Everything posted by Tractorman

-

1998.5 Power loss and shorts to ground.

I can't answer that question as I don't know the purpose of that connector, or what you were trying to figure out with the method of testing you performed. If you don't know what is on either end of the connector, then any values from electrical tests performed are meaningless. Please answer this question - why do you think you have a short to ground in the wiring on your truck? What is drawing you to this conclusion? You may have a valid reason - I am just not getting it. Also, why are you using the "diode check" function on your meter to check for ground continuity (or shorts to ground) instead of using the resistance / ohms function? If you can clear some of this up, then we can move on to trying to figure out the "no power" situation. John

-

1998.5 Power loss and shorts to ground.

Your meter is set to "diode check" which means that current will flow only one way after it overcomes .6 volt. Current will not flow in the other direction. The continuity will be there with the ignition switch turned on for the same reason the continuity was there when the door was open. All it takes is one circuit to be activated with the ignition switch on to make continuity - for example, instrument panel indicator lamps. This would be normal. Am I missing something here? Why do you think you have a short to ground problem? John

-

1998.5 Power loss and shorts to ground.

Before I can offer any help, I have some questions first. Was your meter on the continuity (ohms) setting? Were the batteries connected or disconnected? If the meter was set for continuity (ohms) and the batteries were disconnected, then it would be normal to have continuity between the positive cable and the ground cable when the door switch was activated. The current would be passing through the dome light and through the switch. If the above paragraph doesn't represent what you observed, pleas let me know. Can you provide more detail as to why you think you have a ground problem John

-

ECM failure?

I don't think your truck is burning up crank sensors, I think that the after-market crank sensors are of low quality. Many others have reported the same issue with after-market crank sensors. Good to hear that your are making headway, though. John

-

Front driver's seat removal

I have done the same. Can't remember the details, but I think you have to slide the seat bottom to certain positions to access four bolts (or nuts), but it is an easy task. John

-

Working through miss/studder issues - codes 0237 & 0230

Sounds like you are gaining ground. If I'm understanding correctly, the engine is performing well, but you are still getting voltage fluctuations? Any codes? John

