Everything posted by Mopar1973Man

-

New addition to our family

Loki is similar in that respect. He will follow his family around and watch closely. Like tonight I went to town to pick up Jake from work and Loki was right at the door alerting me to the fact someone was coming to the door. Once he can see us his alert turns to a wagging tail and happy to see us. Dogs are wonderful companions. Some day ill most likely gets me another Dobbie or German Shepherd. I like good working dogs that are large enough that makes people think before just coming in announced.

-

Cyl injector lines loosening up over time- is there a torque spec?

In all the years of doing injectors, I only left one line loose on a member's truck. I never measure line torque. I just go by feel. If you crack a line loose while running you see the required torque to make it seal and run. Then I just add a bit more and that's it.

-

Cyl injector lines loosening up over time- is there a torque spec?

You be correct... I just look in the Dodge FSM to verify...

-

New addition to our family

Stellar looking dog... Kind of has that German Shepherd look. She looks like she is a high-energy dog and loves to be with her humans. Kind of like @Honey Badger has a pup as well just coming up on a year old his name is Loki. Husky and Healer cross and boy he can be an attention hound at times. He loves to go "T R U C K I N ' " if I would ot say it or go for the door with my truck keys he's sitting at the door waiting to be loaded up in the truck. Teach them early and they will travel everywhere.

-

Lower engine noise with bio diesel?

This is because Biodiesel is lower in BTU/Gallon vs Petroleum diesel which is much higher. High the Bio amount the lower the BTU's being its higher cetane fuel and there just isn't the BTU's in the fuel. On my last trip, the previous tune I netted my Boise trip and home 21.6 MPG. I don't know why but I backed the cruise timing down on that one and now brought it back up. Now I'm seeing much better EGT's that are basement low, engine load (amount of fuel) is lower to maintain cruising speeds on flat ground, timing isn't rattling the engine hard at all. I've found some secrets and have been running with them and really making good gains. CLUE: You can crank up some serious timing only if your boost is 10 PSI or less. Also, have to make sure cruise timing drops out at the right time because if you are holding that high timing and start building boost you can take a risk of blowing the head gasket. Also have to be careful about the types of fuel you are going to use being the cetane level in Biodiesel is high. Where petroleum diesel is typically lower with more BTUs so timing you have to look at fuel types and how much cetane and what your IAT temps are like. HINT: Colder air needs more timing to allow fuels to ignite at the proper time.

-

24V NV5600 “runaway” please help!

I've got a Timbo styled APPS in the store. https://store.mopar1973man.com/dap-commercial-grade-throttle-position-sensor-tps9804.html As for wild throttle try down the W-T ground wire mod. https://mopar1973man.com/cummins/articles.html/24-valve-2nd-generation_50/51_engine/electrical/w-t-ground-wire-mod-simplified-r574/page/2/?tab=comments#comment-149 This might fix it. But have the alternator tested for AC noise.

-

Honey Badger's 2001 Jeep Grand Cherokee

Yep. Needs work too. Currently Mark is the owner of it needs tires and valve cover gaskets.

-

98.5 crank no start

Sorry I got crossed up with being interrupted and came back thinking about another thread...

-

Ball joints and Control Arms, Suspension in general

Make things easy for you for the wheel joints. Just remove the shaft from both sides. Now take your hot knife and cut the trunion arms off. Let all that fall out including all the needle bearings. Now lightly heat the yoke ears up and punch the caps inward with a steel shaft and hammer. They will be super easy to bang out without damaging the yoke ears.

-

Honey Badger's 2001 Jeep Grand Cherokee

I've got @Honey Badger 2001 Jeep Grand Cherokee here and we started doing some serious repairs to her Jeep. What started out as cleaning the interior up and the carpet was well pretty nasty. I suggested to Mark to pull up all the seats and trim and remove the carpet so we could power wash the carpet. That option uncovered another major issue. The passenger side floor is rotten. While the Jeep in the state Honey Badger wants to make this her own kind of vehicle. So like in the picture above we are going to paint all the tan interior parts in a color-changing paint of blue/purple. We did a dry run last night of painting the driver-side kick panel. I had to do a bit of plastic welding on the corner of the panel then she cleaned, lightly sanded, primed, and then shot the color. Photos don't give this much justice but it looks awesome. So all the tan interior is going to be this new color changing blue/purple, then if you look at the exterior the factory fender flares will be painted the same color as well. Now we found a spray on paint that can be peeled off later. Has a bit of purple and metal flake but it would be a good rock chip protection. More to come on this project as it slowly comes to life. I've got mechanical stuff to fix like finding all the parts for the cooling system that her ex-boyfriend pulled off like the mechanical fan, fan clutch, electric fan, etc.

