- Replies 49

- Views 6.5k

- Created

- Last Reply

Top Posters In This Topic

-

dodgedieselnewbie 24 posts

-

Mopar1973Man 16 posts

Mopar1973Man 16 posts -

Me78569 4 posts

Me78569 4 posts -

notlimah 3 posts

notlimah 3 posts

Most Popular Posts

-

Well... I ran around to 4 different auto parts stores. I asked if I could check for AC noise and a couple looked at me like I was nutzzz as I explained why. I put my meter on them at 2 stores but coul

-

Think of all the times people have run there batteries dead and jump started the truck and drove on. Nothing happens just the range of throttle might be affected but most don't even notice.

-

I didn't see that in the image, but I wasn't looking either haha. What decimal point does it read to in AC mode?

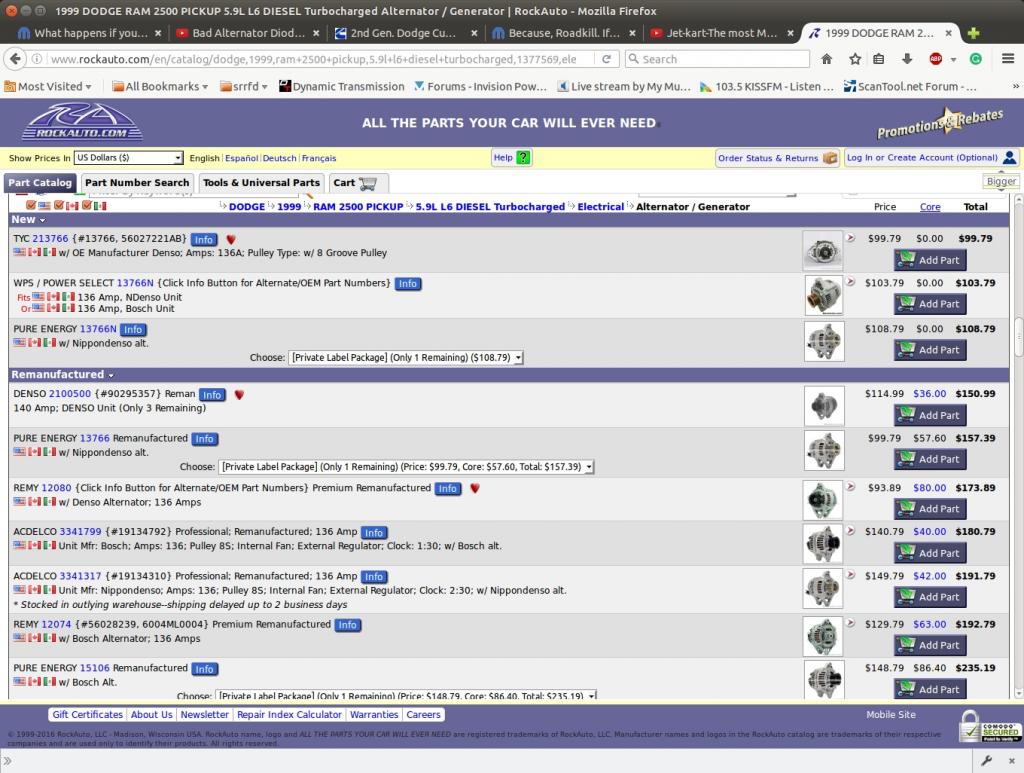

I know a couple of times I've had my batteries disconnected anywhere from 15-30+ minutes. I've never done an apps reset (didn't know about it). I'm asking because I'm still having issues with my truck (at times) dropping in and out of lock up.. like yesterday was horrible. Just releasing the slightest of tension on the accelerator would cause it at 55, 65 and higher. Today.. no issue whatsoever tho.. Ran around 80 miles.. stop and go and highway.. never dropped out once. Not sure why it has good days and bad? I'm getting a TPS low voltage code every time I check and clear. I'm going to try the reset procedure tomorrow based on cumminsdog suggestion. And.. I still need to get a meter and check alternator voltage...

Edited by dodgedieselnewbie