Everything posted by Tractorman

-

Weird rough idle

When it begins to act up, turn off the engine and disconnect the alternator output cable. Restart the truck to see if the problem is still there. You can perform an AC voltage test on the alternator output with everything connected and engine idling. The test should be done after the grid heaters have finished post-cycling and there are no heavy electrical loads present. The reading should be around .05 volts AC or less. Double check your work regarding the W-T ground wiring mod. Make sure all connection points are clean and tight. Make sure you didn't miss a ground connection. How is the condition of the cross-over cable? - John

-

Weird rough idle

You are not the only one to have this problem after installing a circuit breaker. Likely that you have a weak 150 circuit breaker. Prior to the W-T ground wiring mod, there was a 145 amp heavy duty fuse in the distribution center. Try a better quality 150 amp circuit breaker or fuse. I use a 150 amp fuse and I have never had a problem, but I also have a manual grid heater switch control, which means there is no post-cycling of the grid heaters - a lot less work for the alternator after the engine is running. The 1688 code is more serious: - John

-

She's dead. And I'm done with it.

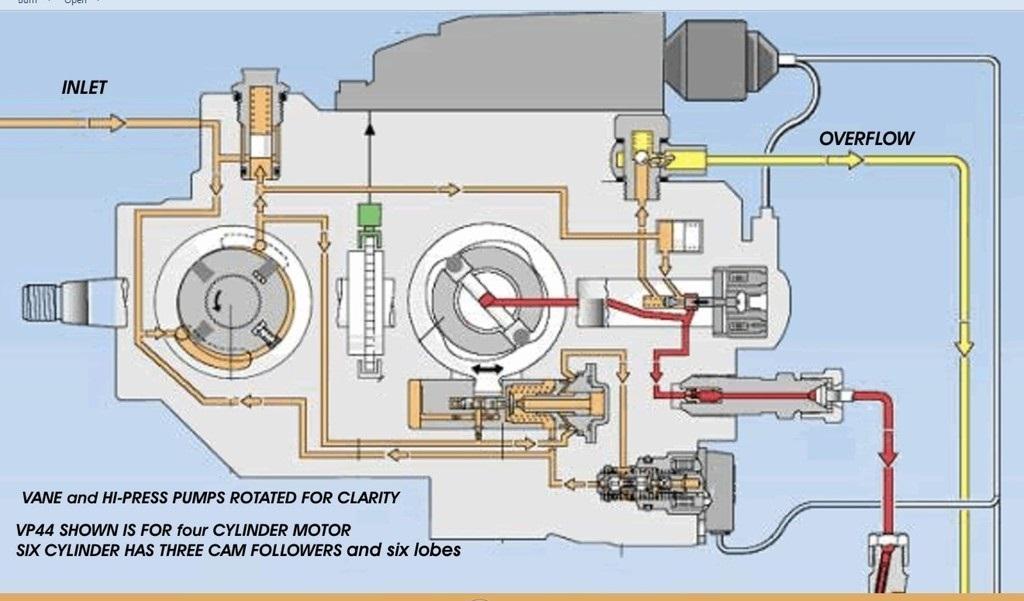

@Max Tune, I really appreciate your response. You ask many good questions. The VP44 fuel system is made up of several series and parallel circuits, especially inside the VP44. That's where the complexity begins. Over the years many observations and decisions about how the VP44 works and how it is cooled have been based upon the only two pressures readings available - lift pump pressure and overflow valve pressure (14 psi). Nothing has been based on flow, mainly because no one really seems to know what the flow is in the various parts of the circuit. The 14 psi overflow valve ensures an even distribution of charge pressure to the fill chamber of the high pressure pump (radial piston design) when the fuel solenoid valve is de-energized. The 14 psi is also a low enough pressure that it easily accommodates returning fuel back to the tank without adding excessive heat to the fuel. This is where some of the confusion lies. The workings of the inside of the VP44 are no different than a sophisticated hydraulic system. All hydraulic systems have calibrated internal leakage for lubrication for every component used inside the system. The inside of the VP44 is no different - it just uses fuel instead of hydraulic oil. Some of those internal components are: positive displacement vane pump, timing piston, timing piston control valve, high pressure injection pump, etc. All of those components are designed with a specific amount of internal leakage for lubrication. With that said, if the VP44 pump is not turning and lift pump pressure is applied, flow will eventually get to the overflow valve. BUT, the overflow valve will not open. The fuel will exit through the tiny orifice just below the overflow valve, acting as a vent. There will only be a continuous dribble. The dribble will be smaller if there is only 10 psi lift pump pressure. It will be larger if there is 20 psi lift pump pressure, BUT, AGAIN, the overflow valve will not open. The most important thing to note here is, the fuel is NOT being pushed through the internal vane pump. It is leaking through all of the internal components at the calibrated leakage rate. The total leakage rate flow is what will be passing through the orifice vent. Knowing how this works will help in understanding how air is vented from the VP44 after a fuel filter change. This part is the hardest part for me to explain, partly because I don't fully understand it myself and partly because it is complex. Refer to the photo below as I try to get through this. You will note that when the fuel first enters the VP44, it goes right to the inlet of the internal vane pump (Bosch calls this pump the "feed pump"). Note that the fuel leaving the feed pump has three paths to take. All of these path see the regulated pressure. 1. directly to the feed pump pressure regulator (120 psi approximately) 2. to the accumulator (to the far right (rectangle symbol shown with spring) 3. to the timing piston control valve and timing piston (to the right and down) Now focus on the path after the fuel leaves the accumulator. Here's is where things get complicated. The following is my interpretation of how this system works. The fuel has to pass through the rotor shaft (a small passageway) in order to get to the fill chamber of the high pressure pump. This restriction is why the feed pump pressure falls considerably at this location and the fuel will be subjected to the 14 psi overflow valve pressure as the fuel enters the fill chamber when the fuel solenoid is de-energized. As soon as the fuel solenoid valve energizes, the fill chamber and overflow valve will be isolated from the feed pump / accumulator circuit. When the fuel solenoid de-energizes, the accumulator will absorb the energy left over from high pressure injection and the 14 psi overflow valve will ensure a uniform fill pressure for the next event. Feel free to pick this apart. - John