-

Thor - 2006 Dodge Tachometer issues

This is a known issue of the 2006 Dodge Ram cluster where the tachometer will be wild, erratic, or possibly dead or stuck. The fix is extremely simple. DISCLAIMER: If you do not have soldering experience please do not attempt this repair you might cause more damage to the cluster, electronics, or the truck. On Thor, since I purchased the truck the tachometer would sometimes work fine and on other days it would show wildly high RPMs like 4,000 while cruising 65 MPH in 6th gear. This is due to the fact when they manufacture the clusters they use lead-free solder and which tends to break down and then connections get weak. I just happen to buy a brand-new soldering iron. Now you need to remove the cluster from the dash which is not hard at all. Two screws on the bottom of the knee bolster and pull carefully at the top. This can be removed. Then the bezel for the stereo can be removed just lightly tug on the bezel it should unsnap from the dash base. Then there is 2 screw on the bottom of the cluster bezel then lightly tug and the entire cluster bezel will come out. Now the cluster has 4 screws to remove two on the top and two on the bottom. This is a bit tricky the cluster should have 3 wiring connectors that are not easy to see but the release for the locks is on top of each plug. Carefully pull each connector. Now you can remove the cluster. Now I brought the cluster inside the house and proceeded to remove all the screws on the back of the black plastic cover so as to expose the circuit board below. Now I know currently I don't have photos of this but I will. As you look at the back of the circuit board there are 3 IC chips with about 16 or 18 legs. These are the ones I reflowed the solder on. With the new tip, I heated and tinned the tip and wiped the solder off. Now with the very tip of the soldering iron, I place it on each leg carefully and heated and flowed the solder again. Now after you finish one chip grab your phone and put it into camera mode on my Android I set it for 3x magnification so I can really look closely. Now you need to verify that there are no soldering bridges between the legs of each and every chip if there are fix any solder bridges before you put the cluster into service it will cause damage and possibly require replacement. Now continue on to the next chip and verify after reflowing the solder. After the reflow, you can remove the cluster lens plastic and clean the plastic but be careful not to mess with the needles of the gauges and be careful assembling again for the trip button so that you don't break the trip button. Now you can redo all the screws for the back cover. Now the few forum post I read about this some say shim the right side of the board or different chips need to be reflowed, etc. At any rate, if the tach isn't working right it is a solder joint malfunction. Once the cluster is all assembled again you can take it out to the truck and test the cluster. Plug it in and fire up the truck and see if the tachometer is reading correctly. Before my tachometer would show 0 RPM at idle and 4,000 RPMs at 65 MPH in 6th gear. Now it shows correct at 800 RPM at idle and 2,100 RPM at 65 MPH.

-

Beast - Misc small repairs

That would be stellar. Let me know what I owe you?

