Everything posted by wil440

-

Truck Not Running Right

Best not to pierce wires as that will just cause bigger problems later. Either buy a back probe kit so you can go In to the back of plugs or use paper clips to get into the back of plugs, I prefer back probe kits as they are have lots of different shaped probes, these kits aren't expensive and a very basic kit is good enough

-

Truck bucking

I have a problem with bucking too, injectors on my truck are ready for replacement as my idle is 850 or so warm and load wanders between 4 and 8, tried various tunes, the one I use now was written by @Me78569 for a stock truck and it's the best as of yet but still bucks until it's really warm ? I recently spoke to a diesel shop near me ( Midlands UK) about injectors as I had a JCB head skimmed there and have used them for quite a few years, 7x10's at 320bar would be £80 each no cores and due to the £ to $ shipping and duty from the USA thats a steal. While I do see the reason of setting injection pressure at 320 bar or lets say "over stock" to be better atomization the trained mechanic in me just see's a whole lot more work that the VP needs to do to build that extra pressure. reading the previous posts I might change the cruise timing rpm as if a stomp it it stops bucking I wish I wasn't sooooo busy not

-

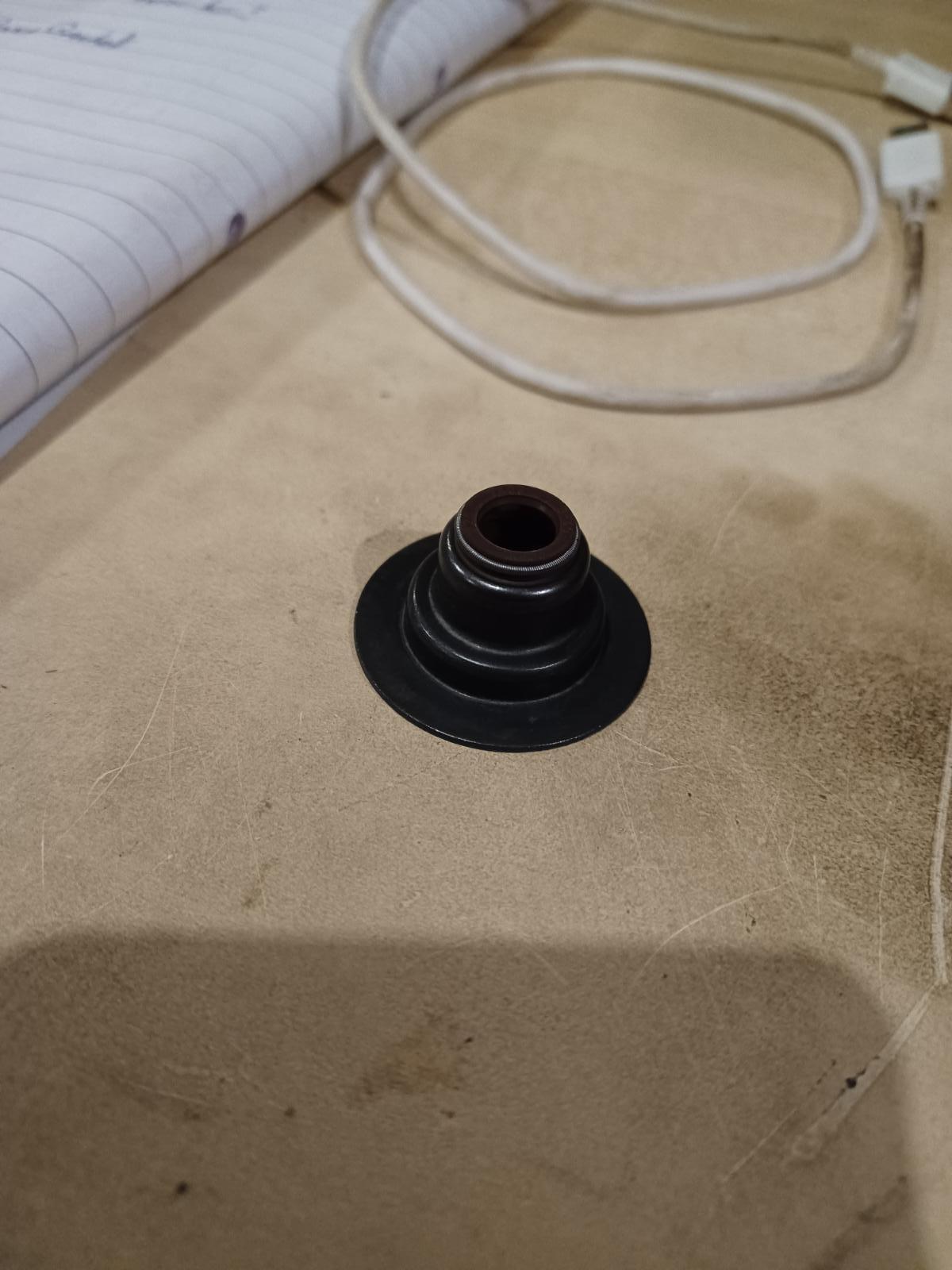

24v valve stem size and guide outer diameter ?

I read a while ago someone used a different valve stem seal to try and make them stay on the guide better or seal better can't quite remember which and who it was. Question 1. What is the valve stem size on a 24v Question 2. What is the guide diameter where the stem seal sits The reason for the 2 questions is I'm right now repairing a Perkins (POS) 4.4 RJ build in a JCB 416 loading shovel that the tip of number 3 injector dropped off, only the very tip below the injector holes so very small and luckily it imbedded straight away into the piston and did not go through a exhaust valve. This has been ongoing for about a month due to being buried in work, the head has been on my bench for a couple of weeks after a skim waiting for me to grind the valves in, 1, 2 and 4 are ok but the fools that drive it ran it for over 3 weeks with diesel dribbling into No3, got the valves all done tonight as I've got a Cat 966 hitch propshaft to repair tomorrow and only one bench, dug the gasket kit out to get the stem seals and these things are rather good, they are all moulded onto the hardened washer that sits under the valve spring so they can never lift off measurements are ID or valve diameter 0.350" OD for the guide 0.500" just checked a Ford 390 valve and it's the same diameter JCB part number here is 02/203213 serial number is 0530400 for the machine

-

Something else to keep me occupied

yeah the rest is a means to an end BUT I now have a TIG

-

Something else to keep me occupied

