Everything posted by Old Blue - 1998.5

-

Seat Belt Timing Module

It is possible to wire in a toggle switch and turn the seat belt lock on or off with that. I did that years ago while I waited six months for a replacement seat belt timer module from Dodge. It is a little black plastic box with a chip in it and a ball bearing switch (in case the vehicle turns over or on its side). When mine went bad it drained the batteries down so low that one froze. Wasn't too happy about that.

-

3rd or 4th gen fuel pump in 2nd gen

@jimmystikx Mine is a February 98.5, so it not have any of that stuff. It had the original Carter on the side of the engine drawing through the 1/4" hose. My VP44 died when the computer on the pump quit communicating with the ECM. So I sprung for the high dollar Blue Chip unit (with the extended warranty on the processor). and after reading, research, and thinking, decided the Fuel Boss was the way to go. Coupled with the big line kit and the good fittings that flow more and a fuel pressure gauge....I am much more confident that I will get a good lifespan out of the VP44. For priming I have fitted an Airtex-Wells replacement tee-ed in at the original location. I can use it to prime at start to 5-6 psi, then after the engine fires the mechanical pump builds pressure quickly to 15-16 PSI. Most of the time, though, it will start immediately as soon as the starter is engaged. After sitting for months through the winter, it fired and ran in like two seconds this spring. (after I re-installed and charged the batteries). One advantage of this system is that the electric lift pump is still in place. If for some reason I need to prime, or of the mechanical should fail, I can throw a switch and turn on the electric pump for a back-up, or to prime for a longer time. Running down the road I usually see 17-18 psi at speed. On a high rev downshift it'll bump up to 19-20 psi. Pressure and flow increase with RPM. And that is a good thing to have.... Good Luck with Yours, whatever you choose to do.

-

3rd or 4th gen fuel pump in 2nd gen

Once you consider how expensive the replacement electrical pumps are, how it seems like they are prone to trouble after three or four years, how a long slow decline in fuel pressure can eventually take out your expensive VP44, and the increased electrical load on the vehicle's ECM (and system as a whole) and the fact that many of the electrical pump motors are not well-shielded against electrical noise and AC....Well. The picture was clear to me. Mechanical pumps are much more reliable, predictable, not prone to as many side issues related to the electrical system as a whole. I love the fact that the rig starts instantaneously and builds good fuel pressure and keeps it, even increasing slighty from idle to max rpm and load. Care and proper feeding of your VP44 is the answer to a long and trouble-free experience....well...at least as that component in your fuel system is concerned. No regrets; expensive, but worth it at the pay-off. Cheers....

-

3rd or 4th gen fuel pump in 2nd gen

Fuel Boss or other mechanical lift pump. Only way to go.

-

01 Idles fine but misses/defuels at 1600 rpm and above HELP!!

When you pressure washed the engine bay, did you happen to pressure wash the wiring connector to the ECM? On driver's side engine block below, in front of fuel filter ? Is there a chance that got damaged-water forced in where it doesn't belong etc?

-

No Start, no check engine light, no 'wait to start' - Code 1694

An update. I had purchased a rebuilt ECM from Auto Computer Specialist. It turned out, after all the trouble-shooting steps and verifications were gone through, that there was no problem with the crankshaft position sensor - the problem was with the 'rebuilt' ECM from Auto Computer Specialist - (The old ECM that was on the truck was purchased from Reman Auto Electronics in Pennsylvania in 2016. I think it had been failing slowly over time, and I finished it off by attempting to start the truck with low batteries.) So, as I was in a big time crunch at the time, I had Reman Auto Electronics overnight an ECM. I can't say enough good things about RAE. I was able to confirm that that they had the ECM I needed in final testing, and that it could be buttoned up and sent out literally within two hours of my phone call. After I replaced the Crankshaft Position Sensor with a new one (I wasn't going to go through all the work to pull the old one just to test it, then put it back in), and installed the 'new rebuilt' RAE ECM, the truck told the DRB III that all the codes were cleared. I used the DRB III to activate the electric lift pump to prime, watched fuel pressure build, and fired Old Blue right up. I still have not gotten back back with ACS over the defective 'rebuilt' ECM - Been too busy. Anyway, Old Blue is going to be loaded down with a lot of my tools, equipment, fishing and outdoor gear and ladders and will be making the trip down to Oregon at the end of the month. Thanks, guys for your help and advice, and for sharing your experiences, so we can all learn.

