Everything posted by Mariocand

-

Dropping below idle

I have rerouted it back to where it dumps out next to transfer case. I didn't get all creative like moparman did with the pvc pipes, but just used a long 3/4" heater hose ran over the top and down along the frame next to fuel line. That oil buildup was caused by front main seal or from the tappet cover leak.

-

Dropping below idle

I pretended that i didnt read what moparman said until i finished my trip. Ignorance is bliss I suppose. However, I found that I could prevent it from happening by rev matching my down shifts and popping the throttle once when I would get to a stop and be in neutral. Stop the issue completly. On a side note, and probably needs it on thread, but I just have to say that the mishimoto radiator I put in during the build, is one of the best investments I have done to the truck. 100+ abiant temps, pulling 14k at 65mph at 5000' above sea level caused it to max at 212° going over some of the steeper passes. But the speed at which it recovered from it was incredible. As soon as the load was removed from the motor it started dropping. It held around 197-203 in the flats. Had the A/C on the whole time and the cruise set. Made for a great first trip on the motor. Worth every penny.

-

Dropping below idle

I have been towing my 5er across Texas on the new rebuilt motor. Started with 1100 miles on her, I am about 750 miles into trip. hot as hell out here. I have been running in 4th gear, nv4500, at 2500 rpm, right around 64ish mph. Wierd thing has started to happen when I start slowing down for an off ramp for fuel, or rest. When the clutch goes in and I amdown shifting as I slow, the idle wants to drop to about 700 before it catches itself and comes back up to about 825ish. After I stop, it smooths out and idles perfect? Anyone ever heard of this? All sensors where replaced during rebuild...

-

When it rains it pours

I definitely took that into consideration when I went this route. However, where I am living at for the forseeable future makes a freeze blow out negligable since it may get into the 20's only a couple times a year. I always have the coolant at 70/30 as well. I spent 7 years in Fairbanks, AK with a 3rd gen 6.7 Cummims and never had issues with it freezing. Although, I did have way more heating elements in it than this one. Besides the block heater in the water jacket, I also had heating pads on the oil and tranny pan and one under each battery all ran to a 4 way plug. Even when the kids or dogs unpluged the truck at -40, no issues, except for batteries not having enough power to cycle heater grid. Usually had to plug it all in for a hour or 2 to get her going again.

-

Dead pedal! Apps Calibration! Help!!!!!!

Just a stupid thought, but did you make sure the floor mat wasn't pushed up under where the pedal is when you did reset? I know my floor mat is pretty thick and I have issues with the clutch switch when I am starting if it gets pushed up there....just a thought.

-

When it rains it pours

-

When it rains it pours

After checking all my before and after pictures, I believe that the shop didnt push the freeze plugs in far enough. They where only about half way in compared to the ones when I pulled the motor out. I am sure that these will fix the issue... I also did a retaining plate from Industrial Injection across the back since that one was still good. Not sure how I would have got that out to begin wirg.

-

Dead pedal! Apps Calibration! Help!!!!!!

Yup.

-

Dead pedal! Apps Calibration! Help!!!!!!

Yes you will need to reset pedal. Key on...slowly depress pedal to WOT, tgen release slowly. Key off. Don't think the edge would matter.

-

Dead pedal! Apps Calibration! Help!!!!!!

If you the oem style APPS which has the oval mounting holes, then you have to calibrate it using these instructions. http://m.cumminshub.com/service/cummins-apps.html You will need a voltmeter and a paper clip.

-

EGT's after the turbo

I personally would take the turbo off. Its not hard to do. 4 bolts on the manifold, oil drain, and seperating the downpipe. No worries no issues, plus you get the piece of mind that nothing went into turbo. However, if that is not an option for you, then a greased bit while motor is running would be my suggestion.

