauto has 'snowplow' springs for $222 pair.. most of the others are less than $100 pair. My old '94 gasser is set up with those springs. There IS A DIFFERENCE!! I like em!

-

Miss at all RPMs

On a stone cold engine, fire it up, just idle it for 30 seconds.. then shut it down. You'll be able to just use your finger (lick it first) OK>> dip it in some water<< and go down the line and find the dead cylinder pretty cheap too. your good cylinders should just make it sizzle, and the cold dead one will just slowly evaporate.. 'warm', but not hot. After a minute, the test gets fuzzy, cause the cold cylinder will gain enough heat from it's buddies Dang, Yesterday I got a 354 perkins that suddenly started a dead miss!!! Upon shut down, It goes 'whoof, whoof whoof...out the straight pipe. My prognosis; dropped valve seat. Always something in the toilet here @ Ranch.

-

Coil Springs

I've replaced coils with aftermarket ones over the years... and just about every one had a instruction sheet stating.." Don't worry if the height of the new spring is actually 'SHORTER' Than the original spring being replaced... The new spring is a different wire size, coil spread... etc, the real difference will be after installation. IT WILL BE TALLER THAN THE TIRED SPRINGS.. Food for thought.

-

antifreeze... long and short

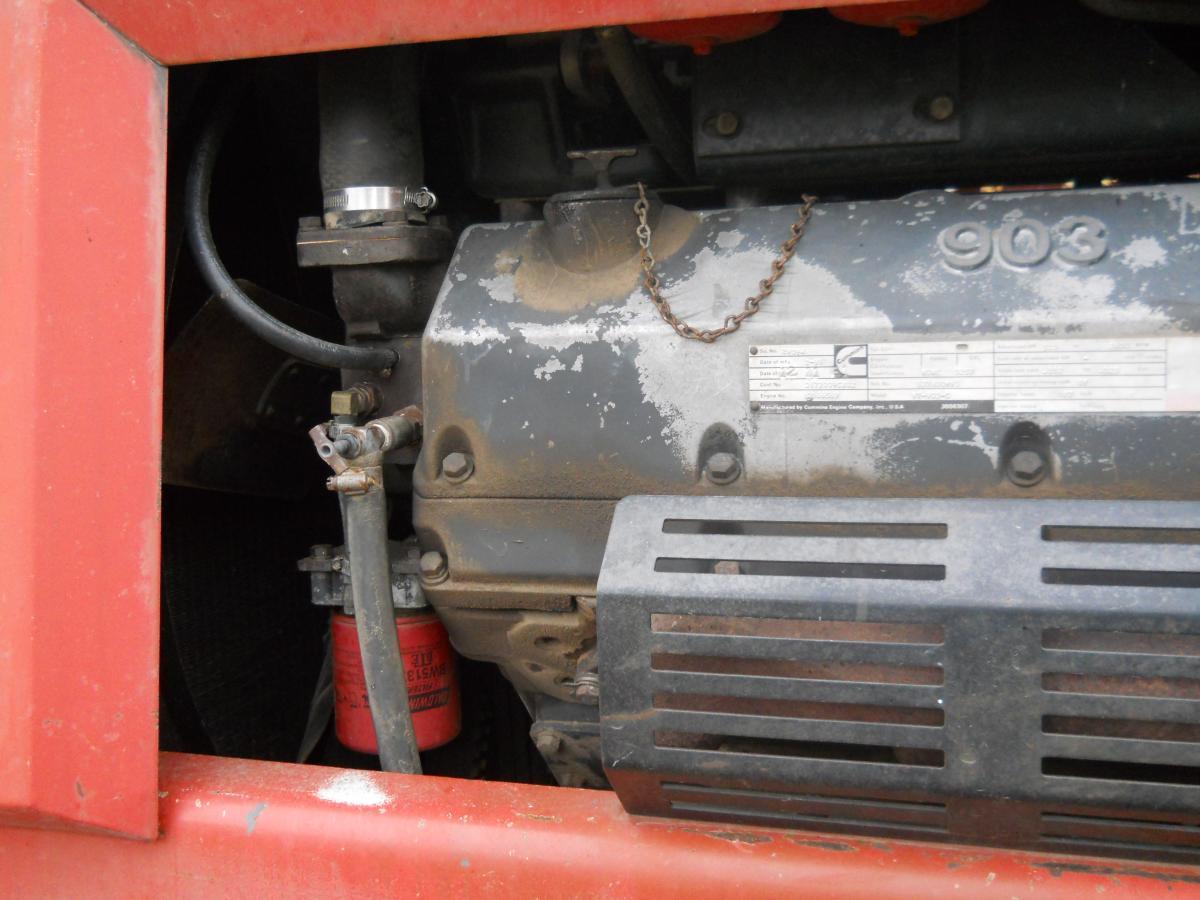

it's a continuous flow. Valves are there just to shut off the water so removal of filter isn't as messy. Whatever that little 3/8ths line can run.. so a tiny amount is always getting treated. As far as testing and treating.. My owners manual on that 903 basically says to 'test' every thousand hours or so.. and add an SCA treatment IF it's getting a little acidy. If antifreeze looks 'clean' that is! I plan on changing the filter every few years, there is a dissolving chunk of 'something' in there to help with PH. I've only owned this machine for about 5 yrs, and it's had at least 2 complete fills with new antifreeze I rebuilt the engine once, and had to replace 1 more cylinder afterwards..... 24 gallons a shot!

