Everything posted by Scottfunk

-

Quadzilla V2 Custom Tunes

That's why I went with the 4.10 gearing. I actually have higher cruising RPM's now. I wouldn't have thought 2cm wider would add that much weight but who knows. Sounds like I need to play around with the timing and see what I can come up with. If I ever have to start paying for my own gas I may have to find something smaller to drive. That'll break my heart!

-

Quadzilla V2 Custom Tunes

Well I recently changed from 265/70/17 tires to 285/70/17 and my fuel mileage sucks now. I swapped gears from the stock 3.54 to some 4.10's and my cruising RPM's are actually higher than before. At 74 mph I'm right at 1960 RPM's, 24% load, and 9psi boost. I do like my level 5 and use that for my dd tune but I'm not using the custom tuning yet...I guess I'm fixing to learn how. My question is two parts: @Me78569 the custom flash you built for my truck to read the trans range off of the data bus, which vehicle do I select in the "select vehicle" menu? The engine is a 2002 non HO. I've read a couple times where you told guys their mileage could be adversely affected by having the wrong vehicle selected. And secondly, is it possible to build a tune that has plenty of power under acceleration but is easier on the wallet under steady rpm and tps? Fortunately I don't currently pay for my own fuel but I just don't believe in wasting. I would be surprised if I'm doing better than 12 mpg right now and it's 80-90% highway miles. Can someone suggest a base tune for me that won't be disappointing between stoplights or between fuel ups? Engine is mechanically stock, externals include FASS150, 5 inch exhaust no muffler or cat, quad of course.

-

4x4 spin free locking hub spindle kits

Denny's driveshaft sells the Dana 60, 30 spline 11.4" stub shaft for $85. I'm building a work truck not a crawler so I think 30 splines it's just fine. I'll be using a pair of those with the ttb 50 spindles, hubs, rotors, and lockouts. Total investment $270 without seals and bearings. Probably happen week after next. Let you know how it goes.

-

New Tire Size found 235's to 245's

Just realized I never posted a picture of the 285/70/17's I put on the Chummy. My wife picked them up at an auction for $13 so they're not exactly brand new but good enough to get an idea of how they look without paying for new ones. And good enough to help me decide to regear to 4.10.

-

New Tire Size found 235's to 245's

Ahhh that makes sense. Since my quad gets gear indicator directly from the tcm then the gear ratio does nothing at all. I'll have my tcm tuner adjust for tire size and gear ratio and then I can fine tune with the tire size in the app.

-

4x4 spin free locking hub spindle kits

Over the coming weeks I'll be collecting parts to do a junkyard free spin conversion. TTB 50 spindles redrilled to match the Dodge unit bearing bolt pattern, 79-87 f250 hubs and rotors, and Ford d60 stub shafts. The last part may prove to be the most difficult piece but I'll be keeping an eye out at the junkyard and watching eBay. Keep an eye out for pictures or see Facebook.com/idahodieselconversions.com for the write-up. Currently featuring disc brake conversion for Dana 70 rear.

-

New Tire Size found 235's to 245's

I don't have an abs computer, my Allison tcm hands the speed straight over to the quadzilla. Guess I'll have my tcm adjusted.

-

New Tire Size found 235's to 245's

Ok so I got the gears swapped out and it feels really great. The turbo lag is all but gone, acceleration is insane, and the load seems to have come down some. Only problem is I can't get the iquad speedometer calibrated. According to the calculator at grimmjeeper.com my road speed at 2000rpm with the old setup was 85 mph and the new setup should yield 77 mph. The problem is when I change the gear ratio in the iquad from 3.55 to 4.10 the speed actually reads FASTER. Has anyone ever had to do gear ratio adjustments? What's the deal?