-

Beast - Misc small repairs

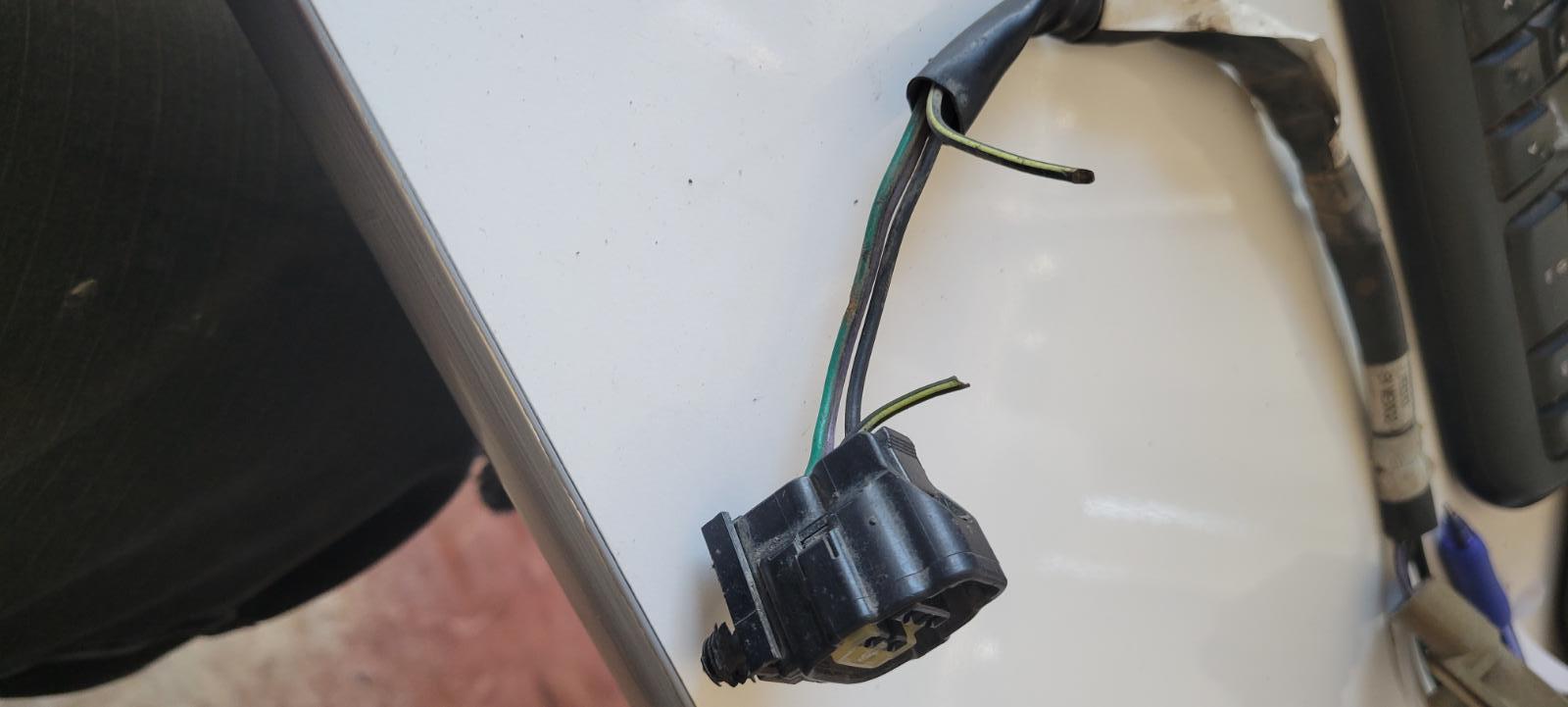

So you all seen my post about being pulled over twice for a failed driver-side tail light? I pulled the entire pigtail out and the bulbs and found a single wire that folded over and broke the wire but the jacket was undamaged. As I gave a small tug on the wire it separated completely. Sadly the wire itself was oxidized pretty badly. The break was within about 1/2 to 5/8 from the plug. I attempted to solder it back together and shrink tube the repair but the wire just refused to accept solder from being oxidized so badly. I opted to use a standard butt splice and seal the ends the best I could and then taped the repair over. Then finally I was cleaning out the cab and found the door cam spring in my driver-side door pocket. I went to work to pry that spring back into position in the door. Sadly this is just a band-aid repair for now but I'm going to need to replace both door hinges soon being the pin bushing is shot for the most part. Being the weather here was warm today I started doing my hinge lubing practice. I grabbed my small oil can and filled it with some 30-weight engine oil and hit all the door hinges, and door latches then moved to the hood and did the pivots on the hinges and the hood latch. Now everything shuts nice and smooth once again and doesn't require much to get a full latch on the doors. While I had the hood open I shot the battery terminals with engine oil as well. On my trip back from Boise I had a popping noise start as @Honey Badger and I left. I shoved the truck into the shop and got Mark to help out and hunt down the popping noise which we thought was the steering box. I quickly pulled the steering box and open it up and didn't find any problems. Quickly reassembled and started rocking the wheel without the engine and popping started again. Come to find out the track bar on the ball stud was moving again. When I tighten it last I tighten as far as I could and ended up passing the hole for the cotter pin so a barely backed it off to hit the hole but that was the wrong move. I ended up laying a washer down to offset the pinhole on the castle nut. Torqued the heck out of that nut with a 1/2 breaker bar and was really close and struggled to just get a bit more out to line up. Nevertheless, I nailed it. The popping noise was fixed. Yeah, I didn't do much for the website for the weekend. But I did get repairs done on Beast to keep it going legally on the highways and fix issues before they become big issues.

