Any helpful tips on doing injectors / valve lash adjustment?

- Replies 9

- Views 3.1k

- Created

- Last Reply

Top Posters In This Topic

-

Tractorman 3 posts

-

Timburrr 3 posts

-

Mopar1973Man 2 posts

-

Doubletrouble 1 post

Popular Days

Most Popular Posts

-

Always the crossover tube first then the hold down next.

-

Yes sir, that's it. Install the injector bolt finger tight at most. Then cross over tube, this way the tube and injector will self align when you torque the cross over nut. I installed all inje

-

I apologize for any confusion with my instructions. Please disregard my initial instructions. As I recall now, I used the method for installing injectors from the service manual for a common rail fu

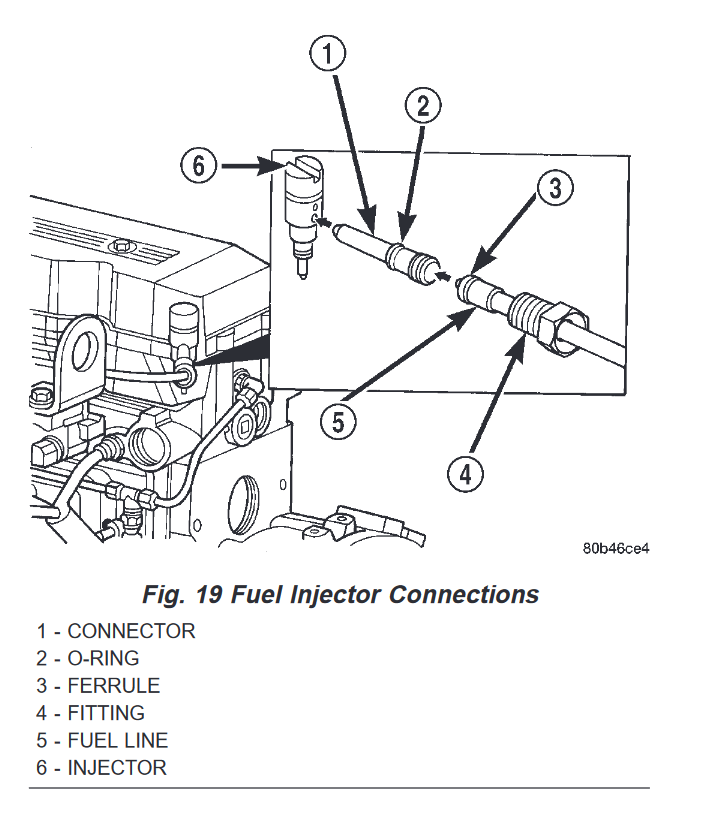

Truck is a 1999 quad cab manual trans with high mileage. Did my VP44 a couple weeks ago and after its hot it gets a bit of a random miss at idle. I think there's a good chance one or more of the connector tubes didn't seat back in properly. Since the injectors have 150K, 200K or even more miles on them I'm going to do new injectors and new connector tubes (I have no record of them ever being done and I've put 100K on it myself and the previous owner didn't ever have them done maybe they are even originals!). While I'm in there I'll check and adjust valve lash.

I'm not super confident on this. The only time I've done injectors and valve lash was doing a quick ISX teardown and rebuild with a couple partners in school. If anybody has any good tips it would be greatly appreciated. My plan is this:

-Remove injector lines in the two bundles

-Rotate engine to TDC #1 on compression (using balancer bolts since I either have a pay big money for a barring tool or wait a week for delivery for an affordable one)

-Do Injectors #1, 3, 5 (I read somewhere its easier if you take off the exhaust bridge?)

-Do Intake valves on #1, 2, 4 and Exhaust valves on #1,3,5

-Rotate to #6 TDC compression

-Do injectors #2, 4, 6

-Do Intake valves on #3, 5, 6 and Exhaust on #2, 4, 6

-Give the engine a few rotations by hand to make sure everything seems happy

-Leave #1, 3, 4 injectors lines loose for bleeding then torque after bleeding procedure.

Treat me like I know nothing!

I'm guessing I won't have to blow out any fuel lines before getting in there. How do you guys pull the injectors? Heel bar? Do you ever have the copper seals get suck in the head? Fish out with a pick? Any nicer ways to rotate the engine? Some people use nut on Alternator it sounds like? Big wrench on fan and turn counter-clockwise? I considered using the nut on the VP44 but don't want to accidentally over-torque that, although it has a big torque value from what I remember. Tighten high pressure lines on head end first? except #1, 3, 4?

Any and all tips would be super helpful. I haven't been on here in a long time. Several jobs and several kids, I don't have a moment to think it seems. Big shoutout to Michael for getting my account set back up - there was some glitch-craft preventing me from renewing my subscription.