-

Working through miss/studder issues - codes 0237 & 0230

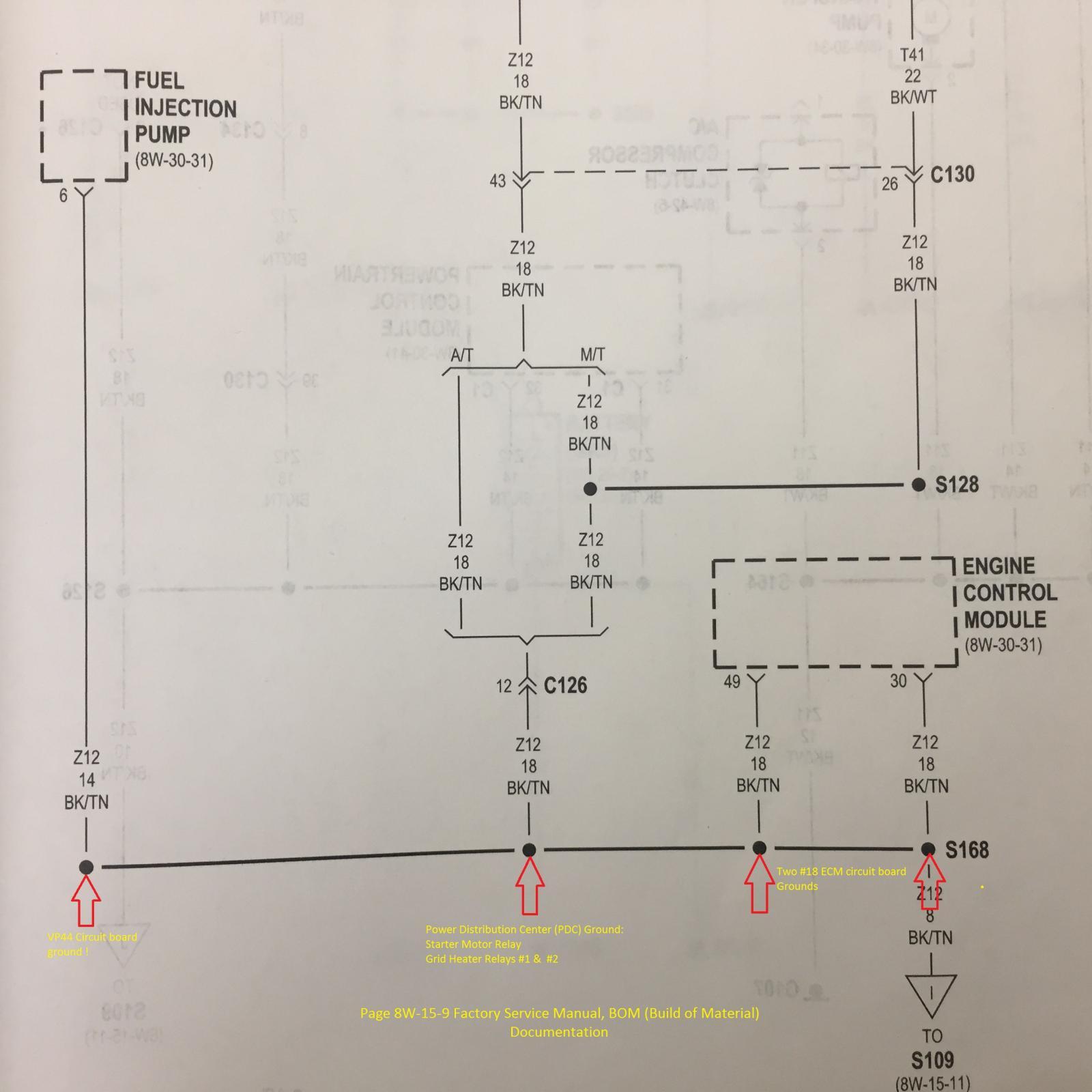

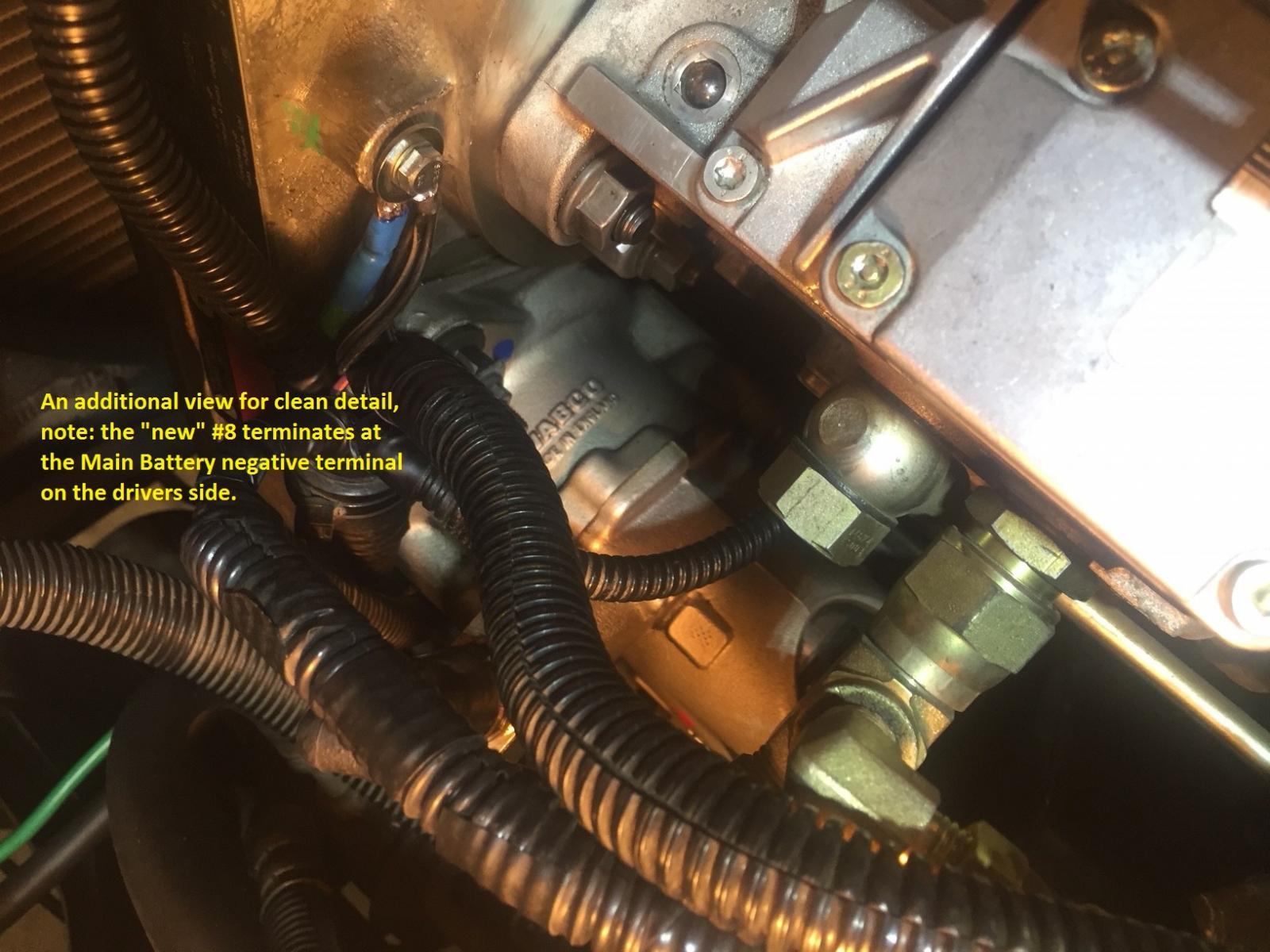

You wrote, "I've decided to do some upgrades to my cables & connections before digging any deeper. Marine grade battery terminals should be in tomorrow." Good plan! Are you referring to ground splice 168 (top photo below)? If you are, then the W-T ground mod wasn't complete. This splice is disassembled and all wires are routed to the front gear case cover with an additional wire to driver side battery ground (see bottom photo). John

-

Last ditch attempt

Also, keep in mind that just because an electrical connection is tight doesn't mean that the electrical connection is good. Tight terminals can be oxidized or corroded leading to a poor electrical connection - all hidden from sight. John

-

Last ditch attempt

@Chickendog73 , how old are your batteries, and are they in good condition? How about the crossover cable? John