-

Death wobble issue rears it ugly head again

Be careful with trying to follow OEM. Like I'm finding out most OEM products are not updated or improved. Where most name brand have improved over OEM (Mopar and/or Cummins). Let's not forget like Cummins thermostats are not produced by Cummins, but Holley/Mr Gasket. Another like Cummins head gasket are produced in China by BLK. So for the steering dampener would do like KYB or similar.

-

Homemade Arduino VP44 & ECM project update #3

@Great work! by chance did you use the stock MAP sensor again? Hopefully, you break that limitation by finding a new MAP sensor that can see boost pressure up to say 100 PSI so then you can extend the fueling maps as far as you wish. The stock MAP sensor is limited to about 30 PSI of accuracy. I know it shows higher but the accuracy isn't there. Like my Quadzilla logs, I've hit 53 PSI and have it show 69 PSI on the logs.

-

Ball joints and Control Arms, Suspension in general

Also, need a set of adjustable control arms too. The lift kit will pull the axle to the driver's side throwing off the thrust alignment. I currently have this issue on Thor where I'm pulling the 2-inch leveling kit out and returning to the stock rake. My problem is with the weight on the rear it looks to be squatting by about 2 inches. (Scaled weight 9,300 pounds). This is an all-steel flatbed and heavy tool boxes. If I was going to keep the lift I would have to do the adjustable track bar, adjustable control arms, and then a set of airbags in the rear to get the rake back.

-

Truck has random misfire when hot

The only other thing I could think of that could be the issue is while hot doing a compression test. I've seen one member here @jlwelding that had a similar problem and found out later it was a cracked piston. It passed on the blow-by test but would have failed the compression test.

-

98.5 crank no start

Personally should have done a Timbo's APPS it's all mechanical and has no electronics like most OE-styled APPS.

-

Death wobble issue rears it ugly head again

Yup. All OE setting on alignment. Track bar just have second person rock the wheel. Watch for movement at both ends. Yes steering damper should have resistance both ways.

-

Truck has random misfire when hot

I'm starting to wonder if the VP44 might have issues with PSG when it get warmed up? I also got to ask which did you tightened first the unjector hold down or connector tubes? Correct is the connector tubes first then the injectors.

-

Death wobble issue rears it ugly head again

Just food for thought why is it that Beast is at 463k miles and never had death wobble? I've still got Y style yet too. Cheap ACDelco ball joints with over 250k miles. Napa track bar and tie rod ends. Current shocks are KYB and Napa steering dampener.

-

Death wobble issue rears it ugly head again

The one I seen was hoping vertical more so that toe wise like the video.

-

Truck has random misfire when hot

What did you have the injectors popped to what pressure? 310 bar is stock. A lot of injector builder will pop them as low as 300 or 305 bar which will give short life being by about 280 bar you can have misfire issues and/or idle issues. I've also seen injectors after a short time have much lower pop pressures due to settling of parts. Like my 7 x0.010 injectors (150 HP) are popped to 320 bar.

-

Death wobble issue rears it ugly head again

Being I witnessed a death wobble while riding my Goldwing I can say that imagine the axle hoping up and down left to right sides. The truck still travels straight but the axle is bouncing up and down.

-

OMG what a night...

Tail light pigtail has a broken wire just near the plug the bulb is good just the wire rubbed on the housing frame and broke the wire in half.