Well just this weekend decided to go halfs on my brothers workshop with him, my brother uses it part time but he does car panel welding, he has a 80's Vauxhall Cavalier to do which to me looks ssrap but the owner wants it done and is prepared to pay for it to be done, I guess as you get older you don't really realise that what younger people class as classic cars are way younger than certainly what I class as a classic car ! We did a 2007 Ford Transit SWB van this weekend, both front steps, both inner cills, both outer cills, big underquote as bro went and checked it out in the DARK ( glad I didn't go look at the job) only panels we had bought were both steps and both short cills so maybe close to 10 to 15 ft of fabrication for cill panels. The good thing is this van repair had half paid for a Lincoln Electric Squarewave 255 TIG welder we bought on friday, is AC/DC so will weld ally, I have a 1920 something JAP engine case to do and just maybe I'll be able to hardtail the Harley frame I have

-

We've all done the W-T mod.. but has anyone dealt with interference from outside the truck?

I'm know nothing about RF absolutly zero BUT I go to a regeneration site in Walsall, West Midlands basically the company I go to repair stuff for is contracted to make a huge area that was once a Dunlop belt factory clean to be rebuilt on, there is also a very old tip at the back of this site, anyway I digress as on my way to the site there is a 100 yard stretch of a road that really seriously bugs out the radio on my truck to the point of a deafening buzz that is much louder than the volume of the station I am listening to was set at, yes the station is on AM so interference is the norn but even electricity pylons don't make that sound, I'm going there on Tuesday so will note what the buildings are but IIRC I'm sure it's an Engineering Company so might be big lathes, mills induction stuff No where else I drive makes a noise like it, it's like a very low frequency drone/buzz and loud

-

Not a Ram fault but relevant in fault finding

Got the last one out today, this was the tightest, actually pulled the damn injector apart, left the screw on nozzle peice behind, just pulled the threads off the thing. Inspected the holes after hand reaming and no damage, tapped out the hold down bolt holes and pulled the valves on no3 .... no damage the tip didn't go through the exhaust valve, cleaned the head surface and can't decide whether to send it for a skim, biggy on that is I know the glow plugs will not come out so unless the skim can be steered around the glow plug tips it won't be skimmed, think I going to get a HG and see what material it is first

-

Not a Ram fault but relevant in fault finding

Same thermostat housing on this thing, it was in the way to get to No1 injector due to the excess material on one side of my made puller which I wanted to leave alone in case I needed to make the bridge wider to pull something else. Took over an hour to remove as the seal is not on the face like anything normal it sits down in the bore. Is the frost plug heater threaded in or pressed in and can you get at it ?