-

She's dead. And I'm done with it.

I will never know. The VP44 was replaced in June of 2005 (at 87,000 miles) under warranty. At that time I didn't know much about the VP44 fuel system, so I never asked any questions about the pump. Ironically, initially I was disappointed that it was a re-manufactured pump. I wanted a new one. However, over the next few months I learned a lot about the VP44 pump and about some of the inferior components inside the pump. It was then I was glad to have received a re-manufactured pump, mainly because of the many improvements done as time went on. As far as filter, I just use the stock filter housing and usually a Napa filter. I have added a 140 micron strainer at the suction of the frame-mounted lift pump. - John

-

She's dead. And I'm done with it.

"The lift pump has no say in when the overflow valve is open." I stand behind that statement. Rarely, does anyone talk about the role of the internal vane pump inside the VP44. Its role is far more important than the role of the lift pump. The only job required of the lift is to always provide a positive pressure at the VP44 injection pump inlet under all operating conditions. The role of the internal vane pump is to supply a flow of fuel (based on engine rpm) to all internal injection pump working components, to the injectors, and to the fuel tank via flowing fuel through the 14 psi overflow valve. The minimum pressure for the internal vane pump regulating valve is 120 psi. The internal vane pump is a fixed displacement pump. When a fixed displacement pump is operating, it is ALWAYS displacing the SAME volume of liquid at a specific rpm, regardless of whether its inlet is being charged with a lift pump, or it is drawing directly from a fuel tank. This volume cannot be changed without changing the rpm of the engine. It's physically impossible. All fuel must pass through the internal vane pump; there is no path around it. The rpm of the vane pump determines the volume of fuel flow. As soon as the engine starts and idles, fuel immediately begins to flow at about 18 gph through the 14 psi overflow valve, regardless of lift pump pressure. As engine rpm is increased, fuel flow through the overflow valve increases immediately. I disagree. If an engine at idle is sending 18 gph through the overflow valve (returning to tank) and the injectors are consuming 1 gph, then 19 gph are entering the inlet of the VP44's internal vane pump, regardless of lift pump pressure. If a 100 gph lift pump is providing fuel to the VP44 inlet, this means that 81 gph are being returned to the inlet of the lift pump (or to the fuel tank from the lift pump, if a dedicated return line is being used), and the other 19 gph are flowing into the VP44 injection pump. If a 150 gph lift pump is being used, then 131 gph are being returned from the lift pump and the same 19 gph are flowing into the VP44 injection pump. In both cases , fuel volume flowing into the VP44, fuel volume consumed by the injectors, and fuel volume returning to the fuel tank via the overflow valve remain unchanged. Back in April of 2001, some members of the TDR performed some extensive testing with the use of a flow meter in the fuel return line circuit from the VP44. Many tests were done - all tests were done at engine idle, cruising speed, and wide open throttle. Tests were done with different lift pumps and different tuning levels. EVERY test showed the same results - 18 gph at idle, 24 gph at cruising speed, 30 gph at wide open throttle. One of the tests even had 0 psi lift pump pressure at wide open throttle, but the fuel return flow remained unchanged. By the way, the maximum lift pump pressure recorded for ALL of the testing was 11 psi - and that was at idle. Three years ago I performed some fuel return flow tests on my truck. I didn't have access to a flow meter, so I used a container that showed graduated volume measurements. At idle ....... lift pump pressure 12 psi, return flow from VP44 - 19 gph A 2000 rpm.... lift pump pressure 8 psi, return flow from VP44 - 28 gph I repeated the tesst with VP44 pulling directly from the fuel tank (no lift pump). Fuel return flows were exactly the same. I even drove a 28 mile round trip to town without the lift pump in operation. No performance issues whatsoever. My replacement VP44 has now logged just over 294,000 miles - all of the miles with 12 psi or less lift pump pressure. Most of the miles with less than 6 psi. So, yes, I stand behind what I am saying here. I don't expect others to accept this information at face value. But, so far, I have yet to hear of any documentation that shows that lift pump pressure must always be over 14 psi in order for fuel to return to the tank from the VP44. - John

