- Replies 6

- Views 15.7k

- Created

- Last Reply

Top Posters In This Topic

-

Dieselfuture 2 posts

-

Rather Be Wheeling 2 posts

-

Mopar1973Man 1 post

-

hdpwipmonkey 1 post

Popular Days

Most Popular Posts

-

When I did mine I shoved all injectors in, then put all shoulder bolts in and torque them to 90, then put hold downs straps in to center injectors, then get cross over tubes in and snug injector lines

-

I am not a professional by any means... but if it was me, I'd do the 80in/lbs then some vs going 24in/lbs over spec. From what I read though the important torque is the fuel supply lines. Over torqu

-

89 inch / pound on the injector hold down. This is not tighten first. The cross over tube is first to center the injector first. Once the cross over tube snugged up you can do the injector

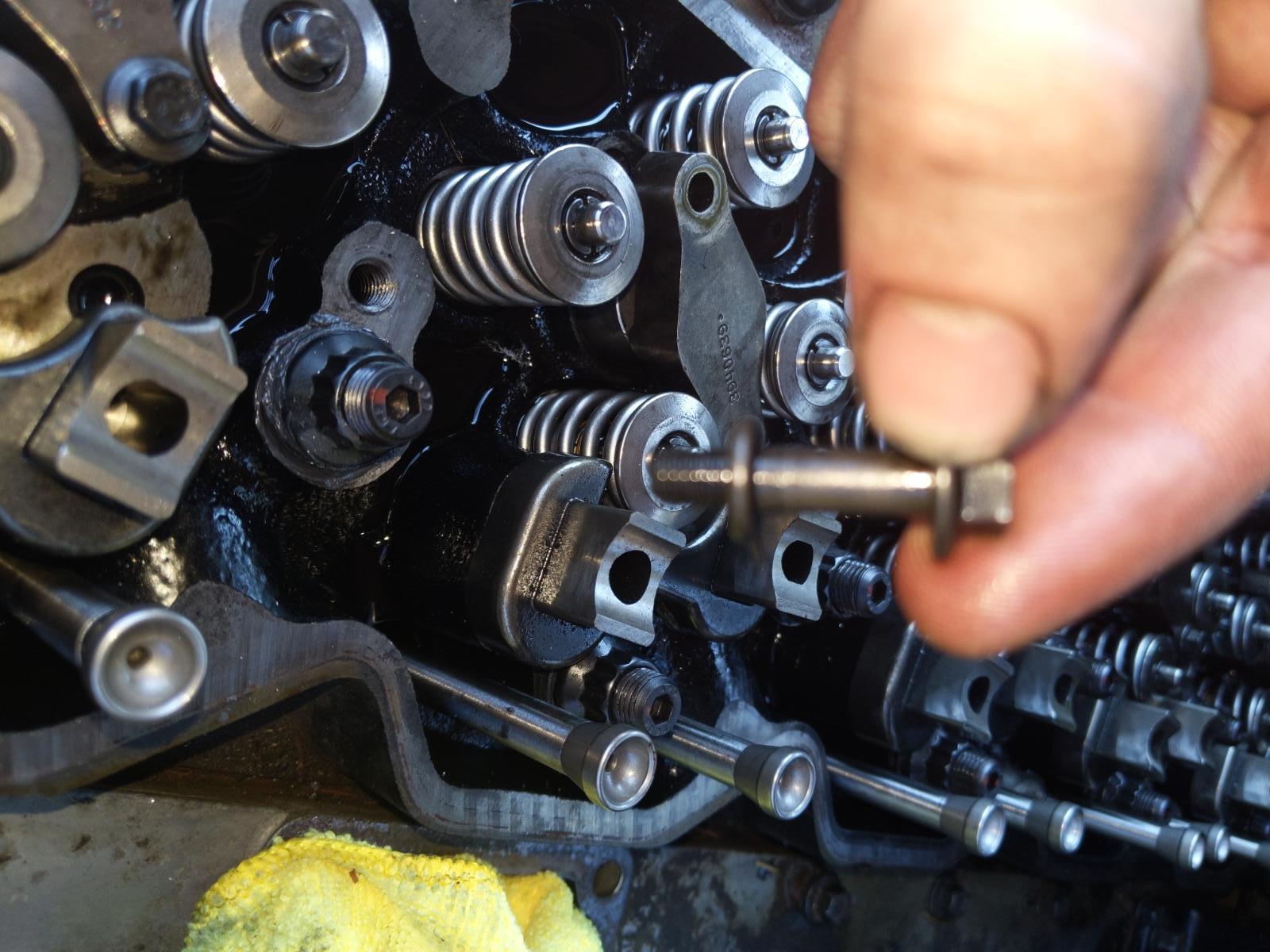

Having a little trouble finding this answer. My service manual says 89 in lbs for the clamping bolt but nothing for the shoulder. I'm assuming it's the same but I just want to make sure. Pic for reference but I'm sure y'all know what I'm talking about

Also, just realized I forgot my in lb torque wrench that goes up that high at my house an hour away. And I don't have a torque wrench that goes to 8 ft lbs. So either I can torque it to 80 in lbs or 10ft lbs with what I currently have. I'm assuming it's not going to hurt anything giving it a little more on my inch lb torque wrench or going up to 10 ft lbs on my other torque wrench. Any insight would be appreciated