- Replies 9

- Views 1.7k

- Created

- Last Reply

Most Popular Posts

-

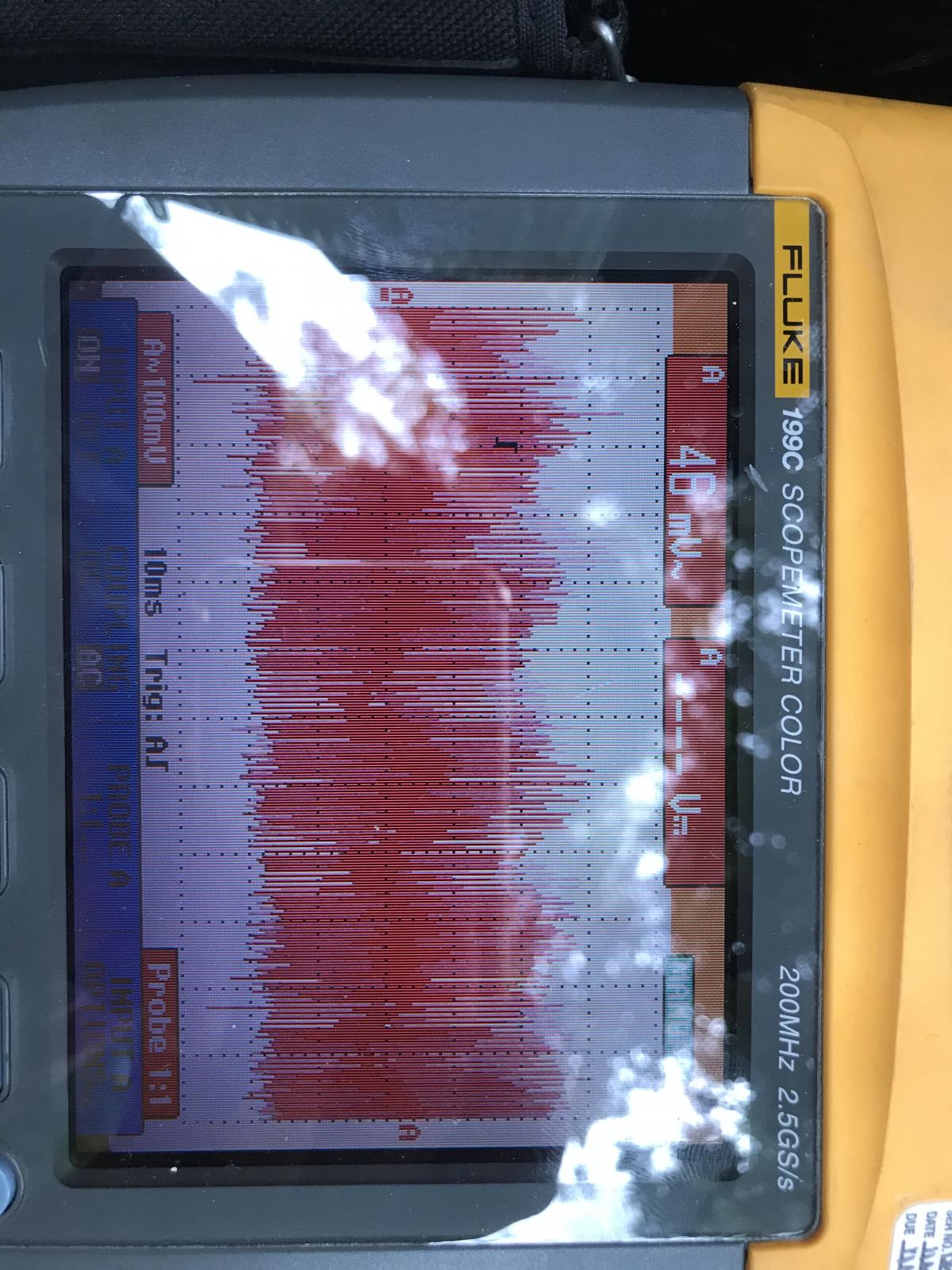

The truck transmission was experiencing the torque convertor lock/unlock problem and that part was thought to fix it. The real problem is high ac voltage from the alternator caused by leaking diodes

I’m new to the forums and would appreciate any help. Just purchased a 2001 Ram 2500. It has a mild case of previous owner syndrome that I’m trying to correct. Most of the wiring issues have been pretty straightforward but there’s one in the engine bay that I need some advise on. It appears that the Org\Blk leaving the ECM has been tied directly to ground, effectively eliminating intake air heater relay 2. Anyone venture a guess on why someone would do this?

here’s a pic of the wire. https://imgur.com/BtAmNmw