-

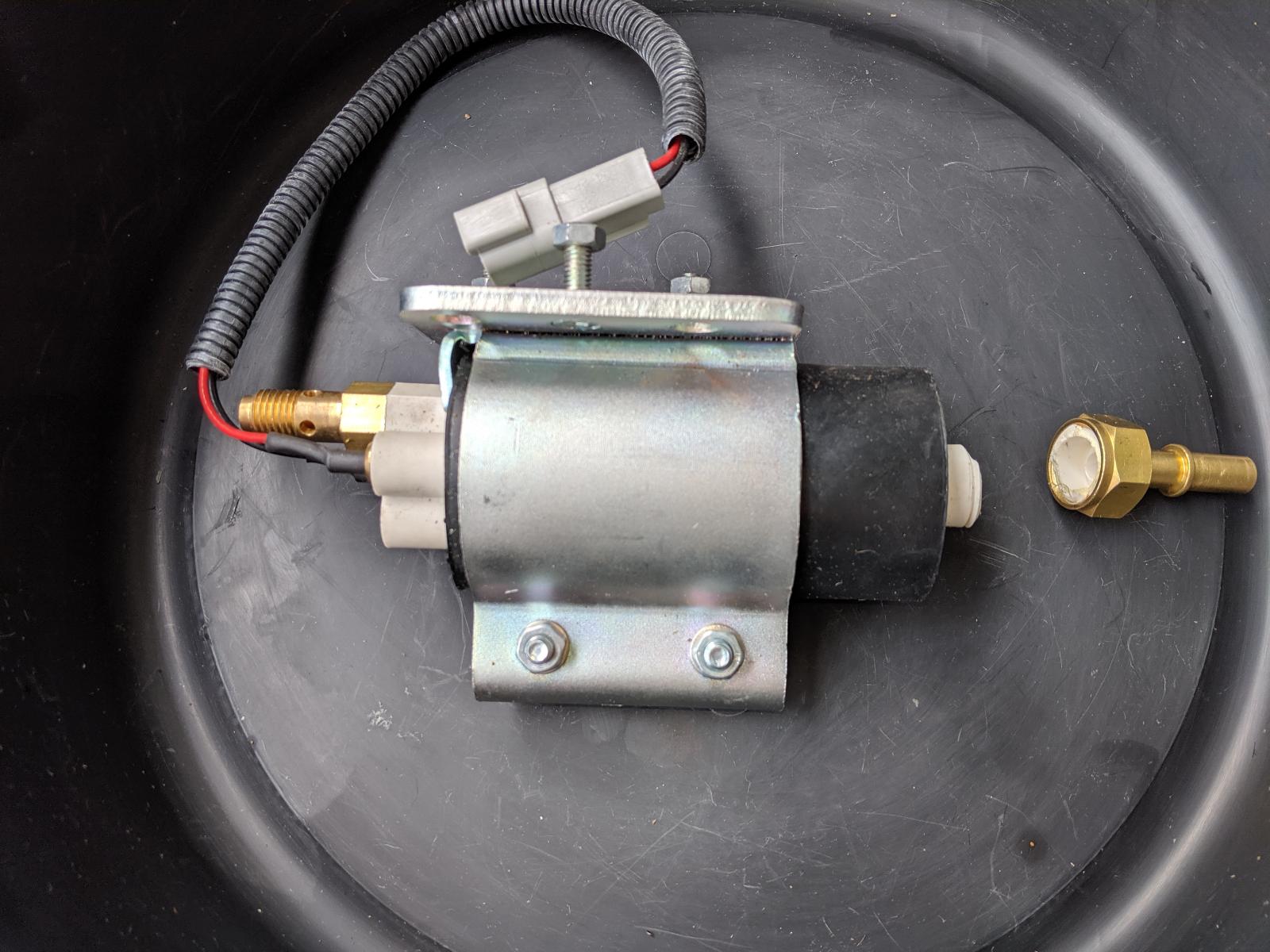

Tried The Herko Fuel Transfer Pump - With Test Video

I had to replace my VP44 after the computer in the VP44 quit. I purchased my replacement pump from Blue Chip Diesel, and determined after reading all the information about the problems with the original fuel system, determined that the Glacier Diesel Fuel Boss was the best way to go. I also installed a fuel pressure gauge and big line kit, along with replacing the original lift pump. The electric lift pump is a back up, and runs to prime the fuel system after a filter change or maintenance. The engine usually fires almost instantly with the mechanical pump, pressure builds quickly at idle to 17 pounds pressure. The Fuel Boss Pump consistently maintains minimum fuel pressure at 17 pounds, and will rise to around 18 if engine RPM is increased to around 3000 rpm or over. I also practice premixing about 1 ounce per gallon of two-stroke oil in the diesel at refueling time. VP44's are expensive, and if treated right, they can last and be reliable. Best of Luck with yours....

-

Need tires this fall.... Dealing With Tire Rack......

I have used Tire Rack several times now. (4 sets of tires for the 'other vehicles). We found a shop up in Bend that matches Tire Rack's prices and we get a small break in mounting and balancing when we order through their shop. But the same shop have also happily mounted and balanced tires purchased directly through Tire Rack and had delivered to them. Tire Rack has provided very fast service and delivery - they get a definite Four Thumbs up from us...

-

Strange brake rotors

IMHO -That color change on the metal surface (blue tint in the photos) is the result of a lot of heat. Brakes work by scrubbing off rotational energy, converting it to heat. Ceramics are hard and can withstand much more heat than organics, so they wear longer. But the rotor needs to be up to the task of withstanding the additional heat generated by the harder ceramics and be able to dissipate that