-

Not a Ram fault but relevant in fault finding

I got called out to a site that has a JCB 416 loading shovel, 4.4 Perkins 4 cylinder diesel that was misfiring (or so the muppets at the site said. Got there and started it to check, misfiring was an understatement, fuel filters all clean, air cleaner too. Slackened injector lines off one by one 1. RPM dropped a lot barely running, good spray 2. Same as No1 3. Ran much better with no3 line slightly loosened and rpm actually increased, bubbling air when loosened, rpm decreased on tightening injector line. 4. Same as 1 and 2 So decided to pull no3 injector as I figured injector pintle not closing for some reason IE tip dropped off or pintle seized Made a slide hammer as per jcb tooling... no movement ( injector is outside rocker cover) Found a M12x 1.5mm metric fine nut to screw onto injector pipe thread, dug out a chevy damper puller centre bolt and a 1/2 unf nut and welded that to the M12 nut, made a bridge and started to pull it out. Loud bang and the top of the injector snapped off. Took the head off (no easy task) tip of no3 injector had dropped off, luckily it was imbedded into the piston, got the head back home. Got 3 out of 4 out today, all 3 tops broke off so welded hardened Washers onto the tops and then welded a Cat loader frame collet bolt to the washer and then welded 2 good weld straps down 2 sides, the collet bolt is 1" unf so same thread as the hardened nut on my chevy puller, after maybe 3 attempts on each injector, 3 out, 1 to do tomorrow, luckily injectors for it are quite cheap. Been in from new, 18 years Going to glass paper the bore..... yes with the piston still in there as the muppets ran it for over 2 weeks and there is some bore wash but it will clean up First picture is the injector with the missing tip. 2nd picture is the puller I made, not quite the right angle hence the washers and 2 strips of aluminium so as not to damage the rocker gasket face Motto of this post..... never give in and find the patience of a saint and if you have air in just one line with a dead cylinder and lots of blue smoke it COULD be a tip dropped off

-

Something else to keep me occupied

No nothing at all Still waiting for the call to say the motor machining is finished. The company I took it to is not far from Donnington race track and they are the choice for the entire race fraternity both cars and bikes, just a couple of old guys and they go there own pace and that's that, first used them over 35 years ago to rebore a yamaha RD 400. When I dropped the harley engine off the shop floor was buried in engines, parts etc must have had a 100 jobs ongoing easily. I'm really busy anyway so not too bothered at the moment. Hopefully work will slack off some soon. I recently got 3 land regeneration sites for one company that I look after quite a bit of mobile plant plus the 11 sites for the Co I used to work for. And I thought I was semi retired, my diesel bill isn't far off £300 per week because of the miles I'm doing site to site

-

Compound Turbo install complete

I could use a new tune, just do not get any time at all to mess with my truck ever but it would need to be for towing I just dropped my timing down a degree across the whole range and EGT are a little down and coolant a little higher, It feels better and I guess it's burning more of the charge in the cyclinder hence the coolant increase and the EGT decrease maybe ?? still bucking a little towing in LU OD off so going to take some more timing out and see when I get the time, right now I just pedal back a little when it starts bucking, at least it's a sure way of NOT reducing the trans to metal filings

-

Rockauto dealer closeout

Just had am email from Rockauto dealer closeout on parts for 1998 to 2000 ram

-

Truck Not Running Right

A while back you posted that you had VP codes coming back after clearing them and then driving the truck, is this still happening?? If you still have P0216 coming back after clearing there's your problem, follow the process for P0216 diagnosis

-

Idle at 750 rpm-normal?

Far as I know ijectors in my truck haven't been changed and it's at 178k , idle is around 850 fuel economy is ok, but with the £ nearly at parity with the $ injectors in my truck will not be getting replaced any time soon nor will anything else for that matter if I haven't got it on the shelf. When I first got into American cars/trucks it was nearly $2 to the £ that made parts costs ok I can see the reasoning that injection pressures will fall off as the miles or better still operating hours increase, that is a given

-

Idle at 750 rpm-normal?

Have a got it wrong then as I though I read here several times when injectors are worn idle increases ???

