Everything posted by KATOOM

-

fuel pressure gauge install question.

I "think" the reason you see an isolator comes with all mechanical fuel pressure gauge kits is because its not legal for them to sell a kit which plumbs fuel directly into the cab. I may be wrong but I remember hearing that before.

-

fuel pressure gauge install question.

Oh I did..... And I also saw '02 Dodge in the post, and you have an '02 Dodge so I was confused since I couldn't imagine you were changing things up on your truck. I was going to have to question your logic.

-

fuel pressure gauge install question.

Your truck Moparman?

-

fuel pressure gauge install question.

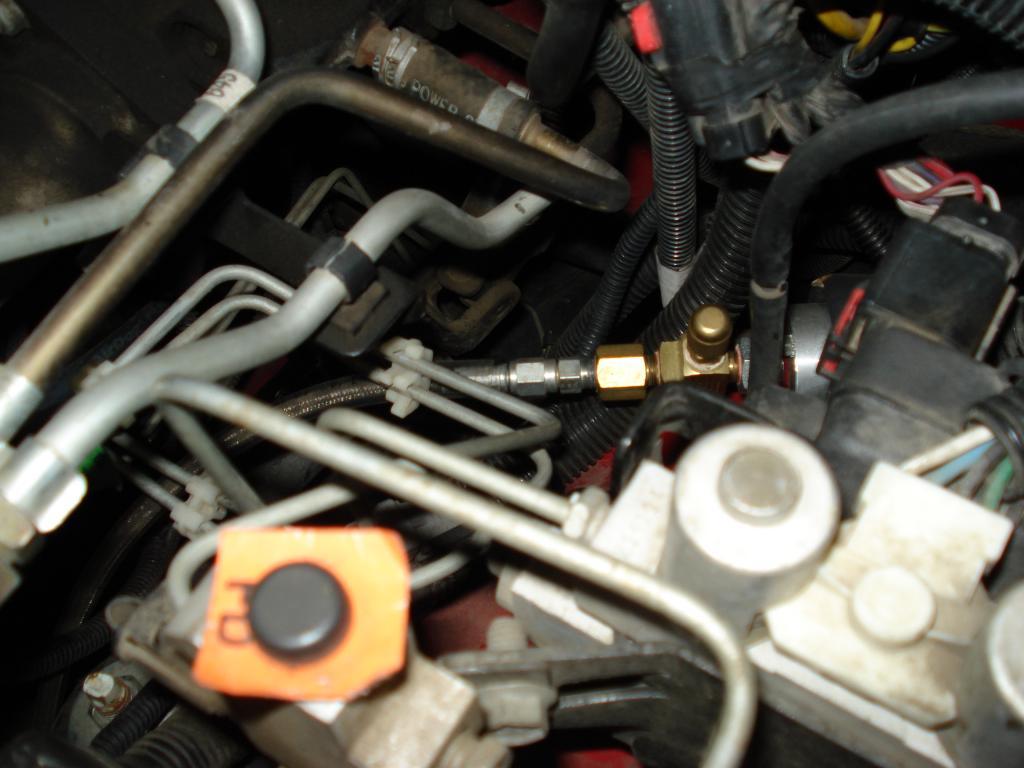

Here's another tip.....I ran an electric fuel pressure gauge for years and I liked it, that is until the sender failed. For multiple reasons not related to this topic, instead of replacing exactly what I had, I chose to go mechanical but I was afraid of fuel in the cab so I used an isolator.I always research something to the level of neurotic obsession, so I feel the isolator is the right choice for me. But my point is..... No matter what gauge brand or type anyone uses, I highly suggest plumbing in a test port to have the option of comparing your gauge against another gauge without tearing everything apart. So many times I read of guys confused by their gauge readings or wonder if what the gauge is telling them is right, but obviously they have no way to confirm anything since the only way would be to remove the gauge. Really guys, that's not being proactive at all. I say that sheepishly because I was in the same boat too when my electric gauge started acting up. So knowing from experience, when I changed to a mechanical gauge, I simply purchased a cheap T fitting, plumbed it in just before the isolator, and placed one of the original OEM schrader test valves in the T. This way I can hook up a test gauge and know whether my gauge is telling the truth. Matter of fact, just because I'm me, I tested my current gauge against a test gauge and the two gauges were within about 1 lb of each other. I was happy with that.Here's a picture of the T and the schrader valve pointing up. Its brass and really the only thing in focus in the picture.