additional heat effectively... If it were mine, I would replace 'em. If the original rotors aren't too worn, I like your idea of having them refaced and using them again with organic pads. Where I live in Alaska, we have a lot of volcanic ash, which under a microscope looks like bits of sharp broken glass. Since a disc brake rides at 'zero clearance' that can lead to faster wear and (if not caught soon enough) scoring - proper pad selection and maintenance is a must. They last about half as long in this country...

-

No Start, no check engine light, no 'wait to start' - Code 1694

Found another thread about this and learned that the if the ECM does not get an RPM reading from the crank sensor then it will not pump fuel...which makes sense. Learning all the time....

-

Tried The Herko Fuel Transfer Pump - With Test Video

Roger that. I hope so too. The one I had for two days had great fuel pressure - tested by removing the drive belt from the mechanical pump and observing fuel pressure on my FP gauge. That is- until the back cracked and leaked air in. My first clue should have been how hard it was to get installed on the bracket, and the extreme hard angle on the fuel line. Good Luck with yours.

-

Tried The Herko Fuel Transfer Pump - With Test Video

A word of caution and advice.... I purchased a Herko pump for my 1998.5 3500 4x4 Quad Cab with auto trans in 2016. It was to be used as a priming pump only, as at that time I had converted to the Fuel Boss mechanical pump. from Glacier Diesel Power. The pump was a 'tight fit' on my vehicle, and after two days...this happened. (It leaked first as it had cracked leaking air into the fuel stream, causing the engine to run very rough- It broke completely as I was trying to remove it. Major PITA.) The Airtech-Wells pump comes with the needed 90 degree adapter fitting, and so far has not leaked or broken off. It costs about four times as much, but it works. YMMV.

-

No Start, no check engine light, no 'wait to start' - Code 1694

Thanks dripley.....