-

Gearing help

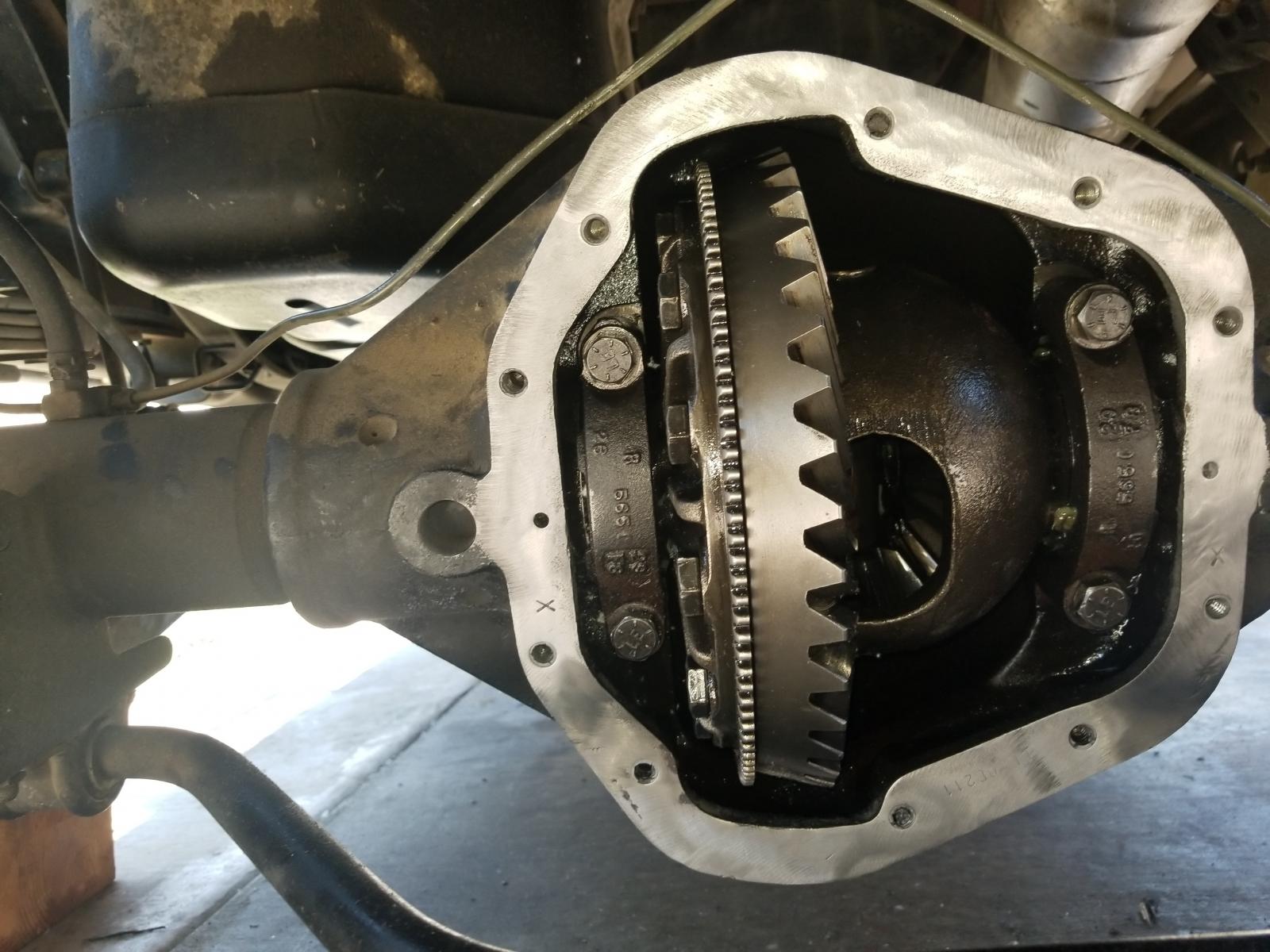

The pattern looked good and will also not be suffering from diaper rash. I beat the carrier in with a rubber mallet but it took like 5 tries cuz the damn carrier shim kept spitting out. Saw this guy in a video with this little ratchet deal to test the pinion preload instead of a nut. I will definitely be figuring that one out. That and dummy bearings everywhere. All in all I think it went well and it's tons better than it was when I took it apart the first time. I had almost a quarter inch play in the pinion and there were no shims in there. I am seriously dying to test drive!