-

Power Steering Pump bad after flush?

Maybe this will help. The photo below shows a simplified drawing of a recirculating ball type power steering gearbox. Your objective is to achieve zero clearance with the slightest preload between the ball nut rack and the sector gear when the steering gearbox is centered (tires in straight ahead position). Normally, this adjustment is done on a work bench using an inch-pound torque wrench, so there is no friction interference from other steering components. Note the adjusting screw and lock nut on top of the Pitman shaft (also called sector shaft). This is what you are adjusting. Raising the Pitman shaft increases clearance - lowering decreases clearance. Because you are making this adjustment in the vehicle, it is better to have a very slight clearance than no clearance. I use a different method than Moparman. I note the position of the adjusting screw before loosening the jam nut. I loosen the jam nut and then tighten the screw 1/8 turn (clockwise from top view). I tighten the jam nut. Without starting the engine, I just barely move the steering wheel left and right - there should be virtually no friction. I then test drive the truck. I will continue to make 1/8 turn adjustments until I think it is right. If, when you are driving straight ahead, the steering becomes sticky (this can be very subtle), then the adjustment is too tight. Back off the adjusting screw 1/8 - 1/4 turn. Again, better too loose than too tight. Hope this helps. - John

-

Power Steering Pump bad after flush?

The front tires can be on the ground. What does matter is that the tires must be pointed straight ahead with the steering wheel centered. This is the position where the steering gear lash clearance is the tightest. This is important. I will let @Mopar1973Mananswer your first question. - John

-

P0121, P0237, P0234, P1689,p0236 all at once.

Wow! Same thing happened to me, and I have a manual transmission! What are the odds?! - John

-

P0121, P0237, P0234, P1689,p0236 all at once.

Glad to hearing everything is working properly and no codes. Would have been interesting to know if the W-T ground wiring mod would have corrected the old alternator high AC voltage. - John

-

P0121, P0237, P0234, P1689,p0236 all at once.

Double-check that your positive cross-over cable is connected. Verify that you didn't miss any other wiring connections. I would start the engine and quickly check voltage at each battery individually to see if it agrees with what dash voltmeter is showing. Both batteries should read the same voltage. Report back what you find. - John

-

P0121, P0237, P0234, P1689,p0236 all at once.

I would do the W-T ground wiring mod first and then recheck the alternator for stray AC voltage. Also, I think the test should be done after the grid heaters stop their post cycling, otherwise you can have higher than normal readings. I am still running my original alternator (replaced brushes and bearings at 216,000 miles) Currently at 380,000 miles with no AC voltage issues. - John

-

Lift pump

The bouncing needle could be caused by a lift pump ball check valve vibrating or by a faulty gauge sending unit depending on your gauge setup. - John

-

Lift pump

The fuel pressure gauge should always be steady, regardless of the pressure reading. That needs to be corrected. A reading of 5 psi at WOT is fine for the needs of the VP44 injection pump. Moving to a 150 gph pump will raise the fuel pressure somewhat, but it does not change the volume of fuel returning to the fuel tank from the VP44. The VP44 has its own fixed displacement vane pump inside that controls fuel flow and pressure for the VP44's internal components, and for the fuel volume returning to the fuel tank. - John