-

No Start, no check engine light, no 'wait to start' - Code 1694

Howdy all, So here is what happened. I did not identify any problems with wiring. I had gone through the tests, clearing out the steps in the first procedure that Mopar1973Man had posted above, one by one, and finally got down to the Step 5 - (Using ohmmeter, check resistance between ground and terminal No. 30 (Black/Tan wire) on ECM connector. If resistance is less than 10 ohms, replace ECM.) and with my ohmmeter showing less than 10 ohms of resistance, determined that it was appropriate to replace the ECM. Contacted Auto Computer Specialist, and after a week or so delay, received the rebuilt ECM and installed on truck. So the CCD Bus seems to be communicating as that error code cleared, but now it shows a 0387 code "Crankshaft Position Sensor Supply Voltage Low" along with the 1693 code "DTC Detected in PCM" - the engine cranks but will not fire, and the lift pump is not priming. I used the DRB III to activate the lift pump and fill the filter can with fuel, but engine will not start, and lift pump will not run and pump fuel while cranking and attempt to start - Does it make sense that the presence of the sensor DTC is preventing the engine from firing? How common is the failure of the Crankshaft Position Sensor? While reading around the net, it seems like a bunch of folks have had to replace them, and judging by what I have read so far, it seems like it can be a real pain. Any advice or knowledge about this would be helpful to me, and is appreciated. Thank You to Mopar1973Man.....

-

No Start, no check engine light, no 'wait to start' - Code 1694

Any ideas? Truck sat for a month, batteries disconnected. The fuel tank was topped off before it was shut down, and the darn thing seemed to be running fine. Return after a month down South, charged batteries, reconnected them, attempt to start. No wait to start light. Electric lift pump ran for maybe a minute, not much fuel pressure. Bump starter, wait for fuel pressure...nothing. Crank engine, fired once and disengaged starter but did not run. No check engine light. Tried several times, but now not getting any fuel pressure and no fire from engine. Finally dragged out my DRB III (its the only tool that can reliably read these early 1998.5's) and can see message: PCM DTC's 1 of 1 NO BUS MESSAGE RECEIVED FROM COMPANION MODULE CHRYSLER HEX CODE $DE SAE TROUBLE CODE P 1694 I expect I'll be cracking the big Dodge book and sorting out my testing procedures, but I would appreciate any helpful hints about things to look for. Old Blue had some trouble about three years ago when the computer failed in the fuel injection pump. At only 29,200 miles, It got a Blue Chip Diesel injection pump, a Reman Auto Electric ECM, a Glacier Diesel Power mechanical lift pump, and Airtex-Wells electric lift pump for priming, a fuel pressure gauge, and a diode bridge replacement for the alternator. Last year it got the harmonic balancer replaced after a curiously strong vibration at idle was noticed; the old one was shot with bonded rubber swollen and displaced. It did stop lighting the 'wait -to-start' light about a year ago, and the temperature display in the overhead console started not to function from time to time. I also noticed that the transmission seemed to be acting like it was hunting between the two top gears from time-to-time. I usually drive with the OD off since it rarely sees more than 55 mph on limited road system where I live up North. I've taken some hints here and since the new fuel injection pump was added, it has had a diet of 1 ounce per gallon of very high-quality PennzOil two-stroke oil blended at every fueling, to compensate for the lack of lubricating sulfur in the Ultra Low Sulfur Diesel Fuel. Any Help or advice is certainly welcome and appreciated. I have had a lot of help here from you Good Folks. Thank You.

-

ECM information

So the trick needed is how to get the circuit boards detached from the aluminum case without destroying the circuit boards.... Some type of solvent? How about using a controlled hot air heat on the aluminum side to see if the circuit board will detach (or release) after reaching a certain controlled temperature?