-

Gearing help

Well I never did figure out what 5.735 means but I got the gears in. I may actually be getting pretty good at this. I even got a carrier bearing shim from the donor vehicle so I ended up with some carrier preload which I didn't have before. Next time I'll have dummy bearings for sure, what a pita! The ring gear in a 4.10 is a beast compared to the ring gear in the 3.55. I'm anxiously counting the hours until the rtv is cured and I can test drive her!

-

Gearing help

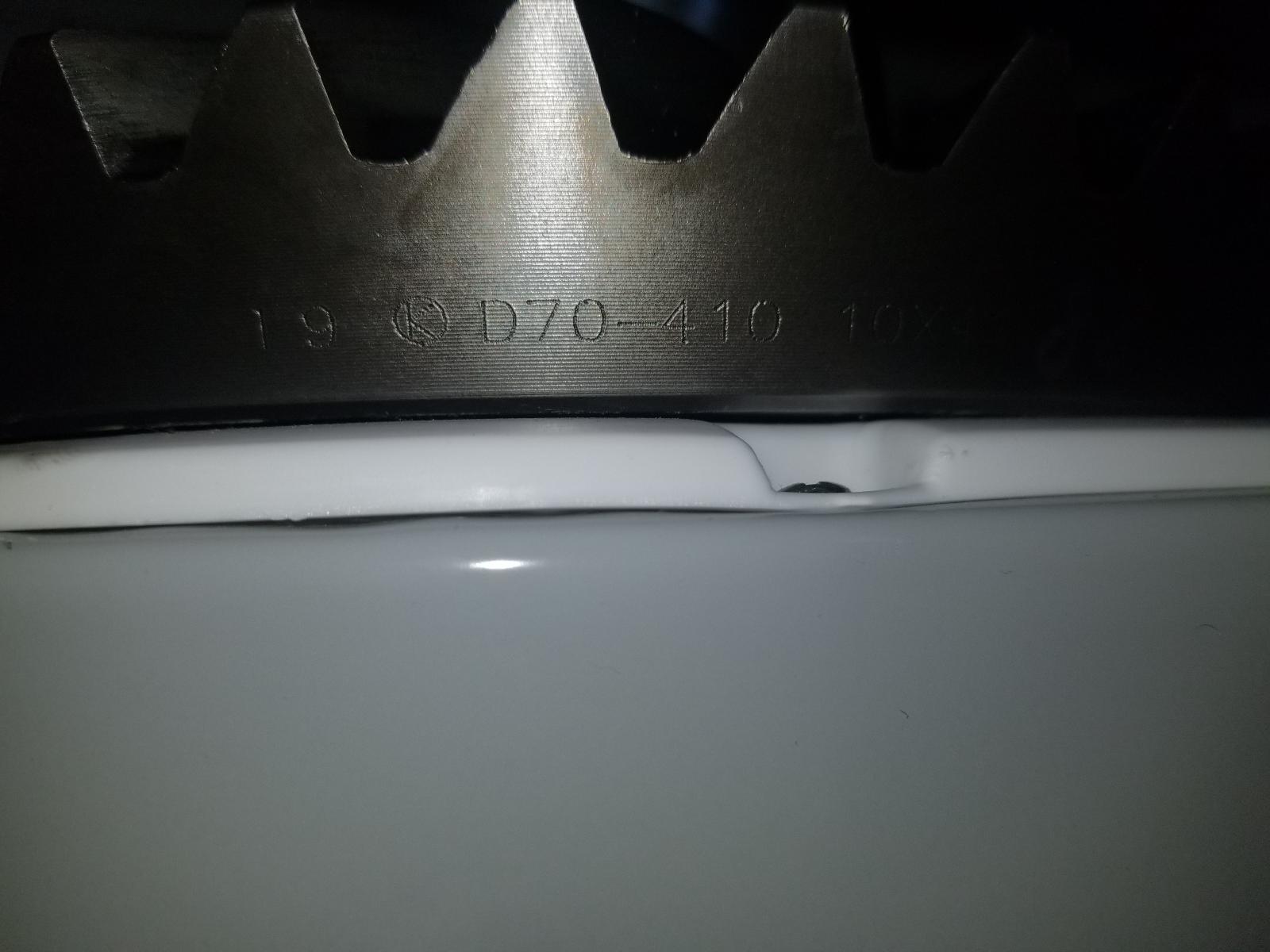

The marks on my gears indicate that they're a matched set ton tre same run. The part that I'm curious about and I'm hoping someone can help with this is the "5.375" engraved into the nose of the pinion. And no, it's not a 5.375 gear set as indicated by the "10/41" stamp on both parts. @Mopar1973Man ? Any insight?

-

Gearing help

Every single search result I've ever seen on the topic says the Dana 70 carrier break is between 4.10 and 4.56. I just picked up a set of 4.10's this morning from the junkyard and I'll be doing the install tomorrow so I'll let you know (changing from 3.55). I've only got 33's on my truck and I never even considered 3.73. I guess the final drive ratio of my Allison being so much higher (.61) probably helps. I'll let ya know how everything goes in the morning @tylertrebilcock

-

New Tire Size found 235's to 245's

I just had the best luck at the junkyard today! I scoped out a Dana 70 that was under an E-350 last weekend that, according to the BOM tag, was a 70-U with 4.10 gearing. I studied up a little on it over the course of the week and decided that as long as I scavenged all the parts that go along with the r&p, like bearings and shims, I should be able to plug it in to my 70-2U and just reuse my old pinion bearing. Well I got the assembly out from under the truck this morning and lo and behold it's a 70-2U. Well the pinion nut kicked my butt and almost won. It broke my breaker bar so I tried a pipe wrench but it just wouldn't find purchase on the socket. Next I ran home and welded a huge nut onto the end of the pinion socket so I could turn it with my 3' crescent wrench. Success! This is all incredibly difficult after the axle assembly is removed from the vehicle and I probably won't try that again. I am looking forward to getting the 4.10's all setup under the Chummy and seeing what that does for my turbo lag and fuel mileage. Cheers!

