- Replies 38

- Views 9.8k

- Created

- Last Reply

Top Posters In This Topic

-

Daleb 17 posts

-

Tractorman 9 posts

-

JAG1 5 posts

-

Mopar1973Man 4 posts

Most Popular Posts

-

I do remember that you had trouble with the Joint connection #2 , but don't recall all of the details. However, many times people associate things like burnt electrical connections, melted solder, et

-

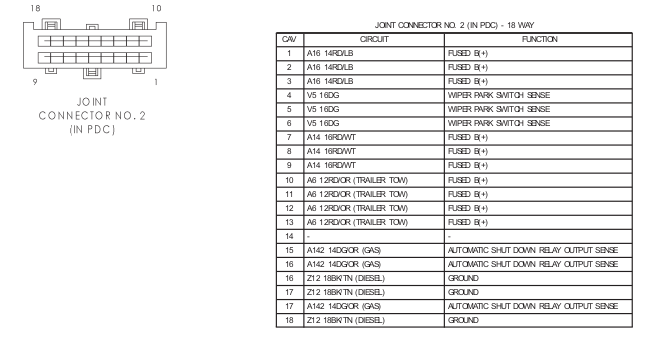

Well there is a 98 24v in my area that just had his joint connection 2 burn up. That makes 2 total failures in the last few months also I have one here off a parts truck that got hot enough to blacken

-

@dripley, I checked where the power for the lift pump relay contacts come from on my truck. As you suggested, it comes from the battery connection at the PDC. A short distance away is a 15 amp in-li

Well I have finally have the PDC and harness installed in the truck .If you remember the old PDC burnt up at Joint connection 2.I was checking for dead shorts with the pos connected to the battery and using my test light on the neg post of the battery and on the disconnected neg cable.the test light lit so i know there is a short and started to pull fuses.When I pulled the 50amp battery fuse the light dimmed and the next fuse was no change.Pulled the 20amp engine control 2 fuse the light dimmed more. Pulled all the rest of the fuses and the light stayed on but was dim.I am at a loss as to whats going on and am looking for advice.

Thanks

Dale