-

Hello; New Member from Kodiak, Alaska

Permanent fix was to replace the'"Seat Belt Control Module" - If I remember correctly the Dodge Dealer charged me around $70 once they got them in stock and sent a new one to me. The seat belt control module is a small box (containing an inertia switch and a small circuit board) under the center portion of the front seat. In a quad cab it is responsible for unlocking and locking the solenoid lock for the seat belt reel - the reel and electrics are all buried in the seat back of the front seat (in a quad cab.) It unlocks the reel so you can pull the belt out, and then locks it, after you go driving, to provide shoulder restraint. After I figured out what was wrong, I called the dealer up in Anchorage. (I used to work the parts department for a Ford/Volkswagon dealer, and also a time selling GM parts and parts for Mercury Recreation Products and Yamaha recreation products, so the first thing I always ask -'Is this a stock item?' If it is, the dealer is stocking and selling them for a reason - like a lot of trouble with them or a lot of 'replacing' going on....) So the dealer told me that they normally have them in stock, but they were on 'backorder' and he could put me on the list and notify me once they had arrived. As it turned out, that took over 4 months, as I recall. Since I needed to use the truck, I identified the wire for the switched lead coming out of the box going up to the seat belt reel latching mechanism. I used my PowerProbe tool to quickly determine which wire unlatched the reel when 12V was applied and wired in a temporary toggle switch, bypassing the control module. To unlatch, apply power to pull back the lock plunger, to drive with seat belt latched, turn the switch off. The symptom, that I missed, is when that control module starts to fail, it will not respond to a timer circuit in one of the IC's on the circuit board in the module. That means DC Current will be applied continuously to the two solenoids in the front seats (even with the truck off and the doors closed), and it will kill your batteries over time, especially quickly once it is cold out. The darn thing killed my batteries in the middle of the winter, before I knew what was going on. What I meant to say is that the I learned never to use the Cruise Control below 35 degrees F - The truck had made one of its first long trips hauling 3500 lbs of camper up the Alaska Highway in early November one year, when we encountered temps as low as around -20 F. On 'cruise control', the problem that sometimes occurred was that the vehicle would start gaining speed like it was being 'commanded' to accelerate. One time, on a long straight stretch, while my wife was napping in the co-pilots seat, it did it while we were cruising about 53 MPH with the camper on and loaded - I watched ahead, we had a long straight stretch and I just let the thing go, but kept a steady hand on the wheel and watched for traffic. Road was clear and straight. Co-pilot woke up and immediately got a set of very big eyes -"What the Heck is going on??" and I tapped the brakes and turned the cruise control off. We were going 95 MPH when I shut it off, and it was still gaining speed..... And when we lived in Anchorage I made a couple of trips out to Glennallen in the dead of winter and encountered some -35 F - No problem with the truck, as long as I didn't engage the cruise control. I once left it parked on the roof of the parking garage at (then) Anchorage International for a week in the dead of winter. (Not plugged in.) Got back in town, late night, -25 F and a wind blowing - Wondered if I would be calling my lovely wife for a ride....It started right up, no problem. But then it was only two years old and probably had less than 25000 miles on it. Mike, Thanks for your help and advice. I had to get a spanking new upgrade to my test/diagnostic stuff, but my shiny new Fluke 115 tells me a I have a consistent 13.85 to 13.90 Vdc at the alternator hot stud and the passenger side battery, and I am consistently seeing 0.059 Vac on at the hot stud on back of alternator. Truck is warmed up (as much as I can in driveway w/o driving) and no accessory loads other than the under-hood lamp. It is a Denso 136 amp - Can you recommend one brand alternator over another, or any advice on whether NAPA might be a good place to pick up a replacement? Next, I'll be checking again between the fuel injector pump wiring and the ECM. I'll be checking all connections to the ECM and special attention to the grounds. Does the ECM ground to the engine block through the mounting bolts? I also have a new replacement lift pump (The one on the truck now is the original.) I'll also be installing a fuel pressure gauge. Does anybody know of a good mail-order ECM rebuilder that I can 'scout out'? Thanks Guys....

