Welcome To Mopar1973Man.Com LLC

We are privately owned, with access to a professional Diesel Mechanic, who can provide additional support for Dodge Ram Cummins Diesel vehicles. Many detailed information is FREE and available to read. However, in order to interact directly with our Diesel Mechanic, Michael, by phone, via zoom, or as the web-based option, Subscription Plans are offered that will enable these and other features. Go to the Subscription Page and Select a desired plan. At any time you wish to cancel the Subscription, click Subscription Page, select the 'Cancel' button, and it will be canceled. For your convenience, all subscriptions are on auto-renewal.

- Replies 73

- Views 12.8k

- Created

- Last Reply

Top Posters In This Topic

-

AH64ID 27 posts

AH64ID 27 posts -

Wild and Free 14 posts

Wild and Free 14 posts -

dorkweed 10 posts

dorkweed 10 posts -

Mopar1973Man 5 posts

Mopar1973Man 5 posts

Featured Replies

Did This Forum Post Help You?

Show the author some love by liking their post!

Welcome To Mopar1973Man.Com LLC

We are privately owned, with access to a professional Diesel Mechanic, who can provide additional support for Dodge Ram Cummins Diesel vehicles. Many detailed information is FREE and available to read. However, in order to interact directly with our Diesel Mechanic, Michael, by phone, via zoom, or as the web-based option, Subscription Plans are offered that will enable these and other features. Go to the Subscription Page and Select a desired plan. At any time you wish to cancel the Subscription, click Subscription Page, select the 'Cancel' button, and it will be canceled. For your convenience, all subscriptions are on auto-renewal.

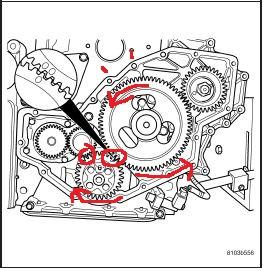

On my way to elk camp I developed a whine from the engine. I presumed it was the vacuum pump failing and removed the belt to install my non-vacuum pump belt. While the belt was off I started the motor to verify the noise was belt driven, it wasn't, pointing to a gear noise. Due to my remote location I drove the truck 15 miles to camp, 45 miles closer than town. I shut the truck down and waited. Two days later I started the truck and the noise was present instantly and got much louder when the oil pressure came up, I have a real gauge. This further led me, and my mechanic, the believe it was the gear train. We decided I should have it towed, and my insurance covered the tow (what a PITA) 255 miles to the shop. The truck got delivered yesterday and the mechanic got the timing cover off today, and it's amazing I made it to camp. The oil pump housing broke right where the idler gear is. The broken housing caused the gear to contact the housing and allowed the gear to run crooked and damage the crank gear. Somehow the cam gear also has a broken tooth, probably from a piece of the broken housing contacting the gears. The oil filter was full of metal, some of which was copper colored. The magnet in the pan had some metal on it, but not overly fuzzy. The big questions are how much metal got thru the filer? I run a 15um filter vs the OEM 40um filter. How much contaminated oil splashed up on the crank and cylinders while I was driving after the failure? I probably put about 45-60 minutes of run time on it from when I heard the noise. Before hearing the noise I was doing 30-50 on a dirt road with mud tires, the noise could have been masked for several miles. What else is damaged that we cannot see?The engine is coming out this week.. time will tell how far we tear it down. But probably all the way if it's out. I will be rebuilding it with QSB early CR pistons and nozzles. I have 93k miles and 2800 hours on the motor, surely no where near soon enough for this kind of failure. I bought a Cummins because they don't this!!Have any of you seen this before? My mechanic hasn't. Sorry, no photos yet. I wasn't thinking about that when I got to the shop. On a positive note I had a great week with my dad and brother, and filled my elk and deer tags.