-

Last ditch attempt

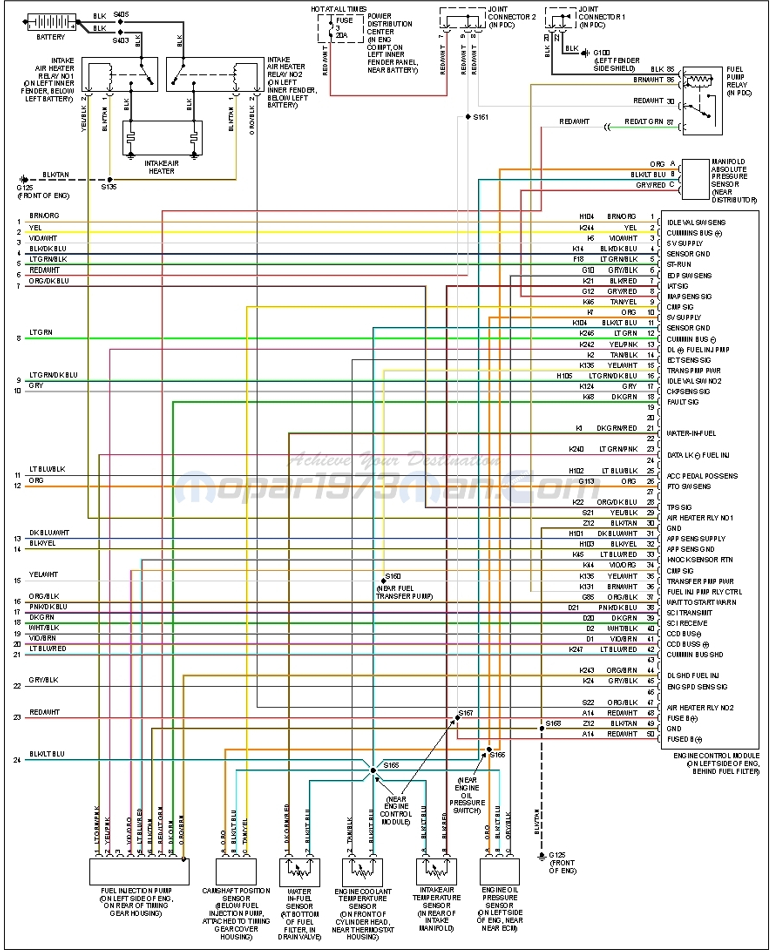

Good documentation on your part for your initial post regarding this problem. You definitely need to figure this out - you have a good truck with low miles. I don't know if you have a good wiring diagram for the engine controls, so I am posting a diagram below. I suspect that the collision with the rock wall is related to your symptoms. A couple of questions, though: Did the "stutter" show up right after the collision, or after the VP44 replacement? How much time and miles elapsed between the collision and the VP44 replacement? You mention testing the red / white wire from the PDC - I am assuming this is the wire that supplies power to the ECM and the injection pump. If so, I would continue to check voltage (engine running and voltage spikes occurring) downstream from there. As you can see in the wiring diagram, Joint Connector #2 (inside the PDC) and Splice #161 are part of that circuit. I would also verify the condition of ground Splice 168 to Ground 125 on front of engine. If you are using another ground connection point with your test lead and there is truly a ground problem in the ECM / injection pump circuit ground, you will get a steady voltage reading because you are bypassing the potential ground fault. Also, I believe there is one more splice that is not shown in the diagram - that would be S109 that is between S168 and G125. Are you familiar with the W-T ground reference modification? If so, has it been done? John

-

Working through miss/studder issues - codes 0237 & 0230

You can just swap out another like fuse and another relay and go for a quick test drive. John

-

Working through miss/studder issues - codes 0237 & 0230

There is a single connector with two black wires that are connected to the positive post of the driver side battery. These wires supply power to the intake manifold heaters (grid heaters). Within a few inches of the battery connection, you will see two fusible links - no fuses. Disconnect the the single wire connection. There are two fuse group locations. One is called the Power Distribution Panel (PDC), and the other is called the Junction Block. The PDC is located right beside the driver side battery. Th Junction Block is located on the left end of the dash. The driver's door must remain open for access. Hope this helps. John

-

Working through miss/studder issues - codes 0237 & 0230

Sounds like you are on the right track. The intake manifold heaters draw about 100 amps each - there are two of them. They are automatically in operation below 60°F ambient temperature. With the key on, engine off, the heaters are on while the "Wait to Start" lamp is lit. After the engine is started, the heaters post-cycle until a specific engine operating temperature is reached, or the vehicle speed reaches approximately 25 mph. The post-cycling current is higher than the alternator output, so it is normal to see the dash voltmeter drop significantly. This is why I recommend disconnecting the intake manifold heaters while diagnosing a low voltage electrical problem. John