-

Hello; New Member from Kodiak, Alaska

Hey Thanks Guys, for the welcome messages and the help-suggestions- advice. Especially to Mopar1973Man - Invaluable! Many Thanks. I'll be doing some more research on the truck and we'll see what happens with that. We still have many gravel roads here, but a lot more pavement too - Old Blue was purchased new in Anchorage in May of 1998. There were some signs early on that some aspects of the vehicle were going to be trouble - I'll never buy a first-year design again...The first thing that the dealer could never really fix, were some issues with the cruise control. I learned early on that it needed to be constantly monitored, and that sometimes (especially when it was around 35 F and below...Not to Use it - (At All). The second thing was the Seatbelt Control Module that ruined a perfectly good set of batteries before I finally got wise to that. The third thing was generally what I consider to poor practices and poor design of many electrical components and wiring, compared to how I would do it. Profit margins and 'planned short life span' I guess. But besides that, I still love that old truck. I was offered a smokin' good deal on a 2012 'Tradesman' Cummins 1-ton SRW 4x4 crew cab at a dealer in Vancouver, WA some years ago. My wife said I should take it, but we still had Old Blue.....Oh well. Thanks again - Enjoy your Independence Day! p.s. Apologies if this should have been in another thread. Please feel free to move or relocate as needed.

-

Hello; New Member from Kodiak, Alaska

Thanks -- So in the AC Noise test....What is a good number? You're showing around 0.033VAC- and I understand that could vary as far as load - No accessories running etc. What is a bad number? Seems like I remember reading you tested one that had 0.5VAC and you replaced that alternator. I'll be checking that out tomorrow....Thanks Again....

-

Hello; New Member from Kodiak, Alaska

Thanks Mopar1973Man -- I think I read something about the alternator noise issue here before. I was going to fire it up and check DC voltage at the pass. side battery terminals with the engine running, and then switch my Digital VOM to AC and note what I see there - Is that the correct procedure? My truck pitched a "Check Engine Light' while easing down the road at around 45mph - Not loaded or pulling hard. My throttle was not responsive and, engine 'limited' to around 1400 rpm and I couldn't hear the turbo anymore, so I assumed it was in some sort of limp home, protect itself mode. Since then, it has gotten worse and is pretty much 'not drive-able'. I either have idle output, or a jerky, unsteady (and quick!) back and forth between idle and 1400 rpm. I actually bought a DRB III tool and found a P1689 code in the ECM. (No Communication between ECM and Injector Pump Module). I have been working through the troubleshooting steps in the Dodge Factory Manual and am down to the point of checking out connections between the ECM and the computer in the fuel injection pump - So I have some more verification to do on the truck before I actually get to the stage of picking out a good ECM place to deal with. The next thing will be pulling off the fuel filter housing and cleanup so I can get that 50-pin plug off of the ECM (without issue) and verify good connections and no shorts or opens between the 50-pin plug and the Fuel Inj. Pump computer. I have checked and cleaned all the grounds and they check out good. Good connections and good fuel injection pump relay. I didn't want to mess with, and so put off to last, getting at the ECM and that 50-pin connector. I guess I'm concerned that if something is not broken or damaged now, it will be by the time I get that plug off - ha ha . Any help or advice you or others may offer is greatly and sincerely appreciated. No Dealer here anymore, so I am on my own. Truck is a 'boat ride' away from the mainland and dealer help. Previously, successfully diagnosed and made temporary work around for Dodge's Fantastic Seatbelt Retractor Controller Module - What a fiasco that was. I finally wired in a switch to turn the solenoids off and on, because I had to wait four months for the new part to get to me. Ha ha ha . Hence the purchase of the DRB III.... Thank You....

-

Hello; New Member from Kodiak, Alaska

Hello from Kodiak Alaska! I've been lurking around here for years, and have found many helpful tips and much information when finding and fixing the first problem I had with my Dodge - Old Blue. Old Blue is an early 1998.5 with the 215hp Cummins 24V and automatic transmission. It is a Quad Cab 4x4 dually. Nice big truck - God help me check my sanity if I ever buy another one like this....Just Kidding. Been a good rig, but not without some problems with design and 'quality' issues. I'll be looking for some help and more information. Its looking more and more like I may be trying to find a replacement ECM for Old Blue. Thanks-