-

fuel pressure gauge install question.

Well that depends. How comfortable are you with fuel going directly to the gauge in the cab? Some people are very against setting up their fuel pressure gauge that way in case there's a leak, whereby you could have a lot of fuel pumping in the cab until you have the opportunity to shut the engine off. Then there's the people who have it setup that way and are happy.Electric gauges are so popular because you dont have that variable. The problem with electric is they can be unreliable and potentially inaccurate because of the dynamic fuel pulses from the VP and how corrosive ULSD is to the senders.The fuel isolator is not hard to install and removes the fear of fuel in the cab. It just takes a couple more steps in the installation process.

-

Fan Clutch

I understand that using OEM Cummins fan clutch is the best. May cost more but will outlast any over the counter clutch.

-

Better Filtering

I think thats just an o-ring leaking. I've heard of guys using a little sealant there too.

-

Better Filtering

I dont know the reason why you're unhappy with the OEM fuel filter but no matter what you choose, DONT throw the OEM filter housing away. They cost around $1000 to replace.

-

Truck won't start...

Thats enough fuel but I should have been explicit by asking the question. I asked because its not to uncommon for someone to find that their fuel level gauge/sender is wrong and there's not as much fuel in there as you think. This was a far fetch reason for your problem but I thought I'd throw that out there.

-

Truck won't start...

If you're getting considerable fuel out of the injector lines at the head when you crank them loose, then try more lines to see if your problem is simply air in the system. Also, are you sure you have enough fuel in the tank?

-

Truck won't start...

Zero fuel pressure is normal ONLY if you have set up your fuel pump to not run while the engine is cranking. From the sounds of it and because you say everything is stock, then you have not. Which means you should definitely be seeing some fuel pressure on your FP gauge while trying to start the truck. It sounds to me as if you've forgotten to re-hook something up or blew a fuse or somethings wrong and whats happening is that when you installed the fuel pressure gauge line, you released the "prime" in the fuel system and until the VP receives enough fuel to start and/or the prime is regained, the truck wont start. This is why you hear of guys having to crack their injector lines to bleed the air out. And if you're fuel pump isn't pumping while your cranking the engine then there's no way the VP will ever see fuel. Because you have an OEM lift pump, I'm leaning toward your lift pump isnt working (pumping) and your VP was sucking the necessary amount of fuel to run.....until now whereby the VP cant suck air to re-prime itself so.....

-

Happy Independance Day!!!!

I love to see threads like this reassuring me that there's still patriotic people out there who understand that the 4th of July is a very important day. Matter of fact.....I feel this holiday should rival all other holidays except Christmas. A day to recognize the miraculous event which took place hundreds of years ago whereby this great land became independent of the British crown. Imagine that.....if there wasn't people who were willing to die for that freedom so that other could prosper, things would be seriously different today. In saying that, my local town failed to even put on a firework show, so my friends and family simply had a BBQ and enjoyed the cheap sparklers and whistlers.

-

Mopar1973Man's Crankcase Vent Modification

There are ZERO emission components on the 2nd gen ISB trucks. Matter of fact, the engine vent we're all discussing here is internal crankcase vent which vents into the atmosphere!!!!! How many vehicles do you run across on a daily basis that vent their engine directly to the wide open spaces with no EGR? I'd probably be safe to say not many. So in regards to your question, yes, extending the "open loop" engine vent hose to a different location is perfectly CA diesel smog legal and any smog tech who tries to tell you otherwise shouldn't be a smog tech.

-

EGT temp.

As much as I commend you for thinking outside the box, what you did is not really telling you anymore than what you already know, and that being that the thermocouple is reading something. Accuracy is what you really want to know. Is what the gauge is showing you the right reading.

-

EGT temp.

dripley, You're anything but a beginner and I'm sure you are completely aware of your gauge readings. I've become so accustomed to watching my pillar that I forget to watch important things like MPH. :)And I'm not sure if there's amplifiers in tuners.

