- Replies 31

- Views 6.8k

- Created

- Last Reply

Top Posters In This Topic

-

2000Ram2500 17 posts

-

Mopar1973Man 8 posts

-

dripley 2 posts

-

JAG1 2 posts

Most Popular Posts

-

Made it around to doing the W-T wiring mod this weekend. Alternator now charges the passenger battery and the ground goes to the timing case with an extra ground to the drivers side battery. Did a fai

-

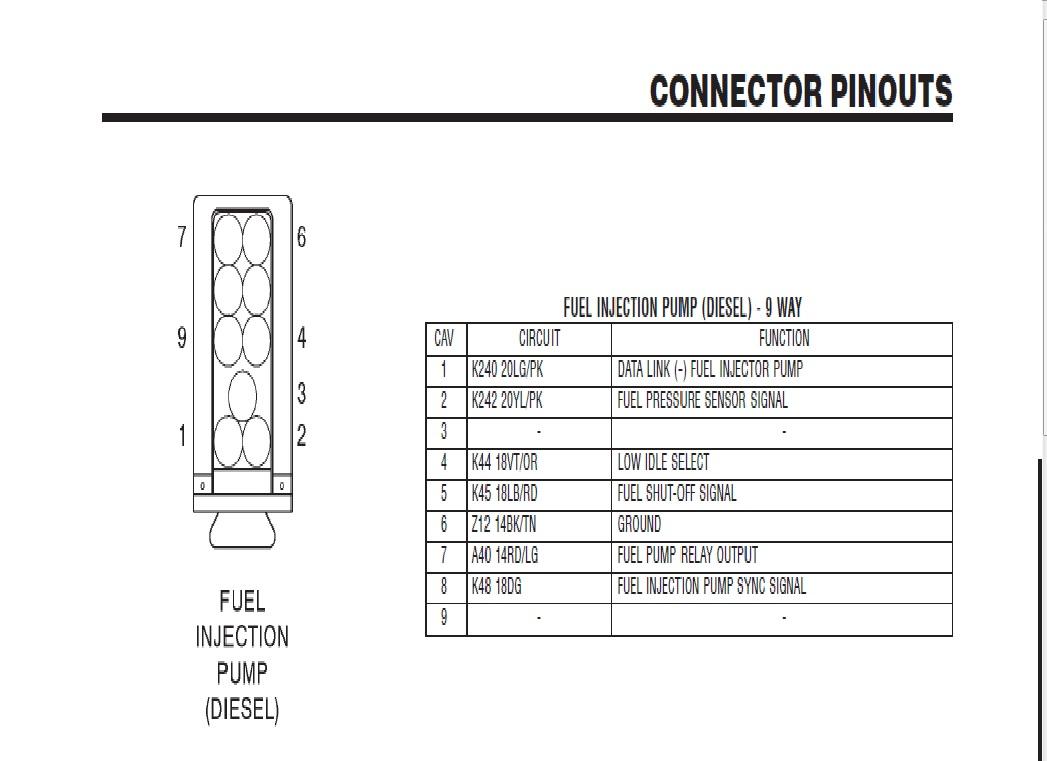

Edge tuner is built the same way our trucks are. The sensor power lead is 5V and the sense in on the same wire. This means the Juice is looking for ground bias to report fuel pressure. Since the senso

-

Oh i see so i need to be looking into that circuit then and trying to find a short or break in the wire. I'll have to reference the edge instructions and see what im dealing with here. And obviously g

Did some searching around and figured I would post my experience here. Alot of people replacing the VPs over this it seems like. I went onto the dealer site and found the diagnostic tree for this code. Nowhere does it say replace the pump. It says either electrical/wiring issue which I understand could be the circuit in the pump, or the ECM.

Personally I am assuming my circuit board is fine and I have a problem elsewhere. I live where there is an issue with rat damage. My pump is tapped for the Edge. I had a spare APPS to try. I tried the relay swap that moparman suggests. I cant fully rule out alternator noise but i have the BD kit and keep that ground wire routed over my intake tube to keep it off the back of the alternator and I haven't had the torque converter issue in months which I would notice because I have a triple disc converter you know when it locks up. I've been researching all week and finally yesterday had a chance to do some actual work on the truck.

I disconnected the batteries and left the key on the whole time to do a reset as I saw someone suggest I just did it for a couple hours while i was working on it and so i didnt zap myself somehow. I got the APPS out of the way so i could really look at the wiring underneath. The plug on the VP looks fine and the terminals had plenty of grease, same for the APPS connector. The APPS sensor itself had a rusted out imprint of the bellcrank arm in it which im sure is to be expected from snaps of the throttle and years of weather and maybe it was causing the sensor some confusion? I changed it anyways.

Given that my pump is tapped for the Edge i suspected possibly an issue there but the tap was still in there nice and solid. I looked and felt around as best as i could to hopefully rule out rat damage and I couldnt see or feel any chewed up wires all the way up to the ECM connector. However i did notice a tiny little nick in the tap wire itself right next to where the grid heater wire comes up to the intake horn. I fixed that little nick and got the wire cleaned up. It got me wondering though, could the grid heater have caused the intermittent loss of power somehow because it runs so close to the tap wire, and i know those relays kick on randomly while driving. It would cut out more so right after start up and really only from 25 to 45, and on a longer trip across town by the time i got by my destination the loss of power was gone i had no symptoms of the code anymore other than the light on the dash. I've been running the edge on stock all week just to be safe and even cranked it up to 5 and it was running like a beast.

So this is where I'm at with this. Basically Im just wondering if that huge grid heater wire was giving off interference through my edge tap wire and causing my problem. Gotta run errands and will see if what i did yesterday fixed my issue.