-

Working through miss/studder issues - codes 0237 & 0230

I would be looking into this before doing any parts replacing. Was the intake manifold heater post-cycling when you were seeing the voltage drop on your test drive. If you are not certain, then I recommend to disconnect the intake manifold heater to simply troubleshooting the voltage drop. In normal operation, when the manifold heaters have finished their post-cycling, the voltage powering the VP44 should be steady around the 13.5 - 14.2 volt range. Steady is the key word. If the voltage continues to fluctuate wildly at the VP44, then you should check the power supply to the VP44, ECM and the PCM; but more importantly you should check that you have good operating ground circuits. John

-

Radiator Lifespan

I agree. John

-

Radiator Lifespan

@Mace , I think you saying that your are at 442,000 kilometers (275,000 miles) on your truck, currently? I know other people (not very many) that also have had the same long life on their injection pump. I'm at 402,000 miles on the truck with 315,000 miles (507,000 kilometers) on a replacement injection pump. The first pump was replaced under warranty at 87,000 miles. Also, a new in-tank lift pump was installed under the same warranty, even though the original lift pump was still in good working order. My replacement fuel injection pump operated with only 6 psi @ idle and 3 psi @ WOT from the in-tank pump for the first 150,000 miles. I replaced the in-tank lift pump with a used frame mounted FASS 65 gph lift pump - the in-tank pump was still fine, I just wanted the ability to do a road side repair if the lift pump failed. The used FASS pump is currently in use - 12 psi @ idle and 6 psi @ WOT. My replacement fuel injection pump has never received any two-stroke oil, nor any fuel additives, nor any other special attention. I have run the Smarty tuner on a mild tune for 150,000 miles, and RV275 hp injectors for 150,000 miles. John

-

Radiator Lifespan

Ok, What is the secret? John

-

Electric vacuum pump

He removed both units and installed a gear driven power steering pump directly onto the accessory drive gearbox. He also installed a remote power steering pump reservoir. Here is a link to his original post regarding the conversion. You will need to scroll through the whole post as he talks of other conversions, as well. I made the same conversion myself - very happy with the results. It's nice having an accessible see-through reservoir. The direct mount power steering pump definitely out performs any of my previous pumps, including the OEM pump. John

-

Front lower shock bolt size

That makes more sense. Since the sleeves have been loose for awhile, they probably have worn into the clamping "ears" of the mounting assembly. This will make it more difficult to achieve the right clamping force so that the steel sleeves don't move around after you install the new bolts. I recommend to closely monitor that clamping force for a few months after the truck is back on the road. John

-

Front lower shock bolt size

I am not understanding cause and effect here. Since the lower shock bushings have an inner steel sleeve that gets clamped tightly by the compression of the mounting bolt, there would never be any wear on the bolt. The only way that I can think of in which a shock bushing would be destroyed after 5 minutes of operation, would be that the incorrect shock absorber is being used (resulting in the lower mount receiving the full weight of the vehicle during compression, or the full weight of the axle assembly during a rebound). If you are getting aftermarket bolts, be sure the bolts have a hardness of 10.9. John

-

Front lower shock bolt size

Your truck: 2wd or 4wd? John

-

Help me build the perfect motor

My vacuum pump (a Dorman) is protected by a 15 amp fuse. The vacuum pump probably draws around 8 amps. John

-

ECM failure?

How are you checking voltage for the lift pump? Where are your test leads connected? Ignition key on - lift pump runs for 1/4 second Bump start, leave ignition key on - lift pump runs for approximately 20 seconds The ignition key must be turned off between bump start tests. John