-

EGT temp.

My Isspro uses an amplifier box and a couple years ago it started reading low. A quick call to Isspro and they told me how to test it and the gauge to determine what the problem was.Thats not to say your gauge or thermocouple is bad though, unless you're very aware of normal gauge readings.

-

starter or solenoid going out? possible rebuild?

Sounds like your starter contacts need attention. Very easy to do yourself so unless you have no skills or tools, dont pay someone to do this. Sometimes they click and sometimes they click once and internally short out and cause the starter fuse to pop. There are many vendors who carry replacement contact kits which include the plunger for about $25.And also the OEM starter is very stout. If you ever need to change it out, I highly suggest having someone rebuild it since the over the counter life time warranty ones are usually junk. Sure you can get a new one for nothing but who wants to go through that over and over?

-

I ran the #6 coolant port to the heater line

Interesting approach. I guess we'll have to wait until winter to find out. In saying that, the only thing I've noticed is that the original heater core inlet line and the new 5/6 port line to the return line feel the same temperature by simply touching them. I know that's not scientific by any means but it at least tells me that there's equally hot coolant flowing through both of them.

-

I ran the #6 coolant port to the heater line

I'm not sure what you mean Mike since I didn't bypass anything. I left the existing heater lines in place and simply added an additional line to the return. Why would that bypass the core? If anything, I'd think it would potentially increase the heater core temp a little. Not sure. Test time will tell.

-

I ran the #6 coolant port to the heater line

Good question. The only reason I didn't run it right into the heater core inlet line was because there was a lot of talk about all the pressure being built up in that portion of the head at upper RPM levels. Since this whole concept is kinda new territory for everyone.....the question remains whether or not there is more pressure coming out of that coolant port than the one feeding the heater core already. Meaning, will running that line into the inlet side allow for an increase in pressure inside the heater core which could potentially cause a leak? I cant answer that so I simply ran it over to the return side of the heater core. All of this would be interesting to know if someone had time to hook up a few pressure gauges and temp gauges in random areas of the head ports. So..... Is it helping? I've only had a little time in the seat but this is what I've found so far. Engine temps "seem" to be running a little milder during freeway runs. Again, I haven't had a chance to do much else and what I'd really like to know is how it will run towing a heavy trailer.

-

Timing a VP44 - Quest for MPGs..

The Comp on 5x5 and 275's..........I'm sure you have zero trouble with any loads. Anyone need more towing power than that and they're hooked up to something far to heavy. :)Along with my mild EZ, I'd have either 275's or 75 hp sticks by now if it wasn't for having to replace the clutch with that additional power.

-

I ran the #6 coolant port to the heater line

I'll keep you guys posted.And.....I'll clean the engine a bit too.

-

Timing a VP44 - Quest for MPGs..

Mike, I know injectors can help with MPG (which is a good reason why I want some), but do you think that camper shell helps you some?

-

I ran the #6 coolant port to the heater line

Just for sake of information in case anyone's wants to know.....In attempt to reduce the "hot spot" of stagnant coolant and see if I can mildly reduce towing temps, I removed the coolant port plug between the #5 and #6 cylinder, installed a barb and ran a line over to the heater core return line. I haven't had a lot of test time since I just finished it.....and given who overly anal I am, I'm not finished with it either. I set it up by trying to have the new 5/6 line run lower than the original heater inlet line. Cold the two lines are about 1/4" apart but after the engine warms, they just touch. I'm not happy with that. :thumbsdown:On a side note, doing stuff like this would be sooooo much easier if the parts guys actually knew what they had in stock and what they could get. I usually end up driving all over the north state looking for stuff. No fun. :spank:Also, no making fun of my dirty engine. Haven't had time to wash it. :hehe:

-

EGT and thermo couple

I dont know how to test those but I experienced something similar awhile back with my pyrometer. I have an Isspro and my EGT's were acting up and clearly reading inaccurate. I called Isspro and they showed me how to test both the gauge and the signal box. If either of those checked out then it was the thermocouple. Maybe Banks can do the same for you if you give them a call.