- Replies 211

- Views 24.2k

- Created

- Last Reply

Top Posters In This Topic

-

Marcus2000monster 98 posts

Marcus2000monster 98 posts -

Mopar1973Man 32 posts

Mopar1973Man 32 posts -

Shainer 17 posts

Shainer 17 posts -

dripley 16 posts

dripley 16 posts

Most Popular Posts

-

I would not do that. If air intrusion is suspected the last thing you want to to is suck water and soap onto the fuel stream and send that to the IP and injectors. Besides you will never see a singl

-

For now i would clean up the connection and make sure you seat it good to see if that's the problem. I know those quick disconnects have a bad rep but mine have been in use for 6 plus years and they a

-

Let’s say eating cuz I don’t have a friggen clue how to bake a pie! Hehe

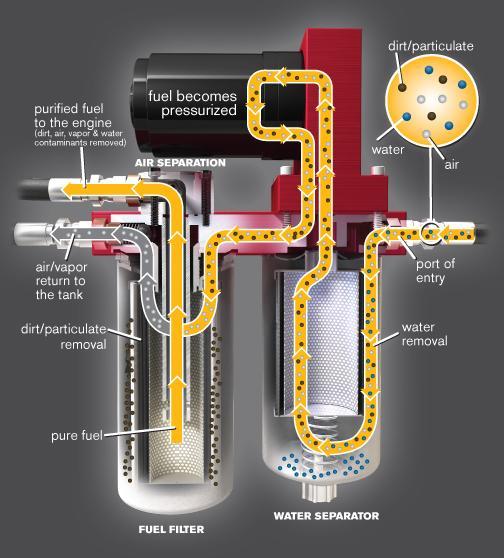

Well I thought the truck was running good... It sat last night and most of today and I went to start her and she fired first crank but idle extremely erratic and had a nasty lope and unloaded a mass cloud of white smoke... New injectors went in a week and a half ago and all seemed well until the lift pump failed. I'm thinking the LP took the VP too. Fuel pressure went straight to 20 psi so that's not a issue. Ran the key trick and got P1693 and then -------- and then P Done. checked for codes and found nothing.