-

New Tire Size found 235's to 245's

Well I sold some equipment out of the garage that I don't use anymore so I'll be junkyarding a 4.10 gear set in the morning. Can't wait to see what kind of a difference it makes with engine load and ECT's. I'll post up some results although mpg's are beyond my capabilities since I still don't have an odometer. @Mopar1973Man I'd like to try the quad update that has the fuel data available but I am curious...Will this override the custom program @Me78569 wrote for me to use the Cummins programming with the Allison? Also, shy of changing injectors I think I've done just about everything that can be done to squeeze every last drop of power out of the 24 valve. I use level 5 as my daily tune and have used level 7 to wipe out a couple snot nosed punks in Subaru' s but I've never even used level 10, so I feel like I'm going to stick with what I got there. Only thing I'd like to see is a little less lag time. I can count slowly to 3 from the time I mash the pedal until when the turbo kicks in and I was wondering...would looking into a vgt and the lilblackbox be the best way to get the turbo up to speed quicker or is it possible to use a smaller turbo to drive the hx35? I'm not scared to build adapters and piping and such I just want to know which would yield the most satisfying results.

-

4x4 spin free locking hub spindle kits

@AH64ID got the ac hooked up last night. I figured the tonnage of my coil on the square footage of the house, but apparently there's a special allowance you have to make when a significant portion of your house is underground; turns out my coil was only 2.5 tons. Fortunately my buddy who installed it is an absolute genius and knew exactly how much refrigerant to put in the system to account for the difference. We are now once again living like civilized human beings, in a house cooled to 68°. Thanks again!

-

4x4 spin free locking hub spindle kits

@AH64ID thank you so much for the ac. If you ever need help building something all you gotta do is let me know!