-

Flatbed is bolted down... getting close!

pics of what I've got so far. This pic is the rear section, using the 2x3x 1/4 rectangle tubing. They are welded permanently to the 'c' channel on the flatbed, and uses 5/8ths bolts through the original box mounting holes on the frame. The 'foward' of the two shown, is smashed a little. The truck frame has a slight bubble "UP" at this point, meaning the tops of the tube wouldn't be even. All the rest of the tubes came out even. This pic shows the middle pair of stringers. This is the part that 'ties' in the actual hitch plate (gooseneck ball) to the frame of the truck. Again, the 2X3 tubing, with more tubing 'stacked' up to the 1/2 inch ball plate. I used 3/8ths plate welded to the stringers, and used existing 5/8ths holes already in the truck frame. This whole mess is permanently welded to the flatbed. Notice the 'notch' at bottom of plate.. to clear the brake line attaching bolt.. Might be handy to put a wrench on it someday! This is a shot of the view looking upwards to the opening for the ball. Showing the 'stacking' of the tubing, which ties the original ball plate into the stringers. This dude is solid. Finally, the forward 2 stringers. same tubing, welded to the C channel, and re using the original box mounts. Theoretically, I could pop the 12 bolts, and remove the whole system and re attach to another Dodge of same vintage.. 12 5/8ths bolts hold the whole contraption down, I didn't use lock washers. I used loc-tite and grade 8 flat washers. Lock washers tend to spin out/break.. and then you've got a loose fastener. DOT is getting pretty snarly about what is getting drilled or welded on our pickups frames. Reusing existing holes is a safe bet. I think I've a pretty good idea on how to plumb the fuel neck now.. I'm also going to re use the receiver hitch to tie into the drop down hitch on the flatbed. It'll be in the original position, but will be just to the front of the flatbed's dropdown. That'll really stiffen up the whole rear end. Lord help anyone who rear ends me!

-

antifreeze... long and short

I'll snap a pic of the SCA filter off my big Massey. Simple little filter head with a spin on filter. Hang on...

-

Miss at all RPMs

my experience with dead cylinders, when you see puffs of smoke @ idle, (white to bluish white) means she is getting fuel. It just isn't getting lit. ....usually goes away @ speed, since the other hot exhaust eventually lights it in the exhaust pipe. On a turbo engine, a burnt valve, flat cam, REALLY SCREWS with the operation of the turbo, and tons of black smoke/low power are evident. Had a JD tractor 466 turbo, that had just 1 rocker arm wear through, (exhaust) and was the smokiest dud. ( freight train type coal)

-

Flatbed is bolted down... getting close!

I'll have pics soon! Basically I used 6 'stringers' of 2X3X 1/4 rectangular tubing, and used the original box mounting holes. I welded the tubing to the channels of the flatbed. The extra 2 stringers were tied in with the gooseneck hitch area, welded to 3/8ths plate, and then THOSE were bolted to the existing frame holes (right beside the tires).. Lights are now installed, but need to string out the wiring harness, then finish up on the fuel neck, and of course the mudflaps!

-

antifreeze... long and short

So, to bring this post here to bed.... If I drain my Jeep, flush it a couple times, and refill it with Peak global, I'll be good. What I've found in this forum, and others, Is the various additives being used over the years for longer life, corrosion resistance in many, many different metals, plastics, and electrical currents passing through them, all have their merits, but sure don't 'play well' with the others! (don't mix!)

-

Flatbed is bolted down... getting close!

THANKS!!! Forward HOOOO!

-

antifreeze... long and short

Where does everyone go with their waste antifreeze? Poll here: I save mine, and use it for ballast in the tractor rear tires. No rust problems as with the calcium chloride!

-

Flatbed is bolted down... getting close!

yah, yah, yah!!! I know!!! Here is a pic from 2 months ago.. I can't find the camera for the current progress on the flatbed project. here is a pic of the front 3/4 view, which shows all the holes for the lights On the front corner, you'll notice 2 holes. One facing front, the other 'just around the corner, facing to the side'.

-

antifreeze... long and short

I'd even follow up with a Cascade dish soap type rinse.. it's a PH+ (base) type detergent that would help neutralize the acid.. Then flush a few times with clear water