- Replies 28

- Views 4.1k

- Created

- Last Reply

Top Posters In This Topic

-

SVALIN 12 posts

-

Silverwolf2691 5 posts

-

Mopar1973Man 4 posts

-

Tractorman 4 posts

Most Popular Posts

-

The drilled hole is a vent and it is needed to make the boost elbow work. If there is no vent, the boost flow can be restricted, but air will eventually fill the wastegate actuator chamber resulting

Hi All,

longtime reader, first time poster. Most of my build is a recipe from here and other parts of the community, so thanks. Finally thought Id join and contribute because Im spinning wheels in my head more than the truck on this issue. Also see if I can help contribute to other headaches too.

Issue relates to not achieving max boost out of the turbo, unless the wastegate is pinched. I dont see any boost leaks, and have plenty of fuel, more later.

in case sig doesn't appear or post. (Only listing relevant items)

2001 24v, S&B cai, banks monster ram, afe bladerunner, headstuds, hamilton valves and rods, DFI 7x.010, BD exhaust brake, Quadzilla, 3.54 on 275/70R18 (yes, its a little low on the gearing). Turbo is a Hx35 64/64 its set from factory at 40 psi. Valves adjusted recently.

Ive reached out to the vendor and theyve been helpful. Sent an additional WG actuator but have the same results. Im hoping Im missing something obvious.

Backing up a bit on build. Had RV275, hy35 j hook, original edge j w a. 0-60 8.5s not hard launch, at 34 psi boost (side note, this setup was almost completely clean except for boosted launches on 5x5 or other silly things also 19-21mpg). Bolted on this turbo, 0-60 7.5s at 29 psi.

Cool on right track, need more fuel I figure. Added DFI 150s and a quad. Still 29 psi..

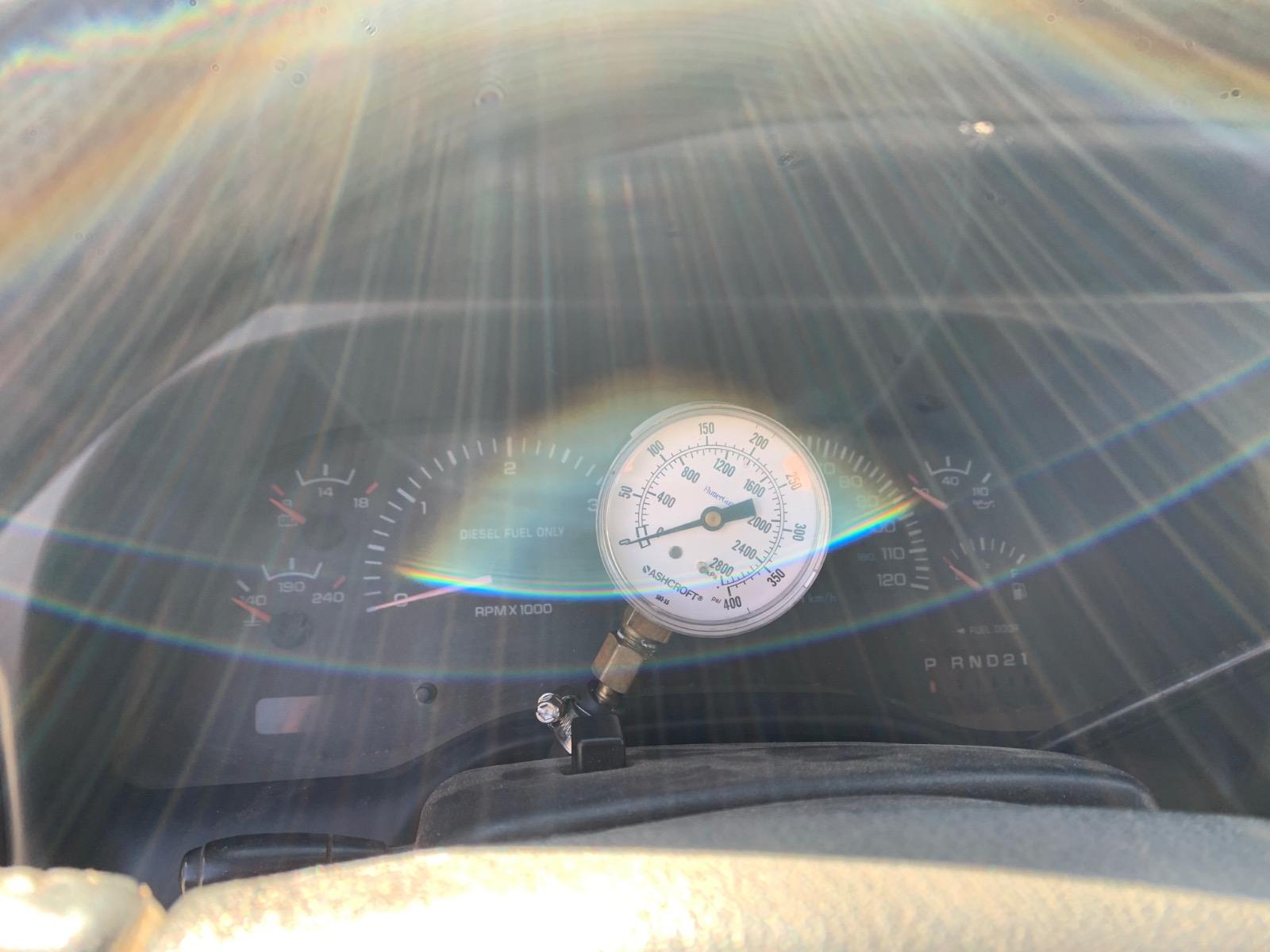

Adjusted wastegate rod in, 34 psi max, about a dozen different times and adjustments. Used shop air gauge on boost reference hose to set 40-60 psi opening, with same results. Removed downpipe and plate, to visually inspect wastegate, appears all good.

Set quadzilla all the way frickin up, also different timing variations. 34 psi, and high egt cutout.(1400).

Built adapter plate for turbo intake to pressure test and look for leaks, all good. New MAP sensor from NAPA

The only way Ive found to go over that is pinching reference hose. Thats why Im leaning so heavy on the WG. Itll shoot up to 44 no problem quick, either my foot or defueler kicks in and backs out, and egts cooler (11-12?) these numbers are mostly from the quad, but had same from the edge too.

Please help, this is supposed to be the end of my build and having trouble. Id like to focus on more tuning soon and getting best mpgs out of this or possibly slight smaller injector setup.

Tomorrows saturday, so open to testing suggestions. Probably at least post a shot of hose pinched and unpinched. Although not handy with the excel to graph it.

Thanks for reading, and getting me this far along.