-

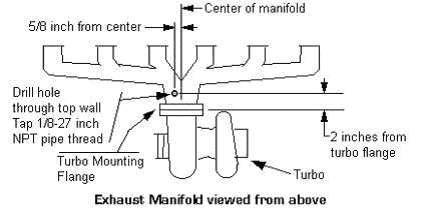

EGT's after the turbo

- Tach

Crank sensor by starter.- When it rains it pours

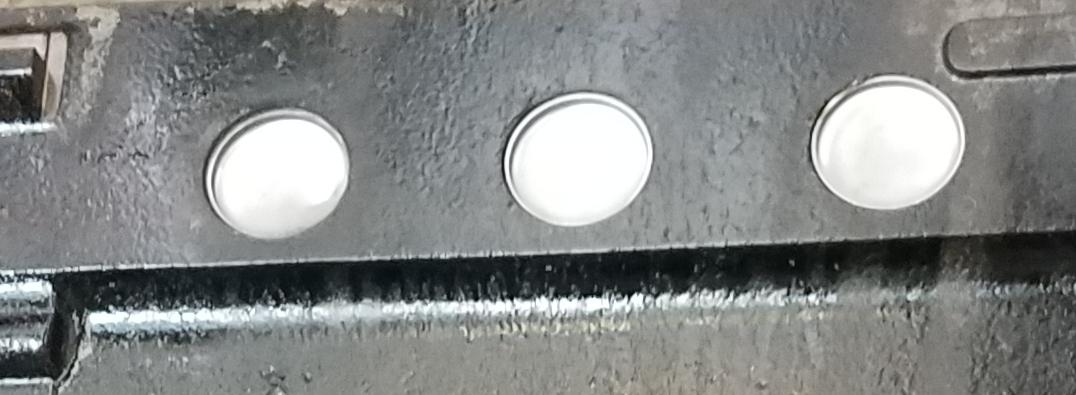

http://www.xtremediesel.com/attitude-performance-1009-bolt-on-side-freeze-plug.aspx Any thoughts on putting these in instead of the regular ones? I'd do the 3 on side and the one in back.... Or, how about one of these.... http://www.enterpriseengine.com/product/cummins-coolant-water-bypass-kit-89-02-dodge-3-9-5-9-4bt-6bt-12v-24v-diesel-engine-12-24v-water-bypass-kit/- When it rains it pours

So, finally got the truck all ready to go since rebiild. I got 1100 trouble free miles on it. Been pushing it hard, trying to weed out any bugs or issues. Hook up the 5th wheel, get going down the road, 4 miles....4 #@&#$! miles... And I blow a freeze plug on right under turbo on the water jacket. 4 miles.... Now, before ya ask, yes, I replaced all the freeze plugs during the build. However, I had them done at the machine shop when the block was getting worked over. So, now what...roadside assistance got me home....but for some reason I don't think the answer is to just put in a new freeze plug and then "go see what happens." I will be calling the machine shop on Monday to see their thoughts, and to give them a piece of my mind. Any thoughts on better freeze plugs? I know a block off plate would probably just cause a different one to blow...Can I trust that the rest of the plugs where done properly? Once it is fixed, how do I load the motor down to the point where it would be the same as towing the 5th wheel so I can test it out without risking the trailer or having to have both towed back home.- Front outer axle seal leaking, help

Wouldn't it also suck because you will have to remove all the stuff on the driver side...i.e. tire, brakes, axle nut from hell, hubs, and steering knuckle. And then at that point, you can pull out the axle to reseal it..... If your truck is anything like mine, your going to be replacing way more than just an axle seal because you will be finding broken parts along the way, or breaking parts trying to remove them.- Tappets

Watch "First full throttle test. Tuner on level 1. 650 miles on motor" on YouTube I let off when it hit 30 psi. I was stoked about how little the lag is just to get up to 20 psi. And since I haven't done the write up of build or created my signature I'll add a brief description of what it has..... Rv275 injectors. 103# springs. Stock turbo hx35 with wicked wheel. Banks big head wastegate. Banks 4" monter exhaust turbo back. Afe intake, dry filter. Edge juice with attitude and cs2 monitor. Pusher intake horn. Grid heater deleter by xdp Mishimoto radiator. New pistons, bearings, and seals from mahle. All standard size. My reason for the rebuild...- Brakes

I was afraid that was going to be the answer. Awesome. I really hate thay store. I always wind up buying way to much crap that I didn't intend to.- Brakes

Any special trick to getting the axle nut to break loose? I have already broke 3 breaker bars in my futile attempts. I was able to move the nut just enough to mot be able to put cotter pin back in. Which means it is now inoperable. Thankfully I still got the motorcycle to run to town and exchange tools and test the lifetime warranty on them.- Cummins ISB tappet cover gasket replacement