-

You learn something everyday

Yes the link mentioned that, litres added for Canada iirc

-

You learn something everyday

Didn't realise we as in the UK had 10 definitions of a gallon over 100's of years https://en.wikipedia.org/wiki/Gallon

-

Towing a large bumper pull on Monday

Yes me too

-

Oil coming out of intake horn/grid heater spacer..

As you say remove the intake, inspect, clean it then use the truck keeping an eye on the engine oil level If the engine oil aint going down any oil in the intake isn't from the sump/turbo In my line of work (mobile plant) if a turbo leaks oil into the intake then the intercooler is usually removed and cleaned out or at the least the intercooler removed and stood up to allow the oil to drain out, sometimes the angles and contruction of the hose stubs mean just removing the lower hose allows it all to slowly drip out

-

Oil coming out of intake horn/grid heater spacer..

What do you mean by " a little bit of oil" ? easiest way of checking is to remove the intake horn and take a look at what oil is around inside, just easy it off slowly and you should get away without renewing the gasket and if it does get damaged a little silicon and it will be fine until you can get another, OR make a gasket out of a cereal box, and yes oil in an intercooler can and will get blown into the engine, can you remove the lowest intercooler hose and see whats in there ? Have you got a blue haze now ??? If a turbo is passing oil you would know about it, it goes from nothing to a lot in a very short time and as you say the oil level is staying constant I doubt you have a turbo problem and I also doubt you've "overspun " it .... you'd hear that like a 747 landing in the bed All engines breath a little through the breather it would be spluttering oil out if it was serious

-

Coolant temp gauge bad or ecu failure?

As I posted before. My truck goes to 140f with key on engine off, start it and it then reads temp. With a 190f thermostat 200 before it opens is OK just as long as it drops back to 190f PDQ Do you know anyone with a scanner that reads live data? That would show you what's going on but I think you are fine. I take it if you drive it hard pulling a good grade temp is 190f or so ? I have a 190 stat and working hard mine gets to 197 ish and doesn't go higher for very long at all, I did see 200 Tuesday pulling the T Trailer in another thread but only for a few seconds and that was on a long 11% grade in 2nd gear

-

Towing a large bumper pull on Monday

Thanks, not sure why most if not all of my pictures come out upside down on here, they are right on my mobile, laptop etc, thing is if I rotate them first so they are upside down on my stuff they still come out upside down on here, same outcome if I post from Mobile or laptop too My truck lights and brake are on UK 13 pin plug, my truck also has a UK 7 pin but the brake controller wire isn't fitted into that one as there wasn't a spare pin hence why I went 13 pin This trailer had 7 pin plug, I took a quick look but couldn't see the brake wire, thinking about it now (after the event) it had a 12v battery on the front with a couple of relays along side it wired into what I figured was the brake control, I wonder if it was actually 24v control hooked to a relay to operate the 12v brakes. The Scania that was used to tow it was HGV so brakes wouldn't have been an issue anyway as it would weigh around 18k kg or more

-

Towing a large bumper pull on Monday

Well got it all moved 768 miles round trip, 300 towing the trailer which turned out to be probably the worst 300 miles ever as the trailer brakes weren't working and Cornwall gets rather hilly, steepest was 11% up not bad, down not so good, only good thing motorway the whole way except for first and last mile or so. The trailer had been towed before by a Scania truck so all the bulbs were 24v so lights were like candles Glad it's done truck used £350 in diesel And can someone turn the picture the right way up

-

Factory Heated Seat Replacement

Not much use to you as I'm in the UK. I had the same problem on a Volvo A35 6 wheel artic dump truck. Seat heat pad was shorting out, and when it did there was no seat air suspension, volvo option was a new complete seat at close to £2k Got a generic 24v pad from a company called RS here and wired it in, lasted over 2 years of over 12hrs a day being sat on and cost less than £30. Replaced with another and still ok now. Ideally replace with one that's close on the circuit resistance and for 12v

-

RIP Her Majesty The Queen

Wallis Simpson was an American divorcee, that's the reason for his abdication as at the time he wouldn't have been allowed to marry her, no problem their that was his choice but what they did afterwards was also his choice, he fed secrets to Hitler and our monacy and the country did what needed to be done and booted both and IF I'm correct they never set foot in the UK again. Died pretty much penniless but before that scrounged off of rich people who stupidly thought he was still royal, bit like Harry and Megain