-

Lift pump

That sounds about normal for a 100 gph lift pump. What is your lift pump pressure at wide open throttle driving with engine under full boost at around 2200 rpm? Is your lift pump mounted in the OEM position on the engine block? Or, is it frame mounted (a better option)? This site owner uses a frame mounted Air Dog lift pump. He will probably post the specific information about his pump in a little while. - John

-

Lift pump

What is it that you are not satisfied with? What are your mods? - John

-

Fast Idle Solenoid Install

I used that same system before, but I couldn't figure out how to drive the truck without the clamp falling out all of the time. - John

-

Fast Idle Solenoid Install

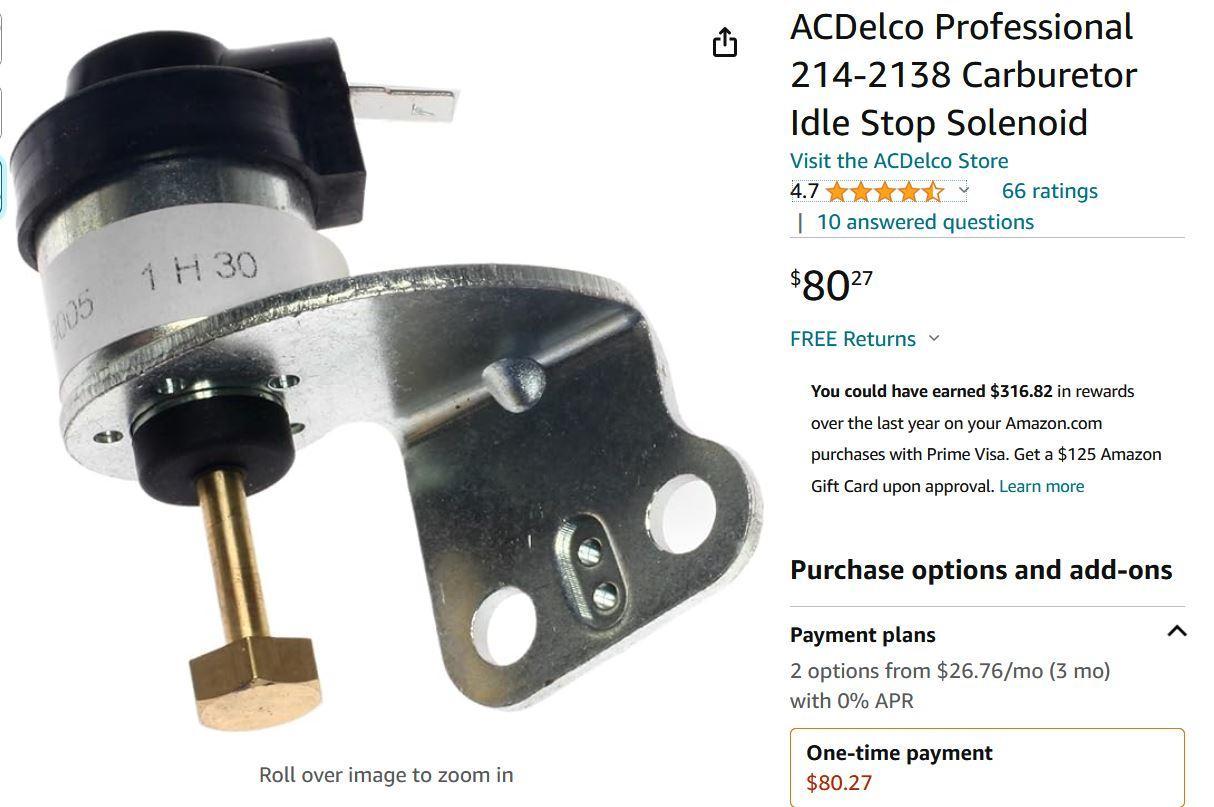

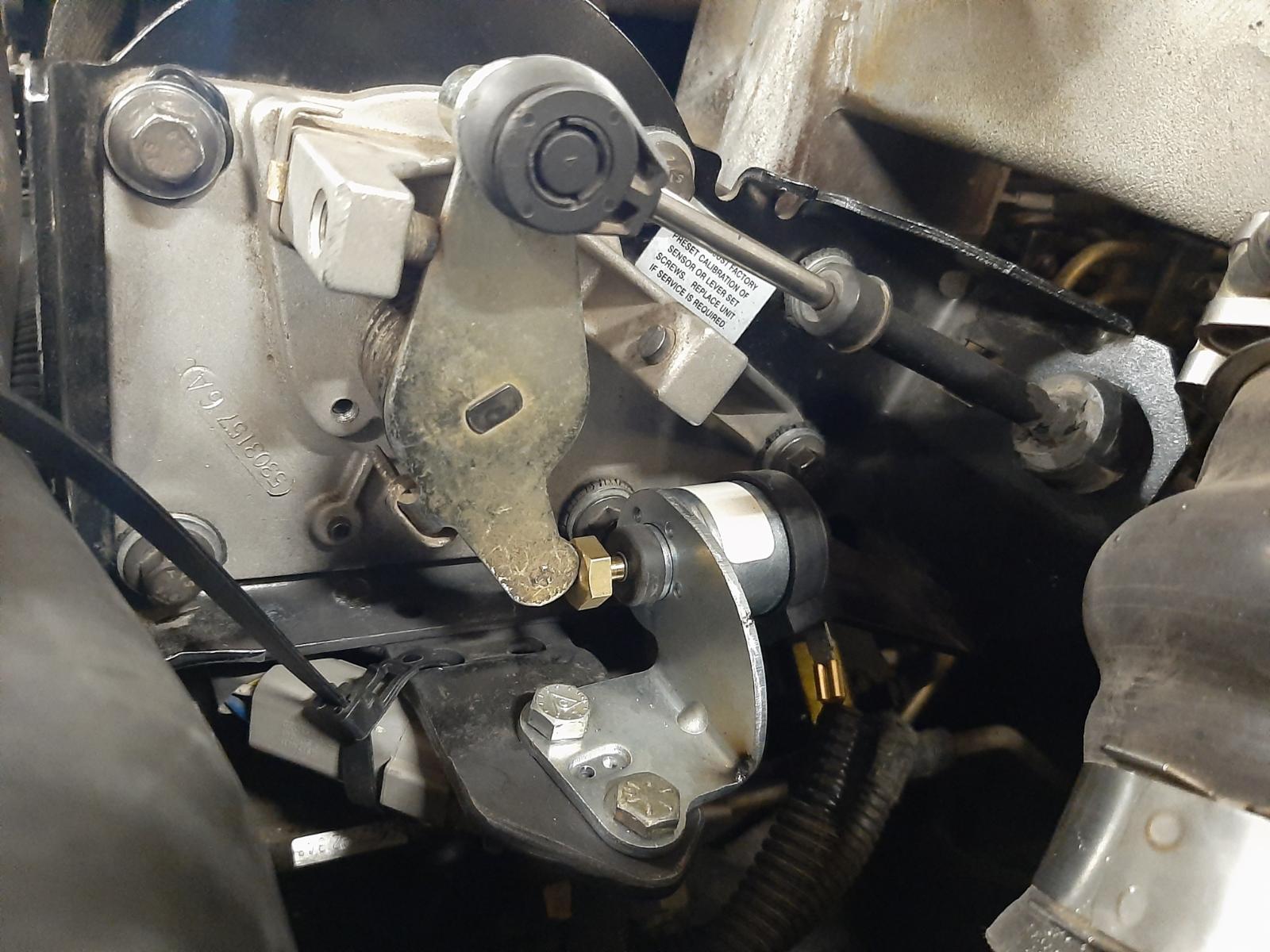

Back in July, I installed an adjustable idle solenoid on my truck. I wanted the engine to run at about 1150 rpm fast idle for winter time warm-ups and for summertime air conditioning during hot weather, should I need to be parked for a while and want to be comfortable. After some research, I decided on an AC Delco carburetor idle stop solenoid, part number 214-2138. It looked durable and the idle stop was adjustable. Under the hood I removed the APPS mounting bracket and fabricated a mount for the idle stop solenoid bracket to bolt to. I welded the new idle stop solenoid mount to the APPS mounting bracket. I installed the idle stop solenoid in a location that utilized the lever that operated the cable that would control shift points for an automatic transmission. Before I welded the mount onto the APPS mounting bracket, I did some measuring and I adjusted the solenoid plunger to its center position with the solenoid activated. I then determined where to weld the mount onto the APPS bracket. I installed a switch with an indicator lamp to operate the fast idle solenoid (not shown). Note - because of the mounting location, this install can only be done on a manual transmission truck. After the install was completed, I adjusted the fast idle to 1150 rpm using the threaded hex head adjusting screw. To operate - activate the fast idle switch. Slightly depress the throttle and the solenoid will snap into place giving the 1150 rpm fast idle. Turn off the switch and the engine rpm's drop back to normal idle. I decided to wait awhile before I posted this modification because I wanted to make sure that it worked reliably over a period of time. So far, it has passed the test. After strapping down three pallets of pavers in the 95° heat, the cab is nice and cool and the AC doesn't have to struggle to keep it that way. Definitely worth the effort. - John