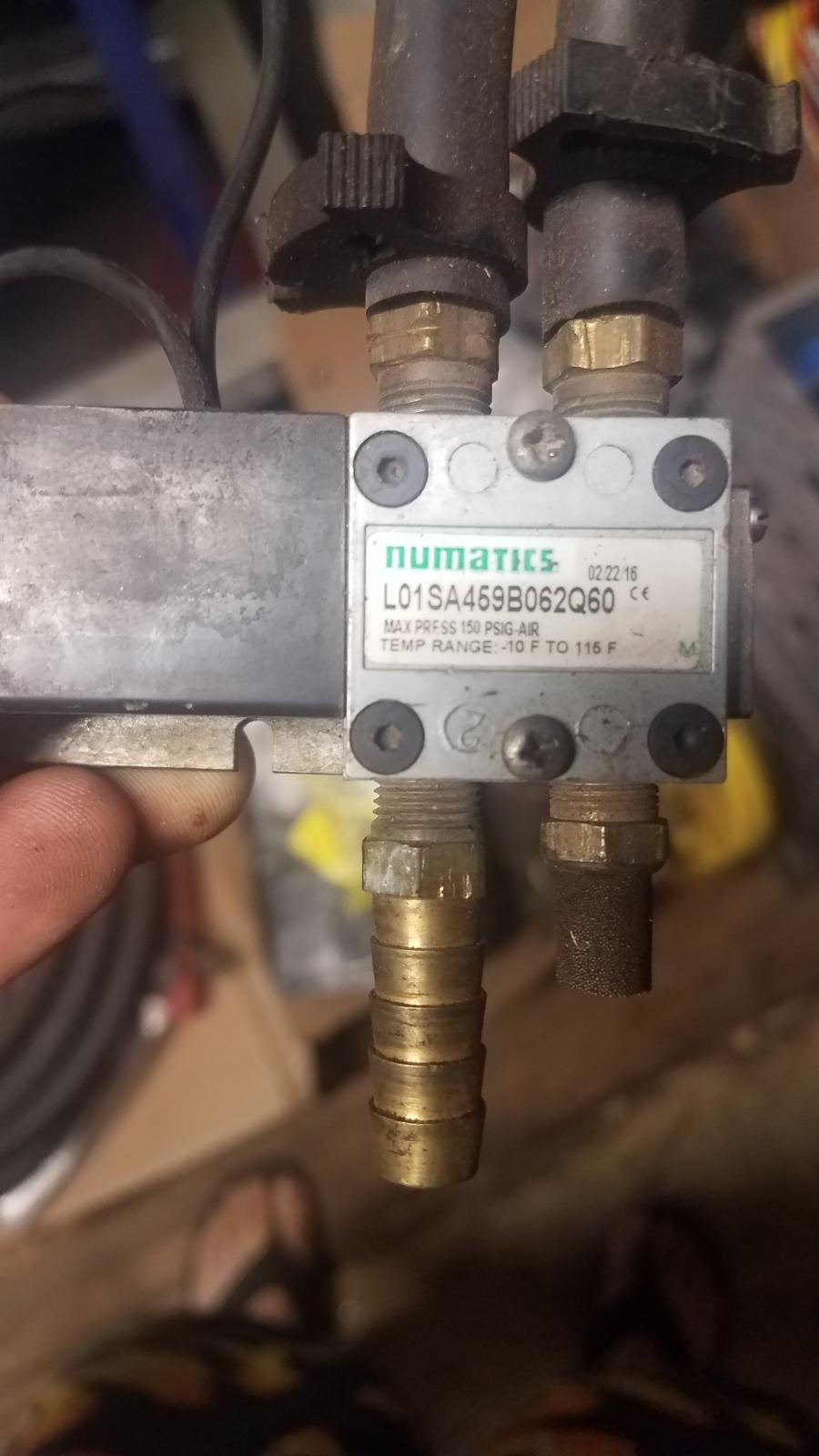

I bought a new T, and all the lines a week ago. They came with brand new rubber on them as well as banjo bolt washers. The one in the pic is the old one. I had initally suspecred that I had smashed it against firewall during install. However, after tgrowing my wallet at the truck and showering it with money for new parts, I found the issue was a rubber gasket. The new parts did not leak for 2 days, then right back where I was... I am going to take the whole thing out again to see whats up....is it ok to locktight the bolts on the T?- Cummins ISB tappet cover gasket replacement