-

Help me build the perfect motor

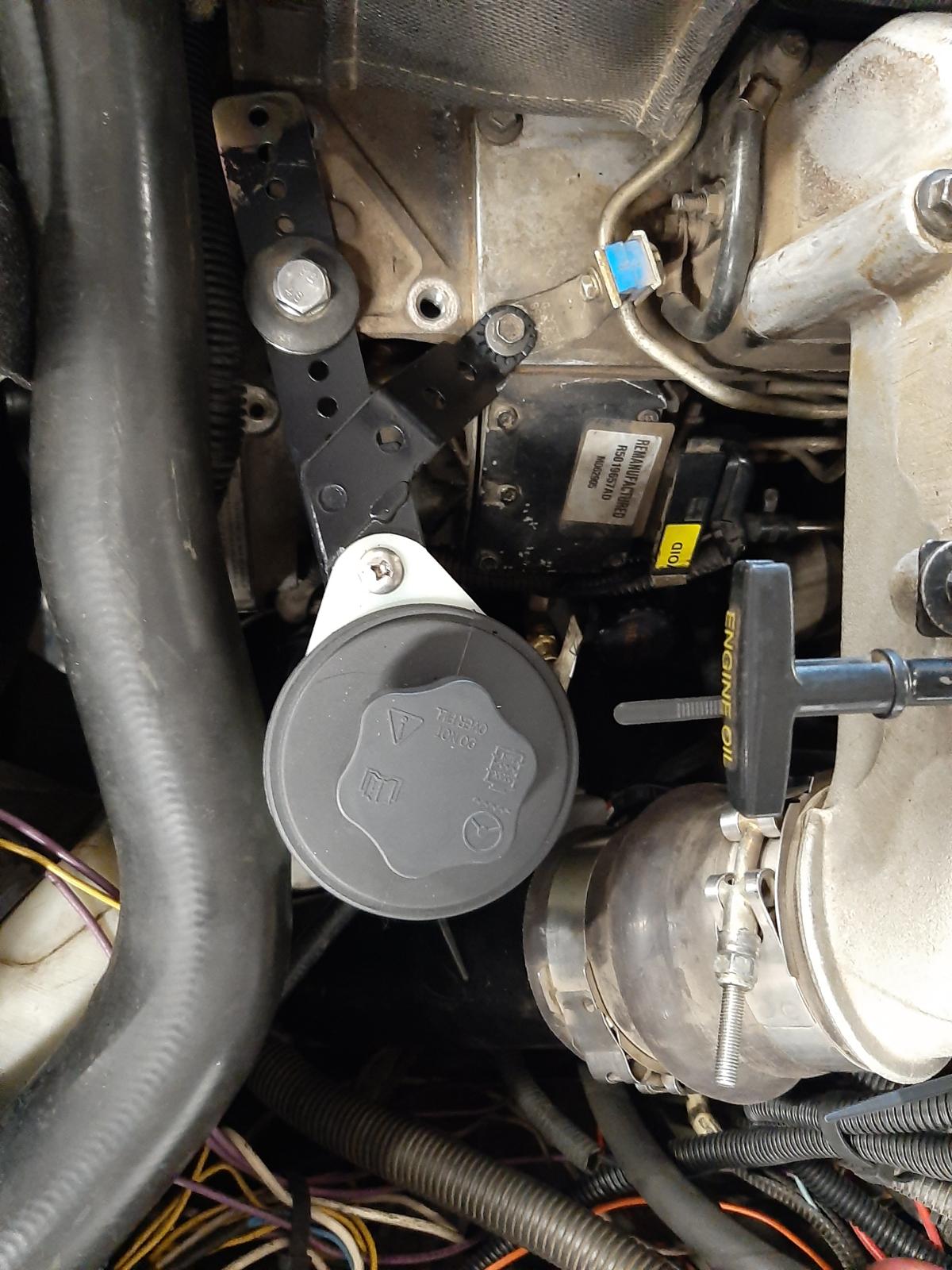

You may want to consider @Mace 's vacuum pump removal / direct mount power steering pump / remote reservoir conversion. The vacuum pump would be replaced by a small electric vacuum pump. I did this conversion myself and I a very happy that I did it. The best part of this conversion was a far better performing power steering pump, a see-through remote power steering reservoir that is very accessible, and the elimination of the gear-driven vacuum pump / power steering pump combination. I went one step further and remounted the APPS throttle control from the engine onto the brake booster / master cylinder mounts. The first two photos are my truck and the third photo is Mace's truck. John

-

NV4500 parts

I have no personal experience, but I have heard that Torque King is a good source. John