-

Trans problems

So, what are the specs on the engine? Bore, stroke, peak torque and peak torque rpm, peak horsepower and rpm, etc? Does it come with a 5 spd manual transmission? Is there an auxiliary gearbox or a two-speed axle? I think you should at least put the Dodge Sport Headlights on it. - John

-

Trans problems

So, is this what you bought to replace your 98.5 Dodge Cummins truck? (Note that the photo is right side up) - John

-

1999 Dodge lift pump

@WesHawkins, the 10 amp draw sounds like a healthy lift pump. You are probably right regarding an overlooked fuse holder condition. - John

-

AC from AC?

@Andyba20, I think you are being led astray here. There are many, many things that affect compressor cycle time. Here are a few dynamic variables that occur every day and have a major affect on compressor cycle time in a fully charged and properly functioning air conditioning system: * blower fan speed * recirc or outside air * ambient temperature * ambient dewpoint * engine rpm * air flow across the condenser * sun load So, without naming some parameters, no one can say what is normal for compressor cycling frequency. On our 2nd generation trucks, compressor cycling is controlled by a low pressure switch downstream of the evaporator core. When refrigerant pressure falls to around 30 psi, the compressor will cycle off. 30 psi equates to about 30°F. This means that condensation from air passing through the evaporator core can collect and freeze onto the core which would impede air flow into the cabin if the refrigerant pressure remains at 30 psi or lower for a long period of time. When the cooling demand is low (75°F ambient air, 45° dewpoint, blower fan on low bringing in outside air, truck parked in the shade), the compressor will cycle frequently - I am not going say how frequently. When the cooling demand is high (85° ambient air, 70° dewpoint, blower fan on medium bringing in outside air, truck parked in the sun), the compressor will probably run continuously. It isn't "locked on", it simply cannot reach a low enough suction pressure to cycle off. Now, with all of that said, if your truck's cooling demand was high and it was hot outside and your compressor is cycling frequently, then it is likely there is a low charge of refrigerant in the system. Recovering the refrigerant and weighing what goes back in is the most accurate method for charging the AC system. - John

-

Bent Rear Sway Bar

I fully agree with you there. Not even close to being heavy duty. - John

-

1999 Dodge lift pump

Personally, I have never found a multi-meter with a DC amp clamp connector to be reliable for direct current measurements. I think you are having the same issue with your meter. From a couple of other sources, 12 amps was the response for current draw for stock lift pumps. Years ago my truck had a factory in-tank lift pump with relay installed under warranty by a Dealer. The power to the relay was supplied by an added 20 amp fuse. If the lift pump truly only drew .5 to 1.5 amps, then a 5 amp fuse would be more than adequate. There is a positive displacement vane pump (called the feed pump) inside the VP44 injection pump. It is this pump that drew the fuel into the VP44 without the lift pump operating. As long as there is not a blockage from the fuel tank, the engine will run. The purpose of the lift pump is only to supply a positive pressure at the inlet of the VP44. - John

-

1999 Dodge lift pump

Not sure how you are testing for current draw, but those numbers are way low. I don't think they are real. The current draw should be more like 8-12 amps. I would suspect that you are getting a severe voltage drop across the fuse connections while the pump is running, which will generate lots of heat, even from a perfectly good lift pump. Since the fuse holder was already damaged from a previous situation, the fuse holder needs to be replaced. I would jumper the existing fuse holder with an in-line 20 amp fuse and re-test the lift pump. If the fuse holder still gets hot, then you have a lift pump that is beginning to seize. If the fuse holder stays cool, then you have found the problem. - John

-

Bent Rear Sway Bar

Your hitch receiver should be a Class 4 - 1000 lb / 10,000 lb with weight distribution, but only 500 lb / 5,000 lb weight carrying. Horrible safety factor. Is the label still on your hitch receiver? - John