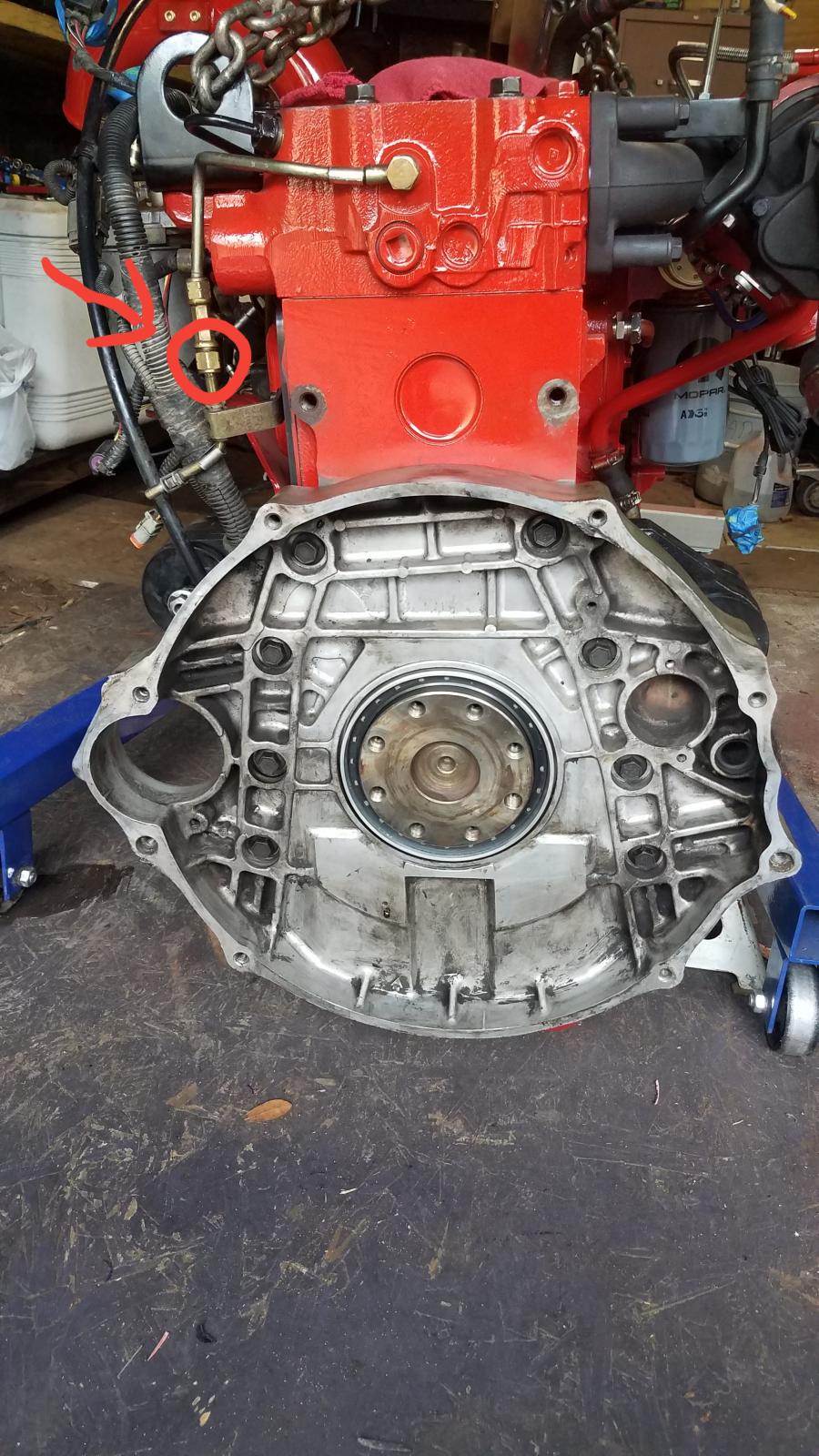

Have you ever heard of the fuel return line that goes to the T leaking? I know there are issues wirh older ones because of the rubber gaskets that are in the fittings, but I replaced all the lines and fittings, still leaks fuel. Still driveable, it is not dumping put, but I can smell it in cab while driving, and it drips off of the clutch housing when I park. Besides the obvious, i.e. tighening the bolts, again, is there something I am missing? This is where I suspect it is leaking from, however, as you know, it is not an easy thing to get to when the motor is in.......- 5.9 engine blocks, Killer Dowel pin a concern?

I agree with me, however, if you happen to be taking the gear case cover off for something else, might as well do it while you are in there. It'll help ya sleep better at night knowing its done.- Front Axle CAD Vacuum Actuator to Manual Posi Lock

- Tappets

Just a quick video. I owe you guys a full write up on the build and will in the future. This video is of me running at 60mph and about 10% throttle. I went to about 50% throttle for a couple seconds amd then let off. Still keeping it easy on motor....only 130 miles on it so far. The exhaust is so loud because I only have the downpipe on as of yet. 20170516_104927.mp4- Tappets

- Tach

Account

Navigation

Search

Configure browser push notifications

Chrome (Android)

- Tap the lock icon next to the address bar.

- Tap Permissions → Notifications.

- Adjust your preference.

Chrome (Desktop)

- Click the padlock icon in the address bar.

- Select Site settings.

- Find Notifications and adjust your preference.

Safari (iOS 16.4+)

- Ensure the site is installed via Add to Home Screen.

- Open Settings App → Notifications.

- Find your app name and adjust your preference.

Safari (macOS)

- Go to Safari → Preferences.

- Click the Websites tab.

- Select Notifications in the sidebar.

- Find this website and adjust your preference.

Edge (Android)

- Tap the lock icon next to the address bar.

- Tap Permissions.

- Find Notifications and adjust your preference.

Edge (Desktop)

- Click the padlock icon in the address bar.

- Click Permissions for this site.

- Find Notifications and adjust your preference.

Firefox (Android)

- Go to Settings → Site permissions.

- Tap Notifications.

- Find this site in the list and adjust your preference.

Firefox (Desktop)

- Open Firefox Settings.

- Search for Notifications.

- Find this site in the list and adjust your preference.