-

4x4 spin free locking hub spindle kits

Same way I get away with having a full 5 inch exhaust with no muffler...oh yeah and a tow hitch rack on the back with an ice cooler that blocks most of the license plate. Ya drive it like ya stole it haha. I had full hydro steer for about 6 months too. Nobody ever looked twice

-

4x4 spin free locking hub spindle kits

I've read several writeups about putting the ttb 50 outside c's and everything from there out on a 60 but I have a custom made passenger side steering knuckle with a high mounted steering arm so I don't want to swap out the c's. I'm hoping I can do some modification to the 50 spindles and get them to fit my knuckles. I aim to try this weekend I'll let you know. As far as the cad there are numerous vendors that sell a cable operated manual kit for the cad 60's so that's what I'll do there. Check the sig, adapting is what I do best hehe.

-

4x4 spin free locking hub spindle kits

I think I'm going all mechanical for the t case, cad, and hopefully hubs. That way I can unlock everything for highway driving and when snow season comes around I'll lock the hubs and be able to lock the cad and t case from inside. As far as hvac controls I'm still working on that. Basically I have an app that I built for my phone. The app will communicate with a microprocessor in the can to activate zone controls, blower motor, and an electronic bypass valve. Basically you will be able to select a temperature on your phone and the microprocessor will fine tune the bypass valve so that the air coming out is the same as the temperature you selected. The code is all written I'm just debugging hardware right now. Regarding hydraulics, my brakes are hydraulic and I have power steering with hydro assist. Any other equipment will be a winch, log splitter, and hopefully soon a trailer mounted mini excavator, all of which will not be operating while the truck drives so the supply for these comes from a t installed in the line that feeds my hydroboost brakes. JThe pump itself is this beast. It ran the 3x10" ram I had up front for full hydro steering while a guy was building me a high steer knuckle with a dodge Dana 60 knuckle without breaking a sweat.

-

4x4 spin free locking hub spindle kits

Sure but there has to be something to tell the vacuum when to apply/not apply. This usually takes a button and a transfer case control module. In any event I don't have vacuum, I ditched the dodge style power steering pump in favor of a pump that moves enough fluid to run hydraulic equipment when I need it.

-

4x4 spin free locking hub spindle kits

I don't think I'll be doing anything with the cad except maybe a manual kit since I don't have the computer to lock/unlock like you guys do. I'm mostly after eliminating the unit bearing and adding some hubs to reduce rotating mass

-

4x4 spin free locking hub spindle kits

So I wanted to revive this for a minute. I am wondering why no one has come up with a conversion that replaces the carrier bearing spindle with a spindle that uses a conventional, rebuildable bearing and finishes the conversion with parts we can scavenge at the junk yard or already have? There's a Ford f250 rotting in a field in a town just a few miles from me, has the ttb 50 front axle as the guy wants next to nothing for it. Maybe I'll drive out there this weekend and tow it home for the sake of tearing it down and seeing what can be done.

-

24 Valve ECM overheating?

Electrical issues are always the worst. When I was in the Navy my mos was Aviation electronics. You'd be amazed by how many boxes would come back over and over to be repaired. It could be so simple as a unit fails when placed in the sun because a weak connection expands. In my case, with the pdc I used, I had to do some internal modifications to make it work for my purposes. All of the #86 pins on the relays were hooked to a common ground making them useless for cooling unit fans. I have a spare now that I'm working on and a complete new under hood wire harness I built, just waiting for the right timing.

-

24 Valve ECM overheating?

Well the Chummy left me stranded at the gym last night so I had no choice but to try and figure out what was wrong. Bad connector in the power distribution block that powers everything hooked up too the engine. I run my ignition hot signal to a relay that in turn signals all the other relays (ecm, tcm, pcm) that the ignition is on. What a relief to know for sure it's not the ecm.

-

New Tire Size found 235's to 245's

@Mopar1973Man how do i get all those fancy gadgets on my quadzilla screen like fuel usage and instant economy?